Piping System Model

Navigation: Models ➔ Pressure Changing Models ➔ Piping System Model

General Description

The Piping System Model is used in dynamic projects with Transfer mode. It allows the user emulate a full piping system, including Pumps, Valves, Pipe lengths, etc. in a single Piping System model. The user specifies the number and type of sub-units in the piping system and can configure each sub-unit individually. The user must configure the individual sub-units within the Piping System Model so that they comprise a reasonable system.

The piping system model calculates the pressure drop across each sub-unit, and hence across the entire system.

If required it will also calculate the estimated flow through the system, consistent with specified inlet and outlet pressures. This estimated flow can be used to set a Capacity Tag upstream of the Piping System inlet to make the inlet flow equal to the calculated flow.

The available sub-units in a Piping System Model are:

- Head - Elevation Head - the head due to the height of the liquid at the start of the piping system;

- Pipe - pipe lengths and fittings can be included - the pressure drop in the pipe due to change of height, friction losses, etc. will be calculated;

- Orifice - pressure reduction / flow restriction.

- Pump2 - pressure boost provided by a pump; and

- Valve2 - pressure drop provided by a valve.

Notes

- If the flow entering the Piping System comes from a Tank with WithStaticHead selected, a Head sub-unit should not be selected.

- The Pump and the Valve have control settings that the user may dynamically change. These settings will change the calculated pressure drop of the system.

- The Piping System Model will NOT automatically adjust the flow, but can be set to calculate the estimated flow through the system. This estimate can then be used to set the actual flow in the system, if required.

- The Piping System Model is designed to emulate an entire piping length, without any split flows.

- The Piping System Model requires a single input and a single output and will not operate unless both of these streams are connected. The physical location of the connections is not important - the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Input | Required | In | 1 | 1 | Input stream to Piping System Model. |

| Output | Required | Out | 1 | 1 | Output stream from Piping System Model. |

Model Theory

For Valve and Pump theory please see:

- Valve Theory and

- Pump Theory.

Data Sections

The default access window consists of the following sections:

- PipingSystem tab - Allows the user to insert sub-units and displays the calculated results.

- Control tab - Allows the user to set any valve positions and Pump speeds.

- Settings tab - Allows the user to specify the sub-unit methods and enter the required data.

- QFeed - Available from Build 139. Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- QProd - Available from Build 139. Optional tab, visible if ShowQProd is enabled. This and subsequent tab pages, e.g. QProd.. and Sp, shows the properties of the product stream. The tags in the QProd tab are valid even when the ShowQProd option is not selected.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Piping System Page

Unit Type: PipingSystem - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

|

Requirements | ||

| On | Tick Box | This allows the user to disable the unit. If the unit is Off then the pressure drop across the unit = 0. |

Options (Flow Estimate Calculations) | ||

| FlowEstimateMethod | None | The user does not wish to calculate the estimated of the flow through the unit. The pressure drop WILL be calculated. If this option is selected, no other options will be visible. |

| Simple | The flow through the unit will be calculated with no time delays or transient effects. This is useful for short piping systems. | |

| MaxiumFlowEstimate / QmMaxEst | Input | User estimate of the maximum flow rate through the Piping System. If no value is specified, 10000 t/h is used. |

| InletPressureMethod | FeedPipePressure | Inlet pressure to the Piping System is the exit pressure from the upstream Pipe. |

| Value | User specified inlet pressure. | |

| Tag | Tag whose value is to be used as the inlet pressure | |

| AtmosphericPressure | Inlet pressure is the Project Atmospheric Pressure. | |

| PressureIn.Val | Input | Visible if Value is the Inlet Pressure Method selected. The required inlet pressure. |

| PressureInTag | Input | Visible if Tag is the Inlet Pressure Method selected. The Tag from which the required inlet pressure is to be read. |

| PressureInTag.Meas | Display | Visible if Tag is the Inlet Pressure Method selected. The required inlet pressure read from the Tag. |

