Sugar Crystalliser

Navigation: Models ➔ Sugar Models ➔ Sugar Crystalliser

| Sugar Properties | Sugar Unit Models | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sugar Species Model | Sugar Cane Shredder | Sugar Crusher | Sugar Crystalliser | Sugar Dryer | Sugar Fugal | Sugar Fugal 2 | Sugar Juice Screen | Sugar Mud Filter | Sugar Vacuum Pan |

Latest SysCAD Version: 25 February 2025 - SysCAD 9.3 Build 139.37016

General Description

The Sugar Crystallizer unit operation is available with the Sugar add-on.

The sugar crystallizer is used to precipitate aqueous sugar from molasses onto existing sugar crystals. The SysCAD sugar crystallizer unit operation can be used to represent a single channel, chamber, stage or pass in a larger sugar crystallizer. Multiple SysCAD crystallizer unit operations can linked together to create more complex crystallizer models as required.

Massecuite is fed into the crystallizer which may also have an additional molasses stream or dilution water fed it. The model also has optional connections for both cooling water and for heating water. An optional vent connection removes any vapours from the system. The residence time in the unit is defined by its geometry (volume) and the mass flow through the unit. There are different options to describe precipitation rate and a temperature profile may be imposed. There is a single product stream exiting from the unit.

A numerical solution is found by dividing the volume into a user specified number of independent segments. The process is modeled as a series of continuous well stirred tank reactors (CSTR). The flow into each segment is assumed to be perfectly mixed with the contents of the segment. Massecuite properties and precipitation rates are calculated at the outlet conditions from each segment.

A linear temperature profile for the unit may be specified. The outlet temperature may be specified either as a fixed temperature or as a temperature difference from the feed temeprature. The temperature is assumed to vary linearly from the feed temperature to the outlet temperature. If molasses or dilution is added at some point along the unit, then a new linear temperature profile is calculated from that point to give the target outlet temperature. The temperature profile may be specified even if there is no cooling or heating water to the unit. The amount of heating or cooling required to give the temperature profile is always calculated and displayed. If an optional heating or cooling stream is connected, this amount of heat will be removed or added from the appropriate stream and the heating or cooling outlet stream temperature will be adjusted accordingly. This allows crystallizer thermal demands to be accurately included in plant models.

A heat loss option is included that allows heat loss from the unit. Environmental heat loss is calculated and displayed for information and it is also included in the heating or cooling load calculations. The environmental heat loss is essentially a side calculation which is used to adjust the heating or cooling load to improve the accuracy of thermal modeling.

The number of sugar crystals is assumed to be constant through the unit and the precipitation of sugar is defined by the growth rate of those crystals. The crystal population is described by a mean equivalent diameter and a coefficient of variation. Growth rates are calculated in microns per hour. The change in the coefficient of variation through the process may be calculated as an option and dispersion may also be optionally included in the calculation.

There is an option for grid data display so that data for up to 256 points may be displayed. The actual number of increments allowed is limited to 2000 (this should be many more than is necessary - additional increments only serve to slow computation - somewhere around 30 to 50 segments should be about optimal). If there are more segments used than display points, the display points are evenly spaced.

Input and Output Connections

A number of the inputs and outputs for the sugar crystallizer are optional. You connect the ones that you want to use depending on how you want the unit to operate.

| Label | Required / Optional | Input /Output | Number of Connections | Description | |

| Min | Max | ||||

| Feed | Required | In | 1 | 5 | Massecuite Feed to the Cystallizer. |

| Molasses | Optional | In | 0 | 1 | Additional Molasses stream. |

| DilnWater | Optional | In | 0 | 1 | Dilution Water stream to Crystallizer. |

| CoolingIn | Optional | In | 0 | 1 | Cooling Water into Crystallizer. |

| CoolingOut | Optional | In | 0 | 1 | Cooling Water out of Crystallizer. |

| HeatingIn | Optional | In | 0 | 1 | Heating Water into Crystallizer. |

| HeatingOut | Optional | In | 0 | 1 | Heating Water out of Crystallizer. |

| Product | Required | Out | 1 | 1 | Massecuite stream out of Crystallizer. |

| Vent | Optional | Out | 0 | 1 | Vent outlet containing all Vapours - NB required if there are vapours present. |

