Evaporator

Navigation: Models ➔ Energy Transfer Models ➔ Evaporator

| Flash Tank | Evaporator | Falling Film Evaporator | Shell&Tube Heat Exchanger | Simple Heat Exchanger | Barometric Condenser | Direct Contact Heater | Simple Heater | Simple Evaporator | Simple Condenser |

|---|

Related Links: Solid-Liquid Separator, Potash Evaporator, Embedded Heat Exchanger (part of Evaporator)

General Description

The Evaporator is used to 'flash' a feed stream to produce a liquid and vapour product at a set pressure or temperature. The unit may also have connections to an Embedded or External Heat Exchanger.

There are two operational modes for the Evaporator:

- as a stand-alone unit; or

- as part of a Flash Train.

The user sets the operational mode of the Evaporator. However, if the user sets the mode as Flash Train and the Evaporator is NOT connected to another Evaporator (Embedded Shell), Barometric Condenser, Heat Exchangers of any Flash Train aware destination unit, the model will go to an error state.

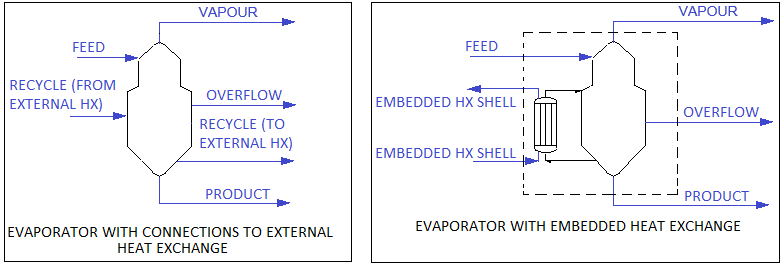

Diagram

- The diagram shows default drawings of the Evaporator with connecting streams, with heat exchanger connections.

- The Heat Exchanger connections are optional.

- The user does not have to connect a stream to the 'Overflow' connection, as the Evaporator will operate without this connection.

- The physical location of the streams connecting to the Evaporator is unimportant. The user may connect the streams to any position on the unit.

- When inserting an Evaporator into a flowsheet, the user may choose a different symbol from the menu.

Crystallization

The Evaporator model may be used as a Crystallizer, as it behaves in the same way. Vapour is flashed off and the remaining solution is then supersaturated with the required species. This species then precipitates out as the crystal product.

If the user has solubility data for the species, then they may enable Solubility and SysCAD will automatically calculate the amount of species that precipitates. This will work for the standard solubility data and for Potash solubility.

Alternatively, the user may use the Reaction Block (RB) to set the precipitation reaction and extent.

Heat Exchange Options

The user may select any of the following 3 options for heat exchange:

- None - no Heat Exchange is required.

- Embedded - The Embedded Heat Exchange model uses a Shell and Tube style heat exchanger. The user connects the Steam (or other cooling or heating medium) to the Embedded HX Shell connection and the Condensate (or return heat exchange medium) to the Embedded HX Shell. The recycle flow to the heat exchanger must to be specified, but this is handled internally within the unit.

- External - External Heat Exchange models the use of external heat exchangers taking a recycle stream from the Evaporator contents and heating, or cooling, this recycle stream. The user must connect the Recycle stream from the Evaporator to an external heat exchanger. This recycle stream is either heated or cooled then returned to the Evaporator via the Recycle stream. The recycle flow to the heat exchanger must to be specified, and this is sent to the Recycle connection.

NOTES:

- The difference between the two heat exchange methods:

- With Embedded heat exchange, the steam and condensate streams (or other heat exchange medium) are connected directly to Evaporator via the Embedded HX Shell connections. The Recycle stream to the heat exchanger is handled internally within the unit.

- With external heat exchange, the recycle stream is sent to an external heat exchanger via the Recycle output connection and returned to the Evaporator via the Recycle input connection.

- For both Embedded and external heat exchange the user must set the recycle flow to the heat exchanger.

Available Sub-Models

- Solubility may be enabled in an Evaporator.

- Makeup Blocks (one or more) may be enabled in an Evaporator. This allows the user to control the addition of streams such as reagents, water, air, etc. to the Evaporator, often without having to use a PID or General controller.

- The Reaction Block (RB) allows the user to configure any number of reactions within the Evaporator.

- The Environmental Heat Exchanger Block allows the user to add or remove energy from the Evaporator using a number of different methods.

- The Vapour Liquid Equilibrium Block is ALWAYS enabled in an Evaporator. This will attempt to ensure that the vapours and liquids of the selected species (normally H2O) will be in equilibrium in the Evaporator.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | Feed to the Evaporator. |

| Embedded HX Shell | Optional | In | 0 | 10 | Inlet stream to the Shell side of internal Shell and Tube Heat Exchanger (often the steam inlet). |

| Recycle | Optional | In | 0 | 1 | Recycle stream from an external Shell and Tube Heat Exchanger to the Evaporator. |

| Product | Required | Out | 1 | 1 | Product Slurry outlet - this stream normally contains the majority of the solids. |

| Vapour | Required | Out | 1 | 1 | Vapour (vent) outlet containing all Vapours from the unit. |

| Overflow | Optional | Out | 0 | 1 | Overflow liquor outlet. |

| Embedded HX Shell | Optional | Out | 0 | 1 | Outlet stream from the Shell side of internal Shell and Tube Heat Exchanger (often the condensate). |

| Recycle | Optional | Out | 0 | 1 | Recycle stream from the Evaporator to an external Shell and Tube Heat Exchanger. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- All material in streams connected to the 'Feed' and 'Recycle' inlets will flow straight out of the 'Product' outlet, with no change in phase or energy exchange with material flowing through the internal heat exchanger;

- All material in streams connected to the 'Embedded HX Shell' connections will have no change in phase or energy exchange with material flowing through the Evaporator;

- No sub-models will be called.

So basically, the unit will be 'bypassed' without the user having to change any connections.

Model Theory

Vapour Liquid Equilibrium

The unit is configured to achieve vapour : liquid equilibrium at a required pressure (or temperature) using the user defined VLE method. Any solids that may be in the stream entering the unit are ignored in the flash calculations. However the enthalpy balance does include the solids. For further information on the theory for the VLE calculations see Vapour Liquid Equilibrium (VLE).

Pressure used for Evaluation Block Calculations

For an Evaporator in the Stand Alone mode the calculations, including the Solubility calculations may be performed at either:

- The Feed pressure; or

- The final pressure; or

- The pressure into the Body of the Evaporator if the user has chosen Final Temperature as the mode.

The user enables the 'UseFeedP' tickbox on the first tab of the Evaporator to use the Feed pressure.

Using the Feed or other pressure may produce small differences in the final results from the Evaporator.

