Piping System Model: Difference between revisions

Merry.Huang (talk | contribs) |

Adrian.Paine (talk | contribs) |

||

| Line 25: | Line 25: | ||

== Inputs and Outputs == | == Inputs and Outputs == | ||

{| border="1" cellpadding="5" cellspacing="0" | {| border="1" cellpadding="5" cellspacing="0" | ||

|- | |||

| valign="top" rowspan="2" | '''Label''' || valign="top" rowspan="2" | '''Required<br>Optional''' || valign="top" rowspan="2" | '''Input<br>Output ''' || colspan="2" | '''Number of Connections''' || valign="top" rowspan="2" | '''Description''' | |||

|- | |||

| '''Min''' || '''Max. ''' | |||

|- | |- | ||

| Input || Required || In || 1 || 1 || Input stream to Piping System Model. | |||

|- | |- | ||

| Output || Required || Out || 1 || 1 || Output stream from Piping System Model. | |||

|} | |} | ||

Revision as of 07:09, 30 October 2012

Navigation: Main Page -> Models -> Pressure Changing Models

This model is only available in SysCAD 9.2 Build 133 and later.

General Description

The Piping System Model is mainly used in dynamic projects with Transfer mode. It provides the means to enter elevation and other parameters to calculate pressure change within the piping system.

The 'Piping System' model consists of a number of sub-units, the user specifies which sub-units will comprise the piping system and configures them so that they comprise the total piping system. The piping system model then calculates the pressure drop across each sub-unit and hence across the entire system. If required it will also calculate the estimated flow through the system, based on the calculated pressure drop.

The sub-units that can comprise a Piping System Model are:

- Head - Elevation Head - to determine the pressure change due to height at the start of the piping system;

- Pipe - calculated the pressure change in the pipe due to change of height, friction and so on

- Pump2 - pressure boost provided by a pump; and

- Valve2 - pressure drop provided by a valve.

The user must configure the individual sub-units within the Piping System Model so that they comprise a reasonable system. The sub-units that can be controlled, the Pump and the Valve, will have control settings that the user may dynamically change. These settings will change the calculated pressure drop of the system.

Notes

- The Piping System Model will NOT automatically adjust the flow, but can be set to calculate the estimated flow through the system. This estimate can then be used to set the actual flow in the system, if required.

- The Piping System Model is designed to emulate an entire piping length, without any split flows.

- The Piping System Model requires a single input and a single output and will not operate unless both of these streams are connected. The physical location of the connections is not important; the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max. | ||||

| Input | Required | In | 1 | 1 | Input stream to Piping System Model. |

| Output | Required | Out | 1 | 1 | Output stream from Piping System Model. |

Model Theory

For Valve and Pump theory please see:

- Valve Theory and

- Pump Theory.

Data Sections

The default access window consists of the following sections:

- PipingSystem tab - Allows the user to insert sub-units and displays the calculated results.

- Control tab - Allows the user to set any valve positions and Pump speeds.

- Settings Tab - Allows the user to specify the sub-unit methods and enter the required data.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Class: PipingSystem The first tab page in the access window will have this name.

|

Tag / Symbol

|

Input / Calc

|

Description/Calculated Variables

|

|

Options | ||

| On | Tick Box | This allows the user to disable the unit. If the unit is Off then the pressure drop across the unit = 0. |

Options (Flow Estimate Calculations) | ||

| FlowEstimateMethod | None | The user does not wish to calculate the estimated of the flow through the unit. The pressure drop WILL be calculated. |

| Simple | The flow through the unit will be calculated with no time delays or transient effects. This is useful for short piping systems. | |

| User Damping | The flow through the unit will be calculated with a time delay, or transient effect. The user may set the fraction of damping required. | |

| Length Damping | The flow through the unit will be calculated with a time delay, or transient effect, based on the length of the piping system. This is useful where the user wishes to emulate a long pipeline so that a change in feed pressure does produce an instantaneous flow change in the pipe system. | |

| DampingRate | Input | Visible if User Damping is the Flow Estimate Method selected. The required amount of damping on the estimated flow. 0% represents no damping (changes are instantaneous - so equal to using Simple), and 99% represents large damping. |

| SpecifyTargetP | Tick Box | The user may specify a target outlet pressure from the system. If this is NOT enabled, then the outlet pressure is assumed to be the system inlet pressure. This is not visible if the user selects None as the Flow Estimate Method. |

| TargetExitP | Input | If SpecifyTargetP is enabled then this field is visible and the user may set the required outlet presusre from the piping system. |

