Precipitation3: Difference between revisions

Adrian.Paine (talk | contribs) |

Adrian.Paine (talk | contribs) |

||

| Line 129: | Line 129: | ||

===Precipitator3 Tab=== | ===Precipitator3 Tab=== | ||

'''Class: Precipitator3''' | |||

{| border="1" cellpadding="5" cellspacing="0" | {| border="1" cellpadding="5" cellspacing="0" | ||

| '''Tag / Symbol'''||'''Input / Calc'''||'''Description/Calculated Variables / Options''' | | '''Tag / Symbol'''||'''Input / Calc'''||'''Description/Calculated Variables / Options''' | ||

Revision as of 01:34, 1 November 2012

Navigation: Models -> Alumina Models

Related Links: Precipitator3 Model Theory, Alumina3 Precip - Full PSD

General Description

The Precipitator is modelled as a continuous well-mixed tank reactor with Gibbsite precipitation. The model may be configured either as a simple tank with reactions, or it may use a Yield Model to calculate the Gibbsite Precipitation. If the Yield Model is selected, the unit uses Rosenberg-Healy[1] equation to calculate the alumina equilibrium concentration at the tank conditions.

The Precipitator expects the feed to be Bayer Liquor and precipitates Gibbsite, Al[OH]3(s). There is an option to include the precipitation of bound soda either as NaOH*(s) or Na2O(s). With bound soda precipitation it is also possible to have a fraction of the total bound soda precipitate as bound organics, the bound organic should have the same composition as the the organic compound used in the project. An example of the generic organic and bound organic (pair) is: Na2C5O7*(s).

The model calculates yield, residence time, mass of bound soda precipitated with the Alumina, and the change in species concentrations and temperature in the tank. The Precipitator receives up to 10 feed streams and calculates a single product stream. The model can also account for flow bypassing, in which some fraction of the feed remains unmixed (and unreacted) and diverts directly to the product stream.

The model has options to include heat transfer to coolers, evaporation and environmental heat loss. The user may also specify additional reactions using the Reaction Block. Heat of crystallization for Gibbsite precipitation, heats of reaction for any additional reactions and heat transfer with evaporation, environment loss or coolers are all solved simultaneously to calculate outlet stream properties.

It is also possible to bypass some fraction of the input stream directly to the product stream: this simulates a poorly mixed tank.

Notes:

- The Precipitation3 model is designed to operate with an Alumina 3 Bayer Species Model format and will NOT operate with the Generic Bayer Species Model (Alumina1) format.

- The Precipitation Projects, which are distributed with SysCAD in the Examples Folder, demonstrate the use of this model in a SysCAD project.

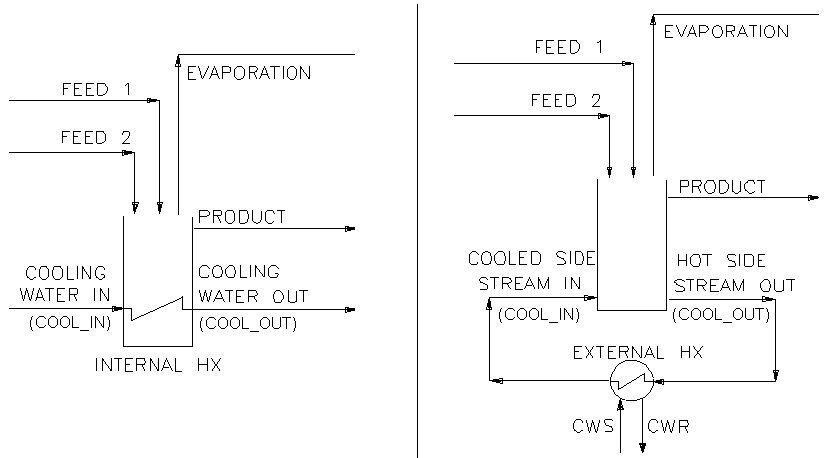

Diagram

The diagram shows the default drawing of the Precipitator, with the required and optional connecting streams.

Cooler Options

User can select from the following 3 options:

- None - no cooling is applied.

- Embedded - Embedded or Internal cooling models the use of draft tube coolers or external heat exchangers, where cooling water is used to directly cool the contents of the tank. For internal cooling, at least one Cool_in and one Cool_out streams must be connected for cooling water supply and return.

- This option also includes the case where there is an external heat exchanger (such as a cooler mounted outside the tank) but considers this integral (embedded) in the model, so that the cooling calculations are done in parallel with the precipitation calculations. In this case the liquid flow to the heat exchanger needs to be specified.

- The advantage of Embedded cooling is that the heat transfer calculations are done as part of the evaluation of the precipitator unit model, so there is a gain in efficiency.