Behaviour when Model is OFF

The sugar crystallizer may be turned Off by de-selecting the On tick box in the access window. When the unit is off the following behaviour occurs:

- All input streams (Feed, Molasses and Dilution Water) are perfectly mixed and exit via the product stream. Energy is conserved and product temperature will be adjusted accordingly. NB any gases in any of the input streams will remain with those streams when the unit is off and are not sent to vent.

- There is no heat exchange and cooling and heating water exit at their respective inlet temperatures.

Model Theory

Environmental Heat Exchange Options

The sugar crystallizer may lose heat to the environment. The heat loss options are set from a drop down list and include;

- None - No Heat Exchange occurs.

- Fixed_Loss - A Heat Flow Rate to the Environment is specified by the user.

- Ambient - A Heat Loss Constant is specified and heat loss is calculated as heat loss constant times the temperature difference between the product stream and ambient temperatures, Qloss = Constant * (Tprod - Tamb).

The Heat Flow is displayed for all options and heat flow from the crystallizer to the environment is positive in sign.

NB If a negative heat flow is reported, it indicates heat flow to the crystallizer from the environment.

Physical Model

The crystallizer model follows the flow of massecuite through the crystallizer.

The only required input stream to the crystallizer is the Feed stream. The optional inputs include Molasses Addition, Dilution Water, Cooling Water and Heating Water streams.

The only required output stream is the product stream. However, when there are gases in any of the input streams a Vent stream is also required. The optional output streams are the Cooling Water and Heating Water outlet streams.

Geometry - The Crystallizer is modeled as a series of equal volume segments. For calculations the crystallizer is specified only by its volume and the number of segments it is divided into. The number of segments is user defined. Flow in the crystallizer is assumed to be plug flow and move from one segment to the next with no forward or backward mixing. The residence time in any segment is determined by the volume of the segment and the volumetric flow rate of massecuite (at the exit conditions). There is a Residence Time Efficiency parameter which effectively adjusts the working volume and can be used to account for the effects of by-passing or loss of working volume. The length of the unit may also be entered and a cross sectional area will be calculated from the length and volume and displayed. These data are not used for any calculations, but are displayed for information only. The X-distance is displayed in the grid data.

Shear - The shear rate is entered as a user defined input. The units of shear are per second.

Feed - All feed streams to the crystallizer are assumed to mix perfectly. The feed must be a sugar type stream, must contain some aqueous sucrose and must have some sugar crystal or a warning will be displayed.

Molasses Addition - A molasses stream may be added anywhere along the length of the crystallizer unit. The addition point is specified as percentage of the length or of the progress through the unit (i.e. 50% means molasses is added halfway through). When molasses is added, it is assumed to go into one segment (as defined by the length %) and mix perfectly with the contents of that segment. A molasses stream is not required. The molasses stream is not checked for composition and it may have solids content. The mass flow of molasses is shown in the grid display.

Dilution Addition - Dilution water may be added to the crystallizer. The dilution may be added either as a point addition (all into one segment and mixing perfectly with the contents) or it may be added as a spray across the whole unit. When it is added as a spray, it is assumed that an equal amount of spray is added to each segment and mixed perfectly with it contents. The addition of of dilution is optional and the composition of the dilution is not restricted to pure water (i.e. it could be a dilute molasses stream) and it may also contain solids. NB any solids in either the molasses or dilution streams are accounted for in the crystallizer calculations.

