Sugar Crusher

Navigation: Models ➔ Sugar Models ➔ Sugar Crusher

| Sugar Properties | Sugar Unit Models | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sugar Species Model | Sugar Cane Shredder | Sugar Crusher | Sugar Crystalliser | Sugar Dryer | Sugar Fugal | Sugar Fugal 2 | Sugar Juice Screen | Sugar Mud Filter | Sugar Vacuum Pan |

Latest SysCAD Version: 25 October 2024 - SysCAD 9.3 Build 139.36522

General Description

The sugar crusher unit operation is available with the Sugar add-on.

The sugar crusher receives shredded cane (or bagasse from an upstream mill) and passes it through rolls to squeeze juice out of it. There may be an optional imbibition streams added to help wash out sucrose rich juice. There is a product juice stream, a delivery (or product) bagasse stream and a vent stream exiting the crusher.

All streams entering the crusher are assumed to mix perfectly and then the flow of solids, sucrose and impurities are split between juice, bagasse and vent to meet the specified operating parameters.

Solids are split between the juice and delivery bagasse streams according to the user specified separation efficiency.

Water and various solutes may be split in different relative proportions to the juice and bagasse streams to allow the product streams to have different Brix, overall purity and specific impurities ratios. The splits are calculated to satisfy the user specified Imbibition Coefficient, Ic and when the optional Purity Control is selected a user specified purity ratio. The feed and product streams in sugar crusher would typically use the Sugar Species Model.

The volumetric flow of liquid going to the delivery bagasse stream is determined by the volumetric flow of solids to the bagasse stream and the user specified Filling Ratio, C and Re-absorption Factor, K.

Any vapours in the input streams are sent to the vent stream - a warning is displayed if there are vapours in any of the input streams and there is no vent connected.

The exit pressure of all streams is atmospheric pressure (NB the atmospheric pressure that is specified in the project - see Plant Model - Environment).

The crusher model includes optional heat loss to the environment and there are several different heat loss models available. The crusher also includes the option to specify evaporation rate from it and this is included in the energy balance.

The crusher has the option to use a user specified reference stream. Data from this stream may then be used for doing purity, extraction and volumetric flow calculations relative to the reference stream. Typically the reference stream would be the shredded cane going into the first crusher in a milling train.

Inputs and Outputs

| Label | Required / Optional | Input /Output | Number of Connections | Description | |

| Min | Max | ||||

| FeedBag | Required | In | 1 | 1 | Feed Bagasse to the Crusher - shredded cane or bagasse from a previous mill stage. |

| Imbibition | Optional | In | 0 | 5 | Optional Imbibition Streams. |

| Juice | Required | Out | 1 | 1 | Primarily liquid squeezed from the bagasse - may have some solids content. |

| Bagasse | Required | Out | 1 | 1 | Delivery (or Product) Bagasse - most of the input solids, with some liquid. |

| Vent | Optional | Out | 0 | 1 | Vent outlet containing all Vapours - not required if there are no vapours present. |

NB Aqueous Sucrose must be present in the Feed Bagasse stream or an error will be reported.

Behavior when Model is OFF

The sugar crusher unit may be turned Off by deselecting the On tick box in the access window. When the unit is off it is basically bypassed and the following behavior occurs:

- All material in streams connected to Feed will flow straight through to the product Bagasse stream with no changes or heat exchange.

- All material in streams connected to Imbibition will flow through to the product Juice stream with no changes or heat exchange.

- There will be no heat transfer to the environment.

NB any gases in either feed or imbibition streams will remain with those streams when the unit is off.

Model Theory

The input streams to the crusher are the Feed Bagasse stream which is the shredded sugar cane or bagasse from a previous mill stage and the Imbibition stream which is usually lower Brix juice from a downstream mill stage or water. All of the input and output streams are a mixture of solids and liquids. The solids are primarily plant fiber but may contain mud and other material. The liquids are primarily sucrose-water solutions with some aqueous impurities. NB Brix refers to all solutes in the liquid phase - or basically everything except water.

The model allows for multiple imbibition streams. All the feed and imbibition streams are assumed to mix perfectly in the crusher. The flows of solids, Brix and water must then be split to satisfy the user specified operating parameters.