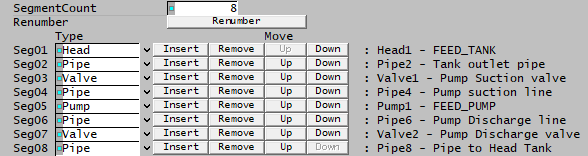

Sub-unit Selection | ||

| SegmentCount | Input | The user may define the number of sub-units in the Piping System Model. For example, if a system consists of a Valve, Pump, Valve and pipe then the number of sub-units, or segments = 4. |

| ReNumber | Button | This re-numbers all of the sub-units so that they are all in ascending order. |

| Segment Specification | ||

| Type | List | The user may choose any of the sub-units that are available, i.e. Head, Pipe, Valve or Pump. |

| Insert | Button | The user may insert a new sub-unit above the current sub-unit. This will automatically increase the Segment Count. The default sub-unit that is inserted is a Pipe, but the user may change this by selecting any of the available sub-units from the drop down list. |

| Remove | Button | The user may remove the sub-unit from the Piping System Model. This will automatically decrease the Segment Count. |

| Up | Button | The user may move the current sub-unit up in the order of sub-units. The sub-unit number will NOT change, i.e. Pipe3 can be moved above Pipe1. The user may click on the ReNumber button to automatically number the sub-units in ascending order. |

| Down | Button | The user may move the current sub-unit down the order of sub-units. The sub-unit number will NOT change, i.e. Pipe1 can be moved below Pipe2. The user may click on the ReNumber button to automatically number the sub-units in ascending order. |

Results | ||

| Overview | ||

| Feed.Qm | Display | The mass flow through the Piping System Model. |

| Feed.T | Display | The inlet temperature to the Piping System Model. |

| Feed.P | Display | The inlet pressure to the Piping System Model. |

| Sub-unit(i).Po | Calc | The pressure from sub-unit(i), where this could be Head, Valve, Pump or Pipe. The pressure from each sub-unit will be displayed. |

| Prod.P | Calc | The exit pressure from the Piping System Model. |

| Prod.T | Calc | The exit temperature from the Piping System Model. |

| Totals | ||

| Sub-unit(i).dP | Calc | The pressure change across sub-unit(i), where this could be Head, Valve, Pump or Pipe. The pressure change across each sub-unit will be displayed. |

| dP | Calc | The total pressure change across the Piping System Model. |

| PDrop | Calc | The pressure drop across the entire Piping System Model. |

| PBoost | Calc | The pressure boost across the entire Piping System Model. |

| Closed | Tick Box | If this is True, then a sub-unit, either a Valve or Pump, is set to 0% and is the flow estimate = 0. |

| Head | Calc | The calculated Head from the Piping System Model. |

| HeightChange | Calc | The calculated change in Height across the Piping System Model (-ve indicates a drop from Feed to Product) |

| Relative Heights | ||

| Feed | Calc | The relative height of the feed to the Piping System Model. |

| Sub-unit(i).Out | Calc | The relative height of sub-unit(i), where sub-unit can be Head or Pipe. All Head and Pipe sub-units will be displayed. |

| Prod | Calc | The relative height of the product of the Piping System Model. |

| Flow Estimate These fields are only visible if the user has selected a Flow Estimate method. | ||

| Qm | Display | The actual mass flow through the Piping System Model. |

| QmEstState | Display | The state of the Piping System Model estimate. This lets the user know what state the model is in, i.e. OK, No Flow, sub-units closed, etc. |

| ExtraTargetdP | Calc | The extra pressure drop required IF the user has specified a Target Exit Pressure from the unit. |

| TotalK | Calc | The calculated resistance, or loss coefficient value, K, of the Piping System Model. |

| TotalHead.dP | Calc | The total pressure change across the Piping System Model. |

| DiamUsed | Calc | The piping diameter used to calculate the velocity and estimated flow through the Piping System Model. |

| VelocityEst | Calc | The estimated velocity in the Piping System Model. |

| QmEst | Calc | The estimated mass flow rate through the Piping System Model. |

| QvEst | Calc | The estimated volumetric flow rate through the Piping System Model. |

| PrevVelEst | Calc | The velocity in the Piping System Model estimated in the previous iteration. (This is only useful if Damping is used.) |

Control

If the user selected either a Pump or a Valve as one of the sub-units and a controlled mode for either of these, then this tab will allow these units to be controlled.

Please see the relevant sub-unit for a description of the fields:

Settings

The user must configure each sub-unit that is specified on the first tab.

Please see Valve Settings and Pump Settings for the configuration of the Valves and Pumps.