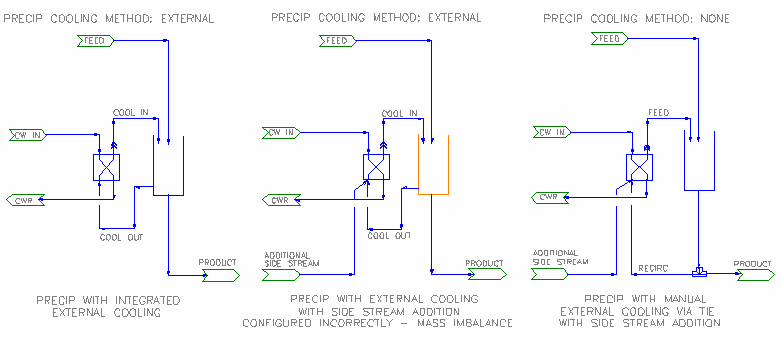

- External - External cooling models the use of external heat exchangers taking a sidestream of the tank contents and cooling this sidestream. User connects a side stream (Cool_out IO) from the Precipitator to an external heat exchanger, where this side stream is cooled then returned to the Precipitator via the Cool_in IO.

NOTES:

- The difference between the two cooling methods:

- With embedded cooling, an external coolant stream (usually water) is connected to and from the unit model.

- With external cooling, the stream takes liquor from, and returns it after cooling to the unit model.

- With both internal and external cooling the cooling connections must be connected to streams. The unit will not solve unless they are present. If a simplified cooling model is required, just use direct thermal loss via ThermalLossMethod

- The external cooling method determines the cooling load based on the outgoing and incoming temperature difference of the cooling stream. It then uses this cooling load to determine the thermal balance. The actual stream flow is ignored, i.e. it does not mix it with the tank contents.

- External cooling allows you to use a separate specific exchanger model in the simple case of a single stream being returned directly to the tank so that you can get reporting information from the exchanger.

- If the recycle stream must be changed, say by mixing with cool liquor from another source, then you should take a side stream from a splitter on the outlet stream, cool this, then return this to the tank inlet along with any added liquid.

Thermal Modelling

There are a number of options related to thermal energy balance. Normally, the unit model will calculate HOR, cooler losses and so on, then apply a correction to the tank temperature based on these determinations. However in some circumstances it may be desirable to simply specify the final tank temperature directly, either as a temperature drop from the liquor inlet temperature, or even as a fixed final temperature. These cases may be physically unrealistic and should be used with care, however the ability to override the internal thermal calculations is there.

Thermal Override

If Thermal Override is selected, then other thermal calculations have no effect. Cooler calculations are still performed, so that the performance of the coolers is still available, but they do not affect the actual final temperature.

Thermal Loss Method

An additional thermal loss (or gain) may be specified by this selection, which is only available if Thermal Override is disabled. It is applied in addition to any cooler or reaction heats. Either a fixed temperature drop, fixed thermal loss, or ambient loss may be specified. A fixed thermal loss can be used to model internal or external cooling in a simplified fashion.

Ambient Interactions

The unit also allows thermal and mass loss to the environment. Thermal losses are due to convective cooling on the tank and free surface. There can also be mass losses due to evaporation at the free surface for an open tank; this mass loss is accompanied by a thermal loss due to evaporative latent heat.

There is a simple ambient loss model and a more detailed model which accounts for wind speed effects. The more detailed model calculates a heat or evaporation loss per unit area, so the actual tank geometry is needed.

If evaporation loss is implemented a stream may optionally be connected to accumulate the lost vapor.

Bypassing

If a precipitator is poorly mixed, then some of the input stream may never enter the tank and simply bypass directly to the outlet. This typically occurs when row tanks are connected by launder weirs which are simply open overflow channels running from one tank to the next. The model allows for bypassing by specifying a fraction of the incoming flow to pass directly to the outlet.

Evaporation

Losses of water due to evaporation can be important and these also lead to significant overall thermal losses because of the latent heat of evaporation. Evaporation may be specified as:

- Fixed - constant mass rate or

- Ambient - proportional to ambient temperature difference.

Using the constant mass rate, it is possible to implement a function in PGM to calculate evaporation. For an example of a user defined Evaporation Correlation, please see Example Evaporation Correlation.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max. | ||||

| Feed | 1 Required | In | 1 | 10 | Precipitator Feed stream(s). |

| Product | Required | Out | 1 | 1 | The product stream from the Precipitator. |

| Cool In | Optional | In | 0 | 5 | Optional Cooling Water input(s) to the Precipitator cooler / Cooled side stream return to Precipitator. |

| Cool Out | Optional | Out | 0 | 1 | Optional Cooling water return from the Precipitator cooler / Hot side stream drawn from Precipitator . |

| Evap | Optional | Out | 0 | 1 | Optional Evaporation outlet. |

Model Theory

This has been moved to a separate section on its own:

See also Alumina3 Precip - Full PSD for notes on the new PSD option (included in SysCAD 9.2 Build 133 or later).

