Conveyor Belt

Navigation: Models ➔ Material Handling Models ➔ Conveyor Belt

General Description

The Conveyor Belt model is used to transfer material from one point to another in a Dynamic project. The Conveyor Belt can have multiple feed points and multiple product points.

This unit operation is used extensively in Solids material handling projects.

The Conveyor Belt can be configured to operate in any one of a number of different ways. These will be described below:

Standard Conveyor Belt

A conventional Conveyor Belt which may have multiple feed points and either a single fixed discharge point or multiple fixed discharge points. A conveyor with stationary trippers is included here.

Apron or Belt Feeder

The Conveyor Belt model may be configured to act as an Apron or Belt Feeder, in which required feed flow is based on the speed of the belt.

To configure a Conveyor Belt as an Apron Feeder or Belt Feeder, it must be located downstream of a surge unit in the flowsheet - such as a Tank or Multi-Storage.

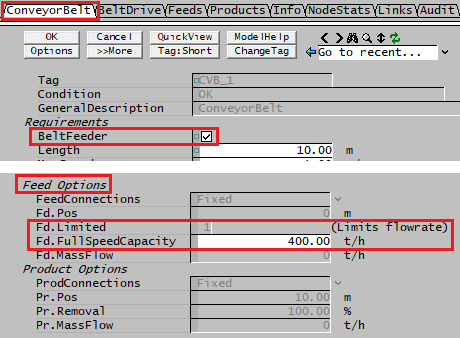

Select the BeltFeeder tick box on the ConveyorBelt Tab and specify the Fd.FullSpeedCapacity as shown below:

This will restrict the feed to one fixed feed (at start of belt) and the product to one fixed product (at end of belt).

As the speed of the belt changes, the amount of material withdrawn from the upstream bin will change, up to the maximum defined by the user. The Conveyor Belt will set the required capacity in the link between the conveyor and the upstream bin.

Movable Tripper or Shuttle Conveyor

- A Shuttle conveyor with 2 or more products. The user may set the speed of the shuttle drive.

- A Tripper conveyor, with a tripper drive.

NOTE: All connections to and from the conveyor belt will operate in the transfer mode.

Improvements

Some improvements were implemented in the latest version of Build138 and Build139, these include:

- Added options to specify length of belt to feed onto when stopped.

- Improved Loading display to show sections conveyor belt is divided into internally.

- Added Copy to Clipboard option for Sections data. Allows users to analyse the data in other packages, mainly for debugging purposes.

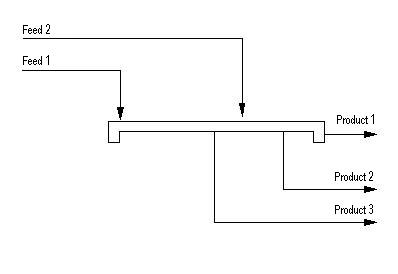

Diagram

The diagram shows the default drawing of the Conveyor, with streams that may be connected to the unit. All of the connections are optional, i.e. the user does not have to connect any streams to either the Feed or the Product connections.

The user may have only a single Feed and a single Product connection, or any number of each.

The contents of the conveyor belt are only saved and recovered if the option "Save Object Files (extra state.result info)" in the save project dialog is selected. If this is not selected, the conveyor belt is empty at project load.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | Optional | In | 0 | 20* | The Feed to the Conveyor |

| Product | Optional | Out | 0 | 20* | The Product from the Conveyor |

- If the Belt Feeder option is chosen, the the number of feeds will be restricted to one and the number of products will be restricted to one.

Model Theory

Power Draw - CEMA Method

This method is based on a graphical method described in the following reference:

"Belt Conveyors for Bulk Materials", Second Edition, 1979, Conveyor Equipment Manufacturers Association.

Regression analysis has been performed on the graphs provided in the reference to determine constants required to turn this into mathematical formulas.

There are three user specified values required for this method, the empty belt density, the belt width and the belt elevation.

The following steps are the followed to calculate the power requirements of the belt:

- Calculate the loading of the empty belt from the empty belt density and the belt width.

- Calculate the power required to drive the empty belt from the empty loading (step 1) and the belt speed.

- Calculate the power required to elevate the material from the belt elevation and average flow of material on the belt.

- Calculate the power required to convey the material from the conveyor length and average flow of material on the belt.

- Calculate the total (ideal) power by adding the calculated power requirements of the previous three steps together.