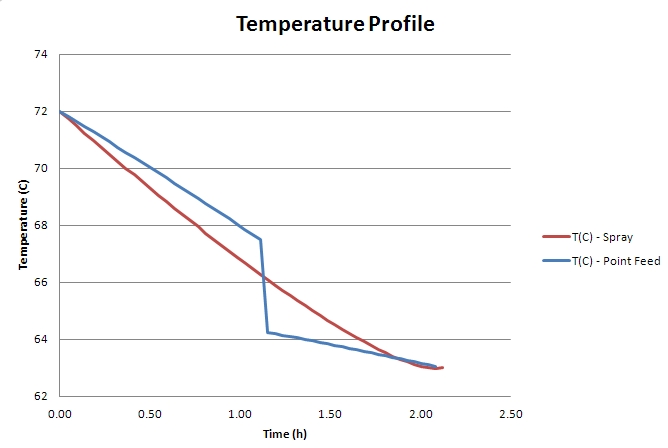

Temperature Profile - The crystallizer may be heated or cooled during operation and may also exchange heat with the environment. There is an option to impose a linear temperature profile through the unit. The product temperature is either set explicitly or set as a difference from the feed temperature. The temperature profile is assumed to change linearly from the inlet to the product. If a side stream comes in and changes the temperature of a segment when it mixes in, then the rate of temperature change is recalculated to give a linear drop from that point to the target temperature. when a spray is used for dilution, the required temperature drop is recalculated at each step. The plot below shows temperature profiles for a crystallizer with the same amount of cold dilution water being added as a spray and as a point source. The start and finish temperatures are the same, but the paths are somewhat different depending on how the water is added.

A fixed temperature profile is used because heat transfer is difficult to calculate explicitly for these very viscous sugar-molasses slurry flows. However, the model does calculate the amount of heat that would be transferred to heating or cooling streams and the environment which allows modeling the impact of the crystallizer on plant energy demands. When heating or cooling streams are connected, the appropriate amount of heat is added or removed from the streams. NB the temperature profile is followed and the heat transfer is calculated even when there are no heating or cooling streams connected (see details below).

Environmental Heat Transfer - Environmental heat transfer is included in the model. It does not enter into the calculation of the temperature profile, but it is included in the heating and cooling load calculations.

Heating and Cooling Water - There are separate connections for cooling water in and out and for heating water in and out. If a cooling or heating stream in is connected, then a cooling or heating stream out must be connected or a warning is issued. The amount of energy absorbed or released to follow the temperature profile is calculated and then adjusted for any environmental heat transfer. If there is a net excess of heat, then this amount of heat is assumed to be removed by cooling water and if a cooling water stream is connected, then this amount of heat will be added to the cooling water so that it leaves hotter. Similarly, if there is a net deficit of heat, then it is assumed to be provided by heating water and if a hot water stream is connected, this amount of heat will be removed from the stream and it will leave colder. A warning is issued when there is insufficient water flow or when the water supply temperature is too hot or too cold for the required application.

Gases - Any gases present in any of the input streams are split off and go to the vent stream. If there is no vent attached, the gases are sent out with the product stream and a warning is displayed that there are gases present, but no vent.

Crystallization Model

The crystallizer volume is divided into a series of equal volume segments. The segments are solved sequentially with any side streams coming in assumed to mix perfectly and the temperature of each segment matching the required temperature profile.

In general the contents of any segment will be supersaturated in sucrose and sucrose precipitation will occur onto the existing crystals. It is assumed that the supersaturation is low enough that there is no homogeneous nucleation and that there is no breakage, thus the number of sugar crystals is conserved. It is further assumed that the growth rate of the crystals is size independent.

The massecuite at any point is characterized by the molasses composition, the temperature, crystal mass fraction, crystal size and CV.

Particle Size Distribution

The particle size distribution of the sugar crystals throughout this process is characterized using a moment description. A normal distribution is assumed so that a volume equivalent size (diameter or U1) and a coefficient of variation (CV) are sufficient to fully describe the distribution. The second and third moments (area is proportional to the second moment and volume proportional to the third moment) may be found from:

[math]\displaystyle{ U1 }[/math]

[math]\displaystyle{ U2 = U1^2 \left(1 + CV^2\right) }[/math]

[math]\displaystyle{ U3 = U1^3 \left(1 + 3 CV^2\right) }[/math]

Particle Growth

The segments are treated as a series non-nucleating crystallizers with size independent growth. When the segment residence time is small, the change in the moments between the inlet and outlet is given by;

