Discussion: Alumina Precipitation and Classification with PSD

Navigation: Product Blog ➔ Discussion Pages ➔ Alumina Precipitation and Classification with PSD

Related Links: Alumina Precipitation and Classification with PSD Example Project, Alumina3 Precip - Full PSD

Introduction to Discussion Pages

Hello and welcome to our first discussion page! These pages will be written in a more informal style by SysCAD developers and engineers, with a focus on new features and advanced techniques. Generally, these posts are targeted at existing users, and will require a more in-depth understanding of SysCAD and specialty engineering topics. Topics will cover how X is done in SysCAD, rather than SysCAD can do X as presented in our online marketing materials (LinkedIn, our website, etc.).

These discussion pages are supplementary material, and are not part of the "official" SysCAD documentation. As such, these pages may become outdated as time progresses.

We would love to hear from you if you find this discussion page useful or have any questions or comments on the technical content. Please reach out to us at [email protected].

With that said, on to business...

Alumina Precipitation and Classification Example Project

With the release of Build 139.29552, we included a new example project: Alumina Precipitation and Classification with PSD. This builds on two older examples:

- Precipitation Project using Full PSD

- Precipitation Project using Full PSD with Oxalate Co-precipitation

The goal of this example project is to demonstrate some of the newer Precipitation3 unit model features while targeting key real-world PSD values throughout the precip and classification circuit. This example project is designed to be a reasonable starting point from which to start your own plant-specific model. The project requires both the Alumina and Size Distribution add-ons.

Please feel free to open a copy of the model while reading this. The project is located at: ..\SysCADXXX\Examples\10 Alumina\PSD Precipitation & Classification Example.spf (available with the latest version of Build 139 or later). This article assumes a basic knowledge of the Bayer process and alumina hydrate crystallisation.

Here we'll run through an overview of the process and controls, and the key SysCAD features used. We'll also look at the challenges faced in building the model and where future improvements could be made when adapting this example to real-world applications.

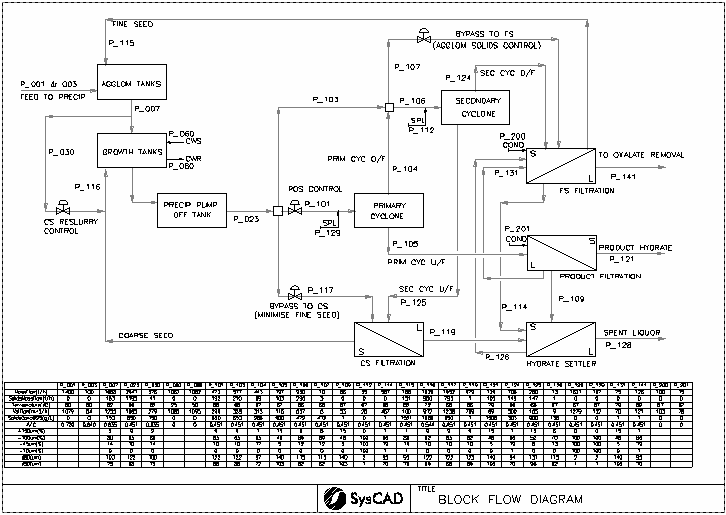

Process Overview

A block flow diagram of the process is given on graphics page 99 BFD. Within the Precipitation area, feed liquors are mixed with fine seed (FS) in Agglom and coarse seed (CS) is added to Growth. Pump-off slurry (POS) is processed in Classification to produce recycled FS and CS streams, as well as product hydrate, spent liquor, and fine seed wash (FSW) for oxalate removal treatment. This design represents a fairly standard precip and 2-stage class circuit.

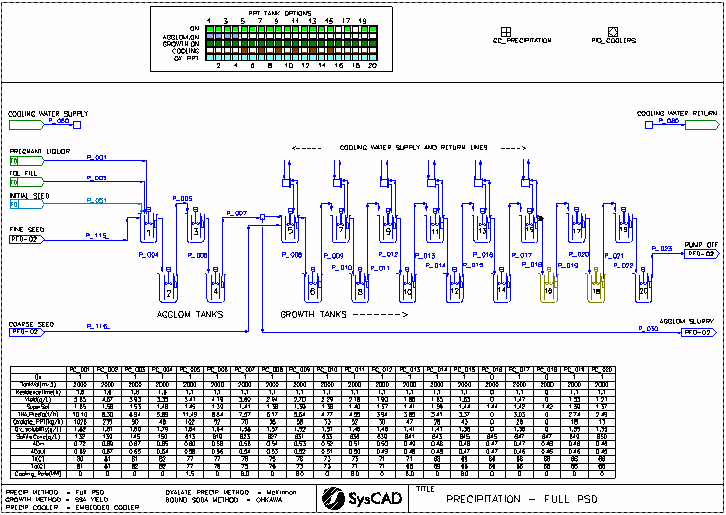

Precipitation Area

In precip (shown on graphics page 01 Precipitation), fixed flows of pregnant liquor (PGL) and filtered dilution liquor (FDL) are added to the lead agglom tank, along with FS from class. The FS is not reslurried, though this could be done using PGL or FDL without changing the mass balance.

From the end of agglom, a portion of agglomeration slurry (APS) is taken to reslurry CS (controlled by Set Tag Controller ratio to CS flow). The remaining APS and returning CS slurry are added to the lead growth tank. Along the growth train, odd-numbered precip tanks 5-15 are supplied with cooling water, using Embedded cooler and Demand flows. Pump-off slurry (POS) from the last tank is sent to the Classification area.