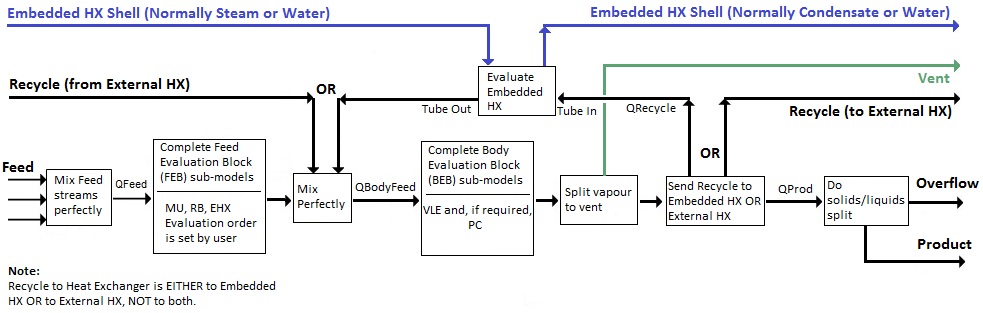

Flow Chart

Data Sections

The default access window consists of several sections:

- Evaporator - The first tab contains general information relating to the unit and allows the user to set the Heat Exchange type and flows.

- Results - This tab contains the results fields for the Evaporator.

- HX - Optional tab, only visible if an Internal Heat Exchanger is selected. (In this case the Internal HX connections should be connected).

- Separ - Only visible if the Overflow stream is connected. The tab allows the user to specify the split between the Product and Overflow streams.

- PC - Optional tab, only visible if the Solubility is enabled in the Evaluation Block.

- VLE - Always visible.

- RB - Optional tab, only visible if the Reactions are enabled in the Evaluation Block.

- EHX - Optional tab, only visible if the EnvironHX is enabled in the Evaluation Block.

- MU - Optional tab, or multiple tabs if more than 1 Makeup is selected. Only visible if one of more Makeup is enabled in the Evaluation Block.

- QFeed - Optional tab, only visible if ShowQFeed is enabled. This page shows the properties of the mixed stream as the feed to the Evaporator.

- This is before any Evaluation Block models are evaluated.

- QBodyFeed - Optional tab, only visible if ShowQBodyFeed is enabled. This page shows the properties of the mixed stream as the feed to the Body of the Evaporator.

- This is before any Evaluation Block models are evaluated.

- QRecycle - Optional tab, only visible if ShowQRecycle is enabled. This page shows the properties of the recycle stream sent to the Embedded Heat Exchanger. This is only relevant if an Embedded Heat Exchanger (Heater or Cooler) is used.

- This is AFTER the flash calculations, but before the split to slurry, overflow and vapour streams.

- QProd - Optional tab, only visible if ShowQProd is enabled. This page shows the properties of the Evaporator discharge as a single stream.

- This is AFTER the flash calculations, but before the split to slurry, overflow and vapour streams.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Evaporator Page

Unit Type: Evaporator - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Requirements | ||

| On | Tickbox | This variable in used to turn the unit ON or OFF. If this not ticked, the material will flow out of the Product outlet with no change in state, i.e. the unit acts as a pipe. |

| Mode | Stand Alone (Manual) | The Evaporator will act as a 'Stand Alone' unit and the user may set the required operating Pressure or Temperature. |

| Flash Train | The Evaporator will act as part of a Flash Train. In this mode the Evaporator vent must be connected to a steam consumer, such as a Barometric Condenser, Shell and Tube Heat Exchanger, Shell and Tube Heat Exchanger 2 or a Direct Contact Heater. The steam requirements of the steam consumer will drive the operating pressure of the Evaporator, therefore the user may NOT set the operating temperature or pressure. | |

| OperatingP The user may only set the operating pressure or temperature of the Evaporator if it is NOT part of a Flash Train. | ||

| Method | Atmospheric | This method is only available if 'Stand Alone' Mode is chosen. All flash calculations will be done at Atmospheric Pressure. The atmospheric pressure is calculated by SysCAD based on the user defined elevation (default elevation is at sea level = 101.325 kPa). The elevation can be changed on the Environment tab page of the Plant Model. |

| RequiredP | This method is only available if 'Stand Alone' Mode is chosen. All flash calculations will be done at the user specified pressure (and saturated temperature @ P). | |

| RequiredT | This method is only available if 'Stand Alone' Mode is chosen. All flash calculations will be done at the user specified temperature (and saturated pressure @ T). | |

| Saturated | The OperatingP - Method will be set to Saturated if 'Flash Train' Mode is chosen. All flash calculations will be done at the saturated pressure. | |

| PressureReqd / P_Reqd | Input | This field is only visible if the RequiredP method is chosen. This is user specified flash pressure. |

| TemperatureReqd / T_Reqd | Input | This field is only visible if the RequiredT method is chosen. This is user specified flash temperature. |

| Result | Calc | The actual pressure used for the sum of the feeds which will also be the outlet pressure (unless further model options change the pressure). |

| MinFlashP | Input | This is only visible when 'Flash Train' Mode is chosen. The Minimum Flash Pressure. |

| TCorrection | Calc | |

| UseFeedP | Tickbox | If this field is enabled then all of the Evaluation Block calculations will be performed at the Feed pressure. Otherwise, if it is not enabled, the calculations will be performed at the final pressure. See also Model Theory. |

| Feed Evaluation Block | ||

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Makeups | Input | The number of Makeup Blocks required. Extra dropdown options Makeup1, Makeup2, etc. will be added to allow these to be switched on and off and prioritised in relation to the other sub-models. |

| MakeupX | List | This can be used to switch the Makeup Block (MU) on or off and prioritise it in relation to the other sub-models. If this is 'On' then the associated page, MUX becomes visible and may be configured. Note: This field is only visible if the entry for 'Makeups' is greater than 0. If there is one makeup then X=1. If there are two makeups, then X=1 and X=2, etc. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

| EnvironHX | List | Environmental Heat Exchanger (EHX) - Enable or disable Environmental Heat Exchange and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, EHX becomes visible and may be configured. Note: The user does not have to configure an environmental heat exchange, even if this block is checked. |

| Body Evaluation Block | ||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. |

