Feeder-Cross Page Connector

Navigation: Models ➔ General Models ➔ Feeder-Cross Page Connector

Related Links: Size Distribution Definition, Qualities Models

General Description

This unit can function in one of three ways:

- A Source of material:

- In this case the user usually sets up the Required Flow from the unit, the Temperature and Pressure AND the species composition, on the Define Species - DSp page.

- The Default species composition in a Feeder is 100% water. Therefore, if the user does NOT change the species composition, the Feeder will deliver water to the project.

- A Sink for material.

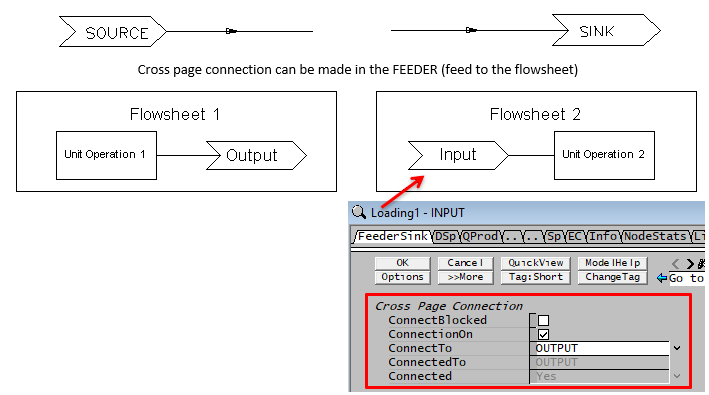

- A Cross Page Connector, in which case it would be connected to another Feeder / Cross Page unit, typically on another flowsheet page.

- You may navigate to the connected Feeder by double clicking with the left mouse button on the Feeder.

- In addition, if the Feeder is not connected, but has the Composition Fetch (CF) enabled, then double clicking with the left mouse button on the Feeder will take you to the CF source (often a pipe).

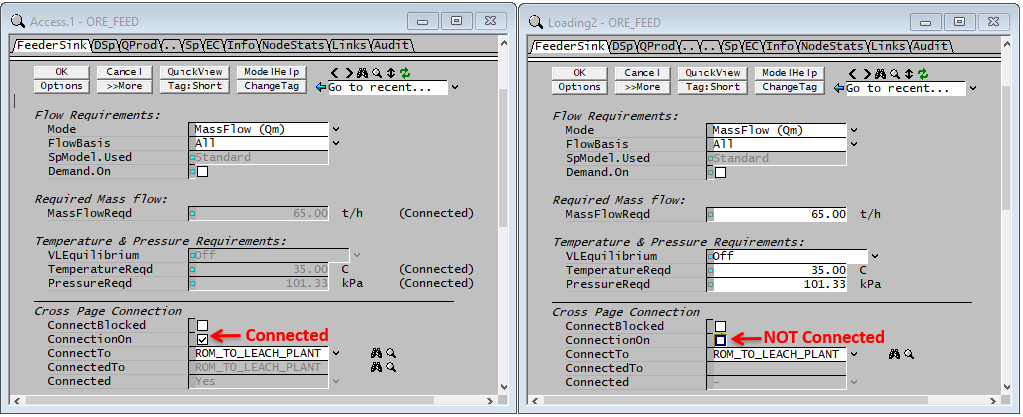

- The image below shows how to connect Feeders.

Connections

- If two units are connected as cross page connectors, as shown in the left hand image above:

- ROM_TO_LEACH_PLANT (operation mode Sink) is connected to ORE_FEED (operation mode Source)

- All the feeder information defined in ORE_FEED is greyed out and will be ignored.

- The down stream link from ORE_FEED will contain exactly the same information as the up stream link of ROM_TO_LEACH_PLANT.

- Any information in the ORE_FEED unit will be maintained and not lost.

- If the cross page connection is disabled, as shown in the right hand image above:

- There is no connection between the ORE_FEED and the ROM_TO_LEACH_PLANT units.

- The input fields in ORE_FEED are white and the user may insert any value, which will be used by the unit.

Notes:

- The model requires either a single inlet or a single outlet, depending upon its intended use.

- A Sink has no input fields - the user may not set anything in this unit - it accepts whatever is delivered by the upstream link.

- The user may not type any Feed data into a Source until it has been connected to a downstream link.

- A Cross Page Connection can only be established between two Feeder/XPG units.

Diagram

The lines show the stream connections.

Inputs and Outputs

| Label | Required / Optional |

Input / Output |

Number of connections | Description | |

| Min | Max | ||||

| Snk | Required | Input | 1 | 1 | OR |

| Src | Required | Output | 1 | 1 | |

Model Theory

Used as a material source or sink; OR as a connector between two feeders (usually on separate graphics pages).

Data Sections

The feeder access window may consist of a number of sections. This number may increase or decrease, based on user configuration and / or number of species. Some of these variables are only relevant in the case of a source. When the unit is connected to another cross page connector, the input variables are not used.

- FeederSink - this is the first Tab. The user accesses this tab to configure the basic manner in which the Feeder works, or to connect to a another Feeder.

- Batch Feed - this section is available on the first Tab in Dynamic projects. This allows users to set the Feeder to deliver a fixed amount of flow.

- VLE - Optional tab that is visible if Vapour Liquid Equilibrium is enabled on the first tab. Only visible for selected Feeder Operation modes.

- PC - Optional tab that is visible if that is visible if Feeder Operation = "General" and EB.Solubility.On and/or [email protected] is enabled on the first tab.

- MU - Optional tab, or tabs if there is more than one Makeup, that is visible if Feeder Operation = "General" and Makeups > 0.

- Content - This tab is only visible if 'ShowContent' is ticked. Contains data on the material from the Feeder and may be spread across one or two Tabs, depending on the project and the selected views. This Tab is not visible if the unit is a Sink.

- WQ - Optional tab, this tab is only visible if WaterQualities in the Plant Model - Views tab page is ticked.

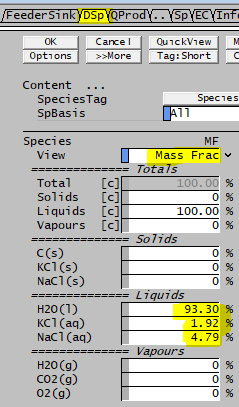

- DSp - this tab allows the user to define the species (Define Species) in the material from the Feeder. This may be spread across one or two Tabs, depending on the number of species in the project. This Tab is not visible if the unit is a Sink. NOTE also that depending on the Feeder Operation selection, the DSp page may display the Full list or a "Pre-filtered" list of species.

- DLockup - Optional tab that is visible if Qualities - "Lockup.Action = Create". Please see LockUp for more information.

- DTrack - Optional tab that is visible if Qualities - "MatTrack.Action = Create". Please see Material Tracking for more information.

- DSz - Optional tab that is visible if Qualities - "SzDist.Action = Create". This allows the user to define the Size Distribution(s) for the solids in the unit. Please see Size Distribution (PSD) for more information. The methods of defining the Size Distribution can be found in Size Distribution Definition.

- DSSA - Optional tab that is visible if Qualities - "SzSSA.Action = Create". Please see Specific Surface Area (SSA) for more information.

- QFeed - Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the combined feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- This is before any Evaluation Block sub-models are evaluated.

- QProd - Optional tab, visible if ShowQProd is enabled. This and subsequent tab pages, e.g. QProd.. and Sp, shows the properties of the product stream. The tags in the QProd tab are valid even when the ShowQProd option is not selected.

- This is after any Evaluation Block sub-models are evaluated.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Feeder-Cross Page Connector

Unit Type: FeederSink - The first tab page in the access window will have this name.

