Urea Demonstration Project

Jump to navigation

Jump to search

Navigation: User Guide ➔ Example Projects ➔ 81 Urea

Urea Project

Project Location

This is a Steady State project and is stored at:

..\SysCADXXX\Examples\81 Urea\Demo Urea Project.spf

Features Demonstrated

- Various processes including synthesis, decomposition, hydrolysis, granulation, separation, evaporation, condensation and off gas scrubbing.

- Reactions including Reaction Heat Exchange.

- Heat Exchanger model (Build 138) or Shell and Tube Heat Exchanger 2 (Build 139 or later).

- Gas Pump model.

- User Property Calculations

- Use of General and PID controllers.

- Use of sample Excel report.

Brief Description

- This project simulates a Urea plant. Ammonia (NH3) and carbon dioxide are reacted together to form a urea solution. The urea solution undergoes decomposition and a two-stage evaporation process to produce urea melt. The urea melt is granulated to produce solids urea granulated product. This model is provided as a template, starting data is an estimate only.

Project Configuration

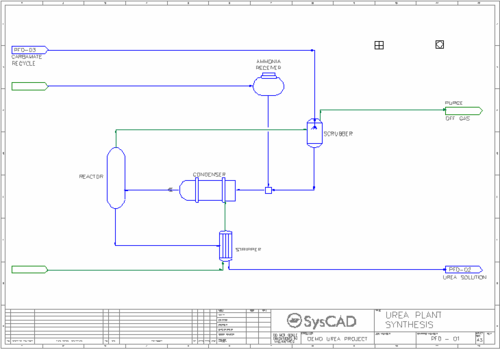

- Synthesis Circuit

- Liquid carbon dioxide is reacted with liquid ammonia in a Reactor to produce liquid Urea and other by-products. The reactions occur at 180 °C and 140 barg pressure.

- A PID controller is used to control the Nitrogen to Carbon ratio in the Reactor outlet by varying the feed rate of the carbon dioxide gas.

- The offgas from the reactor is scrubbed with carbamate recycle solution.

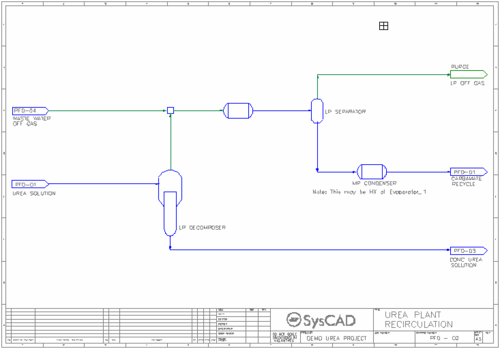

- Recirculation Circuit

- Urea solution from the Synthesis circuit is undergoes decomposition reactions in the Low Pressure (LP) Decomposer. The reactions occur at 180 °C and 4.5 barg pressure.

- Over half of the urea is converted to ammonium carbamate.

- The offgas from the decomposer mixes with the waste water off gas stream and a series of condensation and separation processes produce an offgas stream and a carbamate recycle stream which is returned to the Synthesis circuit.

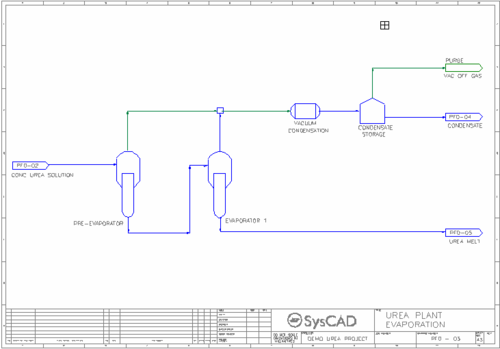

- Evaporation Circuit

- Concentrated urea solution from the Recirculation circuit is passed through a two-stage evaproation process at 135 °C and 0.3 bar pressure (second stage).

- A small fraction of the water evaporates while a small fraction of the urea decomposes to carbon dioxide and ammonia.

- The product from the evaporation process is a urea melt stream.

- The offgas from the evaporators is condensed and after separation of the non-condensables, a condensate stream is produced. The feed to the condensation is under vacuum but the final product is at atmospheric pressure.

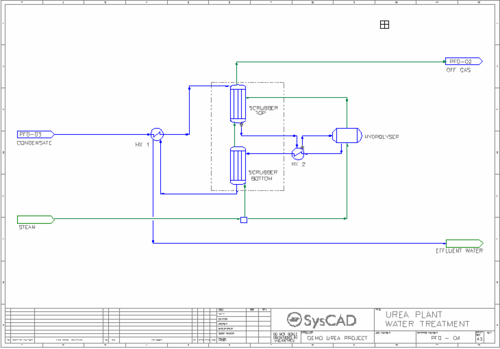

- Water Treatment Circuit

- Condensate from the Evaporation circuit is passed through a series of heat exchangers, scrubbers and a hydrolyser to produce an effluent water stream and an offgas stream.

- Steam is fed to bottom scrubber and hydrolyser.

- Within the hydrolyser, any remaining urea and biuret are decomposed to carbon dioxide and ammonia.

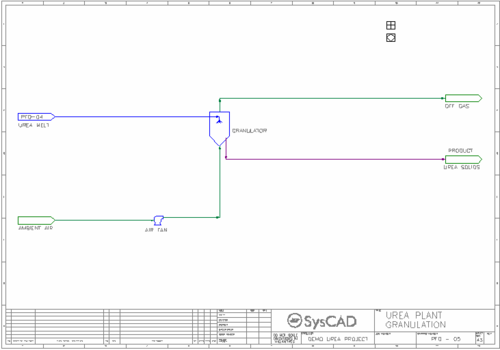

- Granulation Circuit

- Urea melt from the Evaporation circuit is sent to a granulator which produces a granulated solid urea product and an offgas stream.

- Ambient air is fed to the granulator after a pressure boost in the Air Fan.

- A PID controller is used to control the final moisture content of the urea product by varying the evaporation of water in the granulator.

- A PID controller is used to control the temperature of the urea product by varying the amount of ambient air fed to the granulator.

- Setting up and Viewing User Property Calculation

- One focus of this example is to show the user how to add in a user property calculation for their project. Once defined, the user property calculation will be available for all the unit operations in the project.

- In Step 2 of Edit Configuration file, add the user property calculation on the Calculations tab.

- One User Property Calculation has been added for NtoC, the elemental ratio of nitrogen to carbon. This will be visible on the Qo/QFeed/QProd tabs on the access window.

Notes:

- Indirect heating and cooling flows are not shown. Instead Reaction Heat Exchange (RHX) functionality is employed.

- Pumps and compressors are not included, pressures are set in vessels.

- Reaction extents are set in Reaction Blocks directly.

- Generally, all reactions occur in the liquid phase. Product gases are evolved afterwards.

Excel Report

- Urea Demo Report shows an example of a report that can be easily setup using the provided default 04DetailedReport.xlsx file.