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. |

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| VLEquilibrium | List | Vapour Liquid Equilibrium (VLE) - Enable or disable Vapour Liquid Equilibrium and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, VLE becomes visible and may be configured. Note: This option may automatically adjust the species make-up. |

| Vapour Entrainment | ||

| FlashVapToLiquid | Input | This field allows the user to set a proportion of the flash vapour bypassing to the liquid stream. The default is 0%. |

| OtherGasToLiquid | Input | This field allows the user to set a proportion of any non-condensable gas bypassing to the liquid stream. The default is 0%. |

| Evaporator Heat Exchanger Options | ||

| HXType | None | The unit is not connected to a Heat Exchanger. No other fields are visible for the Heat Exchanger if this option is chosen. |

| External | The Evaporator is connected to an External Heat Exchanger unit. This external unit may be any type of SysCAD model. | |

| Embedded Heater | The Evaporator contains an Embedded Heater. If this option is chosen, an additional page HX becomes visible and the user configures the Heat Exchanger within the Evaporator. | |

| Embedded Cooler | The Evaporator contains an Embedded Cooler. If this option is chosen, an additional page HX becomes visible and the user configures the Heat Exchanger within the Evaporator. | |

| HX.HeaterCount / NumOfHeaters | Input | The number of heaters. |

| HXOut.SplitMethod | Off | No flow is sent to the Heat Exchanger. |

| Ratio to Feed MassFlow | The flow to the Heat Exchanger (either Embedded or External) is a Ratio of the Feed mass. The composition and temperature of the stream to the Heat Exchanger is the same as the Combined Feed to the Evaluation Block. | |

| Ratio to Prod MassFlow | The flow to the Heat Exchanger (either Embedded or External) is a Ratio of the Product mass. The composition and temperature of the stream to the Heat Exchanger is the same as the Product from the Evaluation Block. Note: The Product mass includes both the Overflow and the Product streams. | |

| MassFlow | The flow to the Heat Exchanger (either Embedded or External) is a fixed mass flow. The composition and temperature of the stream to the Heat Exchanger is the same as the Product from the Evaluation Block. Note: The Product mass includes both the Overflow and the Product streams. | |

| VolumeFlow | The flow to the Heat Exchanger (either Embedded or External) is a fixed volumetric flow. The composition and temperature of the stream to the Heat Exchanger is the same as the Product from the Evaluation Block. Note: The Product mass includes both the Overflow and the Product streams. | |

| MassFlow Per Heater | The flow to each Heat Exchanger (either Embedded or External) is mass based. The composition and temperature of the stream to the Heat Exchanger is the same as the Product from the Evaluation Block. Note: The Product mass includes both the Overflow and the Product streams. | |

| VolumeFlow Per Heater | The flow to each Heat Exchanger (either Embedded or External) is volume based. The composition and temperature of the stream to the Heat Exchanger is the same as the Product from the Evaluation Block. Note: The Product mass includes both the Overflow and the Product streams. | |

| HXOut.RatioToFeedQm | Input | Only visible if SplitMethod = Ratio to Feed MassFlow. The flow to the Heat Exchanger (either Embedded or External) is Feed Flow times by this Ratio. |

| HXOut.RatioToProdQm | Input | Only visible if SplitMethod = Ratio to Prod MassFlow. The flow to the Heat Exchanger (either Embedded or External) is Product Flow times by this Ratio. Note: The Product mass includes both the Overflow and the Product streams. |

| HXOut.MassFlowReqd / QmReqd | Input | Only visible if SplitMethod = MassFlow. The required Product mass flow to the Heat Exchanger (either Embedded or External). |

| HXOut.VolumeFlowReqd / QvReqd | Input | Only visible if SplitMethod = VolumeFlow. The required Product volumetric flow to the Heat Exchanger (either Embedded or External). |

| HXOut.EachHeaterQmReqd | Input | Only visible if SplitMethod = MassFlow per Heater. The required Product mass flow to each Heater (either Embedded or External). |

| HXOut.EachHeaterQvReqd | Input | Only visible if SplitMethod = VolumeFlow per Heater. The required Product volumetric flow to each Heater (either Embedded or External). |

| HXOut.SolidFracMethod | No Solids | No solids are sent to the Heat Exchanger. |

| Mixture Solids | The feed to the Heat Exchanger (either Embedded or External) will contain the same amount of solids (if any) as the relevant stream (Combined Feed to or Product from the Evaluation Block). | |

| Solids Fraction | The user can specify the fraction of solids in the feed to the Heat Exchanger. | |

| HXOut.SolidFracReqd | Input | The required solids fraction in the feed to the Heat Exchanger. |

| Options | ||

| VapStandardSpModel | Tickbox | This forces the vent stream to revert to the Standard species model. If this is NOT ticked, then the species model in the vent will be the same as the species model used in the Evaporator. Normally this is left ticked, as the vent contains steam and the Standard species model will calculate all of the properties of steam correctly. |

| ShowQFeed | Tick Box | QFeed and associated tab pages (e.g. Qm) will become visible if this is enabled. These tabs will show the properties of the combined feed stream to the Unit. These values are BEFORE the Evaluation Block is processed. |

| ShowQBodyFeed | Tick Box | QBodyFeed and associated tab pages (e.g. Qm) will become visible if this is enabled. These tabs will show the properties of the feed to the Evaporator Body. |

| ShowQRecycle | Tickbox | This is only visible if an Embedded Heat Exchanger is used. If this option is ticked then the recycle stream to the Heat Exchanger is displayed as 'QRecycle' and the user may access properties of the stream feeding the Heat Exchanger. |

| ShowQProd | Tick Box | QProd and associated tab pages (e.g. Qm) will become visible if this is enabled. These tabs will show the properties of the product stream from the Unit, AFTER the Evaluation Block is processed, but BEFORE the stream is split to overflow and product. |

Results Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Operating Conditions | ||

| TemperatureIn / Ti | Calc | The temperature of the combined Feed stream to the Evaporator. |

| PressureIn / Pi | Calc | The pressure of the combined Feed stream to the Evaporator. |

| VapFlashed.MassFlow / Qm | Calc | The quantity of flashed vapour. |

| LiqChange.MassFlow / Qm | Calc | |

| BPE | Calc | The Boiling Point Elevation used in the Flash calculations in the Evaporator. |

| FlashT | Calc | The final temperature (the Flash Temperature) in the Evaporator. |

| FlashP | Calc | The final pressure (the Flash Pressure) in the Evaporator. |

| Flash Train Macro Model These extra fields are only visible if the unit is part of a Flash Train. | ||

| VapourMassFlow / VQm | Calc | The mass flow of flashed vapour. |

| PressureReqd / P_Reqd | Calc | The required flash pressure calculated by the Flash Train. |

| TotalPressChange / TotaldP | Calc | The total pressure change calculated by the Flash Train. |

| FeedSatP | Calc | The saturation pressure of the feed. |

| FlashTrain | Display | A unique tag assigned to the flash train by SysCAD. Each unit in the flash train will have the same tag in this block. |

| FlashTearBlock | Display | Displays the name of the tear block that is part of the Flash Train. |

| FlashTrainEqp | List | This contains a list of all of the equipment tags in this flash train. the list might be as follows: FT_EVAPORATOR_2_HX FT_EVAPORATOR_1_Evap |

