Compressor: Difference between revisions

Adrian.Paine (talk | contribs) |

Adrian.Paine (talk | contribs) |

||

| Line 143: | Line 143: | ||

# '''[[Links Table|Links]]''' tab, only visible in SysCAD 9.2, contains a summary table for all the input and output streams. | # '''[[Links Table|Links]]''' tab, only visible in SysCAD 9.2, contains a summary table for all the input and output streams. | ||

# '''[[Audit]]''' tab - contains summary information required for Mass and Energy balance. See [[Model Examples]] for enthalpy calculation Examples. | # '''[[Audit]]''' tab - contains summary information required for Mass and Energy balance. See [[Model Examples]] for enthalpy calculation Examples. | ||

===Compressor Page=== | ===Compressor Page=== | ||

Revision as of 06:47, 30 October 2012

Navigation: Main Page -> Models -> Pressure Changing Models

General Description

The compressor model can be used to increase the pressure of streams which consist mostly of gases. The user will receive a warning if the fraction of vapours in the feed is less than 99%.

The compressor model can be inserted in a steam line that is part of a Flash Train.

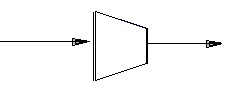

Diagram

The diagram shows the default drawing of the Compressor, with the required connecting streams. The unit will not operate unless all of the above streams are connected.

The physical location of the connections is not important, the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Input /Output | Required / Optional | Number of Connections | Description | |

| Min | Max. | |||

| In | Required | 1 | 1 | Input stream to compressor. |

| Out | Required | 1 | 1 | Output stream from compressor. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the material will flow straight through the Compressor with NO change to either Temperature or Pressure.

So basically, the unit will be 'bypassed' without the user having to change any connections.

Model Theory

Equations

For an ideal gas:

(1) [math]\displaystyle{ \mathrm{C_p = C_v + R} }[/math]

where:

- [math]\displaystyle{ \mathrm{C_p} }[/math] = heat capacity at constant pressure on a per mole basis

- [math]\displaystyle{ \mathrm{C_v} }[/math] = heat capacity at constant volume on a per mole basis

- R = universal gas constant

Then K (Kappa), the ratio of specific heats, can be calculated as follows:

(2) [math]\displaystyle{ K = \frac{C_p}{C_p - R} }[/math]

For an ideal gas with constant heat capacities, which undergoes a mechanically reversible, adiabatic (or isentropic) process, the following equation applies:

(3) [math]\displaystyle{ \frac{T_2}{T_1}=\left (\frac{P_2}{P_1}\right)^{((K-1)/K)} }[/math]

This can be rewritten as:

(4) [math]\displaystyle{ T_{out} = \left (\frac{P_{out}}{P_{in}}\right)^{((K-1)/K)} * T_{in} }[/math]

where:

- [math]\displaystyle{ \mathrm T_{out} }[/math] = outlet temperature

- [math]\displaystyle{ \mathrm P_{out} }[/math] = outlet pressure

- [math]\displaystyle{ \mathrm P_{in} }[/math] = inlet pressure

- [math]\displaystyle{ \mathrm T_{in} }[/math] = inlet temperature

Thus given the inlet temperature and pressure and the outlet pressure, the outlet temperature can be calculated.

The adiabatic efficiency is used for the Isentropic method and is defined as:

(5) [math]\displaystyle{ \mathrm {Adiabatic\ Efficiency (%)} = \frac{dT_i * 100}{dT_a} }[/math]

where:

- [math]\displaystyle{ \mathrm dT_i }[/math] = calculated temperature change for isentropic process

- [math]\displaystyle{ \mathrm dT_a }[/math] = actual temperature change

The polytropic exponent has the following form:

(6) [math]\displaystyle{ \frac{n}{n-1} = \frac{K}{K-1} * \mathrm {Polytropic\ Efficiency} }[/math]

then

(7) [math]\displaystyle{ T_{out} = \left (\frac{P_{out}}{P_{in}}\right)^{((n-1)/n)} * T_{in} }[/math]

For all cases,

(8) Ideal Power = Rate of Enthalpy Out - Rate of Enthalpy In

(9) [math]\displaystyle{ \mathrm {Compressor\ Efficiency (%) = \frac{Ideal Power*100}{Actual Power}} }[/math]

Calculation Steps

Step 1) Determine the outlet pressure based on user specified value, boost or ratio.

Step 2) If the user has specified a value for K, use this value in the calculations, otherwise calculate K as the ratio of Cp to Cv using equation (2).

Step 3) Calculate the outlet temperature based on the outlet pressure:

- a) for the Isentropic method: use equation (4).

- b) for Polytropic method: use equations (6) and (7).

Step 4) Calculate the outlet enthalpy based on the outlet temperature and pressure.

Step 5) Calculate the Power using equations (8) and (9)

Assumptions, Limitations and comments

- This model assumes that the gases behave as ideal gases.