| OutletPressureMethod | AtmosphericPressure | Outlet pressure is the Project Atmospheric Pressure. |

| Value | User specified outlet pressure. | |

| Tag | Tag whose value is to be used as the outlet pressure | |

| PressureOut.Val | Input | Visible if Value is the Outlet Pressure Method selected. The required outlet pressure. |

| PressureOutTag | Input | Visible if Tag is the Outlet Pressure Method selected. The Tag from which the required outlet pressure is to be read. |

| PressureOutTag.Meas | Display | Visible if Tag is the Outlet Pressure Method selected. The required outlet pressure read from the Tag. |

| SetCapacity | Tick Box | The user may choose to set the inlet flow as the flow estimate by setting a Capacity Tag upstream of the Piping System inlet. |

| CapacityTag | Input | Visible if SetCapacity is ticked. The tag whose value is to be set to the flow estimate. This should be a Qm.Capacity tag in a Pipe or Tank. |

| CapacityTag.Meas | Display | Visible if SetCapacity is ticked. The required inlet flow, which should be equal to the QmEst value for the Piping System. |

| DampingRate | Input | Visible if User Damping is the Flow Estimate Method selected. The required amount of damping on the estimated flow. 0% represents no damping (changes are instantaneous - so equal to using Simple), and 99% represents large damping. CURRENTLY UNUSED. |

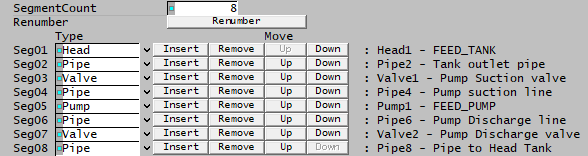

Sub-unit Selection | ||

| SegmentCount | Input | The user may define the number of sub-units in the Piping System Model. For example, if a system consists of a Valve, Pump, Valve and pipe then the number of sub-units, or segments = 4. |

| ReNumber | Button | This re-numbers all of the sub-units so that they are all in ascending order. |

| Segment Specification | ||

| Type | List | The user may choose any of the sub-units that are available, i.e. Head, Pipe, Valve or Pump. |

| Insert | Button | The user may insert a new sub-unit above the current sub-unit. This will automatically increase the Segment Count. The default sub-unit that is inserted is a Pipe, but the user may change this by selecting any of the available sub-units from the drop down list. |

| Remove | Button | The user may remove the sub-unit from the Piping System Model. This will automatically decrease the Segment Count. |

| Up | Button | The user may move the current sub-unit up in the order of sub-units. The sub-unit number will NOT change, i.e. Pipe3 can be moved above Pipe1. The user may click on the ReNumber button to automatically number the sub-units in ascending order. |

| Down | Button | The user may move the current sub-unit down the order of sub-units. The sub-unit number will NOT change, i.e. Pipe1 can be moved below Pipe2. The user may click on the ReNumber button to automatically number the sub-units in ascending order. |

| Options | ||

| ShowQFeed | Tickbox | Available from Build 139. When selected, the QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the feed stream. See Material Flow Section. Tags in the QFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQProd | Tickbox | Available from Build 139. When selected, the QProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the product stream. See Material Flow Section. Tags in the QProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

Results | ||

| Overview | ||

| Feed.MassFlow / Feed.Qm | Display | The mass flow through the Piping System Model. |

| Feed.Temperature / Feed.T | Display | The inlet temperature to the Piping System Model. |

| Feed.Pressure / Feed.P | Display | The inlet pressure to the Piping System Model. |

| Sub-unit(i).Po | Calc | The pressure from sub-unit(i), where this could be Head, Valve, Pump, orifice or Pipe. The pressure from each sub-unit will be displayed. |

| Prod.Pressure / Prod.P | Calc | The exit pressure from the Piping System Model. |

| Prod.Temperature / Prod.T | Calc | The exit temperature from the Piping System Model. |