- [math]\displaystyle{ \text{Growth, } GRDT=\left(\text{Growth Rate, }GR\right) \times \left(\text{time increment, } \Delta t\right) }[/math]

- [math]\displaystyle{ U1_o=U1_i+GRDT }[/math]

- [math]\displaystyle{ U2_o = U2_i + GRDT \left(2U1_i + P\right) + GRDT^2 }[/math]

- [math]\displaystyle{ U3_o=U3_i + 3GRDT\left(U2_i + P\times U1_i\right) + 3GRDT^2\left(U1_i + P/2\right) + GRDT^3 }[/math]

Where P in the above equations is the dispersion coefficient which accounts for the widening of distributions due to randomness in growth velocities. The dispersion (in units of microns) is calculated based on the impurities in the molasses and growth rate, GR, as;

- [math]\displaystyle{ \text{If } GR\lt 0 \text{, then }P_{}=-100 }[/math]

- [math]\displaystyle{ \text{Else }P=Max\left\{100, \cfrac{10,000}{GR\times exp(0.92\, ItoW)}\right\} }[/math]

Where ItoW is the mass ratio of impurities to water in the syrup. The value of dispersion is limited to a maximum value of 100. The SysCAD crystallizer has a user selectable option to use dispersion or not (in which case P is set to 0).

The relative change in crystal mass (which can be used to calculate the amount of sucrose precipitating out of solution) is given in terms of the third moment by;

- [math]\displaystyle{ \cfrac {Mass_o} {Mass_i}= \left( \cfrac {U3_o} {U3_i} - 1 \right) }[/math]

The CV at the segment outlet after growth can be calculated from the new first and second moments by;

- [math]\displaystyle{ CV=\cfrac{\left(U2_o - U1_o^2\right)^{0.5}}{U1_o} }[/math]

NB The SysCAD crystallizer has an option to allow CV to be held constant or to vary according to the above relation ( a new CV is calculated at based on the new U1 and U2 after growth).

The new syrup composition, crystal mass, CV and U1 are the starting input for the next segment.

There are three options for crystal growth - none, fixed growth rate and the SRI Growth Method.

Particle Growth Models

None

There is no crystal growth and no change in composition except for mixing with any molasses or dilution side streams. The crystal size distribution is unchanged through the unit.

Fixed Growth Rate

The growth rate of crystals is assumed to be a user input fixed rate with this option. Precipitation of sucrose in each segment will occur at the rate required to give the specified time rate of change in diameter regardless of any other parameters (such as supersaturation). Growth will continue until the molasses is depleted (or almost depleted) of sucrose. The crystal size distribution is described by the moment equations.

SRI Growth Model

The SRI model for growth rate uses the moment description and calculates a growth rate as a function of sucrose supersaturation in the molasses, mass transfer and diffusion rates. The SRI method calculates a minimum supersaturation for precipitation to occur. When supersaturation is greater than one and less than this minimum, there is no growth. This method also allows for dissolution of existing crystal when supersaturation is less than one.

The calculated growth rates with this model are strongly dependent on impurities concentrations. Temperature and supersaturation also have a strong influence. This model was developed to apply over a specific range of conditions and predicted growth rates outside of this range can be much larger than expected in reality. The model has an option to limit the maximum growth rate used in calculations. Typical values for crystallizer growth rates are about 2 um/h. The model default maximum value is 10 um/h and the upper limit to which this can be set is 50 um/h.

NOTE: Equations for the Growth model is only available via download from SysCAD Website for users with current maintenance contracts.

