PGM Example - PGM Class to assist with solving sensitive PID control loops

Jump to navigation

Jump to search

Navigation: PGMs ➔ Example PGM Files ➔ PGM Example - PGM Class to assist with solving sensitive PID control loops

Related Links: Defining a Class

This PGM class is useful for PID loops with a fast response where oscillations can occur between consecutive iterations for high gain values. Where the response is more slow, i.e. where the control point and measured point in the model are separated by a number of units, this class may not work well.

;This class is used to optimise the value of the gain for a PID controller and apply deadband

DropList Options{"Maximum Gain", "Minimum Gain", "Geometric Mean"}

EnumDropList DeadbandOptions { No_Deadband, Use_Controller_Tolerance, Specified}

Class Class_OptimiseGain

ClassGridColumnWidth 20 ;if you want multiple optimisers displayed as a grid, set this value so that the column displays are wide enough, search for ClassGrid for more details

TextLabel ," ======== Optimise PID Gain ========"

Integer ClassAsArray

String UnitNameTag@{Tag}

Integer PID_Number*<<1>>

String PID_Name@{Tag} ;full name of the PID controller

String PID_Description@ ;description given to the controller by the user

Memo PID_Description2@

CheckBox Optimiser_On*<<1>>

CheckBox SetOutput_MinMax*<<0>>

DeadbandOptions DeadbandOpt*<<No_Deadband>>

Textbreak

Options InitGain*<<0>>{Comment("Initial Gain (if RelError > 0.1%)")}

Real MaxGain*<<0.05>><1e-12,> ;the maximum gain that will be used

Real MinGain*<<0.0001>><1e-12,> ;the minimum gain that will be used (also used as the initial value)

Real CurGain@ ;current gain

Real MinPB@@{Comment("1/MaxGain")}, MaxPB@@{Comment("1/MinGain")}, CurPB@@{Comment("1/CurGain")}

Integer ItersBetweenGainDecrease*<<5>> ; iterations between gain decrease

Integer ItersBetweenGainIncrease*<<100>> ; iterations between gain increase

Real AdjustmentFactor*<<2>><1.1,10> ; adjustment factor for division or multiplication

Real Deadband*<0,100>{comment("Used if Deadband == Specified")}

Textbreak

Real OutputMin**, OutputMax**<<10>>

String GainTag@@{Tag}, SPTag@@{Tag}, MeasTag@@{Tag}, RelErrorTag@@{Tag}, OutMinTag@@{Tag}, OutMaxTag@@{Tag}

String RelativeTolTag@@{Tag}, AutoTag@@{Tag}

Real OldDiff ;holds the previous error

Real Diff ;holds the current error

Integer classtag_length, ItersSinceLastDecrease, ItersSinceLastIncrease

Bit IsFirstIteration, SetOutputState

Sub Initialise()

;Check if the Class is defined as an array, if so, need to remove [index] from the ClassTag()

ClassAsArray = StrFind(ClassTag(), "[" )

if ClassAsArray == -1

UnitNameTag = ClassTag()

Else

classtag_length = StrLen(ClassTag())

UnitNameTag = Left(ClassTag(), ClassAsArray)

Endif

;calculate and store the PID tags

PID_Name = Concatenate(UnitNameTag,".Cfg.[", InttoStr(PID_Number),"]")

GainTag = Concatenate(PID_Name,".Gain")

SPTag = Concatenate(PID_Name,".SptUsed")

MeasTag = Concatenate(PID_Name,".Meas")

RelErrorTag = Concatenate(PID_Name,".RelError (Frac)")

OutMinTag = Concatenate(PID_Name,".OutMin")

OutMaxTag = Concatenate(PID_Name,".OutMax")

RelativeTolTag = Concatenate(PID_Name,".Tol.Rel")

AutoTag = Concatenate(PID_Name,".Auto")

;initialise key values

ItersSinceLastDecrease = 0

ItersSinceLastIncrease = 0

SetConcealedState(OutputMin, (SetOutput_MinMax==False))

SetConcealedState(OutputMax, (SetOutput_MinMax==False))

SetOutputstate = SetOutput_MinMax

IsFirstIteration = True

PID_Description = [Concatenate(UnitNameTag,".Cfg.[",InttoStr(PID_Number),"].Name")]

PID_Description2 = [Concatenate(UnitNameTag,".Cfg.[",InttoStr(PID_Number),"].Description")]

EndSub

Sub Optimise()

If (Optimiser_On)

If (IsFirstIteration)

If (Abs([RelErrorTag]) > [RelativeTolTag]) ;if not currently converged

If InitGain == 0 ;start at max gain

[GainTag] = MaxGain

ElseIf InitGain == 1 ;start at min gain

[GainTag] = MinGain

ElseIf InitGain == 2 ;start at geometric mean

[GainTag] = Sqrt(MinGain * MaxGain)