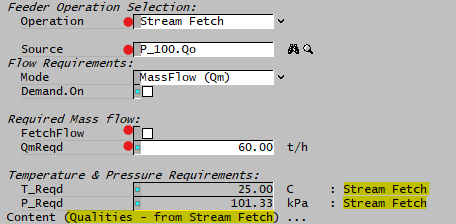

The Data section of the cross page connector changes depending on the Operation Mode. Please click on the relevant mode to see the different settings.

| Tag (Long/Short) | Input / Calc / Options | Description | ||

| Tag | Display | This name tag may be modified with the change tag option. | ||

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. | ||

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. | ||

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the state of the unit, i.e. if it is a Feeder or a Sink, etc.. | ||

Feeder Operation Selection | ||||

| Operation | General | This operation allows user full control for setting all available feeder options. Composition Fetch, sub-models and full species list are available in the DSp tab. | ||

| Solids | This operation mode will apply a solids filter to the DSp tab, all species in other phases are forced to zero. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium is not available as it does not apply to solids. | |||

| Liquids | This operation mode will apply a liquids filter to the DSp tab, all species in other phases are forced to zero. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium selection is limited to Saturated or subcooled liquid. | |||

| Vapours | This operation mode will apply a vapours filter to the DSp tab, all species in other phases are forced to zero. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium selection is limited to Saturated or Superheated vapour mixtures. NOTE: for mixed phases please use the General Operation mode. | |||

| Slurry | This operation mode will apply a solids & liquids filter to the DSp tab, all species in other phases are forced to zero. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium selection is limited to Saturated or subcooled liquid. | |||

| Water | This operation mode will apply a water filter to the DSp tab, the only species shown is Water. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium selection is limited to Saturated or subcooled liquid. NOTE: for non saturated conditions please use the General Operation mode. | |||

| Steam | This operation mode will apply a Steam filter to the DSp tab, the only species shown is Steam. This operation mode does not allow composition Fetch nor sub-models. VLEquilibrium selection is limited to Saturated or Superheated pure steam. NOTE: for steam mixed with other vapours use the Vapours or General Operation mode. | |||

| PlantModel Air | This operation will fetch the Global air specification from Plant Model - Environment Tab, Air Composition section into the DSp Tab. In this mode, only the flowrate can be adjusted. | |||

| PlantModel DryAir | This operation will fetch the Global dry air specification from Plant Model - Environment Tab, DryAir Composition section into the DSp Tab. In this mode, only the flowrate can be adjusted. | |||

| Stream Fetch | This operation will allow user to fetch the stream T, P, and composition information from another stream. User must specify the source stream, e.g.: P_104.Qo OR ROM_STOCKPILE.QFeed. In this mode, only the flowrate can be adjusted. If flow should also be fetched, please tick the FetchFlow tickbox in the Required Mass/Volume Flow section. | |||

| Content Fetch | This is available for dynamic simulation only. This operation will allow user to fetch the T, P and composition information from another content (such as tank). User must specify the source, e.g.: Tank1.Content. In this mode, the flowrate can be adjusted. | |||

| MakeupSrc Fetch | This operation will allow user to fetch the stream information from a Makeup Source. In this mode, only the flowrate can be adjusted. A DirectLink pipe is not created between the feeder and the flow used is NOT reflected in the Makeup source total. The purpose of this operation mode is for the feeder to be a true source of material and to use a Makeup source as a common Composition, T and P template definition. | |||

| Link to MakeupSrc | This operation will allow user to draw the flow from a Makeup Source, the DirectLink is automatically created similar to a Makeup block. In this mode, only the flowrate can be adjusted. The advantage of this operation mode is that the Makeup source is the source of the material, a DirectLink stream is created and the flow used is reflected in the Makeup source total. Click here to see an example. | |||

| Source | Input |

Visible with the Stream Fetch operation. User specified the source stream, e.g.: P_104.Qo OR ROM_STOCKPILE.QFeed | ||

| MakeupSrc | DropList | Visible with the MakeupSrc Fetch operation. User selects the available makeup source unit from the list. NOTE: If setting the makeup source via a controller or Excel, use the tag name of the makeup source. This is a string variable and cannot be set by integer index. | ||

| SrcLink... (This group is only visible with Link to MakeupSrc operation mode) | ||||

| MakeupSrc | DropList | Visible with the Link to MakeupSrc operation. User selects the available makeup source unit from the list. NOTE: If setting the makeup source via a controller or Excel, use the tag name of the makeup source. This is a string variable and cannot be set by integer index. | ||

| DirectLink | Feedback | Lists the name of the direct link (auto added by SysCAD). This auto link can be renamed, the graphics for this autolink can also be adjusted using either 'change symbol' or 'redraw link'. | ||

| Connect | Feedback | Returns the status of the makeup connection with the makeup source. If the makeup source tag is invalid or empty, an error will be given. | ||

Flow Requirements | ||||

| Mode | MassFlow (Qm) | Default. The user may set the Mass flow from the feeder. | ||

| VolumeFlow (Qv) | The user may set the Volume flow from the feeder. | |||

| NVolumeFlow (NQv) | The user may set the Normalised Volume flow from the feeder. | |||

| Const Pressure | The user may set the Pressure at the feeder. This option is only available in Dynamic Transfer mode. | |||

| FlowBasis Only available for Operation - General Mode. (See Example in the Hints and comments section) |

All | The flow specified will be the flow of All phases from the Source, i.e. if Flow Required = 10t/h, then a total of 10t/h will flow out of the Source. | ||

| Solids | The flow specified will be the flow of the Solid phase from the Source, i.e. if Flow Required = 10t/h, then 10t/h of Solids will flow out of the Source. If the user has specified a composition of 90% solids and 10% liquids, then the Total Flow = 10t/h Solids + 1.11t/h Liquids = 11.11t/h. | |||

| Liquids | The flow specified will be the flow of the Liquid phase from the Source, i.e. if Flow Required = 10t/h, then 10t/h of Liquids will flow out of the Source. If the user has specified a composition of 50% liquids and 50% solids, then the Total Flow = 10t/h Liquids + 10t/h Solids = 20t/h. | |||

| Vapour | The flow specified will be the flow of the Vapour phase from the Source, i.e. if Flow Required = 10t/h, then 10t/h of Vapours will flow out of the Source. If the user has specified a composition of 20% vapours, 70% liquids and 10% solids, then the Total Flow = 10t/h Vapours, 35t/h Liquids + 5t/h Solids = 50t/h. | |||

|

The SpModel.Reqd field is only shown if more than one Species Model is available in the project (e.g. Standard and Bayer3). | ||||

| SpModel.Reqd | Inherit | Upstream configuration will be used. | ||

| Standard | All the variables are calculated using the Mass Weighted Mean of the species. | |||

| Species Model | Use an alternative species model, such as 'Bayer3' or 'Potash'. | |||

| SpModel.Used | Standard | The Standard species model is being used. | ||

| Species Model | An alternative species model is being used. | |||

| SpModelType | Display | This field displays the Species Model type used in the unit. | ||

| Calculator | TickBox | Only visible if Species Model used is Bayer3 or Potash. Please see Bayer Liquor Calculator or Potash Liquor Calculator | ||

| Demand.On | TickBox | If this is enabled then the feeder will feed in the required mass as demanded by the connected stream. See Demand. If this is not enabled, then the feeder adds the amount of material as specified by the user. | ||

| Demand.Max | Input | The maximum flow allowed from the Feeder in Demand mode. This field is only visible if Demand.On is enabled. | ||

| When demand.On is in use, the Required Flow (see next group of tags) will become the Demand Minimum (mass/volume) flow. The variable will have text "(Min)" displayed as a reminder. | ||||

Required (Mass or Volume) FlowThis field is not available if the user selects Const Pressure in Dynamic Transfer mode. | ||||

| FetchFlow | Tickbox | Visible when Operation = "Stream Fetch". This allows the feeder to fetch Flow rate from the source unit. | ||

| MassFlowReqd / QmReqd | Input | Visible with MassFlow (Qm) Mode. The mass flow required from the feeder. Note: This will become the minimum flow allowed if Demand.On is enabled. | ||

| VolFlowReqd / QvReqd | Input | Visible with VolumeFlow (Qv) Mode. The volumetric flow required from the feeder. Note: This is minimum flow allowed if Demand.On is enabled. | ||

| NVolFlowReqd / NQvReqd | Input | Visible with NVolumeFlow (NQv) Mode. The normalised volumetric flow required from the feeder. Note: This is minimum flow allowed if Demand.On is enabled. | ||

Temperature & Pressure RequirementsNOTE: The VLE options are only valid for components with VLE information. When one of the VLE options is chosen, the VLE tab will be visible. Some VLE conditions are inherently unachievable: for example you can never have a saturated vapour if there are nonvolatile liquid components present. If you try to set an unachievable condition you will get an error. | ||||

| VLEquilibrium | Off | Default. No VLE data is applied. The user can enter values for both P_Reqd and T_Reqd. | ||

| Saturated_Vap(T) | The Feeder composition will be auto adjusted to saturated VAPOUR conditions at the Temperature in the T_Reqd field. | |||

| Saturated_Vap(P) | The Feeder composition will be auto adjusted to saturated VAPOUR conditions at the Pressure in the P_Reqd field. | |||

| SuperHeat_Vap(dT,P) | This allows the Feeder mixture to be at superheated conditions at the Pressure in the P_Reqd field. The temperature will be automatically adjusted to be at the saturated temperature plus SuperHeatReqd. | |||

| SuperHeat_Vap(T,P) | This allows the Feeder mixture to be at superheated conditions. P_Reqd must be ≤ P_saturated at the specified Temperature (T_Reqd)(SysCAD will auto adjust the pressure if it is greater than the saturated pressure). | |||

| Saturated_Liq(T) | The Feeder composition will be auto adjusted to saturated LIQUID conditions at the Temperature in the T_Reqd field. | |||

| Saturated_Liq(P) | The Feeder composition will be auto adjusted to saturated LIQUID conditions at the Pressure in the P_Reqd field. | |||

| Subcooled_Liq(dT,P) | This allows the Feeder mixture to be at sub-cooled conditions at the Pressure in the P_Reqd field. The temperature will be automatically adjusted to be at the saturated temperature minus SubCoolingReqd. | |||