Data Sections

The default access window consists of several sections:

- Precipitator3 - allows the user to switch on optional sub models, such as cooling, additional reactions, evaporation or heat loss. It also contains a summary table for the precipitator.

- Results - This tab contains the results fields for the Precipitator 3.

- Precip - allows the user to select and enter parameters for the growth method. It also contains a table for Thermal and Mass Balance.

- Cooler - This tab is optional and is only visible if a cooling method is selected (from Precipiator3 Tab). This section allows the user to specify cooling options.

- PSD - This tab is optional and is only visible if Precip method is set to FULL PSD (from Precip Tab). This section allows the user to select the Particle Size Distribution related correlations.

- RB - Optional tab, only visible if the Reactions are enabled.

- QFeed - Optional tab, only visible if ShowQFeed is enabled. This page shows the properties of the mixed stream as the feed to the Precipitator.

- This is before any Evaluation Block models are evaluated.

- QProd - This page shows the properties of the Precipitator discharge as a single stream.

- QEvap - This page if only visible if Evaporation is enabled (from Precipitator3 Tab)

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, only visible in SysCAD 9.2, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Precipitator3 Tab

Class: Precipitator3

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options |

| Common First Data Section | ||

| Requirements | ||

| On | Tick Box | This can be used to take a precipitator off line. When a precipitator is not ON, the input stream will act as though it has bypassed the precipitator, thus no change will occur in this unit. This option is useful for feasibility studies of flowsheet configuration. |

| Cooling | None | No cooling required. |

| Embedded | Uses embedded cooler for cooling. User do not need to add the cooler unit. A Cooler tab becomes visible and can be configured. See Cooler Options for more information. | |

| External | Uses external cooler for cooling. User will need to add the cooler unit separately. A Cooler tab becomes visible and can be configured. See Cooler Options for more information. | |

| Reactions | Off | No extra reactions |

| On | This allows the user to add extra reactions to the model. Note that THA precipitation and Soda co-precipitation are built-in reactions, user do not need to specify these. When this option is on, RB becomes visible and may be configured. | |

| Bypass | Tick box | Allows bypassing of feed directly to outlet. |

| BypassFraction | Input | How much of the feed to bypass, visible if Bypass is on. |

| ThermalOverride | None | Don't override. |

| TempDrop | Overall heat loss based on Temperature Drop. Note that calculated HOR and cooling effects are ignored as this temperature drop is applied as an overall override. | |

| ProductT | Specify the product temperature. | |

| Temp_Drop | Input | The overall temperature drop required, visible with the TempDrop ThermalOverride Method. |

| ProductTRqd | Input | The overall exit temperature required, visible with the ProductT ThermalOverride Method. |

| ThermalLossMethod | None | No additional heat loss to the environment or thermal balance overrides. |

| TempDrop | Additional heat loss based on Temperature Drop. In this case the temperature drop is applied on top of HOR and cooling effects. | |

| FixedLoss | Additional heat loss is expressed as a fixed amount of energy. | |

| Ambient | Additional heat loss is expressed as Energy/degree of temperature difference to ambient. | |

| WindAmbient | More detailed ambient model accounting for wind speed. | |

| TempDrop | Input | The temperature drop required (for energy loss not necessarily the overall tank temperature drop), visible with the TempDrop Method. |

| ThermalLossRqd | Input | The amount of energy to be lost to the environment, visible with the FixedLoss method. |

| ThermalLossAmbient | Input | The amount of energy per degree to be lost to the environment, visible with the Ambient method. |

| WindLossRateK | Input | Rate, visible if WindAmbient option for thermal loss is selected. |

| TankSurfaceArea | Input | Tank external surface area including both top and side, visible if WindAmbient option for thermal loss is selected. |

| Evaporation | None | No evaporation loss to the environment. |

| Fixed | Fixed evaporation rate. Suggested values are in the range 0.25 to 1.0 t/h. | |

| Ambient | Fixed evaporation rate per degree of temperature. Suggested values are in the range of 0.005 to 0.025 t/h.K. | |

| Evap.Rate | Input | The evaporation rate required, visible with the Fixed Method. |

| Evap.Per.degK | Input | The evaporation rate required per degree of temperature, visible with the Ambient method, or overall constant for detailed model. |