| PAdvBase | Input | Additional damping or acceleration for calculated pressure change (DP) for the iteration. DP = DP * PAdvBase when PAdvExtra=0. |

| PAdvExtra | Input | Additional damping or acceleration for calculated pressure change (DP) for the iteration. DP = DP * (PAdvBase + PAdvExtra*(VQmReqd-VQm)/Max(VQmReqd,VQm)). |

| Summary of input and output streams The following tags are shown for Feed, Vapour, Overflow (OF) (if connected) and Product (Prod) streams: | ||

| Temperature / T | Display | The temperature of the stream. |

| MassFlow / Qm | Display | The Mass flowrate of the stream. |

| SolidMassFlow / SQm | Display | The solids Mass Flow of the stream. |

| SolidFrac / Sf | Display | The solids Mass fraction of the stream. |

| Results | ||

| BFeed.Temperature / T | Calc | The temperature of the Feed to the Evaporator evaluation block. |

| BFeed.Pressure / P | Calc | The Pressure used in the calculations in the Evaporator evaluation block. If the user has ticked the 'UseFeedP' then this will be the feed pressure to the Evaporator. |

| BFeed.MassFlow / Qm | Calc | The mass flow of Feed to the Evaporator evaluation block. |

| BFeed.SolidMassFlow / SQm | Calc | The mass flow of solids in the Feed to the Evaporator evaluation block. |

| BFeed.SolidFrac / Sf | Calc | The mass fraction of solids in the Feed to the Evaporator evaluation block. |

| Body.SolidsYield | Calc | (Mass flow of solids in the Product) - (Mass flow of solids in the Feed) |

| SolidsYield | Calc | (Mass flow of solids in the Product) - (Mass flow of solids in the Feed) |

| Evaporator to External Heat Exchanger / Embedded Heater / Embedded Cooler These extra fields are only visible if one of the Heat Exchanger options has been chosen on the first tab page. | ||

| HXOut.MassFlow / Qm | Calc | The mass flow to the specified Heat Exchanger. |

| HXOut.EachHeaterQm | Calc | Only visible if Embedded Heater or Embedded Cooler option is chosen. The mass flow to each Heater/Cooler. |

| HXOut.VolFlow / Qv | Calc | The volume flow to the specified Heat Exchanger. |

| HXOut.EachHeaterQv | Calc | Only visible if Embedded Heater or Embedded Cooler option is chosen. The volume flow to each Heater/Cooler. |

| HXOut.SolidFrac / Sf | Calc | The mass fraction of solids in the Feed to the specified Heat Exchanger. |

| HXOut.Temperature / T | Calc | The temperature of the stream to the specified Heat Exchanger. |

| Embedded Heater / Cooler Recycle Loop convergence These extra fields are only visible if one of the Embedded Heat Exchanger options has been chosen on the first tab page. | ||

| RecycleConvergeMethod | FullStream | User can select to solve the recycle loop using Full stream data (loop has to solve and converge all mass and energy terms.) |

| Stream Mass Only | User can select to solve the recycle loop using mass only. Loop will be solved when mass is converged, ignoring energy. | |

| Duty | User can select to solve the recycle loop using energy only. Duty from "shell" side of heat exchanger is added directly to the feed (recycle mass flow is not actually added). Loop will be solved when duty is matched, ignoring mass balance. | |

| MaxIterations / MaxIter (Global) | Input | The maximum number of iterations allowed within the recycle solver loop. Only shown for Stream Recycle Converge Methods. |

| IterSteps | Calc | The number of iteration used in the current step to solve the recycle loop. Only shown for Stream Recycle Converge Methods. |

| IterLastStep | Calc | The number of iteration used in the last step to solve the recycle loop. Only shown for Stream Recycle Converge Methods. |

| IterMaxInAStep | Calc | The maximum number of iterations (in a step) used to solve the recycle loop. Only shown for Stream Recycle Converge Methods. |

| IterTotal | Calc | The total number of iterations used to solve the recycle loop. Only shown for Stream Recycle Converge Methods. |

| FeedMaxDuty | Calc | The maximum amount of Duty that can be added to feed before temperature exceeds water critical temperature. Only shown for Duty Recycle Converge Method. |

| IterDuty | Calc | The number of iterations to apply duty and flash. When this is greater then 1 then the Duty from the condensing steam is applied in iterations, the values displayed on the VLE page reflect this. Only shown for Duty Recycle Converge Method. |

HX Page

HX - Optional tab, only visible if an Internal Heat Exchanger is selected. (In this case the Internal HX connections should be connected).

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Heater / Cooler Requirements | ||

| On | Tick Box | Switches the Embedded Heat Exchanger on/off |

| HeaterCount / NumofHeaters | Input | Specifies the number of embedded heat exchangers in the evaporator. This can also be changed on the first tab page. |

| Type | Fixed Heat Flow | This will exchange a fixed amount of heat between two streams. No phase change will take place automatically. |

| Sensible | This will allow sensible heat exchange between two streams. No phase change will take place. (not currently implemented) | |

| Condensing | Only visible when Embedded Heater is used. This is used to condense the steam. Steam must be connected to Embedded HX Shell (inlet). | |

| Evaporating | Only visible when Embedded Cooler is used. This is used to evaporate the water. Water (or another component with Predefined Flashing Data) must be connected to Embedded HX Shell (inlet). | |

| DutyReqd | Input | Only visible when Fixed Heat Flow method is used. The required fixed heat flow to be exchanged between the two streams. |

| CondensingMethod (Only visible when Type = Condensing) |

All | The Steam addition is manually specified by the user. All steam will condense. |

| All (Calc Demand) | The steam demand is calculated based on the user specified Heater HTC and Area (UA). User needs to set the steam flow based on the calculated amount. | |

| All-Demand General | The steam supply comes from (directly or indirectly) a Feeder with Demand.on selected. | |

| All-Demand Flashtrain | The steam supply comes from another process unit in Flash train mode (usually the vapour from the preceding evaporation stage) | |

| EvaporatingMethod (Only visible when Type = Evaporating) |

All | The component defined on the VLE Tab will fully evaporate. |

| All (Calc Demand) | The demand is calculated based on the user specified Cooler HTC and Area (UA). User needs to set the flow based on the calculated amount. | |

| All-Demand General | The flow supply comes from (directly or indirectly) a Feeder with Demand.on selected. | |

| UseOldDemandCalc | Tickbox | Visible with method set to any of the demand methods. Allows users to continue to use old demand calculations for backward compatibility. It is recommended to leave this unticked. |

| HTC | Input | Visible with method set to any of the demand methods. The user specified Heat Transfer Coefficient (HTC). |