The settings for Heads and Pipes are described below.

|

Tag / Symbol

|

Input / Calc

|

Description/Calculated Variables

|

| Head | ||

| On | Tick Box | This allows the user to disable the Head. If the Head is Off then Head = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for this, example Head Tank. |

| Head | Input | The actual Elevation Head required. This calculates the pressure boost due to elevation as material enters the Piping System. |

| Pipe | ||

| On | Tick Box | This allows the user to disable the Pipe. If the Pipe is Off then pressure drop across the pipe = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the Pipe. |

| OpType | Fixed dP | The user specifies a fixed pressure change across the Pipe. This will be independent of flow. |

| Fixed Drop | The user specifies a fixed pressure drop across the Pipe. This will be independent of flow. | |

| Fixed Boost | The user specifies a fixed pressure boost across the Pipe. This will be independent of flow. | |

| Darcy | Use the Darcy equation to calculate pressure drop. With this method pressure drop is a function of flow. | |

| dH | Input | The required height difference between the pipe entry and exit. A negative values indicates that the exit is lower than the entry. |

| Fixed dP Fixed Drop and Fixed Boost - The following field is visible for these three modes. | ||

| Fixed.dP/Drop/Boost | Input | The required pressure change, drop or boost (depending on the mode selected) across the Pipe. |

| Darcy The following fields are visible with this mode. | ||

| Diam | Input | The required internal pipe diameter. |

| Scale | Input | The required scale thickness in the pipe. Note, this values will be multiplied by 2 and then used to decrease the actual internal diameter of the Pipe. |

| MinorK | Input | The K value for any fittings on the pipe. |

| KMethod | User Pipe K | The user specifies a K value for the pipeline. |

| Length and Friction F | The user specifies the pipe length and a friction factor. SysCAD will then calculate the equivalent K value. | |

| Length, Colebrook FricF | The user specifies the pipe length, Viscosity and roughness. SysCAD will then calculate the friction factor using the Colebrook equation. | |

| Length, Churchill FricF | The user specifies the pipe length, Viscosity and roughness. SysCAD will then calculate the friction factor using the Churchill equation. | |

| User Pipe K The following field is visible if this method is chosen. | ||

| UserPipeK | Input | The required K value for the Pipe. |

| The following 2 fields are visible for the other methods. | ||

| L | Input | The required Pipe Length. |

| FitL | Input | The equivalent pipe fittings Length. Please do not include a value here for fittings if they are already included under MinorK. |

| Length and Friction F The following field is visible for this method. | ||

| UserFricF | Input | The required friction factor. |

| Length, Churchill and Colebrook Friction Factor The following fields are visible for both of these methods. | ||

| Viscosity | Input | The viscosity of the material flowing through the pipe. |

| Roughness | Input | The roughness of the pipe. |

Adding this Model to a Project

Insert into Configuration file

Sort either by DLL or Group.

|

|

DLL: |

Basic2.dll |

→ |

Units/Links |

→ |

Process: Piping: Piping System |

|

or |

Group: |

Mass Transfer |

→ |

Units/Links |

→ |

Process: Piping: Piping System |

See Project Configuration for more information on adding models to the configuration file.

Insert into Project

|

|

Insert Unit |

→ |

Process |

→ |

Piping |

→ |

Piping System |

See Insert Unit for general information on inserting units.

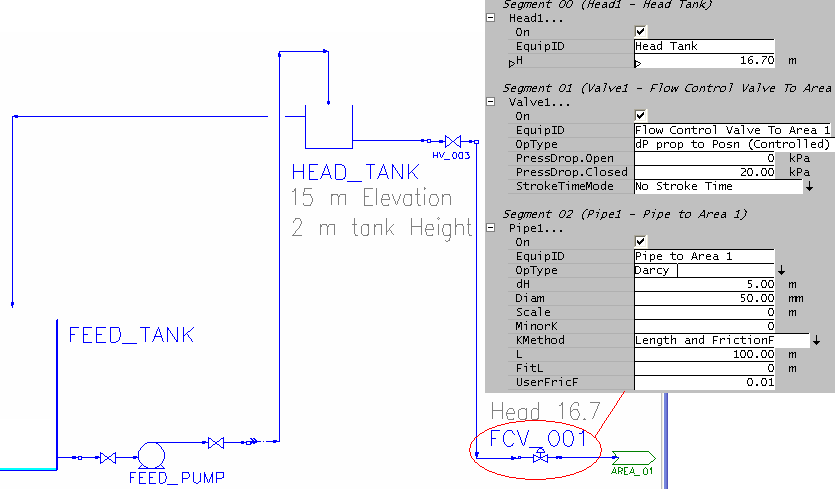

Example - Entering Elevation Information

- Feed_Tank - Assume at 0 m elevation

- Feed_Pump - Piping System : Seg06 (Pipe4 - Pipe to Head tank) has delta height (dH) of 15 m

- Head_tank - Assume at 15 m elevation (tank height 2m) - NOTE that we can't enter an elevation for the tank here, so we need to provide the information in the next unit where the change of height occurs.

- FCV_001 - Piping System : Flow control valve to Area1 (See first picture above)

- Head - 16.7m (this reflects the elevation head from head_tank, assuming tank is 85% full ) - this will calculate the pressure at the start of the FCV_001 piping system.

- Destination elevation is 5m higher