| UseLastConverged | Tick Box | If selected, will restart solution iteration at last converged state. If the solution is nearly converged, this will speed up the iteration. If the solution was converged, and nothing else is changed it should immediately converge. |

| TankVol | Input | The precipitation tank volume, used to work out the residence Time. |

| OperatingP... (available in SysCAD 9.2 or later) | ||

| Method | List | Atmospheric -- outlet streams will be at Atmospheric Pressure. The atmospheric pressure is calculated by SysCAD based on the user defined elevation (default elevation is at sea level = 101.325 kPa). The elevation can be changed on the Species tab page of the Plant Model. |

| AutoDetect -- This option is only available in SysCAD 9.2 Build 133 or later. If there are any liquids AND no vapours present in the feed, outlet streams will take the highest pressure of the feeds. Else (eg. some vapours present) outlet streams will take the lowest pressure of the feeds. | ||

| LowestFeed -- outlet streams will take the lowest pressure of the feeds. | ||

| HighestFeed -- outlet streams will take the highest pressure of the feeds. | ||

| RequiredP -- outlet streams will be at the user specified pressure. | ||

| IgnoreLowQm | Tick Box | This option is only visible if the AutoDetect, LowestFeed or HighestFeed methods are chosen. When calculating the outlet pressure and temperature of the tank, SysCAD will ignore the low flow feed streams should this option be selected. The low flow limit is set in the field below. |

| LowQmFrac | Input | This field is only visible if the IgnoreLowQm option is selected. This is the amount any stream contributes to the total flow. For example, if the total feed to the tank is 10 kg/s, and this field is set to 1%. Then any feed streams with less than 0.1 kg/s will be ignored in the pressure calculations. |

| Reqd | Input | This field is only visible if the RequiredP method is chosen. This is user specified pressure. |

| Result | Calc | The actual pressure used for the sum of the feeds which will also be the outlet pressure (unless further model options change the pressure). |

| ShowQFeed | Tick box | Switches on the QFeed tab pages to display the total feed stream properties into the Precipitator. This is useful if more than one Feed streams are connected to the precipitator. See Material Flow Section. |

| ShowQTank | Tick box | Visible if Bypass is on. Switches on the QTank tab pages to display the tank contents exit stream properties before adding the bypass to give the exit stream (QProd). See Material Flow Section. |

| ShowQProd | Tick box | Switches on the QProd tab pages to display the product stream properties from the Precipitator. See Material Flow Section. |

| ShowQTubeIn | Tick box | Visible if internal cooling. Switches on the QTubeIn tab pages to display cooling tubes inlet stream properties. See Material Flow Section. |

| ShowQTubeOut | Tick box | Visible if internal cooling. Switches on the QTubeOut tab pages to display cooling tubes outlet stream properties. See Material Flow Section. |

Results

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options |

| Residence Time | Calc | The calculated residence time of the slurry in the unit. |

| SuperSat | Calc | The Supersaturation = Product A/C divided by Equilibrium A/C = (A/C) / (ASat@ProdcutT / C@25). |

| Yield in grams Al2O3 per liter liquor @ 25C | ||

| Yield | Calc | The calculated Yield = Gibbsite precipitated as equivalent Alumina per unit volume of feed liqour at 25°C. |

| THA.Precip | Calc | The mass of Trihydrate Alumina Al[OH]3 precipitated in the unit. |

| Solids.Precip | Calc | The mass of solids precipitated in the unit, includes THA and bound soda. |

| Solids.Conc | Calc | The solids concentration in the unit referenced to 25°C. |

| Results | ||

| MassFlowIn | Calc | The mass flowrate at the inlet conditions. |

| MassFlowOut | Calc | The mass flowrate at the outlet conditions. |

| VolFlowIn | Calc | The volumetric flowrate at the inlet conditions. |

| VolFlowOut | Calc | The volumetric flowrate at the outlet conditions. |

| TempIn | Calc | The inlet temperature. |

| TempOut | Calc | The outlet Temperature. |

| ACin | Calc | The A/C ratio at the inlet conditions. |

| ACout | Calc | The A/C ratio at the outlet conditions. |

| ACequil | Calc | The Asat/C ratio at the outlet conditions. |

| BoundSodaFrac | Calc | The bound soda precipitation rate as Na2O / THA precipitation rate as Al2O3. |

| BoundSodaPrecip | Calc | If NaOH*(s) is present in the project, this will show the soda precipitation rate less organic portion as NaOH*(s), otherwise Na2O will be used as the bound soda species. Displays which species represents Bound Soda. |

| BoundOrganicsPrecip | Calc | The soda precipitation rate - organic portion as the bound organic species. For Example Na2C5O7*(s). |