| Area | Input | Visible with method set to any of the demand methods. The user specified heat transfer area per heat exchanger. |

| Heater / Cooler Results | ||

| Duty | Calc | The calculated Heat Exchanger Duty |

| TotalArea | Calc | Visible with method set to any of the demand methods. The total Area used (HX Area * number of HX). |

| UA | Calc | Visible with method set to any of the demand methods. The heat exchanger UA. |

| LMTD | Calc | The calculated log mean temperature difference. |

| TheoreticalDuty / TheorDuty | Calc | Visible with method set to any of the demand methods. The theoretical duty of the heat exchanger. |

| HeatFlow | Calc | The net heat flow to the unit. This should be zero as heat is merely exchanged (no external energy is added or removed). |

| Calculated Vapour/Liquid Flow Demand This group of tags is only visible when one of the demand methods is chosen. | ||

| DemandFlow.Reqd | Calc | The calculated demand flow to meet the Heat Exchanger requirements. When the HX is not in Demand General or Demand FlashTrain mode, use a General controller or SetTag Controller to get this value to set the Embedded HX Shell (in) flowrate. |

| DemandFlow.Actual | Calc | The actual demand flow to Heater Exchanger . |

| DemandFlow.Error | Calc | The difference between the required and actual vapour/liquid flows, (DemandFlow.Reqd - DemandFlow.Actual). This will warn the user if the amount of flow supplied doesn't match the heat exchanger requirements. Most common when the heater is not in Demand General or Demand FlashTrain mode and the steam flow is not controlled. |

| DemandFlow.RelErr | Calc | The relative difference between the required and actual vapour/liquid flows, (DemandFlow.Reqd - DemandFlow.Actual)/DemandFlow.Reqd. |

| Tube Side (Recycle Stream) | ||

| Tube.TemperatureIn / Ti | Calc | Tube in temperature. |

| Tube.TemperatureOut / To | Calc | Tube out temperature. |

| Tube.PressureIn / Pi | Calc | Tube in pressure. |

| Tube.MassFlow / Qm | Calc | The mass flowrate going through the tube side. |

| Shell Side (Condensing / Evaporating) | ||

| Shell.TemperatureIn / Ti | Calc | Shell in temperature. |

| Shell.TemperatureOut / To | Calc | Shell out temperature. |

| Shell.PressureIn / Pi | Calc | Shell in pressure. |

| Shell.MassFlow / Qm | Calc | The mass flowrate going through the Shell side. |

| Shell.DmdQm | Calc | Visible with method set to any of the demand methods. This is the amount of steam needed from connected flash train units (flash tank or steam feeders), not including any fixed amount of steam input. |

| Shell.FxdQm | Calc | Visible with method set to any of the demand methods. This is the amount of steam added in manually, thus not from connected flash train units. Note this portion of steam addition is not included in the pressure calculation of the flash train group. |

| Flash Train Macro Model

Note: Extra fields are visible if the unit is part of a Flash Train. These fields are described below. Please refer to Flash Train. | ||

| VapourMassFlowReqd / VQmReqd | Calc | The calculated mass flow of steam required by the Embedded Heater Condenser. |

| CondMassFlow / CondQm | Calc | The amount of steam condensed by the Embedded Heater Condenser. |

| MinSatPress | Calc | The minimum saturated pressure of steam that could satisfy the heating requirements of the Embedded Heater Condenser. |

| FlashTrain | Display | A unique tag assigned to the flash train by SysCAD. Each unit in the flash train will have the same tag in this block. |

| FlashTearBlock | Display | Displays the name of the tear block that is part of the Flash Train. |

| FlashTrainEqp | List | This contains a list of all of the equipment tags in this flash train. the list might be as follows: FT_EVAPORATOR_2_HX FT_EVAPORATOR_3_Evap |

| PAdvBase | Input | Additional damping or acceleration for calculated pressure change (DP) for the iteration. DP = DP * PAdvBase when PAdvExtra=0. |

| PAdvExtra | Input | Additional damping or acceleration for calculated pressure change (DP) for the iteration. DP = DP * (PAdvBase + PAdvExtra*(VQmReqd-VQm)/Max(VQmReqd,VQm)). |

Separ Page

The page allows the user to specify the split between the Underflow and Overflow streams.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Requirements | ||

| SplitMethod | Mass Fraction | The users may specify the mass fraction split between the Underflow and Overflow streams. |

| Mass Flow | The user may specify the mass flow to either the Underflow or Overflow stream - either as total flow or on a phase basis. | |

| Volume Fraction | The users may specify the volumetric fraction split between the Underflow and Overflow streams. | |

| Volume Flow | The user may specify the Volume flow to either the Underflow or Overflow stream - either as total flow or on a phase basis. | |

| Solid Separation | The user may specify the solid split between the Underflow and Overflow streams. | |

| Each of the above Split Methods will be described separately below: | ||

Mass FractionWith this method the user can specify the mass fraction to either the Underflow or the Overflow on a total or by phase basis. | ||

| SplitTo | Underflow | The user specifies the mass fraction split to the Underflow stream. |

| Overflow | The user specifies the mass fraction split to the Overflow stream. | |

| SplitBy | Total | The user specifies the total mass fraction split to the defined stream. |

| Phase | The user specifies the solid and liquid mass fraction splits to the defined stream. | |

| FracToUF or FracToOF | Input | This is visible if SplitBy = Total. The user sets the total mass fraction split to the defined stream. |

| SolidsToUF or SolidsToOF | Input | This is visible if SplitBy = Phase. The user sets the solid mass fraction split to the defined stream. |

| LiquidsToUF or LiquidsToOF | Input | This is visible if SplitBy = Phase. The user sets the liquid mass fraction split to the defined stream. |

Mass FlowWith this method the user can specify the mass flow to either the Underflow or the Overflow on a total or by phase basis. | ||

| SplitTo | Underflow | The user specifies the mass flow to the Underflow stream. |

| Overflow | The user specifies the mass flow to the Overflow stream. | |

| SplitBy | Total | The user specifies the total mass flow to the defined stream. |

| Phase | The user specifies the solid mass flow and the liquid mass flow to the defined stream. | |

| UF or OF.MassFlowReqd / UF or OF.QmReqd |

Input | This is visible if SplitBy = Total. The user sets the total mass flow to the defined stream. |

| UF or OF.SolidMassFlowReqd / UF or OF.SolidQmReqd |

Input | This is visible if SplitBy = Phase. The user sets the solid mass flow to the defined stream. |

| UF or OF.LiquidMassFlowReqd / UF or OF.LiquidQmReqd |

Input | This is visible if SplitBy = Phase. The user sets the liquid mass flow to the defined stream. |