Data Sections

Summary of Data Sections

The default sections and variable names are described in detail in the following tables. The default Conveyor Belt access window consists of four sections. This number may increase or decrease, based on user configuration.

- ConveyorBelt - This tab page contains general configuration information.

- BeltDrive - This tab page is used to configure the operation of the conveyor belt drive.

- Feeds - This is where the user can define the feed inlet position(s).

- Products - This is where the user can define the product outlet position(s).

- FeedDrives - Optional tab, only visible if NFeedDrives > 0. The number of tab pages available will match the number of NFeedDrives specified by the user. These tab pages are used to configure the Feed Drives.

- ProdDrives - Optional tab, only visible if NProdDrives > 0. The number of tab pages available will match the number of NProdDrives specified by the user. These tab pages are used to configure the Product Drives.

- WtMtrs - This page is used to configure the weightometers. This page will only appear if NWeightometers (the number of weightometers specified on the first tab page) > 0.

- Loading - This page is used to display the belt loading profile. This page will only appear if the ShowLoading option is ticked.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links - This tab page contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

These sections are visible if the user checks the relevant box on the first page.

Conveyor Belt Page

Unit Type: ConveyorBelt - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options | |

| Tag | Display | This name tag may be modified with the change tag option. | |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. | |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. | |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. | |

| Requirements | |||

| BeltFeeder | Tick Box | The conveyor is auto-configured as a belt feeder (or Apron Feeder). Feed and product positions are fixed at the start and ends of the conveyor, respectively. User will be able to set a limit on the feeder capacity. | |

| Length | Input | The total length of the conveyor. Note: This includes any shuttle or tripper attached to the conveyor. | |

| MaxSpeed | Input | The maximum speed of the conveyor. | |

| FullLoad | Input | The loading, in mass per length, that the conveyor is designed handle at the maximum power draw. | |

| MaxSpillLoad | Input | The maximum loading, in mass per length, that the conveyor can handle before spillage occurs. | |

| MaxStallLoad | Input | The maximum load the conveyor can handle before it stalls. | |

| UsePowerSupply | Tick Box | Only available in Build 136 or earlier. If this is enabled, then if the power supply for the project is turned off, then the conveyor will stop. The data fields relating to the Power supply will be visible on all the conveyor drive tabs. | |

| Results | |||

| WasRunning | Display | If the conveyor was running in the previous step, then this will have a value of 1, otherwise it will be 0. | |

| BeltStopped | Tickbox | This will be True if the conveyor is stopped, otherwise False. | |

| BeltSpeed | Calc | The current conveyor speed - BeltSpeed = MaxSpeed * Actual Speed Fraction. | |

| AvgLoading | Calc | The average loading, in Mass per length, of the conveyor. | |

| AvgFullLoadFrac | Calc | This value = Average Loading/Full Load. This is also used to calculate the power draw of the conveyor. This field is only displayed if 'ShowFullLoadFrac' under Options is ticked. | |

| TotalMass / Mt | Calc | The total mass on the conveyor. | |

| InitTtlMass / InitMt | Calc | The initial total mass on the conveyor. | |

| DeltaTtlMass / DeltaMt | Calc | The difference between the current mass on the conveyor (TotalMass) and the inital mass on the conveyor (InitTtlMass). | |

| TotalSpilt | Input / Calc | The total material spilt from the belt. NOTE: This is a read/write field. As spillage occurs, the cumulative amount will be displayed here. However, the user can also enter 0 to reset the spillage count. | |

| TotalVented | Input / Calc | The total mass of gases vented. NOTE: This is a read/write field. As venting occurs, the cumulative amount will be displayed here. However, the user can also enter 0 to reset the venting count. | |

| Feed Options | |||

| FeedConnections | Fixed | All Feed points onto the conveyor are fixed and therefore there are no Feed Drives. This option is forced if the Belt Feeder Option is chosen. | |

| Fixed or Moving | The user may have a combination of Fixed and Moving feed points to the conveyor. In this case the user may select 0 or 1 or more Feed Drives. | ||

| Moving | All feed points to the conveyor are moving. In this case the user must select at least 1 Feed Drive. | ||

| NFeedDrives | Input | The number of feed drives. The FeedDrives tab page(s) will then be visible. This field is NOT visible if the user selects 'FeedConnections' = Fixed. | |