EndIf

EndIf

CurGain = [GainTag]

OldDiff = [RelErrorTag]

IsFirstIteration = False ;reset flag

EndIf

;grab current error

Diff = [RelErrorTag]

If (Diff * OldDiff < 0) ;error has switched sign (oscillating around SP) - decrease gain

If (ItersSinceLastDecrease > ItersBetweenGainDecrease)

CurGain = Max(CurGain/AdjustmentFactor, MinGain)

[GainTag] = CurGain

ItersSinceLastDecrease = 0

EndIf

Else ;error has the same sign (approaching SP) - increase gain

If (ItersSinceLastIncrease > ItersBetweenGainIncrease)

CurGain = Min(CurGain*AdjustmentFactor, MaxGain)

[GainTag] = CurGain

ItersSinceLastIncrease = 0

EndIf

EndIf

;update counter and previous error

ItersSinceLastDecrease = ItersSinceLastDecrease + 1

ItersSinceLastIncrease = ItersSinceLastIncrease + 1

OldDiff = Diff

;apply deadband

if (DeadbandOpt == No_Deadband)

[AutoTag] = 1

elseif (DeadbandOpt == Specified)

[AutoTag] = (abs([RelErrorTag]) > Deadband)

elseif (DeadbandOpt == Use_Controller_Tolerance)

[AutoTag] = (abs([RelErrorTag]) > [RelativeTolTag])

endif

endif

;update concealed state of output min/max if changed

If SetOutput_MinMax <> SetOutputState

SetConcealedState(OutputMin, (SetOutput_MinMax==False))

SetConcealedState(OutputMax, (SetOutput_MinMax==False))

SetOutputState = SetOutput_MinMax

EndIf

;update PID output min/max

If SetOutput_MinMax

[OutMinTag] = OutputMin

[OutMaxTag] = OutputMax

EndIf

CurPB = 1/CurGain

MaxPB = 1/MinGain

MinPB = 1/MaxGain

EndSub

EndClass

;Please make sure there is no dollar sign or end of file marker here for this to be an include file.

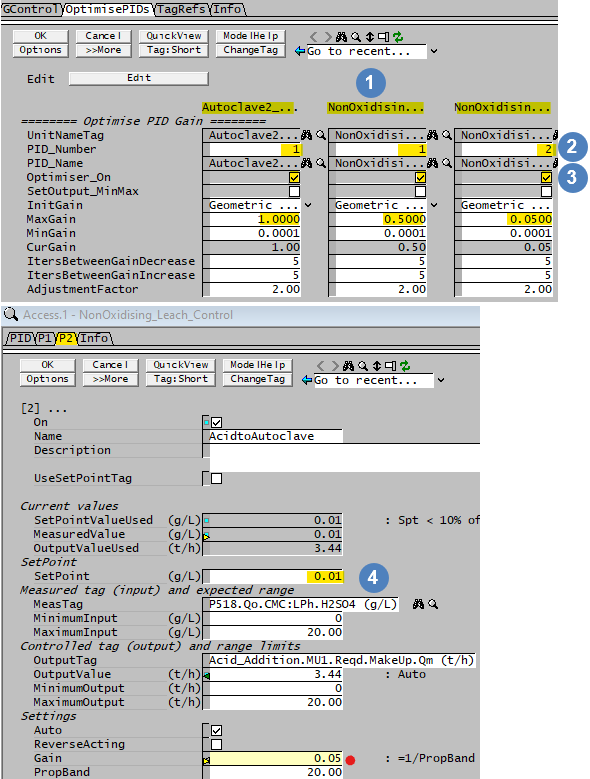

Adding the OptimiseGain class to PGM file.

>>OptimiseGain.pgm

;==================================================================

;Main Program

PageLabel "OptimisePIDs"

Textbreak

;Define the class instances

;For PID Controller with a single control block requiring optimisation, simply define the class instance using the unit tag name.

Class_OptimiseGain Autoclave2_Steam

;For PID Controller with multiple control blocks requiring optimisation, define the class instance using the unit tag name in an array.

Class_OptimiseGain NonOxidising_Leach_Control[2]

;Define class list for use in class macros or class functions

ClassList PIDs{Autoclave2_Steam, NonOxidising_Leach_Control}

;Display results in Grid format

ClassGrid PIDs

;initialise the class tags

Sub PreStart()

ForEachSub(PIDs, Initialise())

EndSub

;execute the optimise sub routine.

ForEachSub(PIDs, Optimise())

$ ; --- end of file ---

|

Setting up the Access Window: For example, user can add the above PGM class and PGM file to the Nickel Copper Project.

NOTE:

|