Evaluation Blocks

Navigation: Models ➔ Sub-Models ➔ Evaluation Blocks

| Project, Model and Solver Settings | Simulation Modes and Solver Setup | Solver Methodology, Convergence and Tolerance | Solving Models | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Project Settings | Solver Settings | Plant Model | Constants | Simulation Modes | ProBal Setup | Dynamic Setup | Solver Status | Solver Methodology | Convergence Methods | Tolerance Testing | Evaluating Sub-Models | Flash Train | Mass & Energy Balance | Referenced Variables | Demand |

Related Links: Feeder-Cross Page Connector, Pipe, Tie, Tank, Batch Centrifuge, Disk Centrifuge, Drum Filter, Classifier, Counter Current Washer, Underflow Washer, Reverse Osmosis (RO) Unit, Flotation Cell, Solids Recovery Unit, General Separator, Thickener, Thickener 2, Multi-Stage Counter Flow Tie, Screen 2, Direct Contact Heater 2, Flash Tank 2, Evaporator, Hot Flash Tie

General Description

An Evaluation Block (EB) gives the user a quick and convenient way to introduce commonly used functionality for things like chemical reactions, phase change and environmental heat loss into unit operations in a generic manner. There are some limitations on what can be done with the EB, but overall it is a powerful tool.

An EB is a set of sub-models with a controller for managing them. The EB control allows sub-models to be turned on or off by the user and allows the user to choose the evaluation order of the sub-models. Evaluation blocks are available in pipes, ties, tanks and some unit operations. They are available in both ProBal and Dynamic modes and work exactly the same way in both.

The sub-models act on the flow in a pipe, a tie, a tank or the feed stream to a unit operation model. For ties, tanks and most units, the EB acts on the combined feed flow. Typically, the sub-models available in an evaluation block include Makeup Block (MU), Reaction Block (RB), Environmental Heat Exchange EHX, Evaporation Block (Evap) and Vapour Liquid Equilibrium VLE. However, not all sub-models are available in all units and in some units some of the sub-models are available separately from the EB. There is also a Phase Change sub-model that may be available in the EB, if it has NOT already been enabled globally in Plant Model.

The sub-models are evaluated sequentially. This means that to some extent the answer may depend on the order in which the sub-models are evaluated (as explained below).

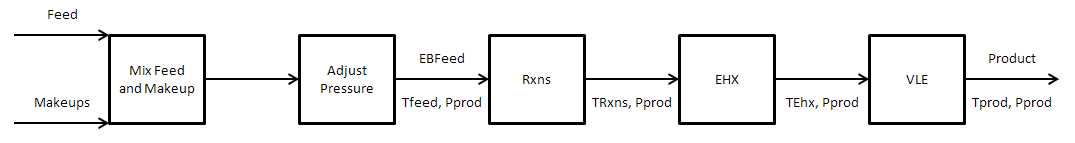

- The general calculation procedure is that all of the feed streams and all of the makeup streams are mixed together and the pressure of the mixed stream is adjusted to the product pressure.

- The product pressure is determined by the pressure sub-model associated with the particular unit operation (the pressure models sit outside of the EB and there are different options depending on the unit).

- Enthalpy is conserved during the mixing and pressure adjustment process and the temperature is adjusted so that the enthalpy flux of the EBFeed matches the sum of the feed and makeup enthalpy fluxes into the unit.

- This mixed, pressure adjusted stream is the EBFeed stream.

The various sub-models then act on the EBFeed stream in series. In effect the EBFeed stream is passed to the first sub-model which acts upon it, then the product stream from this sub-model (the modified EBFeed stream) is passed to the next sub-model and so on. In the example below, a feed stream with makeups is mixed and the pressure is adjusted. It then has the chemical reaction, environmental heat transfer and VLE sub-models acting on it.

- All feed streams are mixed and the pressure is adjusted based on the required pressure method. This sets the EBFeed Temperature.

- The temperature to the Rxn sub-model is the EBFeed temperature.

- The temperature and composition out of the reaction sub-model are determined by the reaction extents and the heat of reaction.

- The feed stream to the EHX sub-model has this composition and temperature.

- The heat loss from the EHX sub-model is determined using the feed temperature to the sub-model and the ambient temperature. The enthalpy of the outlet stream is adjusted for the heat loss to determine the exit temperature. #This stream then feeds the VLE sub-model where flashing or condensation occur to match the given product pressure and stream enthalpy.

