Multi-Storage

Navigation: Models ➔ Material Handling Models ➔ Multi-Storage

General Description

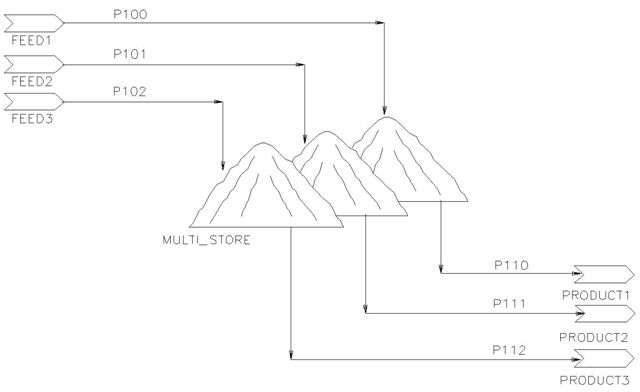

The main purpose of this unit operation is to simplify flowsheet drawing involving storage with multiple feed and product streams.

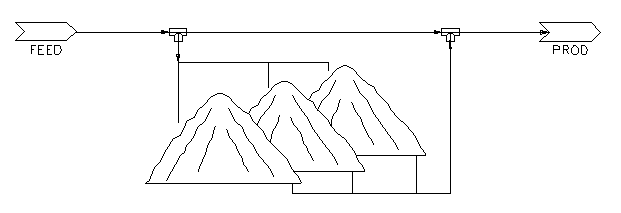

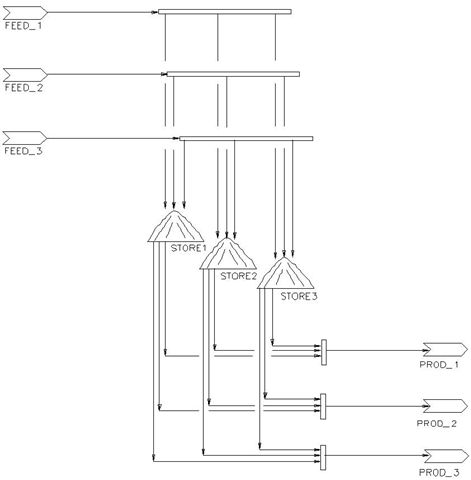

For example, the flowsheet shown in figure 1 below (with 3 storage Tanks) can be simplified to look like figure 2 with the use of a single multi-Storage unit representing 3 tanks.

| Figure1 | Figure2 |

|---|---|

|

|

The distribution of feed and blending of product are done within the multi-storage unit.

Inputs and Outputs

Label Input / Output No. of Connections Description Min Max Input In 0 40* General purpose inlet; *Maximum was 25, limit increased in build 138.25939. Output Out 0 40* General purpose outlet; *Maximum was 25, limit increased in build 138.25939.

Model Theory

The user specifies the number of storage units required. A maximum of 80 storage units can be used per multi-storage unit.

Notes:

- The storage ID starts from 0 and finishes at 79.

- Each feed stream is independent of the other feed streams, there is no mixing of feed streams before they are added to the stores. Similarily each product stream is configured independently and operates independently of the other product connections.

- Each storage may have a reaction. Reactions will take place inside the individual store after feed to the store is perfectly mixed and before product is drawn.

Feed Configuration

Each feed into the multi-storage unit can be distributed into any one or any combination of stores using the following three options:

- Split : the user defines the percentage by mass of the flow to go to each individual store.

- Equal Split : the feed is split equally between all stores. For example, if there are 4 stores, then each store will receive one quarter of the total flow.

- Spec Store : the feed is sent to one store as specified by the user.

Note: the feed option cannot be changed while the model is running but the percentages or store numbers can be changed while the model is running.

Product Configuration

The stored material can be blended in any way to create each product stream using the following four options:

- Flow : the user defines flow from each store to the product stream. This is the only method that can be used with the StoreCentric option.