| Subcooled_Liq(T,P) | This allows the Feeder mixture to be at sub-cooled conditions. P_Reqd must be ≥ P_saturated at the specified Temperature (T_Reqd) (SysCAD will auto adjust the pressure if it is less than the saturated pressure). | |||

| Saturated(X,T) | The Feeder composition will be auto adjusted to saturated conditions at the Temperature in the T_Reqd field, with a vapour fraction (steam quality if the volatile component is H2O) of X_Reqd. | |||

| Saturated(X,P) | The Feeder composition will be auto adjusted to saturated conditions at the Pressure in the P_Reqd field, with a vapour fraction (steam quality if the volatile component is H2O) of X_Reqd. | |||

| Saturated_Non_Cond(T,P) | The vapour fraction of the volatile component (X_Rqd) will be auto adjusted to saturated conditions at the Temperature in the T_Reqd field and Pressure in the P_Reqd field, when non-condensable gases are present. | |||

| Relative Humidity | The Feeder must contain gases. If the user selects this option, SysCAD will adjust the amount of H2O(g) to give the required relative humidity in the gas stream. SysCAD will adjust the fractions of the gases in the Feeder other than H2O(g) proportionally. Relative Humidity = Partial Pressure of H2O(g) / Saturation Pressure of H2O(g) at Stream Temperature * 100 Please see the YouTube link for a video presentation on using this functionality. | |||

| VapourCalcs | Display | This field is only visible if VLEquilibrium is in use. Shows VLE method and component used. | ||

| TemperatureReqd / T_Reqd | Input / Calc | The required temperature of the material from the feeder. This value is calculated if one of the Saturated at pressure or dT VLE options are chosen. | ||

| PressureReqd / P_Reqd | Input / Calc | The required input pressure. This value is not usually required for steady state mass balances. However, for energy balances, especially in the case of steam/water, it is important that the correct pressure is specified. This value is calculated if one of the Saturated at temperature VLE options is chosen. | ||

| StaticHead | Input | Only visible in Dynamic projects. The static head. This will affect the pressure in the downstream pipe. | ||

| SuperHeatReqd | Input | This field is only visible if the SuperHeat_Vap(dT,P) VLE option is selected. This is the degrees of superheat of the stream (T - Saturation temperature). | ||

| SubCoolingReqd | Input | This field is only visible if the SubCooled_Liq(dT,P) VLE option is selected. This is the degrees of subcooling of the stream (Saturation temperature - T). | ||

| X_Reqd(VapourFrac) | Input / Calc | This field is only visible if VLEquilibrium is in use. The required vapour fraction (or steam quality if the volatile component is H2O) of the material from the feeder. This value is calculated unless the Saturated(X,T) or Saturated(X,P) VLE option is chosen. | ||

| RelHumidityReqd | Input | This field is only visible if the RelativeHumidity VLE option is selected. This is the required relative humidity (Partial Pressure of H2O(g) / Saturation Pressure of H2O(g) at Stream Temperature) of the feed. | ||

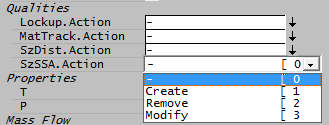

Qualities | ||||

Stream qualities such as "Lockup", "MatTrack - material tracking", "SzSSA - Size using average specific surface area" and "SzDIst - Size distribution" maybe created / removed here. The visibility of this section will depend on user selection and Operation mode selection.

| ||||

| (These options are only available as specified in the model's configuration file.) | ||||

| Lockup.Action | Input | The user may choose to Create the Lockup quality. The 'Lockup' values are set on the 'DLockup' tab. The field displays the actual state of the Lock Up function: If this has been enabled then this will display 'Lockup.Action(On)', otherwise it will display 'Lockup.Action'. Please see LockUp for more information. Note: Lockup must first be enabled on the Plant Model - Qualities Tab before the user may create it here. | ||

| MatTrack.Action | Input | The user may choose to Create the Material Tracking quality. The 'Tracking' values are set on the 'DTrack' tab. The field displays the actual state of the Material Tracking function: If this has been enabled then this will display 'MatTrack.Action(On)', otherwise it will display 'MatTrack.Action'. Please see Material Tracking for more information. Note: Material Tracking must first be configured on the Plant Model - Qualities Tab before the user may create it here. | ||

| SzDist.Action | Input | The user may choose to Create the Size Distribution quality. The 'Size Distribution' values are set on the 'DSz' tab. The field displays the actual state of the Size Distribution function: If this has been enabled then this will display 'SzDist.Action(On)', otherwise it will display 'SzDist.Action'. Please see Size Distribution (PSD) for more information. | ||

| SzSSA.Action | Input | The user may choose to Create the Specific Surface Area (SSA) quality. The 'SSA' values are set on the 'SSA' tab. The field displays the actual state of the SSA function: If this has been enabled then this will display 'SzSSA.Action(On)', otherwise it will display 'SzSSA.Action'. Please see Specific Surface Area (SSA) for more information. | ||

| Lockup.InUse | Display | Displays the state of the LockUp function: Yes or No. | ||

| MatTrack.InUse | Display | Displays the state of the Material Tracking function: Yes or No. | ||

| SzDist.InUse | Display | Displays the state of the Size Distribution (PSD) function: Yes or No. | ||

| SzSSA.InUse | Display | Displays the state of the Specific Surface Area (SSA) function: Yes or No. | ||

Cross Page ConnectionNo connection can be made in a Sink unit - the user MUST connect two cross-page connectors via the Source unit (Feed to the flowsheet). | ||||

| ConnectionBlocked | Tick Box | Marks the unit is a material input or material output and unavailable for cross page connection. Selecting the tickbox on the Sink unit will remove the unit from the "available to connect (ConnectTo)" list. For example, if the Sink is the Product, user may tick this box to avoid accidentally selecting this from the ConnectTo droplist. Selecting the tickbox on the Feeder will break any cross page connections already in place. | ||

| ConnectionOn | Tick Box | This is used to enable the configured cross page connection. This may only be accessed on a Source, it cannot be changed on a Sink unit. | ||

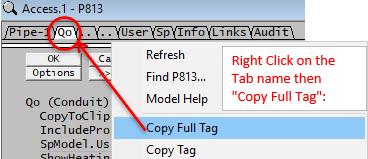

| ConnectTo | Input / List | The required Tag Name of the connecting Sink unit. The drop-down list will contain the tags of all un-connected Sinks in the project. The user may also type in the Tag of the required Sink. NOTE: If setting the connection via a controller or Excel, a string variable is expected, so use the tag name of the connecting sink.

| ||

| ConnectedTo | Display | If ConnectionOn is enabled AND ConnectionBlocked is not selected AND a valid Sink Tag is entered in the ConnectTo field, then the connected Sink tag is displayed in this field.

| ||

| Connected | Display | Displays the status of the cross page connection - either Yes or '-'. | ||

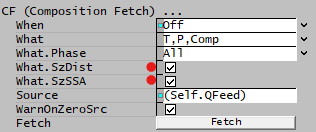

Composition Fetch

| ||||

| CF.When | Off | No information will be transferred automatically. The user may still manually transfer data from the source by pressing the CF.Fetch button. | ||

| OnceOff | This mode allows a once off automatic information transfer of information at the next project step (if the project is solving) or when project solve/run is started (if the project is stopped). Once the data has been transferred, it will revert back to the off mode. | |||

| Continuous | This mode allows continuous automatic information transfer while the project is solving. This is similar to a cross page connector in terms of material flow but the solver will treat the unit operations separately. Therefore, for large projects with difficult to solve recycle streams, this is a great way of breaking up the solver network to improve solve speed. | |||

| CF.What | Nothing | No information will be fetched. | ||

| T | Temperature information from the CF.Source unit (specified by the user) will be used. | |||

| P | Pressure information from the CF.Source unit (specified by the user) will be used. | |||

| T, P | Temperature and Pressure information from the CF.Source unit (specified by the user) will be used. | |||

| Comp | Component make up information from the CF.Source unit (specified by the user) will be used. | |||

| T, Comp | Temperature and Component make up information from the CF.Source unit (specified by the user) will be used. | |||

| P, Comp | Pressure and Component make up information from the CF.Source unit (specified by the user) will be used. | |||

| T, P, Comp | Temperature, Pressure and Component make up information from the CF.Source unit (specified by the user) will be used. | |||

| Flow | Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| T, Flow | Temperature and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| P, Flow | Pressure and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| T, P, Flow | Temperature, Pressure and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| Comp, Flow | Components make up and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| T, Comp, Flow | Temperature, Components make up and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| P, Comp, Flow | Pressure, Component make up and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| T, P, Comp, Flow | Temperature, Pressure, Component make up and Flowrate information from the CF.Source unit (specified by the user) will be used. | |||