The sequence in which these models act can affect the calculated result. For example if a particularly energetic reaction occurs then the temperature out of the reaction sub-model to the EHX sub-model may be significantly different than the feed temperature to the unit and the EHX calculated result will be different than if the EHX sub-model had been called first. In general, this is not usually a problem and often for scenarios where sub-model sequence would be an issue there is an existing dedicated unit operation that solves all of the relevant equations simultaneously. NB as a general rule, VLE should be called last.

Sequencing

Sub-models may be switched on by selecting one of the On options from the drop down menu. They are off by default.

If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto sequence followed will be Makeups, RB, EHX, Evap, VLE, Discards.

If the user wishes to override this sequence, they can choose the order, On-Sequence1 for the first sub-model, On-Sequence2 for the second sub-model, etc. Note that if any sub-models are left as On-AutoSequence these are always first in the order. If two or more sub-models have the same Sequence number then the auto sequence will be followed within this group of equal sequence.

The evaluation sequencing for the Phase Change sub-model works somewhat differently than the other sub-models. The phase change sub-model is evaluated after the initial mixing of all the feed and makeup streams and then again after each of the other active sub-models acts on the stream. It may act on the stream multiple times when multiple other sub-models are used and it is always the last sub-model to act on the stream.

When the reaction sub-model is enabled along with other sub-models and reaction extent is controlled based on some final value (for example final concentration), then the user may need to use a PID controller to adjust the extent of reaction. For example, if we have the reaction A -> B and the reaction extent is controlled to give a final concentration of B and we also have the VLE sub-model acting afterwards. Then if a significant amount of solvent is flashed off, the final concentration may not be correct since the concentration of B will increase as solvent is flashed to vapour. This can be overcome by using a PID with the target concentration as the set point, the actual concentration of B in the product stream as the measured value and allowing the PID to adjust the reaction extent in the sub-model to give the desired value. A separate PID can be used for each reaction.

Evaluation Block Sub-Models

Possible sub-models included are:

- Solubility. This functionality may be enabled here if the following criteria are met:

- Solubility has NOT already been enabled globally via the Plant Model tab (Note: global solubility is NOT available in Build139 or later)

- Solubility data is defined in the Species Database OR Potash Solubility is being used.

- PhaseChange@T. This functionality may be enabled here if the following criteria are met:

- PhaseChange@T has NOT already been enabled globally via the Plant Model tab;

- Phase Change at Temperature data is defined in the Species Database.

- Makeup Blocks (one or more) may be enabled. This allows the user to control the addition of streams such as reagents, water, air, etc. to the stream, often without having to use a PID or General controller.

- The Reaction Block (RB) allows the user to configure any number of reactions on the stream.

- The Environmental Heat Exchanger Block allows the user to add or remove energy from the stream using a number of different methods.

- The Evaporation Block allows the user to set the evaporation of either water only or a mixture of water and all other species that are specified as both liquid and vapour.

- The Vapour Liquid Equilibrium Block will attempt to ensure that the vapours and liquids of the selected species will be in equilibrium in the stream. For example, if the equilibrium species is water and the stream is at atmospheric pressure, then SysCAD will maintain the temperature at, or below, the saturated temperature of 99.97°C by evaporating water if required.

Content Evaluation Block (CEB)

A Content Evaluation Block is only available in units with surge (content). This only occurs in Dynamic projects.

Content Evaluation Block (CEB) sub-models that act on an actual content (for instance, the content of a dynamic tank). The sequence of when these models are implemented is important. For instance, in the dynamic tank, the CEB acts on the content of the tank from the previous iteration plus the feed to the content from this iteration, but before any material is sent to outlets this iteration.

A CEB is NOT available in a Layered Tank.

Content Evaluation Block Sub-Models

Possible sub-models included are:

- The Content Reaction Block (CRB) allows the user to configure any number of reactions on the content of the unit.

- The Heat Exchanger (HX) may be enabled (only available in Tanks. The user must also connect links to the HX input and the HX output. The Heat Exchange page needs to be configured with the relevant heat exchange area and overall heat transfer coefficient. The model carries out the heat exchange operation on the Tank contents and the HX flow. Please note that the fluid in the heat exchanger will transfer energy via sensible heat ONLY. There is NO condensing or boiling in the heat exchanger.

- The Environmental Heat Exchanger Block allows the user to add or remove energy from the content of the unit using a number of different methods.

- The Vapour Liquid Equilibrium Block will attempt to ensure that the vapours and liquids of the selected species will be in equilibrium in the unit contents. For example, if the equilibrium species is water and the unit is at atmospheric pressure, then SysCAD will maintain the temperature at, or below, the saturated temperature of 99.97°C by evaporating water if required.