- Split : the user defines the percentage by mass of the flow to be drawn from each store. The flows obtained will be a function of the pipe capacity of the product stream.

- Equal Split : the product will be drawn equally from all stores. For example, if there are 4 stores, then each store will contribute one quarter of the pipe capacity of the product stream.

- Spec Store : material is only drawn from a single store specified by the user. The flow obtained will be a function of the pipe capacity of the product stream.

Notes:

- The product option (including the StoreCentric option) cannot be changed while the model is running but the flows, percentages or store numbers can be changed while the model is running.

- If the Flow option is used, it is recommended that the pipe capacity be set to undefined (*) to prevent spills.

- If any option other than Flow is used, using an undefined pipe capacity will lead to all material currently in the specified stores being sent to the product stream (i.e. the stores will be emptied).

- If the Split, Equal Split or Spec Store options are used, the product flow achieved will be equal to the pipe capacity if there is sufficient material available in the specified stores. If there is not sufficient material available then the product flow will be less than the specified pipe capacity.

Bypass Function

The Multi-Storage unit has an in-built bypass function which is illustrated by the diagram below:

Based on user specified product flow requirements, the model will attempt to achieve this flow by having a portion of a defined feed stream bypass the stores and sent directly to the product stream. If the feed flow exceeds the product flow requirement then the excess will be sent to the stores. If the feed flow is less than the required flow then the additional material can be made up by drawing material from the stores.

The user must choose a single feed stream and a single product stream to be associated with this function.

There are three main options to choose from when defining the product flow:

- UsePipe : the required flow is equal to the user defined pipe capacity. Defining pipe capacities is the way flows are usually controlled in a dynamic transfer project.

- IgnorePipe : the user sets the required flow using the Qm.Capacity tag in the multi-storage model. The pipe capacity is ignored. To avoid spills it is recommended that the pipe capacity be set to undefined (*) when using this option.

- Combination : this method will allow both the above methods to be used and SysCAD will choose the lowest of the two requirements (thus preventing any spills). An example where this method may be useful is if there are two different pieces of logic setting the capacity of the product, one being the desired flow and the other being a maximum possible flow.

Any excess feed flow will be distributed to the stores using the user defined settings on the Feeds tab page, as for all other feeds.

The user chooses whether to allow makeup from the stores when the feed flow is less than the required product flow by ticking or unticking the MakeupFromStores option. If this option is used, the material will be drawn from the stores using the user defined settings on the Products tab page, as for all other products.

Data Sections

The default sections and variable names are described in detail in the following tables. The default Multi Storage access window consists of seven sections. This number may increase or decrease, based on user configuration.

- MultiStorage -- This tab page contains general configuration information.

- Feeds -- This tab page contains information about the split and flows to the individual units.

- Products -- This tab page contains information about the split and flows from the individual units.

- Sx -- The user can select the individual storage unit to view and the name of this tab will change accordingly, i.e. if the user selects unit 1, then the tab will be S1. This series of tabs also includes a Content section which contains data on the material contained within unit Sx.

- RBx - Optional tab, only visible if the Reactions are enabled in the unit.

- ST -- Only available in Build 139 or later. Optional tab, only visible if the TotalStore.Calculate option is enabled on the first tab page. The combined total of all stores. This series of tabs also includes a Content section which contains data on the material contained within the combined stores.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - Contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

MultiStorage Page

Unit Type: MultiStorage - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Settings | ||

| StoreCount | Input | User specified number of storages required. Up to 80 stores are allowed. Store ID starts from 0. Therefore, if 3 stores are specified, stores available are 0, 1 and 2. |

| BypassOption | ||

| Off | The bypass option is not used. | |

| Combined | The amount of flow required in the ProdStream is the smaller of the user setting for the bypass Qm.Capacity and the pipe capacity. | |

| UsePipe | The amount of flow required in the ProdStream is based on the pipe capacity. | |

| IgnorePipe | The amount of flow required in the ProdStream is based on the user setting for the bypass Qm.Capacity, ignoring the pipe capacity. | |