| CF.What.Phase | Only available in Build 139 or later. Only shown if the CF.What option selected includes Comp and/or Flow. | |||

| All | The fetch will be based on ALL of the phases in the stream. | |||

| Solids | The fetch will only be based on the solid phase in the stream. | |||

| Liquids | The fetch will only be based on the liquid phase in the stream. | |||

| Vapours | The fetch will only be based on the vapour phase in the stream. | |||

| Solids & Liquids | The fetch will only be based on the solid and liquid phases in the stream. | |||

| Solids & Vapours | The fetch will only be based on the solid and vapour phases in the stream. | |||

| Liquids & Vapours | The fetch will only be based on the liquid and vapour phases in the stream. | |||

| CF.What.Quality | TickBox | Only shown if the CF.What option selected includes Comp. Different tick boxes will be visible, depending on the options enabled in the project. Possible options include: LockUp, Size data and so on. See Qualities Models for more information. The project in the example shown below has Size Distribution enabled, and therefore the user may also fetch the size data from the stream in the composition fetch: | ||

| CF.Ratio | Input | Only shown if the CF.What option selected includes Flow. This allows the user to set a ratio of the feeder flow to the source flow. So, for example, if the ratio = 1 (default value, and most commonly used setting) then the flow from the feeder will be equal to the flow in the source. If the ratio is set to 2, then the feeder flow will be twice that from the source. | ||

| CF.Source | Input |

| ||

| CF.WarnOnZeroSrc | TickBox | If this is enabled then the user will receive a warning if the flow in the source is zero (or if the surge content is zero in a dynamic project) | ||

| CF.WarnOnCoExist | TickBox | |||

| CF.Fetch | Button | The required information is fetched from the CF.Source unit operation and used to set the current feeder configuration. | ||

EB(Feed Processing)...NOTE: This section is only visible for the Operation - General Mode only. For other operation modes, EB sub models are either NOT available or available in a simplified form (e.g. Makeup). | ||||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. | ||

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. | ||

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. | ||

| Makeups | Input | The number of Makeup Blocks required. Extra dropdown options Makeup1, Makeup2, etc. will be added to allow these to be switched on and off and prioritised in relation to the other sub-models. | ||

| MakeupX | List | This can be used to switch the Makeup Block (MU) on or off and prioritise it in relation to the other sub-models. If this is 'On' then the associated page, MUX becomes visible and may be configured. Note: This field is only visible if the entry for 'Makeups' is greater than 0. If there is one makeup then X=1. If there are two makeups, then X=1 and X=2, etc. | ||

Results: Flow Conditions | ||||

| State | Display | Displays the state of the unit. Options are: Feeder, Sink, Feeder-Connected, Sink-Connected. | ||

| MassFlow / Qm | Display | The mass flow into or out of the unit. | ||

| VolFlow / Qv | Display | The volume flow into or out of the unit. | ||

| NVolFlow / NQv | Display | The normalised volume flow into or out of the unit. | ||

| Temperature / T | Display | The Temperature of the material flowing into or out of the unit. | ||

| Density / Rho | Display | The density of the material flowing into or out of the unit. | ||

| NDensity / NRho | Display | The normalised density of the material flowing into or out of the unit. | ||

| Pressure / P | Display | The pressure of the unit. | ||

Options | ||||

| PasteData | Button | Allows the user to paste data copied from a stream (using the 'CopyToClipboard' button). The stream may be in the current SysCAD project, or another project. See How do I copy Stream data to a Feeder? | ||

| ShowContent | Tickbox | Allows the user to view the Content tab of the Feeder. | ||

| ShowQFeed | Tickbox | When selected, the QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined feed stream. See Material Flow Section. Tags in the QFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. This is the flow from the Feeder unit, either via the Cross Page Connection or as set by the user, but prior to any Makeups. | ||

| ShowQProd | Tickbox | When selected, the QProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the product stream. See Material Flow Section. Tags in the QProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. This is the actual flow from the Feeder unit, including any Makeups. | ||

Batch Feed

This functionality allows the user to allow the Feeder to deliver a discrete batch to the project. This section is only available in Dynamic mode.

| Tag (Long/Short) | Input / Calc | Description |

| BatchMethod | None | The Batch functionality is not enabled. |

| Total Mass | The Batch functionality is enabled and the required batch size is defined in terms of Mass flow. Further fields will become visible if this option is selected allowing the user to set the required batch mass. | |

| Total Volume | The Batch functionality is enabled and the required batch size is defined in terms of Volume flow. Further fields will become visible if this option is selected allowing the user to set the required batch volume. | |

| The following fields will be visible if Total Mass is selected as the Batch method. | ||

| M.BatchAddition | Input | The Mass of the required Batch. This amount of material will be delivered by the Feeder at the rate specified in Qm.Capacity or Qv.Capacity. When this value is set the amount of material will be added to the amount of material already in BatchRemaining (the field below), and then this field will revert to 0. |

| M.BatchRemaining | Calc / Input | The Mass of material currently in a Batch, i.e. the amount of material in a Batch that still has to be delivered by the Feeder. Normally this value is initialised at the start of a run and then it is calculated by SysCAD from the amount required in M.BatchAddition and the amount already delivered by the Feeder. However, the user may set this value and hence override the calculated Batch amount at any stage. If the users sets this as Undefined (or '*') this is equivalent to any infinite Batch and therefore the flow from the Feeder will not be restricted. |

| M.BatchTotal | Display | The Total Mass that has been added to the Batch using the BatchAddition field. Note this will exclude any Preset Batch amount or any manual changes to the BatchRemaining field. |

| The following fields will be visible if Total Volume is selected as the Batch method | ||

| V.BatchAddition | Input | The Volume of the required Batch. This amount of material will be delivered by the Feeder at the rate specified in Qm.Capacity or Qv.Capacity. When this value is set the amount of material will be added to the amount of material already in BatchRemaining (the field below), and then this field will revert to 0. |

| V.BatchRemaining | Calc / Input | The Volume of material currently in a Batch, i.e. the amount of material in a Batch that still has to be delivered by the Feeder. Normally this value is initialised at the start of a run and then it is calculated by SysCAD from the amount required in V.BatchAddition and the amount already delivered by the Feeder. However, the user may set this value and hence override the calculated Batch amount at any stage. If the users sets this as Undefined (or '*') this is equivalent to any infinite Batch and therefore the flow from the Feeder will not be restricted. |

| V.BatchTotal | Display | The Total Volume that has been added to the Batch using the BatchAddition field. Note this will exclude any Preset Batch amount or any manual changes to the BatchRemaining field. |

| The following fields will be visible if Total Mass or Total Volume is selected as the Batch method. | ||

| BatchState | None | No Batch mode has been set. |

| Inactive | A Batch method has been selected, but the Batch is undefined. | |

| Busy | A Batch method has been selected, there is material remaining in the Batch, and hence there is flow from the Feeder due to the Batch. | |

| Stop Flow | A Batch method has been selected, there is NO material remaining in the Batch, and hence there is no flow from the Feeder, i.e. The Batch will prevent the Feeder from discharging any material. | |

| BatchClearOnEmpty | Tickbox | Available from Build 139.32925. If selected, this clears (i.e. sets to 0) the Batch amount with the Empty Action. |

| BatchUsePreset | Tickbox | This enables the use Preset for the Batch amount. |

| M or V.BatchUsePreset | Input | The Mass or Volume of the Batch when the model is Preset. Refer to Preset for more information. |

Content Tab Page

This section mainly has read only variables, except for the first section, Model.

- Model determines which species model the feeder uses. The options available to the user will depend on the species model used by the project. Please refer to the species model for a description of this page, if a species model is chosen. The default, 'Standard', will be described here.

| Tag (Long/short) | Input / Calc | Calculated Variables / Options |

|---|---|---|

ModelThe SpModel.Reqd field is only shown if more than one Species Model is available in the project (e.g. Standard and Bayer3). On a Content page, it is an input field. If SpModel.Reqd is set to Inherit, then the species model used with the be the default method as selected in the configuration file. | ||

| SpModel.Reqd | Inherit | Upstream configuration will be used. |

| Standard | All the variables are calculated using the Mass Weighted Mean of the species. | |

| Species Model | Use an alternative species model, such as 'Bayer3' or 'Potash'. | |

| SpModel.Used | Standard | The Standard species model is being used. |

| Species Model | An alternative species model is being used. | |

| SpModelType | Display | This field displays the Species Model type (or Name) used. |

Content Properties | ||

| Temperature / T | Calc | The temperature of the incoming material. |

| Pressure / P | Calc | The pressure of the incoming material. |

| Density See the section on Density for further information. | ||

| Density / Rho | Calc | Calculated Density of the material |

| SolidDensity / SRho | Calc | Density of the solids phase |

| LiquidDensity / LRho | Calc | Density of the liquid phase |

| VapourDensity / VRho | Calc | Density of the vapour phase |

| SlurryDensity / SLRho | Calc | Density of the Slurry (Liquid and Solid phase) |

| SolidConc | Calc | The solids concentration at stream temperature. |

| Density Correction | ||

| H2O(l).State | Data | This will be OK if all of the species with density correction functions in the Feeder conditions are within their mass fraction limits. Any species that has exceeded its mass fraction limit will be shown in this field. For example, if the user has a density correction function for NiSO4(aq) that is valid up to a mass fraction of 10% NiSO4 and the stream contains 15% NiSO4(aq), this field will contain: Limit:NiSO4(aq). |

| H2O(l).Rho | Calc | The density of pure water at the temperature and pressure of the Feeder. |

| H2O(l).CorrFactor | Calc | The calculated density correction factor using all the correction factors of aqueous species in the Feeder for which density correction factors have been defined. Please see Density Correction Function. |

| H2O(l).AppRho | Calc | The calculated density of the liquor with only water and the components that have density correction functions.