| Work | Calc | The actual work done. Some segment type has work term (such as pump2). |

| HeatFlow | Calc | The total heat flow. Some segment types allow (such as pipe) allow heat flow to be added. |

| Totals | ||

| Sub-unit(i).PressChange / Sub-unit(i).dP | Calc | The pressure change across sub-unit(i), where this could be Head, Valve, Pump or Pipe. The pressure change across each sub-unit will be displayed. |

| PressChange / dP | Calc | The total pressure change across the Piping System Model. |

| PressDrop / PDrop | Calc | The pressure drop across the entire Piping System Model. |

| PressBoost / PBoost | Calc | The pressure boost across the entire Piping System Model. |

| Closed | Tick Box | If this is True, then a sub-unit, either a Valve or Pump, is set to 0% and is the flow estimate = 0. |

| Head | Calc | The calculated Head from the Piping System Model. |

| HeightChange | Calc | The calculated change in Height across the Piping System Model (-ve indicates a drop from Feed to Product) |

| Relative Heights | ||

| Feed | Calc | The relative height of the feed to the Piping System Model. |

| Sub-unit(i).Out | Calc | The relative height of sub-unit(i), where sub-unit can be Head or Pipe. All Head and Pipe sub-units will be displayed. |

| Prod | Calc | The relative height of the product of the Piping System Model. |

| Flow Estimate These fields are only visible if the user has selected a Flow Estimate method. | ||

| MassFlow / Qm | Display | The actual mass flow through the Piping System Model. |

| QmEstState | Display | The state of the Piping System Model estimate. This lets the user know what state the model is in, i.e. OK, No Flow, sub-units closed, etc. |

| ExtraTarget.Pi | Calc | Inlet pressure used in estimate |

| ExtraTarget.Po | Calc | Target outlet pressure Used in estimate |

| ExtraTarget.PressChange / ExtraTarget.dP | Calc | The extra pressure drop required IF the user has specified a Target Exit Pressure from the unit. (dPinValue - dPoutValue) |

| WeightedTotalK | Calc | The calculated resistance, or loss coefficient value, K, of the Piping System Model. (Sum of diameter weighted pipe K factors) |

| TotalHead.PressChange / TotalHead.dP | Calc | The total pressure change across the Piping System Model. (Due to static head (Head, Pipe) and Pump dP) |

| DiamUsed | Calc | The piping diameter used to calculate the velocity and estimated flow through the Piping System Model. (Reference diameter for weighting) |

| ZeroFlow.Po | Calc | Estimated outlet pressure at zero flow: static head + pump boost |

| MassFlowEst / QmEst | Display | The estimated mass flow through the Piping System Model. |

| VolFlowEst / QvEst | Calc | The estimated volumetric flow rate through the Piping System Model. |

| SystemHasCharacteristic | Tick Box | |

| SystemIsStable | Tick Box | |

Control

If the user selected either a Pump or a Valve as one of the sub-units and a controlled mode for either of these, then this tab will allow these units to be controlled.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Segment xx (Valvex - Description) | ||

| Position.Reqd | Input | The required valve position. Normally this is any value between 0 and 100%. However, if the user has selected Operating type K Open Closed, then only 0 and 100% are allowed. |

| Position.Actual | Display | The actual valve position. This is normally equal to the required position. However, if the user has specified a stroke time, then the actual position will lag the required position by the stroke time. |

| Open Valve | Button | Clicking on this button will open the valve to 100%. |

| Close Valve | Button | Clicking on this button will close the valve to 0%. |

| Open | Tick Box | If this is True then the valve is Open. |

| Closed | Tick Box | If this is True then the valve is Closed. |

| Position.Changing | Tick Box | If this is True then the valve is moving. |

| Segment xx (Pumpx - Description) | ||

| Speed.Reqd | Input | The required Pump speed. Any value between 0 and 100%. |

| Speed.Actual | Display | The actual Pump speed. This is normally equal to the required speed. However, if the user has specified a stroke time, then the actual speed will lag the required speed by the stroke time. |