Precip Tab

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options |

| Precip.Method | User SSA | User specified seed surface area for the growth calculations. |

| Stream SSA | Uses the specified seed surface area estimated from the input stream conditions. NOTE: The feed stream should not have PSD present when selecting this method. | |

| Full PSD | This method is only available in SysCAD 9.2 Build 133 or later. Use the Full Particle Size Distribution (PSD). Refer to Alumina3 Precip - Full PSD for more information. | |

| Hydrate Precipitation | ||

| GrowthMethod | Fixed | User specifies a fixed alumina precipitation rate (as a mass flow rate). |

| FixedRate | The alumina precipitation rate is calculated from a fixed user specified growth rate. | |

| White-Bateman | The alumina precipitation rate is calculated using the White Bateman correlations [2]. See Growth Rate Theory for information. | |

| Veesler-Boistelle | The alumina precipitation rate is calculated using the Veesler Boistelle correlations [7]. See Growth Rate Theory for information. | |

| SSA Yield | The alumina precipitation rate is calculated taking into account factors of free caustic, total organic carbon, soda concentration and SSA. See Growth Rate Theory for information. | |

| BoundSodaMethod (Not visible with the Fixed GrowthMethod) |

Original | Original implementation of Ohkawa, Tsuneizumi and Hirao [5] correlation. This implementation is retained for backward compatibility of tuned models, the Ohkawa method below should be used. |

| Ohkawa | Ohkawa, Tsuneizumi and Hirao [5] method with corrections for bound soda as Na2O and NaOH* - now the default method. See Bound Soda Theory for information. | |

| Hunter | Armstrong, Hunter, McCormick and Warren. [6] correlation, see Bound Soda Theory for information. | |

| Fixed % | Calculates a fixed percentage of soda co-precipitation with the precipitated hydrate. | |

| Convergence.Limit | Input | Global tolerance for testing convergence for iterative calculation in all precipitator tanks. Default is 1.0e-8. |

| Iterations | Calc | Number of iterations solved. |

| Thermal.Damping | Input | Damping for energy convergence. Default of 0. |

| Mass.Damping | Input | Damping for mass convergence. Default of 0. This value may need to be increased, often significantly 80% plus, for a precip tank with a significant change. Try increasing this when failed to converge error message is shown. |

| Vol.Damping | Input | Damping for volume flow convergence when using external cooling. Default of 0. |

| UserHOR | tick box | Option for User to enter Heat of Reaction for Gibbsite Precipitation reaction (kJ/kg-Gibbsite). The default value is -252.3 kJ/kg-Gibbsite at 0°C. NB this is an exothermic reaction and energy is released as Gibbsite precipitates. For reference, please refer to Heat of Dissolution of Gibbsite and Boehmite |

| User.GibbsiteHOR@0C | Input | The Gibbsite precipitation HOR value to be used. Only available when UserHOR is selected. NB a positive entry generates a warning message as the HOR shold be negative. For reference, please refer to Heat of Dissolution of Gibbsite and Boehmite |

| GibbsiteHOR@0C | Calc | The Gibbsite precipitation HOR value used. -252.3 kJ/kg-Gibbsite at 0°C if UserHOR is not selected. For reference, please refer to Heat of Dissolution of Gibbsite and Boehmite |

| AdjustProdSSA | tick box | Adjust product stream SSA to account for particle growth (using spherical model). If unchecked, the product SSA will be the same as the feed SSA (when Precip.Method is StreamSSA) or the user specified SSA (when Precip.Method is UserSSA). Not visible when Precip.Method is FullPSD. |

| SSA | Input | The seed surface area specified directly by the user. Any SSA value, if present, in the feed stream is ignored. Only, visible when Precip.Method is SSAUser. |

| SSAin | Calc | The current SSA value from feed stream. |

| SSAused | Calc | The SSA value used in the calculations as per the above inputs. |

| THA.Density | Calc | The THA species solids density (used in GrowthRate calculation). |

| Variables for the Fixed GrowthMethod | ||

| Precip.Rate | Input | The user specified precipitation rate. |

| Variables for the FixedRate GrowthMethod | ||

| FixedGrowthRate | Input | The user specified growth rate. |

| Variables for the White-Bateman GrowthMethod | ||

| ER_White | Input | The Activation Energy (E) divided by the Gas Constant (R). |

| K_White | Input | The Constant used in the Growth Rate Factor correlation. |

| gF_White | Input | This allows the user to tune the growth rate based on a factor. |