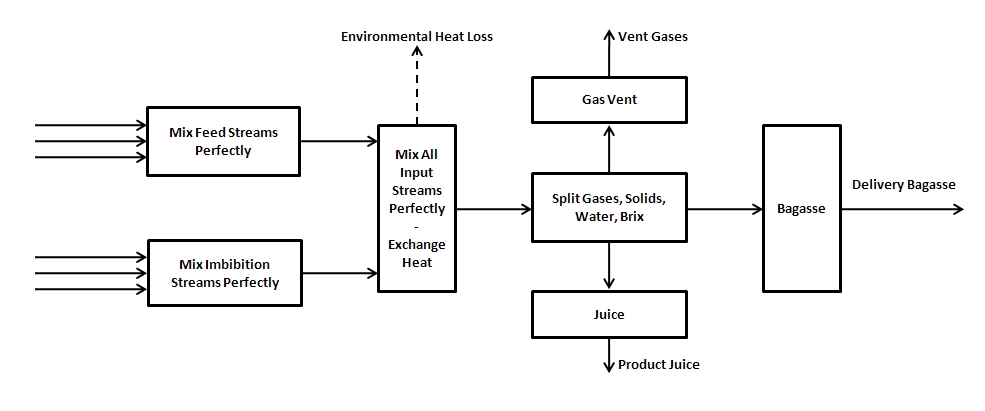

The output streams are Juice which is primarily liquid although may have some solids, Bagasse which is most of the fiber and some liquid and a Vent for gases. These are shown in the flow chart below.

Gases - Any gases present in any of the input streams are split off and go to the vent stream. If there is no vent attached, the gases are sent out with the juice stream and a warning is displayed that there are gases present, but no vent.

Solids - Solids from mixed input stream split according to the user specified Separation Coefficient (which is the mass fraction of solids reporting to bagasse). Generally, most of the solids report to the bagasse stream and any remaining solids report to the juice stream.

Liquids - The overall split of liquid between juice and bagasse streams is calculated to give the required volumetric flow of juice going to the product bagasse stream. This flow is determined by the volumetric flow of solids, the Filling Ratio and the Re-absorption Factor. The required volumetric flow ratio of juice to solids is given by; Vj/Vs = (Re-absorption Factor - Filling Ratio) / Filling Ratio. (NB the mass of liquid going to bagasse depends on the liquid density).

The individual split of water and Brix is based on the Imbibition Coefficient, Ic which is a measure of actual Brix extraction to theoretical Brix extraction. It is possible to have an imbibition coefficient that is greater or less than than one and the Brix of the juice and bagasse streams may be different. When the imbibition coefficient is one the Brix of the juice and bagasse streams are equal, when it is less than one, the bagasse Brix is higher than the juice Brix and when it is greater than one the juice Brix is higher then the bagasse Brix. The SysCAD sugar crusher model splits water and Brix to match the imbibition coefficient with the constraint that the required volume flow to delivery bagasse must be met (and also that various constraints on impurities are met so that the ratio of sucrose to impurities is may also be adjusted between the bagasse and juice streams - see below).

A theoretical Brix is calculated assuming a perfect mixture of all the streams coming in and the imbibition coefficient is the actual Brix mass flow to juice divided by the theoretical Brix mass flow to juice.

- [math]\displaystyle{ \text{Imbibition Coefficient, Ic} = \frac {(\text{Brix into Crusher} \quad - \quad \text{Brix in Delivery Bagasse} \;)}{(\text{Brix into Crusher} \quad- \quad \text{Theoretical Brix in Delivery Bagasse} \;)} }[/math]

Impurities - The impurities include all solutes other than sucrose. The sugar crusher model identifies four specific impurities that normally derived from the analysis of bagasse. These species are managed individually in the crusher model and must be present in the species data base (although their mass flows may be set to zero). The species and the control of them is as follows;

- Reducing Sugars - the ratio of reducing sugars to Pol is assumed to be constant between the feed bagasse and product bagasse.

- Soluble Ash - the ratio of Soluble Ash to Brix is assumed to be constant between the feed bagasse and the product bagasse.

- Soluble Protein - the ratio of Soluble Protein to Brix is assumed to be constant between the feed bagasse and the product bagasse.

- Soluble Other - Soluble Other includes the other soluble species found in sugar cane and not specifically identified as a Reducing Sugar, Ash or Protein. The concentration of Soluble Other may be varied in the model in order to control the sugar purity in the product bagasse stream.

NB there may also be other soluble species in a sugar solution - for example salt, NaCl(aq). Individual species may be specified in the database rather than being lumped with Soluble Other. All solutes are taken into account when calculating the properties of sugar solutions and in the calculation of purity and Brix. However, the split of the solutes for species other than the four listed above will be the same as that for sucrose (e.g. if 40% of the sucrose mass goes to juice, then 40% of the NaCl(aq) mass would go to juice). The Impurities Control option only manages the split of the species Soluble Other.

Temperature - The temperatures of all product streams are assumed to be the same. The product temperature is calculated via energy balance and accounts for any environmental heat loss. Any enthalpy of dilution effects are implicitly included in the energy balance through the sugar properties model.