Volume FractionWith this method the user can specify the volume fraction to either the Underflow or the Overflow on a total or by phase basis. | ||

| SplitTo | Underflow | The user specifies the volume fraction split to the Underflow stream. |

| Overflow | The user specifies the volume fraction split to the Overflow stream. | |

| SplitBy | Total | The user specifies the total volume fraction split to the defined stream. |

| Phase | The user specifies the solid and liquid volume fraction splits to the defined stream. | |

| FracToUF or FracToOF | Input | This is visible if SplitBy = Total. The user sets the total volume fraction split to the defined stream. |

| SolidsToUF or SolidsToOF | Input | This is visible if SplitBy = Phase. The user sets the solid volume fraction split to the defined stream. |

| LiquidsToUF or LiquidsToOF | Input | This is visible if SplitBy = Phase. The user sets the liquid volume fraction split to the defined stream. |

Volume FlowWith this method the user can specify the volume flow to either the Underflow or the Overflow on a total or by phase basis. | ||

| SplitTo | Underflow | The user specifies the volume flow to the Underflow stream. |

| Overflow | The user specifies the volume flow to the Overflow stream. | |

| SplitBy | Total | The user specifies the total volume flow to the defined stream. |

| Phase | The user specifies the solid Volume flow and the liquid volume flow to the defined stream. | |

| UF or OF.VolFlowReqd / UF or OF .QvReqd |

Input | This is visible if SplitBy = Total. The user sets the total volume flow to the defined stream. |

| UF or OF.SolVolFlowReqd / UF or OF.SolidQvReqd |

Input | This is visible if SplitBy = Phase. The user sets the solid volume flow to the defined stream. |

| UF or OF.LiqVolFlowReqd / UF or OF.LiquidQvReqd |

Input | This is visible if SplitBy = Phase. The user sets the liquid volume flow to the defined stream. |

Solid SeparationWith this method the user can choose between setting the solids composition of the Overflow stream or defining the Underflow flowrate and then specifying the solids composition of the Underflow. | ||

| SolidsSeparMethod | OF Solids Fraction | The user specifies the solids mass fraction in the Overflow stream. |

| OF Solids Conc | The user specifies the solids concentration in the Overflow stream. | |

| OF Solids Conc25 | The user specifies the solids concentration at 25°C in the Overflow stream. | |

| Recovery to UF | The user specifies the solids recovery to the Underflow stream, i.e. how much of the solids in the unit reports to the Underflow stream. | |

| UF MassFlow | The user specifies the total mass flow of the Underflow stream. | |

| UF VolumeFlow | The user specifies the total volume flow of the Underflow stream. | |

| Solids Density | Each solid species is split between the Overflow and Underflow streams based on the user specified SolidsCutDensity. | |

| Solids PSD | The user then specifies one of the Solid Methods for defining a partition curve which then separates the solids based on PSD data in the feed. | |

| OFSolidsPriority | Tick Box | New for Build 139.321691. This is visible if SolidsSeparMethod = OF Solids Fraction, OF Solids Conc or OF Solids Conc25. If feed conditions are such that neither OF or UF solids targets can be met, then this determines which stream any solids are sent too. For some flowsheet arrangements (recycles), this can help project convergence reach required OF setpoints and solids flow. |

| OFSolidFracReqd | Input | This is visible if SolidsSeparMethod = OF Solids Fraction. The user sets the solids mass fraction in the Overflow stream. |

| OFSolidConcReqd | Input | This is visible if SolidsSeparMethod = OF Solids Conc. The user sets the solids concentration in the Overflow stream. |

| OFSolidConc25Reqd | Input | This is visible if SolidsSeparMethod = OF Solids Conc25. The user sets the solids concentration at 25°C in the Overflow stream. |

| SolidsToUFReqd | Input | This is visible if SolidsSeparMethod = Recovery to UF. The user sets the mass fraction of solids in the unit that must report to the Underflow stream. |

| UFQmReqd | Input | This is visible if SolidsSeparMethod = UF MassFlow. The user sets the total mass flow of the Underflow stream. |

| UFQvReqd | Input | This is visible if SolidsSeparMethod = UF VolumeFlow. The user sets the total volume flow of the Underflow stream. |

| CutDensityMethod | This is visible if SolidsSeparMethod = Solids Density. | |

| Simple | If the density of a solid species is greater than the SolidsCutDensity then it is all sent to the Underflow stream, otherwise it is all sent to the Overflow stream. | |

| Erf | An error function is used to determine the split of each solid species between the Overflow and Underflow streams based on the species density, SolidsCutDensity and alpha. | |

| Logistic | This method is based on a Logisitic type of function. It is used to determine the split of each solid species between the Overflow and Underflow streams based on the species density, SolidsCutDensity and alpha. | |

| SolidsCutDensity | Input | This is visible if SolidsSeparMethod = Solids Density. The user sets the solids cut density which is used to determine how much of each solid species to send to the Overflow and Underflow streams. |

| ErfAlpha | Input | This is visible if SolidsSeparMethod = Solids Density and CutDensityMethod = Erf. User specified efficiency parameter, alpha. See Erf Cut Density Method for more information. |

| LogisticAlpha | Input | This is visible if SolidsSeparMethod = Solids Density and CutDensityMethod = Logistic. User specified efficiency parameter, alpha. See Logistic Cut Density Method for more information. |

| SolidsBypassToUF | Input | This is visible if SolidsSeparMethod = Solids Density. The fraction of solids which bypasses the separation by density calculations and passes straight to the underflow. |

| The following Solids Method (with Solids PSD) assumes the Solid-Liquid separator is used to emulate the screen. | ||

| Solid Separation Requirements. | ||

| SolidMethod | Simple (no PSD) | The feed does not need size distribution for this method and the unit acts as a simple mass splitter. If the user chooses this mode then they must define the solids and liquids split from the unit. (This option is visible for the Screen 2 model only) |

| Partition Curve | The user inputs a Partition curve (fraction of feed solids per size interval reporting to the oversize) on the PartCrv(deck number) tab. The screen will use this curve, so the size distribution in the feed to the screen has no effect on products. Note: A single partition curve is used for all the size distributions. | |

| Whiten | The screen model will calculate the solids split using the Whiten method. The user must specify the d50 and alpha, a measure of the sharpness of separation. | |

| Karra | The screen model will calculate the solids split using the Karra method. The user may specify either the d50 or the Screen area and Cut aperture. | |

| Rosin-Rammler | This method is based on a Rosin-Rammler type of function with the efficiency curve expression derived by Reid and Plitt. User must specify d50, sharpness of separation, maximum size allowed to undersize and minimum percent of solids reporting to oversize. | |

| Lynch | This method is based on a Lynch type of function. User must specify d50, sharpness of separation (m), maximum size allowed to undersize and minimum percent of solids reporting to oversize. | |

| DelVillar-Finch | This method is similar to Rosin-Rammler, but includes a term for the "fish hook" effect for entrainment. | |