| RPM.Actual | Display | Visible when Settings tab - OpType = xxxx (Controlled) and WithRPM = on. The actual Pump speed in RPM. |

| Run Pump | Button | Clicking on this button will start the Pump at the required speed. |

| Stop Pump | Button | Clicking on this button will stop the pump (set the required speed to 0%). |

| Running | Tick Box | If this is True then the Pump is running. |

| RunningMax | Tick Box | If this is True then the Pump is running at 100%. |

| Stopped | Tick Box | If this is True then the Pump is stopped. |

| Position.Changing | Tick Box | If this is True then the Pump speed is changing. Visible as part of piping system. |

Settings

The user must configure each sub-unit that is specified on the first tab.

Please see Valve Settings and Pump Settings for the configuration of the Valves and Pumps.

The settings for Heads and Pipes are described below.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Head | ||

| On | Tick Box | This allows the user to disable the Head. If the Head is Off then Head = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for this, example Head Tank. |

| Height / H | Input | The actual Elevation Head required. This calculates the pressure boost due to elevation as material enters the Piping System. |

| Pipe | ||

| On | Tick Box | This allows the user to disable the Pipe. If the Pipe is Off then pressure drop across the pipe = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the Pipe. |

| OpType | Fixed dP | The user specifies a fixed pressure change across the Pipe. This will be independent of flow. |

| Fixed Drop | The user specifies a fixed pressure drop across the Pipe. This will be independent of flow. | |

| Fixed Boost | The user specifies a fixed pressure boost across the Pipe. This will be independent of flow. | |

| Darcy | Use the Darcy equation to calculate pressure drop. With this method pressure drop is a function of flow. | |

| DeltaHeight / dH | Input | The required height difference between the pipe entry and exit. A negative values indicates that the exit is lower than the entry. |

| Fixed dP Fixed Drop and Fixed Boost - The following field is visible for these three modes. | ||

| Fixed.dP/Drop/Boost | Input | The required pressure change, drop or boost (depending on the mode selected) across the Pipe. |

| Darcy The following fields are visible with this mode. | ||

| Diameter / Diam | Input | The required internal pipe diameter. |

| ScaleBuildup / Scale | Input | The required scale build up thickness in the pipe. Note, this values will be multiplied by 2 and then used to decrease the actual internal diameter of the Pipe. |

| MinorK | Input | The K value for any fittings on the pipe. |

| KMethod | User Pipe K | The user specifies a K value for the pipeline. |

| Length and Friction F | The user specifies the pipe length and a friction factor. SysCAD will then calculate the equivalent K value. | |

| Length, Colebrook FricF | The user specifies the pipe length, Viscosity and roughness. SysCAD will then calculate the friction factor using the Colebrook equation. | |

| Length, Churchill FricF | The user specifies the pipe length, Viscosity and roughness. SysCAD will then calculate the friction factor using the Churchill equation. | |

| User Pipe K The following field is visible if this method is chosen. | ||

| UserPipeK | Input | The required K value for the Pipe. |

| The following 2 fields are visible for the other methods. | ||

| Length / L | Input | The required Pipe Length. |

| FittingsLength / FitL | Input | The equivalent pipe fittings Length. Please do not include a value here for fittings if they are already included under MinorK. |

| Length and Friction F The following field is visible for this method. | ||

| UserFricFactor / UserFricF | Input | The required friction factor. |

| Length, Churchill and Colebrook Friction Factor The following fields are visible for both of these methods. | ||

| Viscosity | Input | The viscosity of the material flowing through the pipe. |

| Roughness | Input | The roughness of the pipe. |

| Valve | ||

| On | Tick Box | This allows the user to disable the valve. If the valve is Off then the pressure drop across the valve = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the valve. |

