Reaction Block - Other

Navigation: Models ➔ Sub-Models ➔ Reaction Block (RB) ➔ Source, Sink, Heat Exchange

| Overview | Reaction Block Data Section | RB Sub Model (Model Theory) | ||||||

|---|---|---|---|---|---|---|---|---|

| Reaction Editor | Reaction Block Summary | Reaction Block Tabs (Main) | Individual Reactions | Reaction Extents | Source / Sink / Heat Exchange | Solving Order - Sequential or Simultaneous | Energy Balance | Heat of Reaction / Heat of Dilution / Partial Pressures |

Reaction Source

- SysCAD allows the user to define a single Source per Reaction Block. (For how to add a source using reaction editor, please see Adding a New Source)

- The Source can contain any number of species.

- Note the Source species may or may not also be added as part of the feed.

- Reactions using the Source species should not use the extent 'Fraction' = source species, as this may have an infinite number of solutions.

- Water (H2O(l)) and steam (H2O(g)) are not allowed as reaction sources.

- Please also see Advantages and Disadvantages of Sequential and Simultaneous Reactions for more information of Source species.

- NB Some units which allow reactions do not allow reactions with sources. SysCAD will give the error "Reaction block Sources not allowed - Removed" in the message window. The Precipitator3 and ShellandTube2 models do not allow sources.

- There are three options for Source species. They can act as only a Source of material, only as a Recycle species, or as both as required.

Source Only Species |

|

Note: SysCAD will not add recycle species produced in later reactions, it will only add additional species to satisfy all reactions. This may lead to more source species being added then if source and recycle were allowed. |

Recycle Only Species |

|

Note: SysCAD will not add species as a true source to satisfy all of the reactions in which they are used, it will only allow species to be recycled. If the later reactions do not produce enough of the species, then the earlier reactions will not meet their target extents. |

Source and Recycle |

|

Example

Reaction 1: 4 FeSO4(aq) + O2(g) + 2 H2SO4(aq) -> 2 Fe2[SO4]3(aq) + 2 H2O(l) Reaction 2: 3 Fe2[SO4]3(aq) + S(s) + 4 H2O(l) -> 6 FeSO4(aq) + 4 H2SO4(aq) H2SO4(aq) is consumed in reaction 1 and is produced in reaction 2.

Depending on the relative amount of material in the feed and the desired reaction extents, the following scenarios are possible:

- There is enough H2SO4(aq) in the feed to satisfy reaction 1, addition of H2SO4(aq) is NOT required

- There is not enough H2SO4(aq) in the feed to satisfy reaction 1, but Reaction 2 will produce enough H2SO4(aq) to satisfy the demand required by Reaction 1. So Recycle is required.

- There is not enough H2SO4(aq) in the feed to satisfy reaction 1, and Reaction 2 does not produce enough H2SO4(aq) to satisfy the demand required by Reaction 1, so Source and recycle is required.

The best option for this situation is to select the "Source and Recycle" option, as it will recycle the H2SO4(aq) in reaction 2, and top up if there is not enough H2SO4(aq) to satisfy both reactions.

NOTES:

- If H2SO4(aq) is NOT specified as a Source or Recycle species, then Reaction 1 will not reach its target extent in scenarios 2 and 3.

- If H2SO4(aq) is specified as a Recycle only species, then Reaction 1 will reach its target extent in scenario 2, but in for scenario 3.

- If H2SO4(aq) is specified as a Source species, then Reaction 1 will reach its target extent in all scenarios. However, it will not account for the recycle amount from reaction 2, so therefore will add more H2SO4(aq) than required.

- For source and/recycle to work, the reactions must be in sequential order solver mode (i.e. not simultaneous).

See also Example project HP Autoclave Leach Project.

Reaction Sink

- SysCAD allows the user to define a single Sink per Reaction Block. (For how to add a sink using reaction editor, please see Adding a New Sink)

- The Sink can contain any number of species and is used to remove the species from the unit AFTER the reactions are complete.

- Note that the species does not need to participate in the reactions.

- For energy balance calculations, the energy removed from the system is calculated at Product conditions (but prior to any Heat Exchange).

- Water (H2O(l)) and steam (H2O(g)) are not allowed as reaction sinks.

Reaction Heat Exchange

- The user may add a single Heat Exchange per Reaction Block. (For how to add a Heat Exchange using reaction editor, please see Adding Heat Exchange)

- This is used to model additional heat loss or gain from the reaction block.

- In builds prior to Build 139.32925, there must be at least one reaction in the file for Heat Exchange to work.

- The amount of heat added or subtracted is given as the Heat Gain.

- Heat added to the reaction block is given as a positive number.

- Heat removed from the reaction block is given as a negative number.

- If a Reaction Sink is specified, the Heat Exchange is applied after material is sent to the sink.

HINT: In builds prior to Build 139.32925, if you want to add energy into the unit but do not want any reactions to occur. Just define a dummy reaction and set the reaction extent to 0. Then

- define the Heat Exchange using of the specified methods. OR

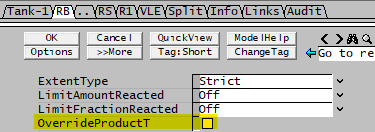

- use the Override Product Temperature option.

The following methods are provided:

| Method | Description | Example |

|---|---|---|

FinalT |

|

|

Power |

|

|

Approach |

|

For a Target of 50 °C, an Approach of 50% and Basis = Feed (assuming the feed temperature entering the reaction block is 30°C), then the Final Temperature is calculated as follows:

If an Approach of 1 (100%) is used then the Target temperature will be achieved. In this case the FinalT method could instead be used. |

Electrolysis |

Thus the Cell Efficiency is defined as follows:

If a cell efficiency of 100% is used then the product temperature = feed temperature. |

Cell efficiency of 90%, feed temperature is 100°C and the energy required to maintain the feed temperature is 22500 kJ. Total energy added = 22500/0.9 = 25000. The extra 2500 kJ energy will heat up the cell further. Thus, the product temperature > feed temperature. |