Scheduled Events

Navigation: Models ➔ Control 2 Models ➔ Scheduled Events

| Get Tag List | Set Tag List | Noise Controller | Slew Rate Controller | Downtime | Events | Scheduled Events | Profile | Queue Profile | Signal Waveform |

|---|

General Description

This model is used in Dynamic Simulation only. This unit is similar to the Downtime model and the Events model.

The Scheduled Events unit operation can be used to simulate periodic events in a plant model, such as Batch Addition, Reagent dosing, Batch Filtration, etc. The model allows a tag to be set to one of two values depending on whether the unit is active or inactive due to a scheduled event.

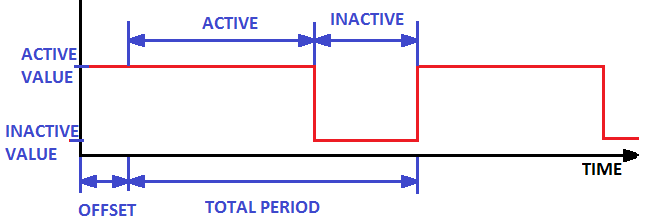

The Required Period of the Scheduled Event includes both the Active and Inactive periods.

The user may configure the unit to set the Output Tag continuously or only once when the scheduled event occurs.

The diagram below shows how the Scheduled Events model sets the value during the Active and Inactive periods and also what happens during the Offset period.

Examples

1. Set the Output Tag once only Use this configuration to set a Batch process such as, trucks off loading ore to a stockpile. The Scheduled events unit can then have the truck capacity as the value to set Once when the Active value is set.

2. Set the output Tag continuously Use this configuration if you require a flow to have a noise component when it is On and then it will be Off during the inactive period.

Diagram

The diagram shows the default drawing of the Scheduled Events unit.

Inputs and Outputs

There are no connections to this unit.

Data Sections

The default sections and variable names are described in detail in the following tables. The default Scheduled Events access window consists of 2 sections. This number may increase or decrease, based on user configuration.

Summary of Data Sections

- ScheduledEvents tab - Contains general information relating to the unit.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

Scheduled Events Page

Unit Type: ScheduledEvents - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Requirements | ||

| On | Tick box | Switch the unit on (ticked) or off (cleared). |

| The following message and field is visible when upgrading the project with existing scheduled event controllers from SysCAD 9.2 (or earlier) to SysCAD 9.3. Change numbering to start from 1 instead of 0. NB this affects Tags. | ||

| ChangeNumbering | Button | Update Numbering to Start from 1 instead of 0. Only visible if the scheduled event controller was added in SysCAD 9.2 or earlier version. NB: this may affect external tag references such as reports, please adjust the external references appropriately if updating the controller numbering. |

| SetTagAlways | Tick box | If not ticked, the model will only set the output tag for first iteration and when the value changes. Therefore if the user or another controller changes the same tag it will not be overwritten by this model until the next event occurs. If ticked the model will set the output tag every iteration. |

| IntegralPeriod | Tick box | This relates to the active period of the unit between scheduled events. If this box is ticked, then SysCAD may adjust the active period entered to suit the stepsize of the project. For example, if the step size is 1 hour, and the period given is not an exact number of hours, then SysCAD will adjust this number to make it an exact number of hours. If this box is left clear, then SysCAD will use the exact number entered. This may lead to some unevenness in the periods but the total amount of active time will be correct over a long period of time. |

| IntegralInactivePeriod | Tick box | This is the same as IntegralPeriod except it relates to the inactive period of the unit due to the scheduled event. If this box is ticked, then SysCAD may adjust the inactive period entered to suit the stepsize of the project. If this box is left clear, then SysCAD will use the exact number entered. This may lead to some unevenness in the periods but the total amount of inactive time will be correct over a long period of time. |