Solution - The model solves for the split of solids, water, sucrose and impurities between juice, bagasse and vent as well as for temperature. The various splits and temperature are all coupled and are solved iteratively within the model.

Filling Ratio and Filling RatioM - The FillingRatioM relates the volumetric flow of solids into a crusher to the escribed volumetric flow of the crusher. The FillingRatio relates the volumetric flow of solids in the product bagasse stream to the escribed volumetric flow of the crusher.

A single crusher generally has filling ratios defined in terms of the bagasse flows into or out of that particular crusher. For an isolated crusher, the FillingRatioM is the volumetric flow of solids into the crusher divided by the escribed volumetric flow. The Filling Ratio is the volumetric flow of solids in the product bagasse stream (or feed flow in times separation efficiency) divided by the escribed volumetric flow of the crusher. The FillingRatio and FillingRatioM are related by the separation efficiency.

- [math]\displaystyle{ FillingRatioM = \left( \; \frac{\text{Volumetric Solids Flow to Crusher} \; }{\text{Escribed volumetric flow}} \; \right) }[/math]

- [math]\displaystyle{ FillingRatio = \left( \; \frac{\text{Volumetric Solids Flow to Product Bagasse} \quad}{\text{Escribed volumetric flow} \;} \right) }[/math]

- [math]\displaystyle{ FillingRatio = \left( \; FillingRatioM \times \text{Separation Efficiency} \; \right) }[/math]

For a crusher operating in a milling train with two or more crushers, the filling ratio may be defined relative to the flow of bagasse into the first crusher. Thus, for a crusher in a milling train that is referenced to a feed stream, the FillingRatioM is the reference volumetric flow of solids (usually the feed into the first crusher) divided by the escribed volumetric flow of the crusher.

- [math]\displaystyle{ FillingRatioM = \left( \frac{\text{Reference Volumetric Flow of Solids} \quad}{\text{Escribed Volumetric Flow of Crusher} \quad}\right) }[/math]

- [math]\displaystyle{ FillingRatio = \left(\frac{\text{Volumetric Solids Flow to Product Bagasse} \quad}{\text{Escribed volumetric flow} \quad}\right) }[/math]

And the FillingRatio and FillingRatioM are related by the reference and the product bagasse solids volumetric flows.

- [math]\displaystyle{ FillingRatio = \left(\frac{FillingRatioM \times \text{Volumetric Solids Flow to Product Bagasse} \quad} {\text{Reference Volumetric Flow of Solids} \quad}\right) }[/math]

Environmental Heat Exchange Options

The crusher unit may lose heat to the environment. All input streams are assumed to mix and come to thermal equilibrium. All of the output streams are assumed to be at the same temperature.

The heat loss options are set from a drop down list and include;

- None - No Heat Exchange occurs.

- FixedLoss - Heat Flow to the Environment is specified by the user.

- Ambient - A Heat Loss Constant is specified and heat loss is calculated as heat loss constant times the temperature difference between the product stream and ambient temperatures, Qloss = Constant * (Tprod - Tamb).

- Set_Tprod - The product stream is set to a User Specified Temperature

The Heat Flow is displayed for all options and heat flow from the crusher to the environment is positive in sign.

NB If a negative heat flow is reported, it indicates heat flow to the crusher from the environment for example if the product temperature is set higher than the input temperature.

Evaporation Loss Options

There may be significant evaporation from a sugar crusher when hot water is used for inhibition. The crusher unit operation has an option to allow water evaporation. The evaporation loss rate, EvapLossQm, may be entered and this quantity of water will be split of from the mixed feed stream to the unit and turned to vapour. It will flow out through the vent (along with any other vapours that enter the unit). The temperature of the vapour stream will be the same as the product bagasse and juice streams. The latent heat of vaporisation is taken into account in the calculation of the product temperature. An estimate of this energy is displayed when there a non-zero evaporation loss is entered.

Flow Chart

Data Section

Sugar Crusher Access Page

Unit Type: SugarCrusher - The first tab page in the access window will have this name. User inputs and results are displayed on this page.

Tag / Symbol |

Input / Calc |

Description

|

| Common Data on First Tab Page | ||

Requirements | ||

| On | Tickbox | Tickbox used to turn the unit ON or OFF (off behavior is described above). |

| ShowQFeed | Tickbox | Optional display of all input material as one mixed stream (including all feed and imbibition streams). |

| TackStatus | Tickbox | Optional display to display warnings. |

| Environmental Heat Loss | ||

| Method | None | No heat exchange with the environment. |

| FixedLoss | User specified heat loss rate. | |

| Ambient | Heat loss determined as a constant times temperature difference from ambient. Qloss = ThermalLossAmbient * (Tprod - Tamb) | |