| Variables for the Veesler-Boistelle GrowthMethod | ||

| ER_VB | Input | The Activation Energy (E) divided by the Gas Constant (R). |

| K_VB | Input | Overall growth rate constant. |

| Beta.Critical | Input | Critical supersaturation (nominally 1), must be exceeded for growth to occur |

| N_VB | Input | Exponent g for relative supersaturation term [math]\displaystyle{ (\beta-\beta_c)^g }[/math] |

| Variables for the SSA Yield GrowthMethod | ||

| ActivationEnergy/R | Input | The Activation Energy (E) divided by the Gas Constant (R). |

| K0 | Input | The Constant used in the Growth Rate Factor correlation. Default value for K_0 is 2.2*1011. This value is typically tuned for plant conditions. It may need adjustment as additional terms described below are adjusted. |

| n_TOC | Input | Organics term = [math]\displaystyle{ e^{-n_{TOC} \times TOC} }[/math]. Using zero for n_TOC will remove TOC dependence. |

| n_s | Input | Total Soda effect = Sn_s. Using zero for n_s will remove the precipitation dependence on soda. |

| n_fc | Input | Free Caustic – Free caustic is the sodium hydroxide in solution that is not associated with dissolved alumina. KFreeCaustic = FCn_fc.Using zero for n_fc will remove the precipitation dependence on free caustic. |

| n_C | Input | Additional Caustic effect term Cn_C. The default value is zero. |

| n_AC | Input | This is the n factor for the supersaturation driving force term. [math]\displaystyle{ \left( \frac{A_{out} - A^*}{C} \right)^n }[/math]. The default value is 2. |

| n_ssa | Input | Specific Surface Area, SSA. This correction accounts for the fact that the effective surface area for precipitation may not scale linearly with SSA. Kssa = SSAnssa. The default value for nssa is 1.0 (making precipitation rates linearly proportional to SSA). |

| GrowthMethod Results | ||

| kG | Calc | kG constant for the GrowthMethod |

| GrowthRateFactor | Calc | Product of kG and [math]\displaystyle{ e^{-E/RT} }[/math] |

| GrowthRate | Calc | GrowthRate G |

| Bound Soda Calculations | ||

| K_tuneBS | Input | The tuning factor for the bound soda calculation. |

| K1 | Input | The soda factor. The default value is 1.27*10-3. |

| E_SODA | Input | Constant used in the bound soda calculation, default is 2535 K-1 |

| BoundSodaFrac | Input | The user specified bound soda fraction. |

| Bound Soda Fraction as Organics | ||

| BoundSodaSpecies | Text | Display the bound soda species used for occlusion. If NaOH* is present, it will be used, if not, the project will use Na2O. If neither is present, the project will force add Na2O(s) to the species list. |

| BoundSoda_OrgPart | Input | The percentage of bound soda precipitated as organics. If the bound organic species is not present in the project, a warning message: Organics precipitation and BoundSoda_OrgPart not available:Matching bound organic solid for Na2C5O7(aq) not found will be given. The bound soda precipitated will not include any bound organic. |

| Thermal and Mass Balance | ||

| Mass.Flow.In | Calc | The mass flow in to the precipitator |

| Mass.Flow.Out | Calc | The mass flow out of the precipitator |

| Evap.Mass.Loss | Calc | The evaporation mass rate |

| Evap.Thermal.Loss | Calc | The amount of energy lost through evaporation. |

| Env.Thermal.Loss | Calc | The amount of energy lost to the environment. |

| Cooler.Thermal.Loss | Calc | The amount of energy transferred through the cooler. |

| Total.Thermal.Loss | Calc | The sum of all thermal losses. |

| ReactionHeat@0 | Calc | The amount of energy released by the precipitation reaction at the 0dC temperature. |

| ReactionHeat(@T) | Calc | The amount of energy released by the precipitation reaction at the product temperature. |

| Total.Thermal.Loss | Calc | Total amount of energy loss: Evap + Env + Cooler. |

| Stream Enthalpy | ||

| HzIn | Calc | Enthalpy flux into Precipitator. |

| HzEvap | Calc | Enthalpy flux to Evaporation. |

| HzOut | Calc | Enthalpy flux out of Precipitator. |

| HzBal | Calc | Enthalpy out minus enthalpy in. This is the net of heat transfer, evaporation loss and reaction heat (NB Rxn heat measured at 0°C reference temperature). |

| FeedHf | Calc | The total energy of the feed. |

| ProdHf | Calc | The total energy of the product. |

| EvapHf | Calc | The total energy of the material evaporated from the precipatator, if evaporation is used. |