There are two different operating classes of valve:

| ||

| OpType | Fixed Drop (Simple) | The user may specify a fixed pressure drop across the valve. |

| Fixed ExitP (Simple) | The user may specify a fixed exit pressure from the valve. | |

| Fixed AtmosP (Simple) | The exit pressure from the valve = atmospheric pressure. | |

| dP Prop to mass Flow (Simple) | The pressure drop across the valve will be proportional to the mass flow through the valve. The user may NOT set the valve position if this operating mode is used, as the mass flow is the only variable used to calculate pressure drop. | |

| Cv Lookup (Controlled) | Use Cv values to calculate the pressure drop across the valve, based on the user defined valve position. | |

| dP Prop to Posn (Controlled) | The pressure drop across the valve will be proportional to the user defined position of the valve. | |

| K Open Closed (Controlled) | The user defines the K value for the 100% open valve. This type of valve may either be fully open (100%) or fully closed (0%) and no other position. | |

| Fixed Drop (Simple) The following field is visible with this mode. | ||

| FixedDrop | Input | The required pressure drop when the valve is in the fully open position. |

| Fixed ExitP (Simple) The following field is visible with this mode. | ||

| FixedP | Input | The required outlet pressure from the valve in the fully open position. |

| dP prop to MassFlow (Simple) The following 3 fields are visible with this mode. | ||

| PressDrop.NoFlow | Input | The required pressure drop when there in no flow through the valve. |

| PressDrop.NominalFlow | Input | The required pressure drop when there is nominal flow (specified below) through the valve. |

| NominalFlow | Input | The nominal flow through the valve. Used for the pressure drop calculations. |

| dP Proportional to Position (Controlled) The following 2 fields are visible with this mode. | ||

| PressDrop.Open | Input | The required pressure drop when the valve is in the fully open position. |

| PressDrop.Closed | Input | The required pressure drop when the valve is in the fully closed position. |

| K Open Closed (Controlled) The following 2 fields are visible with this mode. | ||

| Diameter | Input | The required diameter of the valve. |

| UserValveK | Input | The required K value of the valve in the fully open position. |

| Cv Lookup (Controlled) The following fields are visible with this mode. | ||

| Diameter | Input | The diameter of the entry pipe into the valve. |

| MinorK | Input | The K value for the minor pressure losses into and out of the valve. |

| CvLookup (see Model Theory) |

Single Point | In this case a single coefficient is specified, corresponding to the flow for the valve fully open. For a partially open valve, the flow coefficient is just scaled proportionally. |

| 2pts (100% interval) | Provide a Cv for the valve in the fully closed and fully open positions and assume the Cv varies linearly between these values. | |

| 3pts (50% interval) | Provide Cv values for the valve for 0, 50 and 100% positions. | |

| 5pts (25% interval) | Provide Cv values for the valve at 25% intervals. | |

| 11pts (10% interval) | Provide Cv values for the valve at 10% intervals. | |

| Quadratic | If the variation of Cv with open area is quadratic then you can specify a single Cv (fully open) and the actual Cv will be calculated using the quadratic equation given in Model Theory. | |

| Angle | Provide Cv values at 10 degree intervals for 0 (CV01, fully closed) to CV10 (90 degrees, fully open). | |

| Cv00.. | Input | Depending on the Cv Lookup option chosen above, this may be a single field, or up to 11 fields for the user to enter the Cv values for the valve. |

| LinearInterpolate | Tick Box | This option is only visible if the user chooses 3, 5 or 11 points. If this is enabled then the model will interpolate linearly between the individual points. |

| Stroke Times The following fields are visible if dP proportional to Position or Cv Lookup are chosen. | ||

| StrokeTimeMode | None | The actual valve position will move to the required position with no delay time. |

| Single Stroke Time | There will be a fixed delay between setting the required valve position and when the actual valve position reaches the required position. | |

| Open/Close Stroke Time | The delay between setting the required valve position and when the actual valve position reaches the required position will be different for opening and closing settings. | |

| StrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position. Visible if Single Stroke Time is selected. |

| OpenStrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position, if the valve is opening. Visible if Open/Close Stroke Time is selected. |

| CloseStrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position, if the valve is closing. Visible if Open/Close Stroke Time is selected. |

| Pump | ||

| On | Tick Box | This allows the user to disable the Pump. If the Pump is Off then the pressure boost from the Pump = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the Pump. |

| ProcessType | Isentropic Process | Pressure change across the pump is a nominally isentropic process. |

| Isothermal Process | Pressure change across the pump is a nominally isothermal process. | |

| IsentropicEfficiency / EffIsen | Input | Visible only if ProcessType selected is Isentropic Process - Ratio of enthalpy change for isentropic process to actual enthalpy change. |

| IsothermalEfficiency / EffIso | Input | Visible only if ProcessType selected is Isothermal Process - Ratio of enthalpy change for isothermal process to actual enthalpy change. |

There are two different operating modes for the Pump:

| ||

| OpType | Fixed Boost (Simple) | The user may specify a fixed pressure boost from the Pump. |

| Fixed ExitP (Simple) | The user may specify a fixed exit pressure from the Pump. | |

| Fixed AtmosP (Simple) | The exit pressure from the Pump = atmospheric pressure. | |

| Boost Prop to mass Flow (Simple) | The pressure boost from the Pump will be proportional to the mass flow through the Pump. The user may NOT set the Pump speed if this operating mode is used, as the mass flow is the only variable used to calculate pressure boost. | |

| Fixed Head (Simple) | The user may specify a fixed head from the Pump. | |

| Boost prop to Speed (Controlled) | The pressure boost from the Pump will be proportional to the user defined speed. | |

| Head prop to Speed (Controlled) | The head from the Pump will be proportional to the user defined speed. | |

| There are several different methods for specifying Pump curves. The curves are specified for maximum pump speed and will be modified for speeds less than the maximum. | ||

| OpType | Simple Quadratic (Controlled) | The user may specify Pump head at zero flow and Pump flow at zero head. A monotonic decreasing curve will be fitted to these points. |

| Points Quadratic (Controlled) | The user may specify Pump head at zero flow, runout flow rate (maximum safe flow rate) and Pump head at runout flow rate and at half of the runout flow rate. | |

| Points Cubic (Controlled) | The user may specify Pump head at zero flow, runout flow rate (maximum safe flow rate) and Pump head at runout flow rate, one third of the runout flow rate and two thirds of the runout flow rate. | |

| User Cubic (Controlled) | The user may specify Pump head at zero flow and coefficient value for terms in the flow, square of the flow rate and cube of the flow rate. | |

| Positive Displacement (Controlled)) | The user may specify maximum flow at full speed, maximum head, and other ratios. | |

| Fixed Boost (Simple) The following field is visible with this mode. | ||

| FixedBoost | Input | The required pressure boost when the Pump is running. |

| Fixed ExitP (Simple) The following field is visible with this mode. | ||

| FixedP | Input | The required outlet pressure from the Pump when it is running. |

| Boost prop to MassFlow (Simple) The following 3 fields are visible with this mode. | ||

| PressBoost.NoFlowPBoost | Input | The required pressure boost when there in no flow through the Pump. |

| PressBoost.NominalFlow | Input | The required pressure boost when there is nominal flow (specified below) through the Pump. |

| NominalFlow | Input | The nominal flow through the Pump. Used for the pressure boost calculations. |

| Fixed Head (Simple) The following field is visible with this mode. | ||

| FixedHead | Input | The required pressure Head when the Pump is running. |

| Boost Proportional to Speed (Controlled) The following 2 fields are visible with this mode. | ||

| PressBoost.Running | Input | The required pressure boost when the Pump is running at 100%. |

| PressBoost.Stopped | Input | The required pressure boost when the Pump is stopped. |

| Head Proportional to Speed (Controlled) The following 2 fields are visible with this mode. | ||