- The feed stream should contain only gases. Small amounts of liquids and solids will have little affect. The outlet temperature and pressure are determined by the gases present in the stream only. Any liquids or solids in the inlet will be assumed to exit the compressor at this new temperature and pressure. When the power is calculated using the enthalpy difference between the inlet and outlet, this will include any solids or liquids in the stream. Thus the presence of solids and liquids will usually lead to an increase in power requirements.

- Note: If the stream contains no gases, then the model will produce unrealistic results.

References

1. Bloch H.P. A Practical guide to Compressor Technology, McGraw-Hill 1996

2. Perry et al Perry's Chemical Engineers' Handbook 6th Edition, McGraw-Hill 1984

Data Sections

Summary of Data Sections

- Compressor tab - contains the main configuration information relating to the unit.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, only visible in SysCAD 9.2, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Compressor Page

Class: Compressor The first tab page in the access window will have this name.

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options | |

Requirements | |||

| On | Tickbox | If the unit is disabled, by un-ticking this box, then material flows straight through the unit, with no change to temperature or pressure. | |

| PressMethod | Fixed | The user specifies the outlet pressure from the Compressor. | |

| Boost | The user specifies the pressure boost of the compressor. | ||

| Ratio | The user specifies the ratio of the outlet pressure to the inlet pressure. | ||

| PRqd | Input | Only visible if Fixed is chosen for the Pressure method. This sets the required pressure of the outlet (discharge) stream. | |

| PBoost | Input | Only visible if Boost is chosen for the Pressure method. The difference in pressure between the inlet and outlet streams. | |

| PRatioRqd | Input | Only visible if Ratio is chosen for the Pressure method. The ratio of the outlet pressure to the inlet pressure. | |

| MaxPRatio | Input | The maximum compression ratio that the Compressor can provide. If the required final pressure / inlet pressure > than this value, then SysCAD will restrict the final pressure so that the maximum pressure ratio is not exceeded. The unit will give the user an error message if this occurs. | |

| Method | Isentropic | The isentropic outlet temperature will be calculated using the pressure ratio, inlet temperature and the ratio of heat capacities (K). | |

| Polytropic | The outlet temperature will be calculated using the pressure ratio, inlet temperature, ratio of heat capacities (K) and the polytropic efficiency. | ||

| SpecifyK | Tickbox | This allows the user to specify the value of K, the ratio of heat capacities. If this is left unchecked, then the model will assume ideality and use equation (1) to calculate K based on Cp values in the specie database. | |

| K | Input | Only visible if SpecifyK option is selected. This is the user specified value of k, the ratio of specific heats of the gas in the feed stream. | |

| AdiabaticEff | Input | Only visible if Isentropic is chosen for the Calculation method. This efficiency is used to alter the calculated isentropic temperature change. A lower efficiency will lead to a larger temperature change. | |

| PolytropicEff | Input | Only visible if Polytropic is chosen for the Calculation method. | |

| CompressorEff | Input | This efficiency is used to calculate the Power from the IdealPower. A lower efficiency will lead to a larger Power and a larger difference between Power and IdealPower. | |

Results | |||

| Qm | Calc | The total mass flow through the unit. | |

| Ti | Calc | The inlet temperature. | |

| To | Calc | The outlet temperature. | |

| Pi | Calc | The inlet pressure. | |

| dP | Calc | The pressure change across the Compressor. | |

| Po | Calc | The outlet pressure. | |

| PRatio | Calc | The pressure ratio of the Compressor = Pressure Out / Pressure In. | |

| Vfi | Calc | The fraction of vapours in the inlet stream. | |

| Vfo | Calc | The fraction of vapours in the outlet stream. | |

| IdealPower | Calc | The calculated difference in enthalpy between the inlet and outlet streams per unit time. | |

| Power | Calc | The required power, adjusted by the compressor efficiency. The lower the efficiency the more power required. | |

| Gas.MWT | Calc | The weighted average of the molecular weights of the vapours in the inlet stream. | |

| Gas.Cp | Calc | The weighted average of the heat capacities at constant pressure (Cp) of the vapours in the inlet stream. | |

| Gas.Cv | Calc | The heat capacity at constant volume (Cv) of the vapours in the inlet stream. This is calculated using the heat capacity at constant pressure (Cp). | |

| Gas.K | Calc | The ratio of the Gas Cp to the Gas Cv, i.e. the K value. | |

Adding this Model to a Project

Insert into Configuration file

Sort either by DLL or Group.

|

|

DLL: |

Basic1.dll |

→ |

Units/Links |

→ |

Process Piping: Compressor |

|

or |

Group: |

General |

→ |

Units/Links |

→ |

Process Piping: Compressor |

See Project Configuration for more information on adding models to the configuration file.

Insert into Project

|

|

Insert Unit |

→ |

Process |

→ |

Piping |

→ |

Compressor |

See Insert Unit for general information on inserting units.