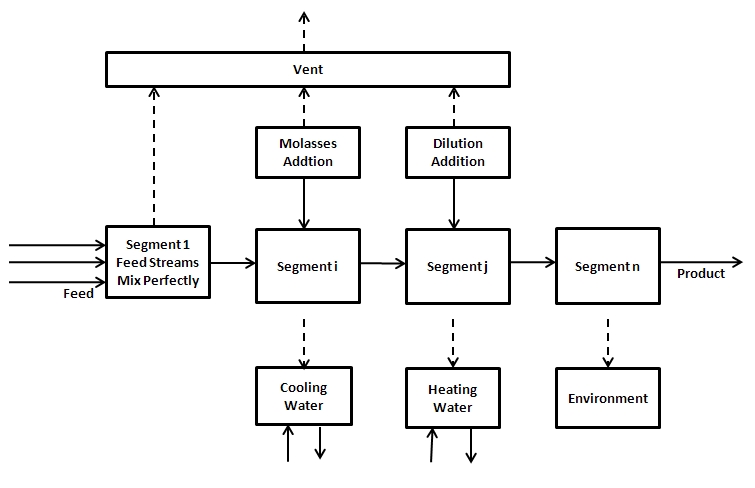

Flow Chart

The process is shown schematically in the flow chart below for a crystallizer with n segments. The segments are numbered 1 to n. Molasses is shown entering at segment i and dilution at segment j, but in the model molasses and dilution may be added in any order and may also go to the same segment. Gases are sent to a vent and any cooling load, heating load or environmental heat loss is a side calculation.

Data Section

Sugar Crystallizer Access Page

Unit Type: SugarCrystalizer - The first tab page in the access window will have this name. Configuration, heat transfer and side stream connection inputs and results are displayed on this page.

Tag / Symbol |

Input / Calc |

Description

|

| Common Data on First Tab Page | ||

Requirements | ||

| On | Tickbox | Tickbox used to turn the unit ON or OFF (off behavior is described above). |

| TrackStatus | Tickbox | Option to display warnings. |

| ShowQFeed | Tickbox | Tickbox to display or hide Feed data tab. |

| ShowQProd | Tickbox | Tickbox to display or hide Product data tab. |

| Dimensions | ||

| VesselLength | Input | Length of Crystallizer (NB information only). |

| VesselVolume | Input | Volume of Crystallizer (NB required for residence time calculations). |

| CrossSectArea | Display | Cross Sectional Area of Crystallizer (NB for information only). |

| AvgShearRate | Input | Average Shear rate from paddles or agitators [1/s]. |

| Segments for Numerical Solution | ||

| Segments | Input | Number of segments to use for solution (maximum = 2000). |

| IncrementLength | Display | Length of each segment. |

| ResidenceTimeEff | Input | Residence Time Efficiency - adjusts effective working volume. |

| IncResidenceTime | Display | Average residence time in each segment. |

| TotResidenceTime | Display | Total Residence time through unit. |

| Environmental Heat Loss | ||

| EnvLossMethod | None | No heat exchange with the environment. |

| FixedLoss | User specified heat loss rate. | |

| Ambient | Heat loss determined as a constant times temperature difference from ambient. Qloss = EnvLossAmbient * (Tprod - Tamb) | |

| EnvLossRqd | Input | The Required Heat Loss Rate - This is only visible if the FixedLoss Method is selected. |

| EnvLossAmbient | Input | The Heat Loss Rate Constant (kW/K) - This is only visible if the Ambient Method is selected. |

| EnvHeatLoss | Display | Heat flow to the environment (positive value is heat flow from crystallizer to Environment.). |

Temperature Profile | ||

| TempProfileMethod | None | Product and all Segment Temperatures equal to Feed Temperature. |

| Fixed_Delta_T | User specified temperature change between feed and product (Tprod - Tfeed). | |

| Set_Product_T | User specified product temperature. | |

| DeltaT_Rqd | Input | The Required temperature change (only visible if the Fixed_Delta_T Method is selected). |

| DeltaTemperature | Display | Temperature change between Feed and Product (Tprod - Tfeed). |

| FeedTemperature | Display | Feed Temperature to Crystallizer. |

| Product_T_Rqd | Input | User specified product temperature (only visible if the Set_Product_T Method is selected). |

| ProductTemperature | Display | Product temperature from crystallizer. |

Heating and Cooling LoadsThese are the calculated loads required to match the specified temperature profile. | ||