| Head.Running | Input | The required head when the Pump is running at 100%. |

| Head.Stopped | Input | The required head when the Pump is stopped. |

| Simple Quadratic (Controlled) The following fields are visible with this mode. | ||

| CutOffHead | Input | The Pump head at zero flow. |

| A1, A2, A3 | Result | Calculated coefficients of the general cubic pump curve. A0 is the cut off head. |

| ZeroHeadFlow | Input | The Pump flow rate at zero head. |

| Points Quadratic (Controlled) The following fields are visible with this mode. | ||

| UnstableOK | Tick Box | The user inputs may generate a Pump curve which is unstable: that is, the head initially increases from the cut off value as flow increases from zero. Tick if this behaviour is as required |

| CutOffHead | Input | The Pump head at zero flow. |

| A1, A2, A3 | Result | Calculated coefficients of the general cubic pump curve. A0 is the cut off head. |

| ZeroHeadFlow | Result | The Pump flow rate at zero head, calculated from input data. |

| HalfFlowHead | Input | The Pump head at half of the run out flow. |

| RunOutHead | Input | The Pump head at the run out flow. This may be greater than zero. |

| RunOutFlow | Input | The Pump maximum safe flow rate. |

| Points Cubic (Controlled) The following fields are visible with this mode. | ||

| UnstableOK | Tick Box | The user inputs may generate a Pump curve which is unstable: that is, the head initially increases from the cut off value as flow increases from zero. Tick if this behaviour is as required |

| CutOffHead | Input | The Pump head at zero flow. |

| A1, A2, A3 | Result | Calculated coefficients of the general cubic pump curve. A0 is the cut off head. |

| ZeroHeadFlow | Result | The Pump flow rate at zero head, calculated from input data. |

| OneThirdFlowHead | Input | The Pump head at one third of the run out flow. |

| TwoThirdsFlowHead | Input | The Pump head at two thirds of the run out flow. |

| RunOutHead | Input | The Pump head at the run out flow. This may be greater than zero. |

| RunOutFlow | Input | The Pump maximum safe flow rate. |

| User Cubic (Controlled) The following fields are visible with this mode. | ||

| UnstableOK | Tick Box | The user inputs may generate a Pump curve which is unstable: that is, the head initially increases from the cut off value as flow increases from zero. Tick if this behaviour is as required |

| CutOffHead | Input | The Pump head at zero flow |

| A1, A2, A3 | Input | User Calculated coefficients of the general cubic pump curve. A0 is the cut off head. The values of the coefficient must be such that the curve has exactly one positive real root. |

| ZeroHeadFlow | Result | The Pump flow rate at zero head, calculated from input data. |

| RunOutHead | Input | The Pump head at the run out flow. This may be greater than zero. |

| RunOutFlow | Input | The Pump maximum safe flow rate. This should exceed the calculated zero head flow rate. |

| Positive Displacment (Controlled) The following fields are visible with this mode. | ||

| MaxHead | Input | The Pump maximum head. |

| MaxFlow | Result | The Pump maximum flow rate at maximum speed |

| MaxVolEff | Input | Max volumetric efficiency. |

| MaxSlip | Result | The Pump maximum slip, which the difference between the zero head flow rate and the maximum head flow rate. |

| CutOffSpeed | Result | The Pump minimum operating speed as a percentage of the pump maximum speed. |

| With RPM The following fields are visible if this tick box is enabled. | ||

| RPM.Running | Input | The speed of the Pump in RPM for the values defined by the user (at 100%). |

| RPM.Stopped | Input | The speed of the Pump in RPM when the pump is at 0%. |

| Stroke Times The following fields are visible if a Controlled mode is chosen. | ||

| StrokeTimeMode | None | The actual Pump Speed will change to the required speed with no delay time. |

| Single Stroke Time | There will be a fixed delay between setting the required Pump speed and when the Pump reaches the required speed. | |

| Open/Close Stroke Time | The delay between setting the required Pump speed and when the Pump reaches the required speed will be different for starting and stopping settings. | |

