SysCAD 137 New Models and Add-On

Navigation: User Guide ➔ SysCAD Version History ➔ Build 137 Release Notes ➔ New Models and Add-On

| Build 137 Release Notes (Summary) | ||||||||

|---|---|---|---|---|---|---|---|---|

| New Models and Add-On | Model Improvements | Reaction Block Improvements | User Interface Improvements | Other Improvements | Project Upgrade And Changes that Affect Results | |||

Latest SysCAD Version: 25 February 2025 - SysCAD 9.3 Build 139.37016

Related Links: Build 137 Revision History, Upgrading Projects

New Models

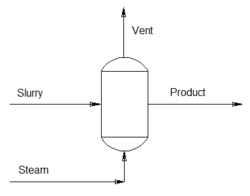

Direct Contact Heater 2

(Full documentation of this unit operation can be found here: Direct Contact Heater 2)

(Full documentation of this unit operation can be found here: Direct Contact Heater 2)

- The new Direct Contact Heater 2 is used to transfer energy from a stream containing live steam to a liquid or slurry stream.

- It has additional options and improved functionality compared to the original Direct Contact Heater model which includes:

- Pressure specification

- Vent stream Handling

- The model can make use of the Demand logic, including as part of a Flash Train.

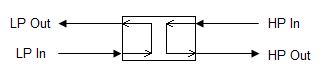

Pressure Exchanger

(Full documentation of this unit operation can be found here: Pressure Exchanger)

(Full documentation of this unit operation can be found here: Pressure Exchanger)

- The new Pressure Exchanger unit model can be used to model energy recovery devices such as those used in reverse osmosis plants to recover energy from high pressure brine streams.

- The unit has two feeds, a low pressure feed and a high pressure feed. The pressure energy in the high pressure feed is transferred to the low pressure stream, thus acting like a pump for the low pressure stream, increasing its pressure.

- The model can be used to model a wide variety of physical devices such as a Pelton wheel, a Francis turbine, a reverse pump, a Turbocharger and a PX.

- The model includes a leakage parameter to allow for modelling of devices where some mixing can occur.

- The model can make use of the Demand logic to set the flow on the low pressure side.

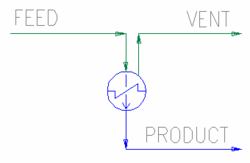

Simple Condenser

(Full documentation of this unit operation can be found here: Simple Condenser)

(Full documentation of this unit operation can be found here: Simple Condenser)

- The new Simple Condenser is a generic "heat exchanger" model without regards to its cooling media or equipment size.

- It can provide estimates of the Duty required to condense an amount of material, or alternatively, determine the amount of condensation for a given duty or temperature.

- The model can make use of the Demand logic, including as part of a Flash Train.

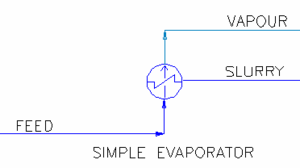

Simple Evaporator

(Full documentation of this unit operation can be found here: Simple Evaporator)

(Full documentation of this unit operation can be found here: Simple Evaporator)

- The new Simple Evaporator is a generic "heat exchanger" model without regards to its heating media or equipment size.

- It is designed to give estimates of the Duty required to evaporate a required amount of material. Only a single component can be evaporated such as H2O(l) or NH3(aq).

Slew Rate Controller

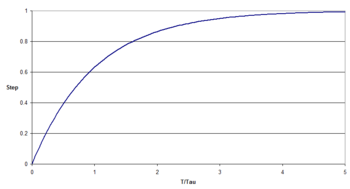

- The new Slew Rate Controller is used to gradually change a process variable to a setpoint.

- It can be used in both steady-state and dynamic simulations for the purpose of making gradual changes.

- It has a number of methods available to make the gradual change including fixed rates and first order response.

(Full documentation of this unit operation can be found here: Slew Rate Controller)

(Full documentation of this unit operation can be found here: Slew Rate Controller)

Thermocompressor

(Full documentation of this unit operation can be found here: Thermocompressor)

(Full documentation of this unit operation can be found here: Thermocompressor)

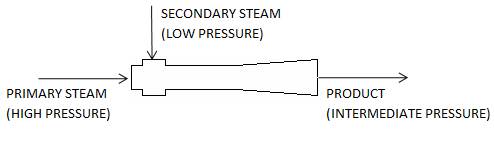

- The new Thermocompressor is a form of steam ejector in which a flow of higher pressure primary steam is used to entrain lower pressure secondary steam.

- The discharge stream is at an intermediate pressure between the high and low pressure steam flows. This potentially enables recovery of some of the energy in the low grade steam.

- The Thermocompressor model in SysCAD is based on data sheets from the Shutte and Koerting company.

Underflow Washer

(Full documentation of this unit operation can be found here: Underflow Washer)

(Full documentation of this unit operation can be found here: Underflow Washer)

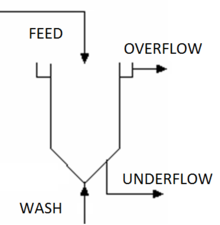

The Underflow Washer is used to separate the solids from the liquids in the feed stream and then wash the solids with a wash stream. This unit is similar to the Washer and the Counter Current Washer.

- The user defines the percentage solids in both the underflow and the overflow from the unit.

- If there is insufficient solids in the feed to the Underflow Washer to satisfy both the under and over flow requirements, the unit will try to satisfy the underflow solids / liquids requirements first.

- The wash stream combines with the underflow solids and 'washes' the feed liquid out of the solid stream.

- The model allows the user to set sub-models in the Feed section, Underflow and Overflow sections. The following sub-models are avaialble in each section:

- The Feed section, EB, allows the user to set Solubility, Reactions, Makeups, Environmental Heat Exchange and Evaporation;

- The Overflow section, OFEB, allows the user to set Solubility, Reactions, Environmental Heat Exchange and Evaporation; and

- The Underflow section, UFEB, allows the user to set Solubility and Reactions.

- The temperature of the solids and liquids is calculated after any reactions and/or heat loss has occurred.

New SysCAD OLI Add-on

Implemented new OLI add-on for SysCAD. OLI Systems provide leading Electrolyte Simulation Software. This SysCAD add-on requires an appropriate license from OLI Systems (olisystems.com) as well as requiring SysCAD "Heat Exchange" and "SMDK Runtime" add-ons. OLI in SysCAD is not implemented as a Species Properties Model but as unit models for use at appropriate locations in a plant model. Currently the following unit models using OLI are implemented:

- OLI Chemistry Model - Used to define and view various options for the selected OLI chemistry model, including management of mapping of SysCAD species list to species list used in OLI.

- OLI Sample Model - Stand alone unit model to perform side calculations using OLI for predicting aqueous chemistry equilibrium conditions and properties including pH.

- OLI Reactor - Include this model in a SysCAD stream to use OLI to calculate predicted outlet conditions. Functionality is similar to SysCAD Reaction Block and FEM where for a given feed reactions occur with optional heat exchange. The model can be configured in a number of ways for different purposes.