| SetTprod | Product temperature is user input. | |

| EnvLossRqd | Input | The Required Environmental Heat Loss Rate - This is only visible if the FixedLoss Method is selected. |

| EnvLossCoeff | Input | The Environmental Heat Loss Rate Coefficient(kW/K) - This is only visible if the Ambient Method is selected. |

| FixedProductT | Input | The Required Product Temperature - This is only visible if the SetTprod Method is selected. |

| EnvHeatLoss | Display | This field displays heat flow to the environment (positive value is heat flow from crusher to environment.). |

| Evaporation Loss | ||

| EvapLossQm | Input | User specified evaporation rate. |

| EvapHeatLoss | Display | Heat loss due to evaporation (latent heat of vaporisation). |

| Use Reference Stream | ||

| On | Tickbox | Tickbox to set the use reference stream option on or off. |

| StreamTag | Input | The name of the stream to use for reference calculations (this would typically be the feed bagasse stream into the first crusher in a milling train). |

| RefQv | Display | Volumetric flow of the reference stream solids flow (for Filling Ratio Calculations). |

| RefPurity | Display | Purity of the reference stream (for purity calculations). |

| RefBrix | Display | Brix mass flow of the reference stream (for extraction calculations). |

Imbibition Efficiency | ||

| ImbibitionCoeff | Input | Imbibition Coefficient, Ic (%). Allowable Input Range is 1% to 200%. |

| FeedBrix | Display | Brix fraction of Cane/Bagasse Feed Stream (includes all feed streams summed into one stream). |

| ImbBrix | Display | Brix fraction of Imbibition Stream (includes all imbibition streams summed into one stream). |

| TheoBrix | Display | Theoretical Massecuite Brix fraction if all input streams are perfectly mixed. |

| JuiceBrix | Display | Actual Juice Massecuite Brix fraction. |

| BagBrix | Display | Actual Delivery Bagasse Massecuite Brix fraction. |

| TheoBagBrixQm | Display | Theoretical Delivery Bagasse Brix Mass Flow. |

| TargetBagBrixQm | Display | Target Delivery Bagasse Brix Mass Flow based on feed flows and input parameters. |

| BagasseBrixQm | Display | Actual Delivery Bagasse Brix Mass Flow. This may be different than the target Brix flow if the model is unable to achieve the flow with the given feed and user inputs. A warning is displayed if any constraints are not met. |

Mill OperationControls liquid flow to product Bagasse stream. | ||

| FillingRatioM | Input | Filling RatioM, Filling Ratio is the total volumetric flow of solids divided by the escribed volume for a single mill referenced to itself. For a mill with another reference stream the FillingRatioM is the |

| FillingRatio | Display | Filling Ratio - solids volumetric flow divided by the escribed volume. For a single mill (referenced to itself), FillingRatio = FillingRatioM |

| ReAbsorptionFac | Input | Re-absorption Factor, K. Allowable Input Range is (FillingRatio + 0.01) to 10.0 (NB re-absorption factor must be larger than the filling ratio). |

| RatioVjVb | Display | Required Volumetric Flow Ratio of Juice to Solids. |

| Escribedvolume | Display | Volumetric Flow - width of rolls times work opening times surface speed of rolls. |

| TotalSolidsQv | Display | Total Volumetric Flow of Solids to the Crusher. |

| BagasseSolQv | Display | Volumetric Flow of Solids to Delivery Bagasse Stream. |

| TheoBagLiqQv | Display | Theoretical Liquid Volume Flow Required. |

| BagasseLiqQv | Display | Actual Liquid Volume Flow to Delivery Bagasse Stream. A warning will be displayed if the model is unable to achieve the required volumetric flow rate. |

SolidsDisplay Solids Concentrations and Mass Flows. | ||

| SepEfficiency | Input | The Required Solids Separation Efficiency. This specifies the mass fraction of total solids input reporting to the delivery bagasse stream. Allowable Input Range is 10% to 100%. |

| JuiceSolids | Display | Mass Percentage Solids Concentration (wt/wt) in product Juice stream. |

| BagasseSolids | Display | Mass Percentage Solids Concentration (wt/wt) in product Bagasse stream. |

| JuiceSolConc25 | Display | Solids Concentration (wt/vol) in product Juice stream. |

| BagasseSolConc25 | Display | Solids Concentration (wt/vol) in product Bagasse stream. |

| SolidsJuiceQm | Display | Solids Mass Flow in product Juice stream. |

| SolidsBagasseQm | Display | Solids Mass Flow in product Bagasse stream. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | SugarUnits.dll |

→ | Units/Links | → | Sugar: Crusher | |

| or | Group: | Sugar |

→ | Units/Links | → | Sugar: Crusher |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Sugar | → | Crusher |

See Insert Unit for general information on inserting units.