| (the following fields are only visible if the BeltFeeder Option is selected) | |||

| Fd.StreamTag | Display | The tag of the feed stream. | |

| Fd.Type | Display | The type of the feed stream connection. | |

| Fd.Pos | Display | The position of the feed stream from the start of the conveyor. | |

| Fd.Limited | Display | The feed flow rate is limited. | |

| Fd.FullSpeedCapacity | Input | This is the maximum capacity that can be fed onto the conveyor. This number will be passed back to the feed stream, thus limiting the flow from a tank or other surge unit to this capacity. | |

| Fd.MassFlow / Fd.Qm | Display | The mass flow rate of the feed stream. | |

| Product Options | |||

| ProdConnections | Fixed | All product points from the conveyor are fixed and therefore there are no Prod Drives. This option is forced if the Belt Feeder Option is chosen. | |

| Fixed or Moving | The user may have a combination of Fixed and Moving product points from the conveyor. In this case the user may select 0 or 1 or more Prod Drives. | ||

| Moving | All product points to the conveyor are moving. In this case the user must select at least 1 Prod Drive. | ||

| Moving (over Bins) | All product points to the conveyor are moving over bins. Each product from the conveyor will discharge to a bin with a user defined start distance and width. In this case there will be 1 Prod Drive. | ||

| NProdDrives | Input | The number of product drives. The ProdDrives tab page(s) will then be visible. Note: If the 'Moving over Bins' option has been selected, then this field will be read only and display the value of 1. This field is NOT visible if the user selects 'ProdConnections' = Fixed. | |

| (the following fields are only visible if the BeltFeeder Option is selected) | |||

| Pr.StreamTag | Display | The tag of the product stream. | |

| Pr.Type | Display | The type of the product stream connection. | |

| Pr.Pos | Display | The position of the product stream from the start of the conveyor. | |

| Pr.Removal | Display | The proportion of material on the conveyor that will be sent to this product stream. | |

| Pr.MassFlow / Pr.Qm | Display | The mass flow rate of the product stream. | |

| Options | |||

| ShowFullLoadFrac | Tickbox | If this is enabled then the fractional average of the full load will be displayed. | |

| ShowLoading | Tickbox | This displays the mass loading along the conveyor length on the Loading tab page. | |

| NWeightometers / NoWtMtrs | Input | Number of weightometers. If this is > 0, a new Tab page WtMtrs will be added in the access Window. | |

| Preset | None | The Preset action will have no effect on the speed or movement of the conveyor. | |

| Off | The Preset action will turn the conveyor off. | ||

| Forward | The Preset action will cause the conveyor to run in the forward direction at speed = 100%. | ||

| Reverse | The Preset action will cause the conveyor to run in the reverse direction at speed = -100%. | ||

| PresetClear | None | The Preset action will have no effect on the material on the conveyor. | |

| End | The Preset action will empty the material between the set take-off point and the end of the conveyor. | ||

| All | The Preset action will remove all of the material from the conveyor, i.e. it will empty the conveyor. | ||

| Tolerances and Configuration for managing queue sections of material | |||

| PrevTotalMass | Display | 'TotalMass' on the previous step. | |

| PrevSpillMass | Display | 'TotalSplit' on the previous step. | |

| PrevVentMass | Display | 'TotalVented' the previous step. | |

| Balance | Display | ||

| StoppedLoadLength | Input | Available in Build 138 or later, user can specify the length of belt that can hold new material while the belt is stopped. This is used to calculate how much new material can be added to a stopped belt before spill occurs. Please note that to avoid spilling, the normal logic would be to stop feed to the belt when stopped. | |

| MinLoading | Input | The minimum loading of a section of the conveyor. | |

| SectionsData | Copy To Clipboard | Available in Build 138 or later. Copies the number of section data (see NSections below) onto clipboard, user can analyse the data in other packages, mainly used for debugging purposes. | |

| NSections | Display | The number of sections into which the Conveyor Belt is divided. For internal recording purposes only. | |

| NSteps | Display | The number of internal steps required by the conveyor model. | |

| MinSect... | |||

| Length | Input | The minimum length of each section as a % of total length. | |

| LoadTol | Input | The load tolerance for determining if adjacent sections should be merged. This field is only visible if the Length field above is > 0. | |

| TempTol | Input | The temperature tolerance for determining if adjacent sections should be merged. This field is only visible if the Length field above is > 0. | |

| MFracTol | Input | The mass fraction tolerance for determining if adjacent sections should be merged. This field is only visible if the Length field above is > 0. | |

| WarningCount | Input | The maximum number of sections into the which the Conveyor Belt can be divided before the user receives a warning. | |