| TotalHeatXfer | Display | Total heat transfer from crystallizer. |

| EnvironHeatLoss | Display | Heat loss to environment. |

| CoolingLoadRqd | Display | Required heat load to cooling water. |

| CoolingWaterQm | Display | Cooling water Mass flow in. |

| CoolingWaterTin | Display | Cooling water temperature in. |

| CoolingWaterTout | Display | Cooling water temperature out. |

| HeatingLoadRqd | Display | Required heat load to heating water. |

| HeatingWaterQm | Display | Heating water mass flow. |

| HeatingWaterTin | Display | Heating water temperature in. |

| HeatingWaterTout | Display | Heating water temperature out. |

Molasses Addition | ||

| MolassesAddX | Input | Location for molasses addition input as percent of length through the crystallizer. |

| MolassesAddL | Display | X location of molasses input. |

| MolassesAddi | Display | Segment number of molasses addition. |

| MolassesQm | Display | Mass flow of molasses added. |

| MolassesT | Display | Temperature of molasses added. |

| MolassesBrix | Display | Brix of molasses added. |

| MolassesPurity | Display | Purity of molasses added. |

Dilution Addition | ||

| Spray | Tickbox | When ticked ON Dilution is added as an even spray over the whole length of the crystallizer. |

| DilutionAddX | Input | Location of dilution addition as percent of length through the crystallizer (not displayed when Spray is selected). |

| DilutionAddL | Display | X location of dilution input (not displayed when Spray is selected). |

| DilutionAddi | Display | Segment number of dilution addition (not displayed when Spray is selected). |

| DilutionQm | Display | Mass flow of dilution added. |

| DilutionT | Display | Temperature of dilution added. |

| DilutionBrix | Display | Brix of dilution added. |

| DilutionPurity | Display | Purity of dilution added. |

Crystallization Access Page

The second tab has the name Crystallization and has inputs and results for the crystal growth process.

Tag / Symbol |

Input / Calc |

Description

|

Feed Crystal diameter | ||

| DiaMethod | Stream_DIA | Use diameter from feed stream. |

| User_DIA | User specified diameter. | |

| InputDiameter | Input | User specified crystal diameter of feed (only displayed when User_DIA is selected). |

| StreamDiameterIn | Display | Crystal diameter of feed. |

| StreamDiameterOut | Display | Crystal diameter of Product. |

Feed Size Distribution CV | ||

| CrystalCVin | Input | CV of feed crystal size distribution |

| CrystalCVout | Display | CV of product crystal size distribution |

| AdjustXtalCV | TickBox | Option to adjust CV during crystallization. |

| UseDispersion | TickBox | Option to use dispersion in growth equations. |

Crystal Growth Model | ||

| DiaMethod | None | No crystallization. |

| Fixed_Growth_Rate | User specified fixed precipitation rate. | |

| SRI_Growth | SRI Growth Rate Model. | |

| FxdPrecipRate | Input | User specified crystal growth rate (only displayed when Fixed_Growth_Rate Method is selected). |

| GRM | Input | User specified growth constant for SRI method, default value is 1.09 (only displayed when SRI_Growth Method is selected). |

| MaxGR | Input | User specified maximum growth rate for SRI method, default value is 10 um/h (only displayed when SRI_Growth Method is selected). |

Crystallization | ||

| AvgGrowthRate | Display | Average crystal growth rate through the crystallizer. |

| AvgPrecipRate | Display | Average mass precipitation rate through the crystallizer. |