| Reactions | Tickbox | Adds the reaction sub model to ALL of the stores. |

| Rct.CommonRctFile | Input | Only visible if reactions have been enabled. Allows the user to load in a common reaction file, this file will be auto added to all the stores. However, the user still has the option to change the reaction file in an individual store if the reaction file differs. |

| Rct.CommonBrowse | Button | Only visible if reactions have been enabled. Allows the user to browse for the common reaction file that will be auto added to all the stores. However, the user still has the option to change the reaction file in an individual store if the reaction file differs. |

| Options | ||

| TrackFlowOutReqd | Tickbox | If enabled, user will receive warnings if pipe capacity requirements are not met. |

| TotalStore.Calculate | Tickbox | Only available in Build 139 or later. If enabled, the contents of all stores will be combined and reported on the ST tab page. |

| TotalStore.TemperatureMethod / T_Method (Only displayed if TotalStore.Calculate has been enabled.) | ||

| Std | The temperature used on the ST tab page when reporting values will be equal to the standard temperature. In SysCAD this is always 25°C. | |

| Ambient | The temperature used on the ST tab page when reporting values will be equal to the ambient temperature. This is set on the Environment tab of the Plant Model. | |

| User | The temperature used on the ST tab page when reporting values will be as specified by the user. See TotalStore.TemperatureReqd field below. | |

| Calculated | The temperature used on the ST tab page when reporting values will be calculated by performing an energy balance when combining the contents of the stores. Note: this is the most computationally expensive of all the methods and so should only be chosen if accurate reporting of the combined temperature or a combined property which is dependent on temperature (such as volume or concentration) is critical. | |

| TotalStore.TemperatureReqd / T_Reqd | Tickbox | Only displayed if TotalStore.TemperatureMethod is set to User. The user specified temperature for reporting of the total contents on the ST tab page. |

| Display Options | ||

| StoreCentric | Tickbox | If selected, allows the user to see the product split (on the Products tab page) on a per store basis, otherwise, the display will be per product stream basis. |

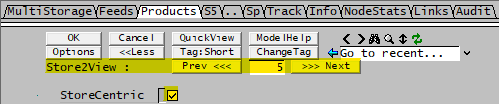

| Store2View | Input | The user defines which storage information to be displayed on subsequent tabs. For example, if 0 is specified, the first store information will be displayed on tabs S0, M and RB0 respectively. Note: The tags for ALL stores are always available for reporting or control, even when they have not been selected for display. |

| Results | ||

| TotalMass / Mt | Calc | The total mass of material in all stores. |

| SolidMass / SMt | Calc | The mass of solids in all stores. |

| LiquidMass / LMt | Calc | The mass of liquids in all stores. |

| VapourMass / VMt | Calc | The mass of vapours in all stores. |

| SlurryMass / SLMt | Calc | The mass of solids and liquids in all stores. |

| InitTtlMass / InitMt | Calc | The mass in all stores at the start of the solver run. |

| DeltaTtlMass / DeltaMt | Calc | The total change in mass in all stores from the start of the solver run. |

| Bypass Operation... (This section only appears if the BypassOption is On (i.e. not Off)) | ||

| MakeupFromStores | Tickbox | Allows additional material to be fed from the stores to the ProdStream if the required flow is not achieved using the bypass of feed material. |

| ShowQBypass | Tickbox | QBypass and associated tab pages (e.g. Qm) will become visible, showing the properties of the bypass stream. See Material Flow Section. |

| Bypass... | ||

| FeedStream | List | The user chooses the Feed Stream to bypass the multistore from a drop down list of all feeds to the multistore. |

| ProdStream | List | The user chooses the Product Stream to which the bypass will exit from a drop down list of all product streams from the multistore. |

| Qm.Capacity | Input | The user specifies the required mass flow in the ProdStream. This will not be an input field if the user chooses the UsePipe bypass option. |

| Qm | Feedback | Displays the mass flow of bypassed material. |

| StoresMakeup... (This section only appears if the MakeupFromStores option has been enabled) | ||

