Valve 2

Navigation: Models ➔ Pressure Changing Models ➔ Valve 2

General Description

The Valve 2 model is only used in dynamic projects with Transfer mode, normally as part of the Piping System Model. It allows users to set the valve opening and calculates the pressure drop due to flow. The valve will NOT control the flow, but the user can use the pressure drop results to set the flow through the Piping System Model.

The valve has two main operating classes:

- Simple - the user may NOT control the valve, it acts as pressure drop unit only. This is only useful for valves that are always open.

- Controlled - The user may control the valve position and the pressure drop across the valve will vary accordingly.

The user may select a number of methods within these two classes for calculating the pressure drop:

- Simple:

- Fixed Drop - the pressure drop across the valve is a fixed value, irrespective of flow.

- Fixed Exit Pressure - the exit pressure from the valve is a fixed value, irrespective of flow.

- Fixed Atmospheric Pressure - the exit pressure from the valve = Atmospheric pressure, irrespective of flow.

- Pressure drop proportional to mass flow through the valve - a simple linear function relating pressure drop to mass flow will be used. This method does not allow the user to set the valve position.

- Controlled:

- Cv Lookup - use the valve Cv values;

- Pressure drop proportional to valve position - a simple linear function relating pressure drop to valve position will be used; and

- K Open Closed - The valve can only be either fully open (100%) or fully closed (0%). The user specifies the K value for the fully open valve.

Diagram

The diagram shows the default drawing of the Valve, with the required connecting streams. The unit will not operate unless all of the above streams are connected.

The physical location of the connections is not important; the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Input | Required | In | 1 | 1 | Input stream to valve. |

| Output | Required | Out | 1 | 1 | Output stream from valve. |

Model Theory

Valve Characteristics

Data Sheets for valves provide a range of information, but we are typically interested in the flow characteristics. This is usually described by a discharge coefficient.

The standard coefficients are [math]\displaystyle{ C_v }[/math] and [math]\displaystyle{ K_v }[/math].

- [math]\displaystyle{ C_v }[/math] is defined as:

- The volume of water in US gpm that will pass through a given opening at a pressure drop of 1psi at 60F

- For the metric system we have a [math]\displaystyle{ K_v }[/math]:

- The volume of water in m[math]\displaystyle{ ^3 }[/math]/h that will pass through a given opening at a pressure drop of 1 bar at 20C

These are related via [math]\displaystyle{ K_v = 0.865C_v }[/math]. Since most data is presented as [math]\displaystyle{ C_v }[/math], we will use this in the subsequent discussion.

The data sheets will provide either tables or graphs of [math]\displaystyle{ C_v }[/math] vs the valve opening.

Valve Opening |

There are different actuators depending on the type of valve, Butterfly and ball valves have rotational actuators which take the valve from closed to open by turning a shaft through 90o, so data for these is typically presented as [math]\displaystyle{ C_v }[/math] vs angle

Linear actuators shift a valve stem up and down to open and close the valve. In this case the data is typically presented as [math]\displaystyle{ C_v }[/math] vs fraction, where 0% corresponds to the valve fully closed, and 100% is fully open. |

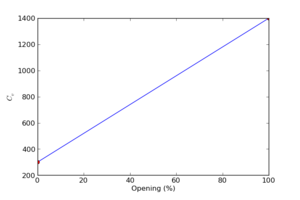

Linear Response |

In simple cases the valve [math]\displaystyle{ C_v }[/math] just varies linearly between fully closed and fully open. There are valves (annular butterfly valves) that do not close off fully when closed, so the [math]\displaystyle{ C_v }[/math] is not necessarily zero |

Cv implementation

Because of these different ways of representing valve characteristics, we implement several variations of specification of valve data.

Single Point |

In this case a single coefficient is specified, corresponding to the flow for the valve fully open. For a partially open valve, the flow coefficient is just scaled proportionally. |

2pts (100% interval) |

In this case we just provide a Cv for fully closed and fully open and assume the Cv varies linearly between these values. Please note that the Cv at 0% may be non-zero if the valve does not close completely. |

3 to 11 pts |

Sometimes the manufacturer will only supply charts of data. If the curve is smooth enough, it is possible to determine the Cv from just a few data points taken from the plot. The 3pts (50% interval) and 5pts (25% interval) cases let you supply 3 or 5 data points from a curve. If the data is represented as a fraction of opening, then we supply 11 data data points, corresponding to opening of 0%, 10%, 20%, ... 100%. |

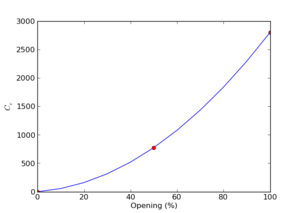

Quadratic Response |

In theory, the pressure drop through a valve is given by [math]\displaystyle{ \Delta p = \frac12 K \rho v^2 }[/math] So the typical variation of Cv with area is just quadratic. This option allows you to specify a single Cv (fully open) and the actual Cv will be calculated by [math]\displaystyle{ C_v = (\frac x{100})^2 \times C_{vo} }[/math] |

Angle |

For this option, values of Cv are specified at 10 degrees intervals from 0 degrees (fully closed) to 90 degrees (fully open). Each interval represents 11.11% of valve position. |

Data Sections

Summary of Data Sections

- Valve2 tab - Allows the user to set the valve position and displays the calculated results.