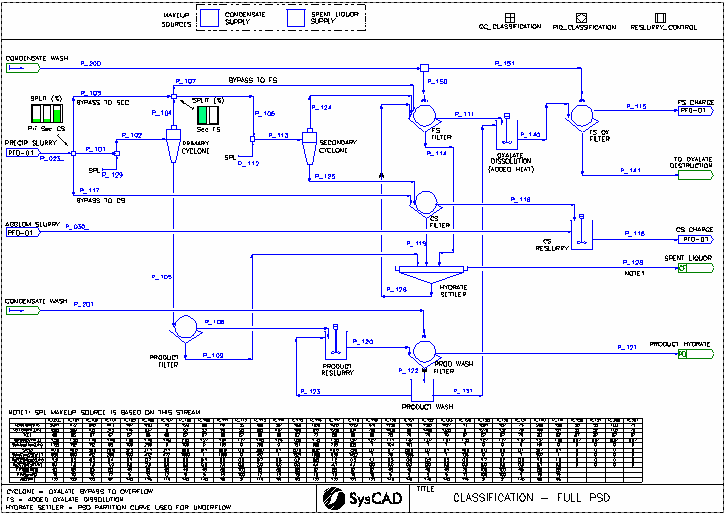

Classification Area

In class (graphics page 02 Classification), POS is split between primary and secondary cyclones, and direct bypass to CS filtration. Cyclone feeds are diluted with SPL using a Makeup Source. The primary cyclones produce product hydrate in the underflow (U/F), and the overflow (O/F) is split between secondary cyclone and direct bypass to FS filtration. Secondary cyclones split CS to U/F and FS to O/F.

Each of the seed streams are deliquored across filters; deliquored FS and product are also washed in a second filtration stage. FS is returned directly to agglom, CS is reslurried with APS and sent to growth, and product hydrate is removed from the system. Filtrate from each of the deliquoring filters is sent to the hydrate settler to recover a small amount of FS and produce a clarified SPL stream, which is also removed from the system.

In a full plant model this SPL stream would typically connect through heat exchange to an evaporation area. Filtrate from the FS dewatering filter may be sent to an oxalate destruction area. Product wash filtrate (PWF) is used to reslurry deliquored product hydrate, as well as for oxalate dissolution in the fine seed tank.

Target Values and Controls

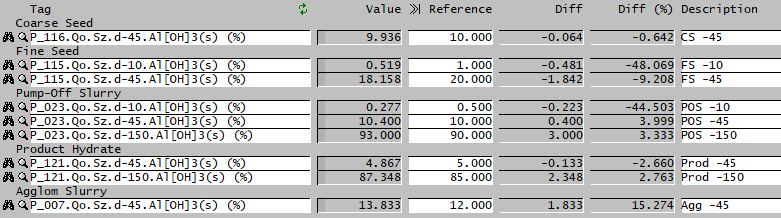

Several key values are targeted through the circuit. These are recorded in GC_PRECIPITATION.

| Measurement | Target Value | Note |

|---|---|---|

| APS Solids | 150 g/L | Controlled by Primary Cyclone O/F bypass to FS Filters. Note: This should be in control but minimised, this is ensured by cascade controller for POS split to Secondary Cyclones. |

| POS Solids | 650 g/L | Controlled by POS split to Primary Cyclones. The remainder is sent directly to CS Filters. |

| Precip Cooling | 1.5-6.0 MW | Controlled by Cooling Water flow to Precip Tanks via Demand. |

Various target PSD values are presented in the included TagList document. These were taken from literature[1] and past experience to represent a generic base case. These PSD values were manually controlled by manipulating various PSD tuning parameters in the Precip tanks, especially the Agglom.Rate.Correction and Agglom.Cutoff.Size factors in the agglom tanks. If you have the example project open, try modifying these values to see their impact.

Challenges and Tips

- A bypass to FS stream is included in case insufficient fine seed is produced to maintain APS solids. A cascade control is implemented to ensure this bypass is in control but minimised (target 1%). In the base case, this bypass could be set to zero and APS solids controlled directly with POS split to Secondary Cyclones.

- The cyclones and filters are configured using generic values. These should be reviewed when configuring a real-world model.

- Previous alumina PSD example projects did not include a POS solids controller, such that circuit solids load was entirely determined by PSD and cyclone splits. Inclusion of this control allows for much more realistic solids and PSD values, while also maintaining a more stable system for solving and tuning.

- Agglomeration PSD option is only enabled in the agglom tanks. This is done for computational efficiency, as the majority of agglom is performed in these tanks. This may be enabled in growth tanks additional accuracy, though additional tuning is also likely required.

- Agglomeration is configured using the new Build 139 default settings: Ilievski kernel, Growth/Beta4(T) rate and Free-in-Space collision. Please see documentation on Agglomeration for full details.

- An Initial Seed feed is included for the first few steps of every solve to ensure an initial Hydrate PSD and oxalate solids feed after reset.

- The included Excel report "Project Report Example.xlsx" contains a PSD Data tab with a useful visualisation of the full PSD of each of the key streams.

References

- [1] D.R. Audet, R. Little, N.J. Hofstee (2012) "Stabilisation of Product Quality at Yarwun Alumina Refinery", Proceedings of the 9th International Alumina Quality Workshop

First Posted: 26 October 2021

Reference Build: 139.29552

For questions or feedback, please contact us at [email protected].