Note: This value may be lower or higher than the actual liquid density if there are other liquid components in the Feeder that do not have density correction functions. |

| If the Additional Density Correction option is selected in the Plant Model - Species tab page or from the Include Properties dropdown list on the first page of the material Flow section, then the following fields will also be shown: | ||

| H2O(l).AppRho25 | Calc | The calculated density of the liquor with only water and the components that have density correction functions, at 25°C. |

| H2O(l).AppQm | Calc | The calculated mass flow of the liquor with only water and the components that have density correction functions. |

| H2O(l).AppQv | Calc | The calculated volume flow of the liquor with only water and the components that have density correction functions. |

| H2O(l).Fct.X(y) | Calc | The calculated density correction factor for species X(y). |

| Mass Fractions | ||

| SolidFrac / Sf | Calc | Solids mass fraction |

| LiquidFrac / Lf | Calc | Liquid mass fraction |

| VapourFrac / Vf | Calc | Vapour mass fraction |

| SlurryFrac / SLf | Calc | Available from Build 139.31388. Slurry (solids + liquids) mass fraction. |

| Slurry.SolidFrac / Slurry.Sf | Calc | Solids mass fraction on slurry basis (solids + liquids) |

| Slurry.LiquidFrac / Slurry.Lf | Calc | Liquid mass fraction on slurry basis (solids + liquids) |

| Volume Fractions | ||

| SolidVolFrac / Svf | Calc | Solids volume fraction |

| LiquidVolFrac / Lvf | Calc | Liquid volume fraction |

| VapourVolFrac / Vvf | Calc | Vapour volume fraction |

| SlurryVolFrac / SLvf | Calc | Available from Build 139.31388. Slurry (solids + liquids) volume fraction. |

| Slurry.SolidVolFrac / Slurry.Svf | Calc | Available from Build 139.31388. Solids volume fraction on slurry basis (solids + liquids) |

| Slurry.LiquidVolFrac / Slurry.Lvf | Calc | Available from Build 139.31388. Liquid volume fraction on slurry basis (solids + liquids) |

| Molar Fractions | ||

| MlSolidFrac / MlSf | Calc | Solids molar fraction |

| MlLiquidFrac / MlLf | Calc | Liquid molar fraction |

| MlVapourFrac / MlVf | Calc | Vapour molar fraction |

| MlSlurryFrac / MlSLf | Calc | Available from Build 139.31388. Slurry (solids + liquids) molar fraction. |

| MoleWt | Calc | The average molecular weight of all the species. |

| SolidMoleWt / SMoleWt | Calc | Available from Build 139. The average molecular weight of all solid species. |

| LiquidMoleWt / LMoleWt | Calc | Available from Build 139. The average molecular weight of all liquid species. |

| VapourMoleWt / VMoleWt | Calc | Available from Build 139. The average molecular weight of all vapour species. |

Content EnergyThese properties will only be shown if the user has chosen to display the Energy (Thermodynamic) Properties on the Plant Model - Views tab page or from the Include Properties dropdown list on the first page of the material Flow section. | ||

| Specific Heat | ||

| Cp@0 | Calc | Cp of the total mixture in the Feeder @ 0 °C. |

| Cp / Cp@T | Calc | Cp of the total mixture in the Feeder @ temperature. |

| SmsCp@T | Calc | Solids Cp at the Feeder temperature |

| LmsCp@T | Calc | Liquid Cp at the Feeder temperature |

| VmsCp@T | Calc | Vapour Cp at the Feeder temperature |

| SLmsCp@T | Calc | Slurry Cp at the Feeder temperature |

| CpCv | Calc | The ratio of specific heat at constant pressure to specific heat at constant volume at the Feeder temperature. |

| Enthalpy - Sensible | ||

| Hs@T | Calc | The change in enthalpy, dH, (excluding phase change) from 0°C to Feeder temperature for the total mixture. |

| SmsHs@T | Calc | The change in enthalpy, dH, (excluding phase change) from 0°C to Feeder temperature for the solids. |

| LmsHs@T | Calc | The change in enthalpy, dH, (excluding phase change) from 0°C to Feeder temperature for the Liquids. |

| VmsHs@T | Calc | The change in enthalpy, dH, (excluding phase change) from 0°C to Feeder temperature for the vapours, or gases. |

| SLmsHs@T | Calc | The change in enthalpy, dH, (excluding phase change) from 0°C to Feeder temperature for the combined solids and liquids. |

| Enthalpy - including Phase Change (Please see What is the difference between Hs and Hz? | ||

| Hz@T | Calc | The change in enthalpy, dH,(including phase change) from 0°C to Feeder temperature for the total mixture. |

| Total Enthalpy (previously heading was Enthalpy of Formation) Total Enthalpy = Heat of Formation at 25 + [math]\displaystyle{ \int\limits_{25}^{T}Cp dT\, }[/math] | ||

| Hf@0 | Calc | Total Enthalpy for the mixture at 0°C and 101.325 kPa, per mass. |

| Hf@T | Calc | Total Enthalpy for the mixture at the Feeder temperature and pressure, per mass. |

| Entropy and Free Energy | ||

| S@0 | Calc | Entropy for the total mixture at 0°C and 101.325 kPa. |

| S@T | Calc | Entropy for the total mixture at the Feeder temperature and pressure. |

| G@0 | Calc | Gibbs Free Energy (mass basis) for the total mixture at 0°C and 101.325 kPa. |

| G@T | Calc | Gibbs Free Energy (mass basis) for the total mixture at the Feeder temperature and pressure. |

| mlG@T | Calc | Gibbs Free Energy (mole basis) for the total mixture at the Feeder temperature and pressure. |

Values at User defined Temperature and PressurePlease see included properties - Values at User Defined T and P. | ||

Solubility ValuesPlease see included properties - Solubility. | ||

Saturation ValuesThese properties are related to the saturation temperature and pressure of solution. These fields are only visible if the Additional Properties option for Saturation values is selected in the Plant Model - Views tab page or from the Include Properties dropdown list on the first page of the material Flow section. | ||

| Saturation... | ||

| Component | List | Any component that has the correct Vp Equations defined in the species database maybe selected here. See VLE sub section for more information. |

| VapourFrac / Vf | Calc | Displays the vapour mass fraction. |

| TotalP | Calc | Displays the total pressure. |

| PartialP | Calc | Displays the partial pressure based on the component selected. |

| SatP@T | Calc | Saturated pressure at the mixture temperature. |

| SatT@PP | Calc | Saturated temperature at the mixture's partial pressure. Will be NAN (displayed as *) when no partial pressure. |

| SatT@P | Calc | Saturated temperature at the mixture pressure. |

| WaterSatT@P | Calc | Displays the Saturation Temperature at pressure based on pure water. This is used to calculate the Boiling point elevation. (Please see Water and Steam Properties for further information on this calculation) |

| BPE | Calc |

Note: User can change the BPE value limits in the Plant Model - species tab. |

| Temperature / T | Calc | Temperature of the Feeder. |

| SuperHeat@PP | Calc | Super Heat at the mixture's partial pressure (T-SatT@PP). Will be NAN (displayed as *) when no partial pressure. |

| SuperHeat@P | Calc | Super Heat at the mixture's pressure (T-SatT@P). |

| Subcooling@P | Calc | The amount of Subcooling at the mixture's pressure (SatT@P-T). |

| LatHtVap | Calc | The Latent heat of vaporisation of the listed component at the temperature and partial pressure of the vaporising species at the local conditions. The latent heat is the difference in enthalpy between the vapour phase and the liquid phase of the species. This is calculated as Enthalpy(VapourPhase at local Temperature and Partial Pressure) - Enthalpy(Liquid Phase at T and Total Pressure). This is the enthalpy difference used in energy calculations. NB unless the partial pressure of the vaporising species is equal to the saturation pressure, the latent heat may not have exactly the same value as for saturation conditions since the vapour phase enthalpy depends on its partial pressure. |

| LatHtVap@SatP | Calc | The Latent heat of vaporisation of the listed component at the temperature and saturation pressure of the vaporising species corresponding to the local temperature. The latent heat is the difference in enthalpy between the vapour phase and the liquid phase of the species. This is calculated as Enthalpy(VapourPhase at Temperature, T and saturation pressure for that T, PSat(T)) - Enthalpy(Liquid Phase at T and Total Pressure). This is the latent heat that would be found in saturation tables for a given temperature. |

| RelHumidity | Calc | The relative humidity of the Feeder. This is only useful if the Feeder contains gases, such as O2, N2, Air, etc. Relative Humidity = Partial Pressure of the Saturation Component (usually H2O) / Saturation Pressure of the Saturation Component at Stream Temperature * 100 |