| Qm.Capacity | Input | The user specifies the required mass flow to be taken from the existing Stores. |

| Qm | Feedback | Displays the mass flow of material drawn from the stores. |

| ProdStream... | ||

| Qm.Capacity | Feedback | Displays the pipe capacity of the chosen ProdStream. |

| Qm.CapacityUsed | Feedback | Displays the pipe capacity used when calculating how much material to be sent to the ProdStream using the bypass. If the UsePipe bypass option has been chosen, then this will be the same as the ProdStream Qm.Capacity field shown above. If the IgnorePipe bypass option has been chosen, then this will be the same as the Bypass Qm.Capacity defined by the user. If the Combination bypass option has been chosen, then this will be the smaller of the ProdStream Qm.Capacity field shown above and the Bypass Qm.Capacity defined by the user. |

| Qm | Feedback | Displays the mass flow in the ProdStream. If the MakeupFromStores option is not selected, then this will be the same as the mass flow of bypassed material. |

| (the following parameters are displayed in a table with 1 row for each Store) | ||

| Mass / Mt | Column Heading | Displays the total mass in each individual store. |

| Volume / Vt | Column Heading | Displays the total volume of material in each individual store. |

| Temperature / T | Column Heading | Displays the temperature in each individual store. |

Feeds

Each Feed pipe can be set to split between the storage units on this page. This describes the different split methods and the fields that are available for each method.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| -------- PipeID -------- | ||

| SplitMethod | Split | The user specifies how the material in the feed stream is split, on a mass basis between all available stores |

| Equal Split | The feed stream is split equally between all the available stores | |

| Spec Store | The feed stream is directed to a specified store only. | |

| TargetStore | Input | Only available if SplitMethod = Spec Store. The user selects the store to which the feed stream will be sent. The full flow from the stream will be sent to the specified store. |

| MassFlowEst / QmEst | Feedback | The estimated total mass flowrate of the feed stream. |

| MassFlow / Qm | Feedback | The total mass flowrate of the feed stream. |

| (the following fields are displayed in a table with 1 row for each store) | ||

| SplitReqd | Input / FeedBack | If the SplitMethod = Split the user may specify the percent split from the feed stream to the relevant store. Otherwise this displays the fraction of material reporting to each store. |

| MassFlow / Qm | FeedBack | The actual mass flow to each store from the feed stream. |

Products

Each Product pipe can be set to obtain material from individual storage units on this page. This describes the different methods and the fields that are available for each method.

Sx

To change the store selection, press ![]() ,

, ![]() or simply entered the desired store number in the field between the buttons.

or simply entered the desired store number in the field between the buttons.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Name | Input | User can give the store a descriptive name here. |

| Mass / Mt | Feedback | The total mass stored in the specified store. |

| Volume / Vt | Feedback | The total volume of material stored in the specified store. |

| Temperature / T | Feedback | The temperature of material in the specified store. |

| FeedRate | Feedback | The current feedrate into the specified store. |

| ProdRate | Feedback | The current product drawn rate out of the specified store. |

| Content... | ||

| Material Content Section | ||

ST

Only available in Build 139 or later. Optional tab, only visible if the TotalStore.Calculate option is enabled on the first tab page. The combined total of all stores.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Name | Feedback | Will always be named "StoresTotal". |

| Mass / Mt | Feedback | The total mass stored in all stores. |

| Volume / Vt | Feedback | The total volume of material stored in all stores. |

| Temperature / T | Feedback | The temperature of the combined material from all stores. Note: This temperature will only be the combined temperature of material in the stores if Calculated has been chosen for the TemperatureMethod on the MultiStorage tab page. |

| Content... | ||

| Material Content Section | ||

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | MatHand1.dll |

→ | Units/Links | → | Material Handling: Multi-Storage | |

| or | Group: | Mass Transfer |

→ | Units/Links | → | Material Handling: Multi-Storage |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Material Handling | → | Multi-Storage |

See Insert Unit for general information on inserting units.