| Count | Input | The number of independent Scheduled Event blocks required. This may be any number from 0 up to 20. The user may also change this number at any time except when the model is running. The unit will always add new Scheduled Event blocks after existing ones, and it will delete them starting from the last block. So, if you have 5 scheduled event blocks set up and you change this to 4, scheduled event block number 5 will be deleted. |

| Total Time | Output | The total time for the Schedule Events has been running. This is usually = the run time of the project. |

| Reset_All | Button | This will reset the results values and restart any offsets. |

| Each independent scheduled event block has the following layout. Additional tab pages will be added as required to fit more scheduled event blocks. | ||

| Summary This shows the summary table with the following values for each individual scheduled event in the unit. | ||

| SE | Display | The scheduled event number |

| On | Tickbox | The user may enable or disable each individual scheduled event on the first page. |

| Active | Display | The current state for each individual scheduled event. |

| Output | Display | The output value for each individual scheduled event. |

| (The user specified scheduled event block name is displayed as the last column) | ||

Individual scheduled event Blocks (SE1, etc.)

Each independent scheduled event block has the following layout. Each block will be on a separate tab page.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| [Scheduled Event Block number] | ||

| Requirements... | ||

| On | Tickbox | The scheduled event is on and the controller will be setting the output tag at the specified period. |

| Name | Input | The user may give the Controller a name that describes the control, such Product_Removal. |

| Description / Desc | Input | Optional scheduled event block description. |

| RequiredPeriod / RqdPeriod | Input | Required Period - The total time period from the start of one scheduled event to the start of the next scheduled event. |

| Offset | Input | The time period before the first scheduled event will occur. The offset can be larger than the Period to effectively allow the output remain active until the scheduled period. The output tag will be set at the start of the offset period. This time is reset if the reset button is pressed. |

| RqdInactivePeriod | Input | Required Inactive Period - The Inactive time period of the scheduled event, i.e. how long the equipment is inactive. This must be less than or equal to the Total Period. If it is equal to the period, the output will always be the inactive value (i.e. it is always inactive). |

| ActiveValueToSet / ActiveVal | Input | The value used for Output. If a TagToSet has a valid tag, then that tag will have this value when the equipment is active (i.e. not stopped) due to the scheduled event. |

| InactiveValueToSet / InactiveVal | Input | The value used for Output. If a TagToSet has a valid tag, then that tag will have this value when the equipment is inactive (i.e. stopped) due to the scheduled event. |

| TagToSet | Input | This input is optional. The tag to be set when the equipment is active or inactive (values as defined above) due to the scheduled event. The current value being set is shown in Output. |

| Results... | ||

| Period | Output | The total time period from the start of one scheduled event to the start of the next scheduled event. This may be different to the number entered if the IntegralPeriod option has been selected. |

| ActivePeriod | Output | This is equal to Period - InactivePeriod. It is the time the equipment is active due to the scheduled event. |

| InactivePeriod | Output | The Inactive time period of the scheduled event, i.e. how long the equipment is inactive. This may be slightly different to the number entered if the IntegralInactivePeriod option has been selected. |

| Active | Output | The current state of the equipment, expressed as a numerical value. This value could be referenced in PGMs for example to perform a series of tasks depending on the state of the equipment. If the equipment is active, then the value is 1. If the equipment is inactive due to the scheduled event then the value is 0. |

| OutputValue / Output | Output | The value that TagToSet is set to (if specified). |

| TtlInactiveTime | Output | The total amount of inactive time due to the scheduled event since the model was last reset. |

| TimeToNextInactivePeriod | Output | The amount of time until the next inactive period due to the scheduled event. |

| NextEvent | Output | The time and date of the next scheduled event. |

| NextEvent.Fmt | Output | The time and date of the next scheduled event in date and time format. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | ControlDyn.dll |

→ | Units/Links | → | Control 2: Scheduled Events | |

| or | Group: | General |

→ | Units/Links | → | Control 2: Scheduled Events |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Control 2 | → | Scheduled Events |

See Insert Unit for general information on inserting units.