BeltDrive

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Power Draw | ||

| Power.CalcMethod | None | The power draw is not calculated. No further fields relating to Power will be visible. |

| Simple (Ref FullLoad) | This method uses simple interpolation between no load and full load to calculate the power draw. | |

| Simple (Ref SpillLoad) | This method uses simple interpolation between no load and the spill load to calculate the power draw. | |

| CEMA | This method uses the belt configuration and loading to calculate the power draw. It is based on a graphical method described in a book by the Conveyor Equipment Manufacturer's Association. Please refer to Model Theory for more information. | |

| The following fields will be visible for Power Calculation Method = Simple (Full and Spill loads) | ||

| Power.Efficiency | Input | The efficiency of the belt drive. |

| Power.NoLoad | Input | The power draw with no load on the belt. |

| Power.RefLoad | Input | The power draw with the belt fully loaded, if the user has chosen Full load. Or at the Spill load point, if the user chose Spill Load. |

| IdealPower | Calc | The calculated power draw of the belt drive, before adjusting for efficiency. |

| Power | Calc | The calculated power draw of the belt drive, after adjusting for efficiency. Power = Ideal Power * Efficiency. |

| The following fields will be visible for Power Calculation Method = CEMA (Please refer to Model Theory for more information) | ||

| Power.Efficiency | Input | The efficiency of the belt drive. |

| Power.BeltWidth | Input | The belt width. |

| Power.BeltDensity | Input | The density of the empty belt. |

| Power.BeltElevation | Input | The change in elevation between the discharge and feed points of the belt. |

| Power.EmptyLoading | Calc | The calculated loading of the empty belt. This is a function of the density of the empty belt (Power.BeltDensity) and the belt width (Power.BeltWidth). |

| IdealPower | Calc | The calculated power draw of the belt drive, before adjusting for efficiency. It is the sum of the power to drive the empty conveyor, the power to elevate the material and the power to convey the material. |

| Power | Calc | The calculated power draw of the belt drive, after adjusting for efficiency. Power = Ideal Power * Efficiency. |

| Speed | ||

| Type | Power & Speed | If the power source is available the conveyor will run at the user specified speed. |

| Fwd Rev | The user may specify if the conveyor is running forwards or in reverse. | |

| Soft Start | The user may specify the time taken to start the conveyor after it has received a run signal. | |

| Soft Start/Stop | The user may specify the time taken to start the conveyor after it has received a run signal and the time for it to come to a complete stop once it has received a stop signal. | |

| Mode | Simple | |

| Command(Latch) | ||

| Command(State) | ||

| FwdRevMode | FwdOnly | This field is only visible if the Soft Start/Stop Type is chosen. |

| Logic | ||

| Regulation | ||

| Run / State / Enable / Permissive | Tick Box | The conveyor Belt is run enabled. The field name used will depend on the Type and Mode chosen. |

| Invert | Tick Box | This field is only visible if the Simple Mode is selected. It is not available for Type = Power & Speed. It inverts the direction of the belt. |

| Start | Tick Box | This field is only available if Command(Latch/State) Mode is selected. |

| Stop | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| StartInvert | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| StopInvert | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| Reverse | Tick Box | This field is only available for the Soft Start/Stop Type conveyor with the Logic FwdRevMode. This reverses the direction of travel of the conveyor belt. |

| Running | Tick Box | This displays the state of the conveyor belt. |

| Tripped | Tick Box | This allows the user to emulate the tripping of the conveyor belt for logic testing. |

| StartTime | Input | This field is only available for the Soft Start and Soft Start/Stop Type conveyors. It is time taken for the conveyor to go from 0 to 100% speed. |

| StopTime | Input | This field is only available for the Soft Start/Stop Type conveyor. It is the time taken for the conveyor to go from 100 to % speed. |

| Forward | Tick Box | This field is only visible for Type = Fwd Rev. If this box is ticked then the conveyor will run in a forward direction. |