Cooler Tab

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options |

|

FOR EMBEDDED COOLING OPTION | ||

| Cooler.On | tick box | Switches the cooler on/off |

| Cooling.Type | Fixed.dQ | User specifies the energy change required. |

| Fixed.dT | User specifies the temperature change required. | |

| HeatExchange | User specifies the HTC, Area and flow for heat exchange. | |

| Variables for the Fixed.dQ method | ||

| dQ | Input | The user specified change of energy. |

| Variables for the Fixed.dT method | ||

| dT | Input | The user specified change of temperature. |

| Variables for the HeatExchange method | ||

| HX.Area | Input | The user specified heat transfer area. |

| HX.HTC | Input | The user specified heat transfer coefficient. |

| By.Vol.Flow | tick box | Slurry to "cooler" can be specified in mass or volumetric flows |

| Heat Exchanger | ||

| Cooling.Flow | Input / Calc | The slurry mass flow to be cooled by the "cooler". |

| Int.Vol.Flow | Input / Calc | The slurry volumetric flow to be cooled by the "cooler". |

| Hx.UA | Calc | heat exchanger UA. |

| Hx.LMTD | Calc | heat exchanger log mean temperature difference. |

| Coolant | ||

| Water.Flow | Calc | Displays the CW mass flow into the "cooler" via the Cool_in connection. |

| Water.Vol.Flow | Calc | Displays the CW volumetric flow into the "cooler" via the Cool_in connection. |

| Water.Tin | Calc | Displays the CW temperature into the "cooler" via the Cool_in connection. |

| Water.Tout | Calc | Displays the CW temperature out of the "cooler" via the Cool_out connection. |

| Liquor.Tin | Calc | The slurry temperature into the "cooler". |

| Liquor.Tout | Calc | The slurry temperature out of the "cooler". |

| Cooling.Rate | Calc | The rate of cooling. |

|

FOR EXTERNAL COOLING OPTION | ||

| By.Vol.Flow | tick box | Slurry to "cooler" can be specified in mass or volumetric flows |

| Ext.Vol.Flow | Input / Calc | Input or displays the volumetric flow into the external cooler via the Cool_in connection, depends on the By.Vol.Flow option. |

| Ext.Cooling.Flow | Input / Calc | Input or displays the mass flow into the external cooler via the Cool_in connection, depends on the By.Vol.Flow option. |

| Ext.Cooling.Temp | Calc | The temperature of the "cooled" side stream returning to the precipitator. |

| Ext.Cooling.TotHzOut | Calc | The total energy of the side stream leaving the precipitator. |

| Ext.Cooling.TotHzIn | Calc | The total energy of the side stream returning to the precipitator. |

| Cooling.Rate | Calc | The rate of cooling. |

PSD Tab

| Tag / Symbol | Input / Calc | Description/Calculated Variables / Options |

|

Only visible when Precip.Method = FULL PSD. Please See Precipitation using Full PSD for more information on theory and method. | ||

| Growth.On | Tick Box | Selecting this will enable growth rate calculation. Please see Growth Rate Methods |

| Agglom.On | Tick Box | Selecting this will enable agglomeration calculation. Please see Agglomeration and Implementation of a size dependent kernel |

| Necleation.On | Tick Box | Selecting this will enable nucleation rate calculation. [math]\displaystyle{ N = 5.0\times 10^8 \left(\frac{A-A^*}C\right)^2\sigma }[/math] Please see Nucleation |

| SeedPSD | Tick Box | Selecting this will allow SysCAD to auto generate a small quantity of seed if NO THA solid was found in the Precipitation Feed. The generated amount will be sufficient to seed a tank and allow precipitation to occur in the tank. When solids returns to the tank via the proper seed streams, the recycled solids will take over and SysCAD will no longer generate any extra solids. |

| ShowRates | Tick Box | Selecting this will enable the display of Particle Size Number Data Table on the PSD tab. Please see Show Rates |

| TrackUltrafines | Tick Box | Warn if mass is present in smallest size bin - this is moved to next bin up. |

| DisplayAsFraction | Tick Box | When this option is ticked, the rates (Growth, Agglo etc) are normalized by dividing by the particle numbers: that is, displayed as a fraction of the particle number. |

| Agglomeration Parameters | ||

| Agglom.Kernel.Type | Size Independent | Ilievski size independent kernel (Light Metals, 1982). This assumes that all interactions are equally likely to cause an agglomeration event, and the rate is governed by a single equation depending on temperature and liquor properties |

| Ilievski | The kernel is of the form: [math]\displaystyle{ \beta_{ij} = \frac G{\beta_4 S_{ij}} }[/math]. See Size Dependent Kernel for more information. | |

| Agglomeration.Type | Restricted-in-Space | This option assumes a particle can only interact with particles in its immediate vicinity, restricting the number of possible collisions. See Free-in-space vs Restricted-in-space agglomeration forms |