Solid Method - Whiten | ||

| Whiten.CalcMethod | d50 | The user specifies the d50 of the screen. |

| d50 with Beta | The user specifies the d50 of the screen and uses the Beta method to adjust for uncertainties in the finer fractions. | |

| Aperture, Eff | The user specifies the Screen Aperture and Efficiency. The unit then calculates the d50 of the Screen deck. | |

| Aperture, Eff with Beta | The user specifies the Screen Aperture and Efficiency and uses the Beta method to adjust for uncertainties in the finer fractions. The unit then calculates the d50 of the Screen deck. | |

| Whiten.Aperture | Input | Only visible if one of the two Aperture CalcMethods are chosen. The Screen Aperture, used to calculate the d50. |

| Whiten.Efficiency / Eff | Input | The Whiten Efficiency of the Screen.

|

| Whiten.d50 | Input/Calc | If either of the d50 methods are chosen, this is entered by the user. If the Aperture method is chosen, this is a calculated value. This is the particle size with a 50% probability of reporting to the over or under size. |

| Whiten.Alpha | Input | The Efficiency parameter, alpha. An alpha value of between 8 and 15 is normal for screening. However, this does depend on the screening conditions and hence experience and/or test or plant data is required for accurate results. |

| Whiten.Beta | Input | Only visible if the d50 with Beta or Aperture,Eff with Beta CalcMethods are chosen. The Beta Efficiency parameter. This value takes into account uncertainties in the finer size fractions. |

| Whiten.Beta* | Calc | Only visible if the d50 with Beta or Aperture,Eff with Beta CalcMethods are chosen. Efficiency parameter. |

| Whiten.MaxSizeToUS | Input | The model will ensure that all particles LARGER than this size all report to the Screen deck oversize product. This value is often = Screen Deck Aperture. (See Model Theory). |

| Whiten.MinToOS | Input | The model will ensure that a minimum fraction of solids in each size distribution reports to the oversize product. For example, if the user specifies a minimum of 5%, then at least 5% of each size distribution will report to oversize. (See Model Theory). |

| Whiten.Rf | Input | The proportion of feed liquid reporting to the over size product to be used in the fines calculation. Note: This value is only used to adjust the solids fine fraction to the screen oversize and NOT to set the fraction of liquid reporting to the oversize stream. |

|

If the user has selected SolidMethod=Whiten and Whiten.CalcMethod = d50 or d50 with Beta, the following fields will be visible: | ||

|

Theoretical Nominal Screen Aperture | ||

| Whiten.Efficiency / Eff | Input | The Whiten Efficiency of the Screen. Used to calculate the Screen aperture. |

| Whiten.TheorAperture | Calc | The calculated screen aperture, based on the specified d50, alpha and efficiency. Refer to equation 2 in Whiten Method. |

Solid Method - Karra | ||

| Karra.CalcMethod | d50 | The user specifies the d50 of the screen. |

| Area | The user specifies the Area and Cut aperture of the screen and the model calculates the d50 of the screen. | |

| Karra.d50 | Input | Only visible if CalcMethod=d50. The user specified d50 of the screen. |

| Karra.TotalArea | Input | Only visible if CalcMethod=Area. The deck area. |

| Karra.Aperture | Input | Only visible if CalcMethod=Area. The deck cut aperture. |

| Karra.Wet | Tick Box | Only visible if CalcMethod=Area. This must be ticked if this is a wet screening application. |

| Karra.Factor | Input | Only visible if CalcMethod=Area. This is a tuning factor that may be used to adjust the calculated d50 of the screen deck. The default value is 1. |

| Karra.MaxSizeToUS | Input | The model will ensure that all particles LARGER than this size all report to the Screen deck oversize product. This value is often = Screen Deck Aperture. (See Model Theory). |

| Karra.MinToOS | Input | The model will ensure that a minimum fraction of solids in each size distribution reports to the oversize product. For example, if the user specifies a minimum of 5%, then at least 5% of each size distribution will report to oversize. This accounts for fines adhering to coarse particles or fines in the liquid. |

| Karra.Calc_d50 | Calc | Only visible if CalcMethod=Area. The calculated d50 of the deck, using the Karra equations. |

| Karra.d50 | Calc | Only visible if CalcMethod=Area. The d50 that is used to determine the screen partition curve. This is normally equal to the field above. But, if the calculated d50 > screen deck aperture, then the model will use the screen deck aperture. |

| Karra.FeedOversize | Calc | Only visible if CalcMethod=Area. The fraction of oversize material (Q) in the Feed to the deck. |

| Karra.FeedHalfsize | Calc | Only visible if CalcMethod=Area. The fraction of half size material (R) in the Feed to the deck. |

| Karra.FeedNearsize | Calc | Only visible if CalcMethod=Area. The fraction of near size material (Xn) in the Feed to the deck. |

| Karra.SolQmPerArea | Calc | Only visible if CalcMethod=Area. The calculated solids flow rate divided by the screen area. |

Solid Method - Rosin-Rammler | ||

| RR.d50 | Input | The user specifies the d50 of the screen, the size which divides equally between oversize and undersize. |

| RR.Sharpness | Input | The user specifies the sharpness factor for separation, high values for sharper separation |

| RR.MaxSizeToUS | Input | The maximum size allowed to report to undersize. |

| RR.MinToOS | Input | The minimum percent solids (from feed) to report to oversize. |

Solid Method - Lynch | ||

| Lynch.d50 | Input | The user specifies the d50 of the screen, the size which divides equally between oversize and undersize. |

| Lynch.Sharpness (m) | Input | The user specifies the sharpness factor for separation, high values for sharper separation. |

| Lynch.Alpha | Calc | Calculated from the Sharpness (m), refer to Lynch Method for more information. |

| Lynch.MaxSizeToUS | Input | The maximum size allowed to report to undersize. |

| Lynch.MinToOS | Input | The minimum percent solids (from feed) to report to oversize. |