Acidity (pH)These values are calculated based on the Ka and Kb values for acids and bases that are defined in the species database. It does not take buffering into account, and hence is, at best, an estimate of the pH. SysCAD does have default Ka and Kb values defined for some acids and bases, and the user may enter values for other compounds. For a description of the method that SysCAD uses to calculate the acidity values see Acidity Calculations. These values will only be shown if the user has chosen to display the pH_Estimate variables on the Plant Model - Views tab page or from the Include Properties dropdown list on the first page of the material Flow section. | ||

| Acidity(@25C) | ||

| pH.State | Calc | Either OK - only acids or bases present, OR Acid and Base present, therefore the calculations will be inaccurate. |

| pH.negLogH | Calc | This is the negative of the log of the Hydrogen ion molar concentration at 25°C. |

| pH.AcidsPresent | List | This lists all of the acids present in the Feeder that are used to calculate [H+] (molar concentration). |

| pH.BasesPresent | List | This lists all of the bases present in the Feeder that are used to calculate [OH-] (molar concentration). |

| pH.H_Cation | Calc | Only displayed if the species list includes H+(aq). This is the negative of the log of the Hydrogen ion molar concentration at 25 °C, due only to the presence of the H+(aq) ion (all other acids and bases are ignored). |

ChargePlease see included properties - Charge | ||

Transport PropertiesPlease see included properties - Transport | ||

Heats of Combustion PropertiesOnly available in Build 139 or later, please see included properties - Heats of Combustion. | ||

Solution ImpuritiesPlease see included properties - Solution Impurities. | ||

H2O PropertiesPlease see included properties - H2O Properties | ||

WQ Tab Page

Please see included properties - Water Quality.

DSp Tab Page

- This Tab will contain a list of all of the species that are specified in the Project configuration file. If a species exists in more than one phase, it will be shown in each phase, e.g. H2O(l) and H2O(g).

- If this Tab is not configured, the default value will be 100% water. Therefore, if a project contains only water, the cause may be that the Feeder species requirements have not been configured.

- The manner in which you can specify the relative amount of the species depends on which View and SpBasis you have selected. The options, and their consequences, are described in the tables below.

| Tag (Long/Short) | Option | Description |

| Content (Tag Display and Flow Basis) | ||

| SpeciesTag | The Species Long / short button is used to change the display of the Species names between the Short form, the Chemical compound, or the longer species names. See Species Long/short Example for more information. | |

| SpBasis | All | The total mass or moles of the stream will be used when calculating fractional values. |

| Phase | The mass or moles of each phase (solid, liquid or gas) will be used when calculating fractional values. | |

| Individual Phase | The mass or moles of each Individual phase (solid, liquid, aqueous, organic, gas, etc.) will be used when calculating fractional values. | |

| Species View Options | ||

| Mass Flow | Mass Flow Rate of the species, phase or total. | This mode will overwrite the QmReqd configured on the first page. The total flow rate delivered by the feeder will be the sum of all the species flow rates. |

| Mass Frac | Mass Fraction of the species or phase. | The total flow rate delivered by the feeder will be based on the QmReqd configured on the first page. The total fractions will always add to 100%. |

| Mole Flow | Mole Flow Rate of the species, phase or total. | This mode will overwrite the QmReqd configured on the first page. The total flow rate delivered by the feeder will be the sum of all the species flow rates. |

| Mole Frac | Mole Fraction of the species or phase. | The total flow rate delivered by the feeder will be based on the QmReqd configured on the first page. The total fractions will always add to 100%. |

| ============== Totals | ||

| Total | Calculated [c] | The total value for the chosen view. For fraction views, the total fractions will always add to 100%. |

| Solids | Input or Calculated [c] | This is the total for the solid phase occurrence. For the FeederSink unit, if the Feeder Operation Selection allows solids, then this field may be set by the user or default to 100%. |

| Liquids | Input or Calculated [c] | This is the total for the liquid phase occurrence. For the FeederSink unit, if the Feeder Operation Selection allows liquids, then this field maybe set by the user or default to 100%. |

| Vapours | Input or Calculated [c] | This is the total for the vapour phase occurrence. For the FeederSink unit, if the Feeder Operation Selection allows vapours, then this field maybe set by the user or default to 100%. |

| Individual phase X | Input or Calculated [c] | If the Individual Phase basis is chosen, then additional fields will appear for the flow or fraction of each individual phase total. The individual phase is defined in the SysCAD database, see Species Definition |

| ============== Phase / Individual Phase (Species layout is set in the cfg file.) | ||

| Species X | Input | User can enter the composition of each species for the chosen view. |

| Species Calculation X | Calculated [c] | Any user defined Species Calculations maybe visible here. |

| Example:

We are given an ore analysis on a dry mass basis with a moisture content of 5% by mass.

| ||

| Global Material View Options | ||

| ImageColumnCount | The default number of columns displayed on the DSp (Define Species Flow) tab is 2. However, the user may change the number of columns displayed by changing this value, the maximum is 4. This can also be changed on the Views Tab of the Plant Model, hot jump is provided by the next variable below. | |

| ViewOptions | Use the magnifying glass hot jump to go to the Views Tab | |

| FixUpStrategy | Only relevant if the Mass Frac or Mole Frac View options are chosen. Allows SysCAD to 'fix' the stream make up to 100% if the sum of the numbers entered is less than or greater than 100%. | |

| Largest | SysCAD will increase or decrease the fraction of the species with the largest unmodified fraction.

| |

| BottomUp | SysCAD will increase or decrease the fraction of the species which is at the bottom (last) of the list of species.

| |

Notes

- The fields can either be calculated (e.g. sum of all species in the phase) or specified. The phase total will be the sum of individual species specified.

- If the Phase flows are adjusted, SysCAD will adjust all the individual species flow to meet the specified total phase flow.

- Similarly, if the Phase fraction is adjusted, the individual species fractions on a phase basis will be preserved.

- Only adjust either the total phase flow or the individual species flow at any one time to avoid over specifying.

DLockup Tab Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Lockup Quality Configuration - Create | ||

| DLockup... | ||

| Each lockup species (selected on the Plant Model - Qualities Tab) will have the following field: | ||

| LockUpReqd | Input | The fraction of the species that is 'locked up', or not available for reaction. |

Please see Lockup - Creating Lockup for more information.

DTrack Tab Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Material Tracking Set Options | ||

| SetMethod | None (Hide) | This method is only available if 'Modify' is chosen on the Qi or Content page. This will hide the configurable fields. |

| Single Material | This method is used if all species are the same material. Select the Material from the drop down list. | |

| Material Fractions | This method is used if all species have the same mix of materials. Enter the fractions for each material. The fractions must add to 1. If the specified percentages add to less than 1 then the leftover is assumed to be 'Other' material. When 'Modify' is being used, a '*' may be entered to allow the feed fraction to be used (i.e. not modified). | |

| All Fractions | This method allows each species with material tracking to have a different mix of materials. As with the Material Fractions method, the user must enter the fractions for each material, but now for each species with material tracking in a table. The fractions for each species must add to 1. If the specified fractions add to less than 1 then the leftover is assumed to be 'Other' material. When 'Modify' is being used, a '*' may be entered to allow the feed fraction to be used (i.e. not modified). | |

| Redistribute Other (All) | This method is only available if 'Modify' is chosen on the Qi or Content page. This will redistribute the fraction of 'Other' material to the other fractions in line with their current fractions for all species. | |

| Redistribute Other | This method is only available if 'Modify' is chosen on the Qi or Content page. For each species selected, the fraction of 'Other' material will be redistributed to the other fractions in line with their current fractions. For example, if a species had 50% Red, 25% Green and 40% Other, this will be changed to 67% Red, 33% Green and 0% Other. If the species is 100% Other, then this will remain as Other. | |

| SetWhen | This method is only available if 'Modify' is chosen on the Qi or Content page, or if 'Modify Content' is chosen on the Content page of a surge unit. | |

| Off | This option allows the user to keep their configuration while not actually modifying the quality. | |

| AtStart | This option is only available if 'Modify Content' is chosen. The modify will only be applied at the start of a run. | |

| Always | The modify will always be applied. | |

| SetNow | Button | This button is only available if 'Modify Content' is chosen. This allows the Modify to be applied when pressed manually or when set via a General Controller (PGM). |

| Material | List | Only visible if SetMethod 'Single Material' is chosen. A list of all Materials as defined on the Plant Model - Qualities Tab. |

| Mat001.Rqd | Input | Only visible if SetMethod 'Material Fractions' is chosen. The required fraction of this material. There will be one of these fields for each material as defined on the Plant Model - Qualities Tab. |

| Other.Rqd | Calc | Only visible if SetMethod 'Material Fractions' is chosen. The fraction which is assumed to be 'Other' material. This will be 1-(sum of all defined material required fractions). |

| SpecieName | Tickbox | Only visible if SetMethod 'Redistribute Other' is chosen. This option determines whether the 'Other' material will be redistributed to the other materials for this species. There will be one of these fields for each species for which material tracking is enabled on the Plant Model - Qualities Tab. |

| AllowDirectSet | Tickbox | This allows the fractions on the Track tab page to be directly set for all species, similar to the way the mass of the contents may be directly changed on the 'M' (Mass) content tab page. |

Please see Material Tracking - DTrack Data Sections for an explanation of the fields.