- Settings Tab - Allows the user to specify the valve method and enter the required data.

- QFeed - Available from Build 139. Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- QProd - Available from Build 139. Optional tab, visible if ShowQProd is enabled. This and subsequent tab pages, e.g. QProd.. and Sp, shows the properties of the product stream. The tags in the QProd tab are valid even when the ShowQProd option is not selected.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Valve2 Page

Unit Type: Valve2 - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

|

Requirements | ||

| On | Tick Box | This allows the user to disable the valve. If the valve is Off then the pressure drop across the valve = 0. |

ControlThis is only visible if the method chosen allows the valve to be controlled. | ||

| Position.Reqd | Input | The required valve position. Normally this is any value between 0 and 100%. However, if the user has selected Operating type K Open Closed, then only 0 and 100% are allowed. |

| Position.Actual | Display | The actual valve position. This is normally equal to the required position. However, if the user has specified a stroke time, then the actual position will lag the required position by the stroke time. |

| Open Valve | Button | Clicking on this button will open the valve to 100%. |

| Close Valve | Button | Clicking on this button will close the valve to 0%. |

| Open | Tick Box | If this is True then the valve is Open. |

| Closed | Tick Box | If this is True then the valve is Closed. |

| Position.Changing | Tick Box | If this is True then the valve is moving. |

| Options | ||

| ShowQFeed | Tickbox | Available from Build 139. When selected, the QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the feed stream. See Material Flow Section. Tags in the QFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQProd | Tickbox | Available from Build 139. When selected, the QProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the product stream. See Material Flow Section. Tags in the QProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

Results | ||

| Ti | Calc | The inlet temperature to the valve. |

| Pi | Calc | The inlet pressure to the valve. |

| Valve.dP | Calc | The pressure change across the valve. |

| Minor.dP | Calc | The pressure change across the valve entry and exit, if specified. |

| dP | Calc | The total pressure change across the overall unit, valve and entry and exit. |

| Po | Calc | The outlet pressure from the overall unit, valve and entry and exit. |

| Cv | Calc | The Cv of the valve at the actual valve opening. |

| Velocity | Calc | The calculated velocity through the valve. |

| ValveK | Calc | The calculated resistance, or loss coefficient value, K, of the valve at the actual valve opening and the entry and exit. |

| TotalK | Calc | The calculated resistance, or loss coefficient value, K, of the overall unit, valve and entry and exit. |

| Total | ||

| Valve.dP | Calc | The total pressure change across the overall valve. |

| dP | Calc | The total pressure change across the overall unit, valve and entry and exit. |

| PDrop | Calc | The total pressure drop across the overall unit, valve and entry and exit. (This will be the opposite sign to the field above) |

| K | Calc | The calculated resistance, or loss coefficient value, K, of the valve at the actual valve opening and the entry and exit. |

| Stream In and Out Summary | ||

| PressChange / dP | Calc | The total pressure change across the valve. |

| MassFlow / Qm | Calc | The mass flow rate through the valve. |

| TemperatureIn / Ti | Calc | The inlet temperature to the valve. |

| TemperatureOut / To | Calc | The outlet temperature from the valve. |

| PressIn / Pi | Calc | The inlet pressure to the valve. |

| PressOut / Po | Calc | The outlet pressure from the valve. |

| VolFlowIn / Qvi | Calc | The volume flow into the valve. |

| VolFlowOut / Qvo | Calc | The volume flow out of the valve. |

| DensityIn / Rhoi | Calc | The density of material at the inlet of the valve. |

| DensityOut / Rhoo | Calc | The density of material at the outlet of the valve. |

| VapourFracIn / Vfi | Calc | Vapour Mass Fraction at the inlet of the valve. |

| VapourFracOut / Vfo | Calc | Vapour Mass Fraction at the outlet of the valve. |

Settings

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Settings | ||

| On | Tick Box | This allows the user to disable the valve. If the valve is Off then the pressure drop across the valve = 0. |

| EquipID | Input | This field is optional. The user may type in an unique ID for the valve. |