Feed Massecuite | ||

| FeedQm | Display | Total Feed mass flow rate. |

| FeedCrystalFrac | Display | Feed Crystal mass fraction. |

| FeedMassecuiteVisc | Display | Feed Massecuite viscosity. |

Feed Molasses | ||

| FeedT | Display | Feed Temperature. |

| FeedWs | Display | Feed Molasses sucrose fraction. |

| FeedBrix | Display | Feed Molasses Brix. |

| FeedPurity | Display | Feed Molasses purity. |

| FeedItoWratio | Display | Feed Molasses Impurities to Water mass ratio. |

| FeedMolassesVisc | Display | Feed Molasses viscosity. |

| FeedSSN | Display | Feed Molasses sucrose supersaturation. |

Product Massecuite | ||

| ProdQm | Display | Total Product mass flow rate. |

| ProdCrystalFrac | Display | Product Crystal mass fraction. |

| ProdMassecuiteVisc | Display | Product Massecuite viscosity. |

Product Molasses | ||

| ProdT | Display | Product temperature. |

| ProdWs | Display | Product Molasses sucrose fraction. |

| ProdBrix | Display | Product Molasses Brix. |

| ProdPurity | Display | Product Molasses purity. |

| ProdItoWratio | Display | Product Molasses impurities to water mass ratio. |

| ProdMolassesVisc | Display | Product Molasses viscosity. |

| ProdSSN | Display | Product molasses sucrose supersaturation. |

Vent Mass Flow | ||

| VentQm | Display | Mass flow of Gases to Vent connection. |

Display Segment Data | ||

| ShowSegmentData | TickBox | Option to display a data grid - when ON adds Data tab for grid data display. |

| Segment.Total | Display | Number of segments used for numerical solution. |

| Segment.Display | Input | Number of data points to display - maximum is 256 and must be < (Segment.Total + 1). When display number is less than total. not all data points are displayed. |

Data Access Page

When the tick box ShowSegementData is selected a tab named Data appears and displays a matrix of results for segments through the process. Data is displayed sequentially in columns with feed at the top and product at the bottom. The data are for the exit properties of the segments.

| Column Heading | Data |

| Display | Display name - part of full tag address for the data. |

| Segment | Segment number being displayed in the row. |

| Time | Residence time through to (and including in) the displayed segment. |

| Temperature | Temperature in the segment. |

| MolPurity | Molasses purity in the segment. |

| XtalFrac | Crystal mass fraction of the segment. |

| Diameter | Crystal diameter in the segment. |

| MolVisc | Molasses (liquid only) viscosity in the segment. |

| MassVisc | Massecuite (slurry) viscosity in the segment. |

| MolAdded | Running total mass of molasses added up to and including the segment. |

| DilnAdded | Running total mass of dilution added up to and including the segment. |

| GrwthRate | Crystal growth rate in the segment. |

| SSN | Sucrose supersaturation in the segment. |

| SSlim | Limiting supersaturation for crystal growth in the segment. |

| Brix | Brix of the molasses in the segment. |

| ItoW | Impurities to Water Mass ratio of the molasses in the segment. |

| Distance | Distance from feed inlet to the segment. |

| CV | CV of the crystal in the segment. |

| Dispersion | Dispersion factor used in calculations in the segment. |

Warnings

The model will report errors and warnings for the following conditions.

| Warning Message | Comments |

| Vapour in Feed or Side Streams and NO Vent Connected | When vapours are present in any input stream a vent stream must be connected. |

| No Sucrose(aq) in Feed - Check Stream Compositions | The feed stream must contain some aqueous sucrose. |

| No Crystal in Feed - Check Stream Compositions | The feed stream must contain some solid sugar crystal. |

| Feed is not a Sugar Species model | The feed stream must be a sugar stream. |

| Cooling Water Connection Missing | Cooling water connection with no cooling water connection out. |

| Heating Water Connection Missing | Heating water connection with no heating water connection out. |

| Insufficient Cooling Water Qm for Required Heat Load | Cooling water is too warm or there is insufficient flow to carry away the required heat load. |

| Insufficient Heating Water Qm for Required Heat Load | Heating water is too cool or there is insufficient flow to supply the required heat load. |

| Crystallizer Volume Incorrectly Specified | Volume should be greater than 0.1 cubic meters. |

| Crystallizer Length Incorrectly Specified | Length should be greater than 0.1 meters. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | SugarUnits.dll |

→ | Units/Links | → | Sugar: Sugar Crystallizer | |

| or | Group: | Sugar |

→ | Units/Links | → | Sugar: Sugar Crystallizer |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Sugar | → | Sugar Crystallizer |

See Insert Unit for general information on inserting units.