DSz Tab Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Inputs | ||

| Distribution | Input / Display | If more than one Size Distribution has been defined for the project, then the user may select the required Size distribution in this field. If only a single Size Distribution is defined for the project, then this field displays the Size distribution. |

| Method | Rosin-Rammler | Mass fraction retained in each size interval is calculated using the Rosin-Rammler equation with two user-specified constants: a & b. |

| Modified Rosin-Rammler | Mass fraction retained in each size interval is calculated using the Modified Rosin-Rammler equation with two user-specified constants: d50 and sharpness constant. | |

| Gaudin-Schuhmann | Mass fraction retained in each size interval is calculated using the Gaudin-Schuhmann equation with two user-specified constants: k & m. | |

| Lynch | Mass fraction retained in each size interval is calculated using the Lynch equation with two user-specified constants: d50 & m. | |

| LinearInterpolate | This method takes a user defined number of data points and interpolates to determine the size distribution across the full range of size intervals. | |

| DataPoints: Interval Fraction | With this method the user directly sets the mass fraction in each individual size interval. | |

| SingleDefn | Tick Box | This is enabled when you are tracking size data independently for multiple solids species. When enabled the user can select this to set a single size distribution definition that applies to ALL solid species (rather then separate parameters for each solid). |

| The required inputs will depend on the Method chosen. The Size Distribution fields will either be display fields, or in the case of Data Entry they will be input fields. Please see Size Distribution Definition for the equations and description of these fields. | ||

| Display Options | ||

| View (Not visible for Data Entry methods) |

Interval Fraction | The table will display the calculated mass fraction in each interval fraction. |

| Cumulative Passing | The table will display the cumulative mass passing through each sieve size. In this case the top size will always display 100%. | |

| Cumulative Retained | The table will display the cumulative mass retained on each sieve size. In this case the top size will always display 0%. | |

| Intervals | Clicking on this button will toggle between displaying the size intervals in Ascending or Descending order. | |

| Size_Units | List | The user may select the display units, i.e. mm, um, etc., from a drop-down list. |

Please see Size Distribution Definition for more information on the methods and constants used.

DSSA Tab Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| SSA Quality | ||

| Method | Display | Independent - when no PSD present and calculated from SAM; or FromPSD - when calculated from full PSD. |

| SetData | Tickbox | Allows the user to set values for SAM or Diameter (D). This is set by selecting Create for SzSSA.Action  . .

|

| SetDiam | Tickbox | Option when SetData is in use. Allows user to define SAM or D. |

| Solids | List | Solids Species that SSA calculations are based on. Result field if SSA solid component is set globally in PlantModel. Otherwise, allows the user to select the solid component to base the SSA calculations on. Note: The selected solid flowrate must be non-zero for the propagation of the following parameters to downstream unit operations. |

| Solids.Qm | Calc | The amount of selected SSA solids species (e.g.: Al[OH]3) present. |

| SeedSurfaceAreaM / SAM | Input | Seed Surface Area, Mass basis (m²/g) |

| SeedSurfaceAreaL / SAL | Calc | Seed Surface Area, Volume basis (m²/L). That is total Liquid Volume basis at temperature. |

| #/s | Calc | Particle number per second. |

| #/L | Calc | Particle number per litre. |

| D / PartDiam | Input | Input when SetData is in use and SetDiam is selected. Particle diameter. |

Please see DSSA Data Sections for more information.

Hints and Comments

- The configuration options for the feeder will be based on Operation mode selected.

- CF and EB groups are only visible for the General Operation mode.

- VLE options will be shortened or not visible for selected modes.

- The DSp tab species list will also be shortened for selected modes.

- The Link to MakeupSrc and Demand.on can be used at the same time, allowing the use of both Makeup and Demand in the same unit.

- The default Mode of the Feeder is MassFlow (Qm). The Const Pressure is only visible in dynamic simulations. The valid modes for Steady State are MassFlow (Qm), VolumeFlow (Qv) or NVolumeFlow (NQv)

- The default for FlowBasis is 'All'. See below for an example of the use of the other FlowBasis options.

- Depending on the method selected in the VLE list box, the feeder composition may automatically be adjusted. Example if VLE saturated_liq is selected and the user sets the species mass fraction to 100% H2O(g), the unit may change this to 100% H2O(l). Please always double check the component make up when changing VLE methods.

- If you are using a Feeder in Demand Mode, the number in the QmReqd, or QvReqd, box will NOT indicate the amount of material flowing from the feeder, but the minimum flow.

- If you have elected to enter Species composition flows on an individual basis on the DSP page, (e.g. using the Mass Flow view), then you will not be allowed to enter flowrates in the QmReqd (Mass flow required) field. This is because the total mass flow will be calculated from the individual Species flows entered. If the total mass flowrate input is necessary, simply switch back to the Mass Fraction view after individual flow data input.

- The feeder unit operation can be used to connect flow information between graphics pages. There are two easy ways of connecting flow information:

- Through the Cross Page Connection. If this is successful, the two unit operations will be connected as though there is a physical connection. Thus, when SysCAD is building the solution, these two unit operations will be included in the same solve network.

- Through Composition Fetch. In this case, an IMAGE of the flow information from the source unit operation is copied onto the current Feeder/Cross Page unit operation. The user can customise the frequency and amount of information fetched.

NOTE: When using composition fetch, the unit operations stay separated from each other. Thus, there is no permanent connections being made even when the frequency is set to continuous. Therefore, when SysCAD is building the solution, the two unit operations can belong to two separate solve networks. The user can use this method to break up a recycle stream if the solution is difficult to obtain in a closed loop.

- If a project is opened using the Open with alternate Configuration command, Feeders MAY lose their species compositions IF the new configuration file does not contain all of the species in the original configuration.

- If Composition Fetch is set to 'Continuous', and depending on the CF.What selection, there may be a conflict with other settings. For example the VLE selection may be configured to set the temperature and you have selected temperature under composition fetch, then there is a conflict. Only one of these conflicting configurations should be configured. When there is a conflict, the CF is ignored.

- To set up feeder information when flowsheets are being solved separately using Activate/Deactive flowsheet option: Use the CF Fetch - Self Flows option.

Examples

1. Simple Composition Fetch from Stream or Contents

|

|

2. Using Full Composition Fetch

- Set Feeder Operation Selection - Operation = General mode, allowing full functionality of the composition fetch.

- In the full composition mode, user has the flexibility to fetch only partial data, as well as control when the fetch will occur.