There are two different operating classes of valve:

| ||

| OpType | Fixed Drop (Simple) | The user may specify a fixed pressure drop across the valve. |

| Fixed ExitP (Simple) | The user may specify a fixed exit pressure from the valve. | |

| Fixed AtmosP (Simple) | The exit pressure from the valve = atmospheric pressure. | |

| dP Prop to mass Flow (Simple) | The pressure drop across the valve will be proportional to the mass flow through the valve. The user may NOT set the valve position if this operating mode is used, as the mass flow is the only variable used to calculate pressure drop. | |

| Cv Lookup (Controlled) | Use Cv values to calculate the pressure drop across the valve, based on the user defined valve position. | |

| dP Prop to Posn (Controlled) | The pressure drop across the valve will be proportional to the user defined position of the valve. | |

| K Open Closed (Controlled) | The user defines the K value for the 100% open valve. This type of valve may either be fully open (100%) or fully closed (0%) and no other position. | |

| Fixed Drop (Simple) The following field is visible with this mode. | ||

| FixedDrop | Input | The required pressure drop when the valve is in the fully open position. |

| Fixed ExitP (Simple) The following field is visible with this mode. | ||

| FixedP | Input | The required outlet pressure from the valve in the fully open position. |

| dP prop to MassFlow (Simple) The following 3 fields are visible with this mode. | ||

| PressDrop.NoFlow | Input | The required pressure drop when there in no flow through the valve. |

| PressDrop.NominalFlow | Input | The required pressure drop when there is nominal flow (specified below) through the valve. |

| NominalFlow | Input | The nominal flow through the valve. Used for the pressure drop calculations. |

| dP Proportional to Position (Controlled) The following 2 fields are visible with this mode. | ||

| PressDrop.Open | Input | The required pressure drop when the valve is in the fully open position. |

| PressDrop.Closed | Input | The required pressure drop when the valve is in the fully closed position. |

| K Open Closed (Controlled) The following 2 fields are visible with this mode. | ||

| Diameter | Input | The required diameter of the valve. |

| UserValveK | Input | The required K value of the valve in the fully open position. |

| Cv Lookup (Controlled) The following fields are visible with this mode. | ||

| Diameter | Input | The diameter of the entry pipe into the valve. |

| MinorK | Input | The K value for the minor pressure losses into and out of the valve. |

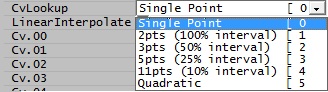

| CvLookup (see Model Theory) |

Single Point | In this case a single coefficient is specified, corresponding to the flow for the valve fully open. For a partially open valve, the flow coefficient is just scaled proportionally. |

| 2pts (100% interval) | Provide a Cv for the valve in the fully closed and fully open positions and assume the Cv varies linearly between these values. | |

| 3pts (50% interval) | Provide Cv values for the valve for 0, 50 and 100% positions. | |

| 5pts (25% interval) | Provide Cv values for the valve at 25% intervals. | |

| 11pts (10% interval) | Provide Cv values for the valve at 10% intervals. | |

| Quadratic | If the variation of Cv with open area is quadratic then you can specify a single Cv (fully open) and the actual Cv will be calculated using the quadratic equation given in Model Theory. | |

| Angle | Provide Cv values at 10 degree intervals for 0 (CV01, fully closed) to CV10 (90 degrees, fully open). | |

| Cv00.. | Input | Depending on the Cv Lookup option chosen above, this may be a single field, or up to 11 fields for the user to enter the Cv values for the valve. |

| LinearInterpolate | Tick Box | This option is only visible if the user chooses 3, 5 or 11 points. If this is enabled then the model will interpolate linearly between the individual points. |

| Stroke Times The following fields are visible if dP proportional to Position or Cv Lookup are chosen. | ||

| StrokeTimeMode | None | The actual valve position will move to the required position with no delay time. |

| Single Stroke Time | There will be a fixed delay between setting the required valve position and when the actual valve position reaches the required position. | |

| Open/Close Stroke Time | The delay between setting the required valve position and when the actual valve position reaches the required position will be different for opening and closing settings. | |

| StrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position. Visible if Single Stroke Time is selected. |

| OpenStrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position, if the valve is opening. Visible if Open/Close Stroke Time is selected. |

| CloseStrokeTime | Input | The required delay between setting the required valve position and when the actual valve position reaches the required position, if the valve is closing. Visible if Open/Close Stroke Time is selected. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Piping2.dll |

→ | Units/Links | → | Piping: Valve(2) | |

| or | Group: | Mass Transfer |

→ | Units/Links | → | Piping: Valve(2) |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Piping | → | Valve(2) |

See Insert Unit for general information on inserting units.