| StrokeTime | Input | The required delay between setting the required Pump speed and when the Pump reaches the required speed. Visible if Single Stroke Time is selected. |

| OpenStrokeTime | Input | The required delay between setting the required Pump speed and when the Pump reaches the required speed, if the Pump is starting. Visible if Open/Close Stroke Time is selected. |

| CloseStrokeTime | Input | The required delay between setting the required Pump speed and when the Pump reaches the required speed, if the Pump is stopping. Visible if Open/Close Stroke Time is selected. |

| Orifice | ||

| On | Tick Box | This allows the user to disable the Orifice. If the Orifice is Off then dP= 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the Orifice. |

| OpType | User K Value | The user specifies a fixed K value |

| K0 value per BS1042 | Uses KO value as per BS1042, Methods for the Measurement of Fluid Flow in Pipes Part 1 - Orifice Plates, Nozzles and Venturi Tubes. | |

| Plate | modelled as orifice plate, returns K value | |

| Nozzle | modelled as flow nozzle, returns K value | |

| Square Edge | modelled as Square Edge orifice, returns K value | |

| Round Edge | modelled as Round Edge orifice, returns K value | |

| Diameter / Diam | Input | The required pipe inside diameter. |

| OrificeDiameter / OrifDiam | Input | The orifice diameter. |

| DiameterRatio/Beta | Input | The ratio of orifice diameter / pipe inside diameter. |

| MinorK | Input | K factor for fittings |

| UserValveK | Input | Visible with OpType = User K Value. The K value for the orifice. |

| Viscosity | Input | The viscosity of the material flowing through the Orifice. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Piping2.dll |

→ | Units/Links | → | Piping: Piping System | |

| or | Group: | Mass Transfer |

→ | Units/Links | → | Piping: Piping System |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Piping | → | Piping System |

See Insert Unit for general information on inserting units.

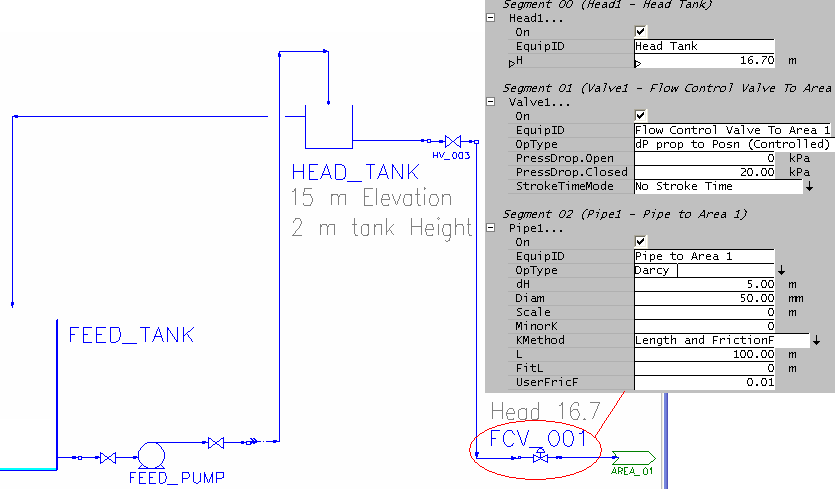

Example - Entering Elevation Information

- Feed_Tank - Assume at 0 m elevation

- Feed_Pump - Piping System : Seg08 (Pipe8 - Pipe to Head tank) has delta height (dH) of 15 m

- Head_tank - Assume at 15 m elevation (tank height 2m) - NOTE that we can't enter an elevation for the tank here, so we need to provide the information in the next unit where the change of height occurs.

- FCV_001 - Piping System : Flow control valve to Area1 (See first picture above)

- Head - 16.7m (this reflects the elevation head from head_tank, assuming tank is 85% full ) - this will calculate the pressure at the start of the FCV_001 piping system.

- Destination elevation is 5m higher