| Manual | Input | The user may manually override the speed of the conveyor. |

| Required / Reqd | Input | The required speed of the conveyor belt. |

| Actual | Calc | The actual speed of the conveyor belt. |

| Regulated | Display | |

| MapLo | Input | This field is only visible for the Soft Start or Soft Start/Stop Type conveyor. |

| MapHi | Input | This field is only visible for the Soft Start or Soft Start/Stop Type conveyor. |

| MapSpeed | Calc | This field is only visible for the Soft Start/Stop Type conveyor. |

| LoSpeed | Calc | Belt is running on low speed. True if speed < LoSpeedLimit |

| HiSpeed | Calc | Belt is running on high speed. True if speed > HiSpeedLimit |

| LoSpeedLimit | Input | Low speed limit for the conveyor belt. |

| HiSpeedLimit | Input | High speed limit for the conveyor belt. |

| AutoReStart | Tick box | Auto restarts the belt. |

| FailMode | None | There is no user specified behaviour after a fail event. |

| No Start | The conveyor will not start. | |

| No Stop | The conveyor will not stop. | |

| No Start/Stop | The state of the conveyor cannot be changed. | |

| RunMemory | Tick box | Enable this to let the unit keep track of running status. |

Feeds

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| [FeedStreamTag]... The number of sections displayed here is equal to the number of conveyor feed streams. | ||

| StreamTag | Display | The tag of the feed stream. |

| Type | (the following two options are only available if the 'Fixed or Moving' FeedConnections option has been chosen on the front tab page. Otherwise the type of connection is forced by the choice on the front tab page) | |

| Fixed | The feed stream will not move and the user may set the feed distance along the conveyor. | |

| Moving | The feed position can move along the conveyor. The user may only set this option if they have enabled at least 1 Feed Drive. | |

| DriveNo | Input | This is only visible when Type = Moving. It allows the user to assign the appropriate feed drive number to the relevant feed stream. |

| Pos | Input / Calc | The position of the feed stream from the start of the conveyor. If the Type = Fixed, then the user may enter this value, otherwise it is a calculated field if the Type = Moving. If the BeltFeeder option is used then the position will be forced to the start of the belt (0m). |

| Limited | Feedback | If enabled (=1), the BeltFeeder option has been enabled and the user can limit the feed flow rate. If the BeltFeeder option has not been enabled, then this will be disabled (=0). |

| FullSpeedCapacity | Input | Only visible if the Limited option is enabled. This is the maximum capacity that can be fed onto the conveyor. This number will be passed back to the feed stream, thus limiting the flow from a tank or other surge unit to this capacity. |

| Qm | Calc | The mass flow rate of the feed stream. |

Products

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| [ProdStreamTag]... The number of sections displayed here is equal to the number of product streams connected to the conveyor. | ||

| StreamTag | Display | The tag of the product stream. |

| Type | (only some of the following options may be available depending on the ProdConnections option chosen on the front tab page. For 'Fixed', the first two options are available. For 'Fixed or Moving', the first three options are available. Otherwise the type of connection is forced by the choice on the front tab page) | |

| Fixed | The product stream will not move and the user may set the take-off distance along the conveyor. | |

| Fixed At End | The product stream will not move and the take-off distance is at the end of the conveyor. If the BeltFeeder option is used then this is the forced choice. | |

| Moving | The product position can move along the conveyor. The user may only set this option if they have enabled at least 1 Product Drive. | |

| Moving (DistributedBins) | This option will be forced if the 'Moving (over Bins)' ProdConnections option has been chosen on the front tab page. | |

| DriveNo | Input | This is only visible if Type = Moving. It allows the user to assign the appropriate product drive number to the relevant product stream. |

| Pos | Input / Calc | The take-off position of the product stream from the start of the conveyor. If the Type = Fixed, then the user may enter this value, otherwise it is a calculated field. This field is not visible if the 'Moving (over Bins)' ProdConnections option has been chosen on the front tab page. |

| BinStart | Input | Only shown if the 'Moving (over Bins)' ProdConnections option is used. The position of the start of the bin that is being feed by the product drive. This should be less than the total length of the conveyor belt. |

| BinWidth | Input | Only shown if the 'Moving (over Bins)' ProdConnections option is used. The width of the bin that is being feed by the product drive. BinStart + BinWidth should be less than or equal to the total length of the conveyor belt. |

| Removal | Input | The percentage of product removal. This option will be forced to 100% if the 'Moving (over Bins)' ProdConnections option has been chosen on the front tab page. NOTE: The last product stream must always have 100% removal if the Conveyor belt is not to spill.