| Free-in-Space | This option assumes the agglomeration rate is proportional to the total number of possible collisions between particles, any particle is free to collide with any other particle. See Free-in-space vs Restricted-in-space agglomeration forms | |

| Agglom.Cutoff | Tick Box | If selected, then particles greater than Agglom.Cutoff.Size will not agglomerate. |

| Agglom.Cutoff.Size | Input | Maximum size for agglomerating particles. Only visible when Agglom.Cutoff is selected. |

| Raw.Kernel | Tick Box | Agglom rate determined solely from numbers and Agglom.Rate.Correction - the user can implement custom calculations to the Agglom.Rate.Correction field. |

| Ilievski.Agg.Rate | Input | G in the Agglomeration Kernel equation. See Size Dependent Kernel |

| Calc.Beta4 | Tick Box | Calculate or user supplied [math]\displaystyle{ \beta_4 }[/math] in the Agglomeration Kernel equation. |

| User.Beta_4 | Input | User specified [math]\displaystyle{ \beta_4 }[/math] for use in the Agglomeration Kernel equation. Only visible when Calc.Beta4 is not selected. |

| Beta_4 | Result | [math]\displaystyle{ \beta_4 }[/math] in the Agglomeration Kernel equation. See Size Dependent Kernel |

| Agglom.Rate.Correction | Input | Overall correction rate for Agglomeration calculations |

| Nucleation Parameters | ||

| Misra.Nucleation.Rate | Input | Nucleation Rate term. See Nucleation |

| Nucl.Rate.Correction | Input | Correction for Nucleation calculations |

| Results | ||

| Growth | Calc | Net rate of increase in particle numbers due to growth. |

| Agglom.Rate | Calc | Net rate of increase in particle numbers due to agglomeration. |

| Nucl.Rate | Calc | Net rate of increase in particle numbers due to nucleation. |

| GrowthYield | Calc | The Growth Yield. Total new mass of THA in tank due to Growth. |

| NuclYield | Calc | The Nucleation Yield. Total new mass of THA in tank due to Nucleation. |

| NumMassIn | Calc | Mass of PSD Solids into the Precipitation Tank (Excludes Non-PSD solids). |

| NumMassOut | Calc | Mass of PSD Solids leaving the Precipitation Tank. |

| Results (Particle Numbers) | ||

| NumbersByMassIn | Calc | Number of particles per mass of slurry entering the Precipitation tank. |

| NumbersByMassOut | Calc | Number of particles per mass of slurry leaving the Precipitation tank. |

| NumbersByMassDelta | Calc | The number of particles generated in the Precipitation tank per mass of slurry in the tank. |

| NumbersByVolIn | Calc | Number of particles per volume of slurry entering the Precipitation tank. |

| NumbersByVolOut | Calc | Number of particles per volume of slurry leaving the Precipitation tank. |

| NumbersByVolDelta | Calc | The number of particles generated in the Precipitation tank per volume of slurry in the tank. |

Hints and Comments

General Configuration Hints:

- The species model, which the Precipitator uses, is important for the calculations. The feed streams to the precipitator must be configured with a Bayer3 species model for the calculations to be valid. For documentation on Bayer3 properties, see Alumina 3 Bayer species model.

- The user may find it more efficient not to use the SSA Yield model when first setting up a complex Alumina Flowsheet, but to set reaction extents for the Gibbsite and soda precipitation. Once the flowsheet is controlled and the Alumina and Caustic concentrations around the plant are close to the expected values, the Yield model may be implemented.

- If using the yield method, the feed to the first precipitator in a precipitation train (either fresh or recycle) should contain some seed. Using the SetData method can modify the seed surface Area. See below for Hints on Setting the Alumina Particle Size Information.

- Compound Al[OH]3(s) must be present as this is the solid precipitated by the SSA Yield model.

- Compounds NaOH*(s) and/or Na2C5O7*(s) are optional, and if present these are the bound soda compounds.

- Occasionally a Precipitator3 tank will return the error "No convergence of precip routine: try increased damping". In the first one or two tanks where there is the most precipitation, damping is sometimes required to achieve convergence. To add damping - go to the access window for the tank, turn on "show all fields" and at the top of the precip tab you will see three damping options. Set the mass damping to 50% and that should take care of the problem.

- If you have a tank with large residence time, high supersaturation and lots of cooling, the calculated precipitation rate may remove most of the aluminate from solution, causing numerical instability. We are looking at other ways of stabilizing the solution, but mass damping allows the precipitation to move the tank to the actual saturation in several steps rather than overshooting. In extreme cases, try setting damping as high as 99%.