Solid Method - DelVillar-Finch | ||

| Finch.d50 | Input | The user specifies the d50 of the screen, the size which divides equally between oversize and undersize. |

| Finch.Sharpness | Input | The user specifies the sharpness factor (m) for separation, high values of m for sharper separation |

| Finch.d0 | Input | The largest particle size affected by the fish-hook for entrainment function. |

| Finch.MaxSizeToUS | Input | The maximum size allowed to report to undersize. |

| Finch.MinToOS | Input | The minimum percent solids (from feed) to report to oversize. |

| Finch.Rf | Input | Proportion of feed liquid reporting to the over size product. |

| UnderFlow (or Oversize Material when using PSD) Requirements | ||

| UFSolidsMethod | UF Solids Fraction | The user specifies the solids mass fraction in the Underflow stream. |

| UF Solids Conc | The user specifies the Solids concentration in the Underflow stream. | |

| UF Solids Conc25 | The user specifies the Solids concentration in the Underflow stream at 25°C. | |

| UF Density | The user specifies the density of the Underflow stream. | |

| UFSolidFracReqd | Input | This is visible if UFSolidsMethod = UF Solids Fraction. The user sets the solids mass fraction in the Underflow stream. |

| UFSolidConcReqd | Input | This is visible if UFSolidsMethod = UF Solids Conc. The user sets the solids concentration in the Underflow stream. |

| UFSolidConc25Reqd | Input | This is visible if UFSolidsMethod = UF Solids Conc25. The user sets the solids concentration at 25°C in the Underflow stream. |

| UFRhoReqd | Input | This is visible if UFSolidsMethod = UF Density. The user sets the density of the Underflow stream. |

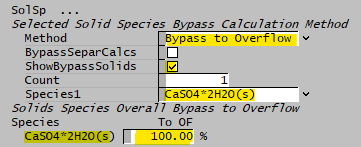

Selected Solid Species Calculation MethodWith this method the user may specify fractions of any number of solid species to bypass to either the Underflow or Overflow streams, or the user may specify the bypass to both Over and Under flow streams. Please see the examples in Model Theory. | ||

| Method | None | There is no overriding of solid species to the Underflow or Overflow streams. |

| Bypass to Underflow | The user may specify the fractions of one or more Solid species that bypass to the Underflow stream. | |

| Bypass to Overflow | The user may specify the fractions of one or more Solid species that bypass to the Overflow stream. | |

| Bypass to Both | The user may specify the fractions of one or more Solid species that bypass the Solid-Liquid calculation block and is then split between the Over and Under flow streams. | |

| BypassSeparCalcs | Tick Box | If this is enabled then the unit will NOT include the bypassed species fraction in the solid/liquid separation calculations. If it is not ticked, then the unit will include the fraction of bypassed species in the solid/liquid separation calculations. Please see the examples in Model Theory for clarification. |

| ShowByPassSolids | Tick Box | If this is enabled then the Count and Speciesx fields will be shown, otherwise they will be hidden. |

| Count | Input | Only visible if ShowByPassSolids is enabled. The number of solid species for which the user wishes to configure bypasses. This may be up to 10 species. |

| Solids Species Overall Bypass to Underflow, Overflow or Both | ||

| Speciesx | Species List | Only visible if ShowByPassSolids is enabled. The user may select a species from a drop down list of all of the Solid species in the project. |

| BypassFracx | Input | The user sets that fraction of species x that must bypass to the Underflow or Overflow streams OR that must bypass Both. Example 1: The user chooses Bypass to Overflow, with Count = 1, Species1 = B(s) and BypassFrac1 = 10%, then 10% of B(s) will bypass the solids separation step and will report to the Overflow stream. 90% of B(s) will be involved in the solid-liquid calculation. Example 2: The user chooses Bypass to Both, with Count = 1, Species1 = B(s), BypassFrac1 = 100% and FracToOF1 = 10%. ALL of B(s) will bypass the solids separation step, 10% of B(s) and will report to the Overflow stream and the remaining 90% will report to the Underflow stream. |

| FracToOFx | Input | This field is only visible if the user selects Bypass to Both. The user sets that fraction of species x that must bypass to the Overflow streams. For example: The user chooses Bypass to Both, with Count = 1, Species1 = C(s), FracToOf1 = 100% and FracToOF1 = 50%. ALL of the C(s) will bypass the solids separation step, 50% of C(s) and will report to the Overflow stream and 50% will report to the Underflow stream. |

Results | ||

| Temperature / T | Display | The temperature of mixture in the solid liquid separator. |

| MassFlow / Qm | Display | The total mass flow to the Underflow and Overflow streams. |

| VapourMassFlow / VQm | Display | The total flow of vapour to the Underflow and Overflow streams. (This does NOT include the vapour to the Vent) |

| UF.BypassMassFlow / UF.BypassQm | Display | The mass flow of the material that bypasses the underflow. |

| OF.BypassMassFlow / OF.BypassQm | Display | The mass flow of the material that bypasses the overflow. |

| BypassMassFlow / BypassQm | Display | The mass flow of the solids in the unit that bypasses the separation section. |

| UF.SolidsTakeoffQm | Display | Only visible for Classifying Precipitator. The solids mass flow takeoff from the underflow for recycle. |

| UF.SolidsTakeoffFrac | Display | Only visible for Classifying Precipitator. The mass fraction of solids in the underflow that reports to takeoff for recycle. |

| UF.FinalSf | Display | Only visible for Classifying Precipitator. The final underflow solids mass fraction after removal of solids takeoff. |

Slurry Separation ResultsIf the BypassSeparCalcs tickbox is selected (visible with Solid Species Bypass Calculation Method used), then the table heading will display "Slurry Separation Results (excluding bypass)" | ||

| UFSolidsRecovery | Display | The fraction of feed solids sent to the underflow. |

| UFLiquidRecovery | Display | The fraction of feed liquid sent to the underflow. |

| The following table displays the flows and compositions of the Underflow and Overflow streams. Note: These are for slurry only, vapours are excluded. | ||

| MassFlow / Qm | Display | The total mass flow in each of the Underflow and Overflow streams. |

| VolFlow / Qv | Display | The total volume flow in each of the Underflow and Overflow streams. |

| SolidMassFlow / SQm | Display | The solids mass flow in each of the Underflow and Overflow streams. |

| LiquidMassFlow / LQm | Display | The liquid mass flow in each of the Underflow and Overflow streams. |

| SolidFrac / Sf | Display | The solid fraction in each of the Underflow and Overflow streams. |

| Density / Rho | Display | The total density of each of the Underflow and Overflow streams. |

| SolidConc | Display | The solid concentration (mass of solids/density of slurry) in each of the Underflow and Overflow streams. |

| SolidConc25 | Display | The solid concentration at 25°C (mass of solids/density of slurry at 25°C) in each of the Underflow and Overflow streams. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Heat Transfer: Evaporator | |

| or | Group: | Energy Transfer |

→ | Units/Links | → | Heat Transfer: Evaporator |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Heat Transfer | → | Evaporator |

See Insert Unit for general information on inserting units.

Hints and Comments

- There may be mass entering or leaving the unit via the Reaction Block source or sink, so if the outgoing mass is not the same as the incoming mass, this may be a place to check first.

- The information in the VLE Section must be correct for the Evaporator to operate as required. If the VLE configuration requires information that is not available, then the flashing will not occur.