Eg: If two product points are assigned and product 1 takes 40% and product 2 takes 60%, then the Removal for Product 1 should be specified as 40% and Product 2 should be specified as 100%. |

| Qm | Calc | The mass flow rate of the product stream. |

FeedDrives

One page for each feed drive. Please see Product Drive below for a description of the fields.

ProdDrives

One page for each product drive. Similar fields to the BeltDrive tab page.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tripper Drive Position Note: The product drive will only move IF the motor is running and the motor speed > 0%. | ||

| Control | None | The product drive will move forward or in the reverse direction, as governed by the direction of the motor. For Example: If the motor is running in the positive direction, then the product drive will move forwards until it reaches the maximum position and then stop at that point. When the motor is changed to the reverse direction the product drive will then start moving back to the minimum position. Note: The required position (Reqd) is ignored with this option. |

| FwdRev | The product drive will move towards the required positon (Reqd) and stop when it is reached. If Reqd = *, then the product drive will automatically tranverse backwards and forwards between the minimum and maximum positions. | |

| Full | This works the same as the FwdRev method. | |

| Reqd | Input | This is only used if the user has selected Control = FwdRev or Full. The user enters the required position of the product drive. If * is entered then the product drive will automatically tranverse backwards and forwards between the minimum and maximum positions. |

| Actual | Calc | This displays the actual position of the product drive. |

| Min | Input | The minimum point along the conveyor length to which the product drive may move, i.e. the point closest to the conveyor feed point. |

| Max | Input | The maximum point along the conveyor length to which the product drive may move. This is normally = the length of the conveyor. |

| MaxSpeed | Input | The maximum speed of the product drive. Normally this is slower than the travel speed of the conveyor belt. |

| Motor | ||

| Type | Power & Speed | If the power source is available the conveyor will run at the user specified speed. |

| Fwd Rev | The user may specify if the conveyor is running forwards or in reverse. | |

| Soft Start | The user may specify the time taken to start the conveyor after it has received a run signal. | |

| Soft Start/Stop | The user may specify the time taken to start the conveyor after it has received a run signal and the time for it to come to a complete stop once it has received a stop signal. | |

| Mode | Simple | |

| Command(Latch) | ||

| Command(State) | ||

| FwdRevMode | FwdOnly | This field is only visible if the Soft Start/Stop Type is chosen. |

| Logic | ||

| Regulation | ||

| Run / State / Enable / Permissive | Tick Box | The conveyor Belt is run enabled. The field name used will depend on the Type and Mode chosen. |

| Invert | Tick Box | This field is only visible if the Simple Mode is selected. It is not available for Type = Power & Speed. It inverts the direction of the belt. |

| Start | Tick Box | This field is only available if Command(Latch/State) Mode is selected. |

| Stop | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| StartInvert | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| StopInvert | Tick Box | This option is only available if Command(Latch/State) Mode is selected. |

| Reverse | Tick Box | This field is only available for the Soft Start/Stop Type conveyor with the Logic FwdRevMode. This reverses the direction of travel of the conveyor belt. |

| Running | Tick Box | This displays the state of the conveyor belt. |

| Tripped | Tick Box | This allows the user to emulate the tripping of the conveyor belt for logic testing. |

| StartTime | Input | This field is only available for the Soft Start and Soft Start/Stop Type conveyors. It is time taken for the conveyor to go from 0 to 100% speed. |

| StopTime | Input | This field is only available for the Soft Start/Stop Type conveyor. It is the time taken for the conveyor to go from 100 to % speed. |

| Forward | Tick Box | This field is only visible for Type = Fwd Rev. If this box is ticked then the conveyor will run in a forward direction. |

| Manual | Input | The user may manually override the speed of the conveyor. |

| Required / Reqd | Input | The required speed of the conveyor belt. |

| Actual | Calc | The actual speed of the conveyor belt. |

| Regulated | Display | |

| MapLo | Input | This field is only visible for the Soft Start or Soft Start/Stop Type conveyor. |

| MapHi | Input | This field is only visible for the Soft Start or Soft Start/Stop Type conveyor. |

| MapSpeed | Calc | This field is only visible for the Soft Start/Stop Type conveyor. |