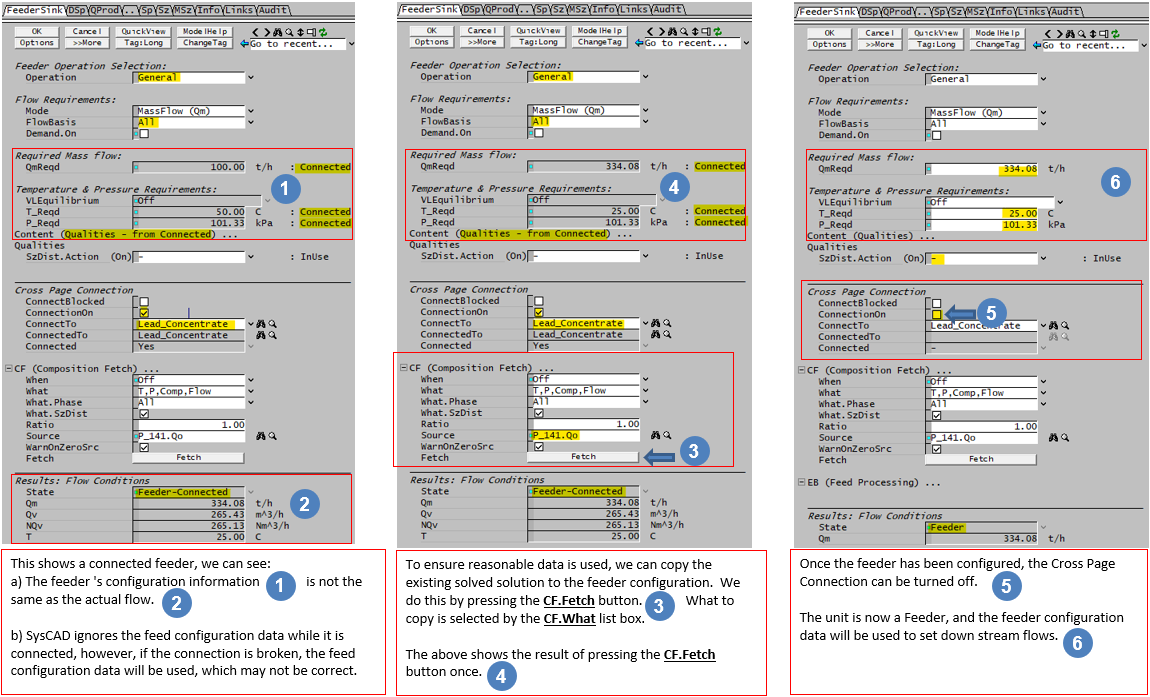

The diagram below shows a feeder (Pb_Concentrate) that has been connected to a sink (Lead_Concentrate). While the connection was still intact, SysCAD was solved, thus the Cross Page Connector carries an image of the flow condition, see Results: Flow Conditions section, the calculated information for Qm, Qv, T etc.

Use Composition Fetch to keep the pre-solved intermediate information as the feeder configuration information, this transfers Qm to QmReqd, T to T_Reqd etc.

If the user sets the frequency of the fetch to Continuous, then whenever values change, the feeder configuration will be updated. Therefore, if the Cross-page connection is disabled, (either manually or through the deactivate flowsheet option), the feeder will always contain the previous solved information.

NOTE: Composition Fetch assumes flow is "ALL" basis, so please make sure the FlowBasis (Under "Flow Requirements" section) is not set to single phase only (e.g.: "Solids").

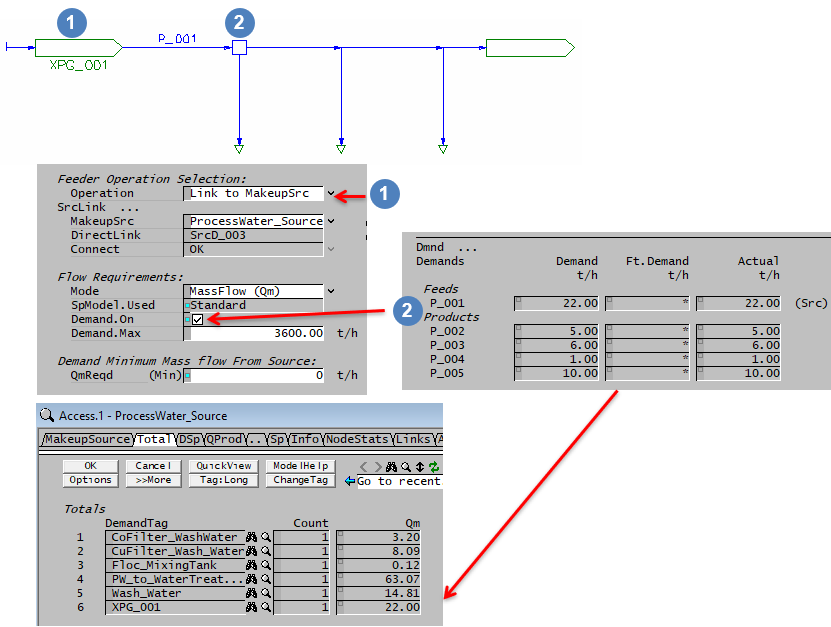

3. Feeder in Demand mode & using Makeup Source

The new Link to MakeupSrc operation mode will allow user to set up the feeder to use both Demand and Makeup. In previous versions of SysCAD, user cannot use these two features together.

For example, consider the following Process Water distribution,

- Operation = "Link to MakeupSrc", this means the flow will come from the Makeup source, user do not have to set up any flow information as the T, P and composition of the specified makeup source will be used.

- A direct link is automatically added to show the makeup.

- The makeup source is set as "ProcessWater_Source"

- The feeder is also set with "Demand.On" ticked, this means the total flow will come from downstream demand, in this case, the Process Water distribution demand.

Each distribution pipe have been set up with a demand flow, as shown in the demand table.

Each distribution pipe have been set up with a demand flow, as shown in the demand table.- When solved, the total water demand will be added as a "ProcessWater_Source" user, the flow is shown in the makeup source summary table, in our case, XPG_001 = 22 t/h.

4. Using Different Flow Basis Options

The user configures the following species make-up in the feeder:

|

This gives |

|

The table below demonstrates how Flow Basis works.

- Set Required Mass Flow (QmReqd) = 10t/h

- Then setting FlowBasis to Solids will mean 10 t/h of solids is required, liquid and vapour flow will be calculated based on the phase mass fraction.

- The results of using all different flow basis are shown below, the blue numbers are calculated values.

Flow Basis Flow Rate All Solids Liquid Vapour Total (t/h) 10 20 20.83 500 Solids (t/h) 5 10 10.42 250 Liquid (t/h) 4.8 9.6 10 240 Vapour (t/h) 0.2 0.4 0.41 10

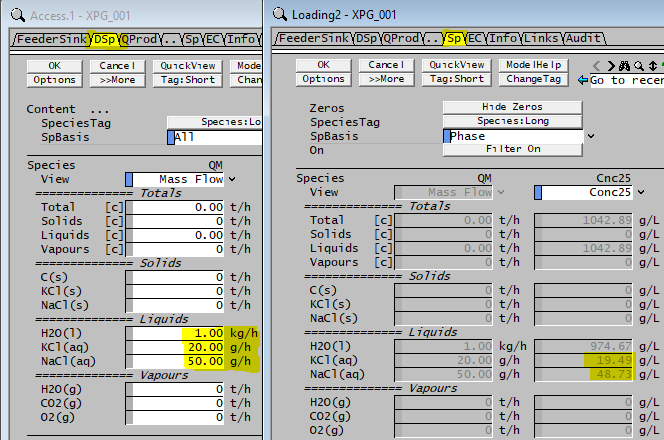

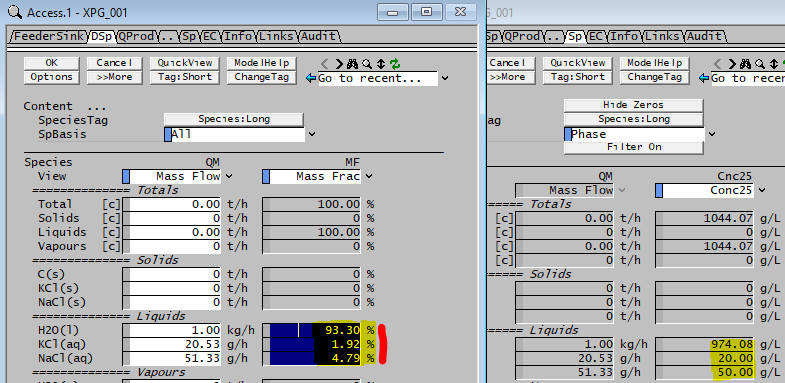

5. Setting Feeder using Aqueous Concentration

The feeder can only be specified in one of the following ways: "Mass/Mole flow of individual species", OR "Mass/Mole fraction of individual species + Total flow".

If user wants to specify the feeder with aqueous concentration values, then they have to work out the "equivalent" mass fraction of the species (on the DSp tab) that gives the correct concentration (on the Sp tab)

For example, we want to set a feeder with 20 g/L of KCl(aq) and 50 g/L of NaCl(aq).

- We can set these values on the "DSp" tab: 1 kg/h of water, 20 g/h of KCl(aq) and 50 g/h of NaCl(aq). After we have entered these values and pressed the OK button, we can go to the Sp tab and look at the "Conc" (or Conc25) column to check the actual concentration values. These will be out as the density will no longer be 1000 g/L.

- We can then manually adjust the mass flow on the "DSp" tab until the concentration on the "Sp" page is correct.

- Once we have the correct concentration, then we can use the mass fraction to set the feeder:

Alternatively, user can work out the mass fractions externally using MS Excel or using a PGM to calculate and set the required values.

- An example PGM file can be found here: Aqueous Feed Concentration Calculator

NOTE: for users with the Alumina or Potash Add-on, the aqueous calculator is part of the species model. User can select those to define the aqueous solution directly.

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Basic1.dll |

→ | Units/Links | → | Process: Feeder/Sink/CrossPage | |

| or | Group: | General |

→ | Units/Links | → | Process: Feeder/Sink/CrossPage |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Process | → | Feeder/Sink/CrossPage |

See Insert Unit for general information on inserting units.