Build139 Model Improvements

Jump to navigation

Jump to search

Navigation: User Guide ➔ SysCAD Version History ➔ Build 139 Release Notes ➔ Model Improvements

Latest SysCAD Version: 25 February 2025 - SysCAD 9.3 Build 139.37016

Related Links: Build 139 Revision History, Upgrading Projects

The following Release Notes represent the state of Build 139 at the time of first release. Please refer to the Build 139 Revision History for subsequent updates.

Model Improvements

Unit Model Improvements

- Reactor (Gibbs FEM) unit

- Significant performance (speed) improvements in Gibbs FEM solver together with a more robust implementation to handle a greater range of conditions.

- Added UseConvergedSoln option to allow model to use previous solution as a starting point if feed hasn't changed much since previous iteration. This provides a significant reduction in solve time.

- New AutoDamping option when using FixedHeat operating mode. This improves robustness and solve time of iterative FixedHeat operating mode significantly.

- Solver settings moved to separate tab page with more user configurable settings.

- Able to be used as a side calculation, where Gibbs FEM calculations are performed and displayed but not applied to the feed stream.

- Sweep action to evaluate Gibbs FEM over a temperature range and copies thermal balance to clipboard. If there are discontinuities in the thermal balance at any point, these indicate phase boundaries or species appearing/disappearing from the product.

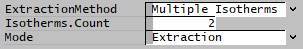

- Solvent Extraction (Mixer Settler) unit - now allows Multiple Isotherms.

- This allows multiple reactions within a single unit to be controlled by isotherms, including different elements.

- The old original method is no longer supported in Build139, please see Project Upgrade for more detail.

- This allows multiple reactions within a single unit to be controlled by isotherms, including different elements.

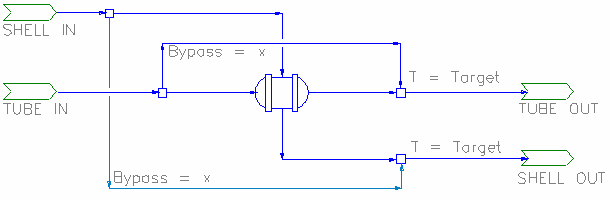

- Shell and Tube Heat Exchanger 2

- New Shell and Tube 2 Evaporating Mode

- New options added to internally bypass a percentage of the primary or secondary streams when using the Sensible HX method. Includes secondary option to calculate and apply the required bypass percentage to achieve a set-point outlet temperature.

The internal built in bypass can be visualised as:

- General Separator - New density separation methods

- Allows user to split solids based on density curve, with user specified efficiency parameter to determine sharpness of split.

- Evaporative Dryer

- Has new UseOriginalMethod option for backward compatibility. Untick this option to allow for a more accurate solution (in some situations) and use of new methods listed below.

- New SolidsLoss methods allow user to specify fraction/concentration of solids/cake in vapour outlet.

- New Moisture method selection allows user to specify either target water or liquid fraction in cake.

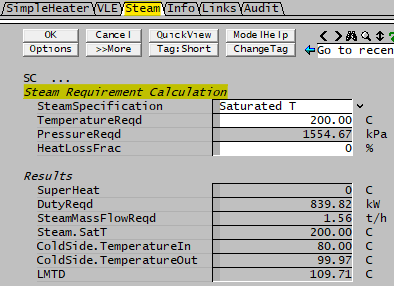

- Simple Heater - New optional side calculation for required Steam flow to achieve specified temperature.

- Can be used to quickly workout the steam flow requirements without having to add the physical stream.

- Requirements specified and results shown on new Steam tab.

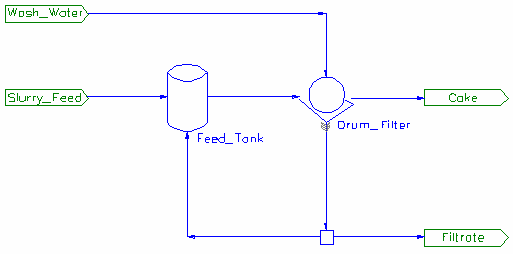

- Drum Filter - Added new option to calculate the required internal recycle of filtrate (which would include wash water) to dilute feed slurry/solids to user-defined solids concentration, representing a feed tank or drum filter bath.

- Reverse Osmosis (RO) Unit:

- Allows Demand to be passed through it, from the Product stream to the Feed stream. Refer to Reverse Osmosis - Demand for more details.

- Allows user to split feed material between Brine and Product outlets when unit is switched off. Refer to Reverse Osmosis - Behaviour when Model is OFF for more details.

- Precipitation3 - Agglomeration terms for kernel, rate and collision have been modularised to allow more variation. See Agglom Parameters for more information.

- Electrowinning Cell - The OverrideProductT and most Heat Exchange methods are no longer allowed in the Reaction Block (RB). Only the RHX-Power option is allowed. Some additional result parameters shown in the access window.

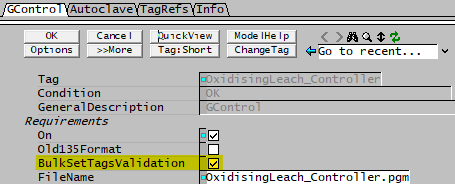

- General Controller - Added option "BulkSetTagsValidation" to the general controller. This allows data validation to apply for groups of tags. This is useful when setting tables of values where the sum has to add up to 100%, such as the Feed composition, size distribution and breakage function tables.

- This option will be enabled by default.

Sub-Model Improvements

- Environmental Heat Exchanger (EHX)

- Added Loss to Ambient 4 method - this is a replacement method for the Loss to Ambient Method.

- Added Loss to Ambient 5 method - this heat loss method accounts for scale build up, and solves for the surface temperature.

Dynamic Unit Model Improvements

- Precipitator3 Dynamic Mode improvements:

- Additional controls are available for tank level control using an Underflow connection, as well as improved bypass options.

- The internal calculation iterations may be decoupled from the project time step using Safety.TimeStep.

- Thickener2 model - New overflow control options. The user can set the level at which the overflow stream is taken from and set the pipe capacity in the overflow pipe.

- Conveyor Belt improvements:

- Added options to specify length of belt to feed onto when stopped.

- Improved Loading display to show sections conveyor belt is divided into internally.

- Added Copy to Clipboard option for Sections data. Allows users to analyse the data in other packages, mainly for debugging purposes.

- Multi-Storage model - New option to display and report the combined total of all stores. Includes options to override the temperature.

- Dynamic Tank displays IOs in order of descending height, also in most recent version of Build138.

- Slew Rate Controller - user can set the "Output" value when stopped. Output Minimum and Maximum now correctly limits the "output" value.