| LoSpeed | Calc | Belt is running on low speed. True if speed < LoSpeedLimit |

| HiSpeed | Calc | Belt is running on high speed. True if speed > HiSpeedLimit |

| LoSpeedLimit | Input | Low speed limit for the conveyor belt. |

| HiSpeedLimit | Input | High speed limit for the conveyor belt. |

| AutoReStart | Tick box | Auto restarts the belt. |

| FailMode | None | There is no user specified behaviour after a fail event. |

| No Start | The conveyor will not start. | |

| No Stop | The conveyor will not stop. | |

| No Start/Stop | The state of the conveyor cannot be changed. | |

| RunMemory | Tick box | Enable this to let the unit keep track of running status. |

| Preset Values | ||

| Preset.Reqd | None | The Preset command will not affect the product drive motor or position. |

| Off | The preset command will cause the product drive motor to be turned off and position = the user defined preset position. | |

| Forward | The preset command will cause the product drive motor to run in the forward direction from the user defined preset position. | |

| Reverse | The preset command will cause the product drive motor to run in the reverse direction from the user defined preset position. | |

| Preset.Posn | Input | The required position of the product drive if the Preset command is enabled. |

WtMtrs

This section is visible if Number of Weightometers (NWeightometers) is greater than 0.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| WtMtr.[0]... The number of sections displayed here is equal to the number of weightometers specified on the first Tab. | ||

| Pos | Input | The position of the weightometer. |

| Loading | Calc | The loading at this position. |

| FullLoadFrac | Calc | Only visible if the "ShowFullLoadFrac" option is selected on the "ConveyorBelt" tab page. Shows the full loading fraction. |

| Rate | Calc | The mass flowrate passing this position. |

Loading

This section is visible if the "ShowLoading" option is selected on the "ConveyorBelt" Tab.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Belt Loading Profile | ||

| Load.DistLength | Input | The number of sections to be displayed in the Belt loading table. |

| Load.Norm.Method | Full Load | All loads will be displayed as normalised values based on the Full load specified by the user on the ConveyorBelt tab. |

| Max Spill Load | All loads will be displayed as normalised values based on the maximum spillage load specified by the user on the ConveyorBelt tab. | |

| Current Max | All loads will be displayed as normalised values based on the current maximum load on the Belt. | |

| Manual Max | All loads will be displayed as normalised values based on a user specified maximum load. | |

| Load.Norm.Max | Input | Only visible if the user has selected Manual Max. This allows the user to set the manual maximum value for displaying the loading on the Belt. |

| Mass.Norm.Method | Current Max | All masses will be displayed as normalised values based on the current maximum mass the Belt. |

| Manual Max | All masses will be displayed as normalised values based on a user specified maximum mass. | |

| Mass.Norm.Max | Input | Only visible if the user has selected Manual Max. This allows the user to set the manual maximum value for displaying the mass on the Belt. |

| LoadPts Table | This first table shows the Load and the Normalised Load at positions along the Belt. The positions are calculated based on the Load.DistLength chosen by the user. These values are for display purposes only. | |

| LoadBins Table | This second table shows the Average Load and Normalised Average Load and the Mass and Normalised Mass on sections of the Belt. The length of the sections is calculated based on the Load.DistLength chosen by the user. These values are for display purposes only. | |

| Belt Loading Profiles shown above built from ___ underlying Sections. Available in Build 138 or later. The variables below show the underlying belt sections. | ||

| NSections | Display | The number of sections into which the Conveyor Belt is divided. For internal recording purposes only. NOTE: If material has the same (or within tolerance) composition, loading and temperature (see MinSect on the First Tab page), they will be merged into the same section. |

| SectionsData | Copy To Clipboard | Copies the number of section data (see NSections above) onto clipboard, user can analyse the data in other packages, mainly used for debugging purposes. |

| Sections.FirstStart | Display | The belt length where the first section starts (contains material) |

| Sections.LastEnd | Display | The belt length where the last section ends (contains material) |

| Sections.TotalLength | Display | The total belt length with material loaded. |

| Sections.SmallestLength | Display | The belt length of the shortest section. |

| Sections.LargestLength | Display | The belt length of the largest section. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | MatHand1.dll |

→ | Units/Links | → | Material Handling: Conveyor Belt | |

| or | Group: | Mass Transfer |

→ | Units/Links | → | Material Handling: Conveyor Belt |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Material Handling | → | Conveyor Belt |

See Insert Unit for general information on inserting units.