Electrowinning Cell

Navigation: Models ➔ Energy Transfer Models ➔ Electrowinning Cell

General Description

The electrowinning cell converts metal in solution into solid elemental metal. The user specifies the reaction in the normal way using the Reaction Block (RB). In the dynamic mode, the solids are removed separately in a batch process, to emulate the removal of cathodes on a plant. The energy required by the cell is calculated from the heats of reaction and the efficiency of the cell. The excess energy is used to heat the contents of the unit.

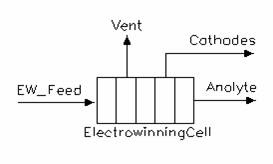

Diagram

The diagram shows the default drawing of the Electrowinning Cell, with all of the streams that are available for operation of the unit.

The physical location of the streams connecting to the Electrowinning Cell is unimportant. The user may connect the streams to any position on the unit.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | The feed to the Electrowinning Cell |

| Anolyte | Required | Out | 1 | 1 | The Liquid outlet from the unit |

| Cathodes | Required | Out | 1 | 1 | Solids, or cathode, outlet from the unit |

| Vent | Optional | Out | 0 | 1 | Vent Stream (Vapour Only) |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- The field MassFracToCath becomes visible and the user may set the fraction of the feed stream that reports to the 'Cathode' outlet. The default is 100%.

- All streams connected to the unit will flow out of the 'Cathode' outlet, unless the user has changed the above field from 100%. In which case the user defined fraction of the feed streams will report to the Anolyte stream;

- No reactions or heating will occur.

So basically, the unit will be 'bypassed' without the user having to change any connections.

Model Theory

The Electrowinning Cell is modelled as a tank that contains an electrolytic reaction, where a metal is plated out onto a cathode from an aqueous solution. The reactions occurring in electrowinning require energy to proceed and the amount of energy is calculated as follows:

At 100% efficiency the energy value calculated by the model is the amount of energy required to maintain the material in the cell at the temperature of the cell feed.

If the cell is less than 100% efficient, then the extra energy increases the temperature of the products from the cell.

The energy required by the electrowinning cell is governed by the enthalpy of the electrolytic reaction occurring the unit. This enthalpy of the reaction is calculated in one of two ways:

- Enthalpy of Reaction = Sum of Heats of formation of the products - Sum of Heats of formation of reactants. (This is the default method of calculating the heat of reaction.) The heats of formation of the species are defined in the species database.

- The Heat of Reaction is specified in the reaction file. This method is often used when the heats of formation are not known.

Note that the above calculations ignore the effect of using the OverrideProductT or Heat Exchange options in the Reaction Block. In Build 139 or later, the OverrideProductT and most Heat Exchange methods are not allowed. Only the RHX-Power option is allowed.

Flowchart

The following shows the sequence of events if sub model options are switched on. See next heading for more information.

Data Sections

The default access window consists of a number of sections, depending on user specifications. The tabs that may be visible are:

- ECell tab - Contains general information relating to the unit.

- RB - Optional tab, only visible if the Reactions are enabled in the Evaluation Block.

- QFeed - Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the combined feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - Contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Electrowinning Cell Page

Unit Type: ECell - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick box | Switch the model on or off. If the unit is 'Off' then by default all Feed reports to the Cathodes outlet. If the user specifies a value (less than 100%) in the MassFracToCath field, then some feed may report to the Anolyte stream. |

| MassFracToCath_WhenOff / MassFracToCath | Input | This field becomes visible when the unit is switched off. The user may set the fraction of the feed stream that reports to the Cathodes outlet. The default is 100%. |

| CellEfficiency / CellEff | Input | The required energy efficiency of the cell. This is used to calculate the energy required by the cell, and the temperature rise in the cell. |

| Reactions | List | This can be used to switch on the Reaction Block (RB). If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user must configure the reaction block, if the Electrowinning cell is to do any work. |

| OperatingP - NOTE: this pressure is applied to the (combined) feed, before sub-models (if any). | ||

| Method | AutoDetect | If there are any liquids AND no vapours present in the feed, outlet streams will take the highest pressure of the feeds. Else (e.g. some vapours present) outlet streams will take the lowest pressure of the feeds. |

| LowestFeed | Outlet streams will take the lowest pressure of the feeds. | |

| HighestFeed | Outlet streams will take the highest pressure of the feeds. | |

| Atmospheric | Outlet streams will be at Atmospheric Pressure. The atmospheric pressure is calculated by SysCAD based on the user defined elevation (default elevation is at sea level = 101.325 kPa). The elevation can be changed on the Environment tab page of the Plant Model. | |

| RequiredP | Outlet streams will be at the user specified pressure. | |

| IgnoreLowMassFlow / IgnoreLowQm | Tick Box | This option is only visible if the AutoDetect, LowestFeed or HighestFeed methods are chosen. When calculating the outlet pressure and temperature of the tank, SysCAD will ignore the low flow feed streams should this option be selected. The low flow limit is set in the field below. |

| LowMassFlowFrac / LowQmFrac | Input | This field is only visible if the IgnoreLowQm option is selected. This is the amount any stream contributes to the total flow. For example, if the total feed to the tank is 10 kg/s, and this field is set to 1%. Then any feed streams with less than 0.1 kg/s will be ignored in the pressure calculations. |

| PressureReqd / P_Reqd | Input | This field is only visible if the RequiredP method is chosen. This is user specified pressure. |

| Result | Calc | The actual pressure used for the sum of the feeds which will also be the outlet pressure (unless further model options change the pressure). |

| Options | ||

| ShowQFeed | Tickbox | When selected, the QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined feed stream. See Material Flow Section. Tags in the QFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

Results | ||

| Feed.MassFlow / Feed.Qm | Calc | Only available in Build 139 or later. The total mass flow of the combined feeds. |

| Feed.Temperature / Feed.T | Calc | The feed temperature. |

| Prod.Temperature / Prod.T | Calc | The final temperature of the cell after the required energy is added. |

| ElecEnergyTotal | Calc | The calculated electrical energy requirements of the cell. This is based on the heat of reaction and the efficiency of the cell. This is the sum of ElecEnergyReact and ElecEnergyHeat or ElecEnergyReact/CellEfficiency, where CellEfficiency is expressed as a fraction. |

| ElecEnergyReact | Calc | The calculated energy requirements of the cell. This represents the energy required to maintain the material in the cell at the temperature of the cell feed. Note: This calculation ignores the effect of using the OverrideProductT or Heat Exchange options in the Reaction Block. |

| ElecEnergyHeat | Calc | The calculated amount of energy that is converted to heat. This is based on the cell efficiency and ElecEnergyReact. For a 100% efficient cell, ElecEnergyHeat = 0. For <100% efficiency, ElecEnergyHeat = ElecEnergyReact*(1-CellEfficiency)/CellEfficiency, where CellEfficiency is expressed as a fraction. |

| RHX.HeatFlow | Calc | Only available in Build 139 or later. The amount of energy that is added by the Reaction Block Heat Exchange. Note: Only the Power method is able to be used. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Heat Transfer: Electrowinning Cell | |

| or | Group: | Energy Transfer |

→ | Units/Links | → | Heat Transfer: Electrowinning Cell |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Heat Transfer | → | Electrowinning Cell |

See Insert Unit for general information on inserting units.

Example Project

Please see Solvent Extraction Project OR Nickel Copper Project