Applications

Jump to navigation

Jump to search

Navigation: General Information ➔ Applications

| General Information | Features | Applications | Solver Mode and Add-On Options | License Options | Support and Services |

|---|

Latest SysCAD Version: 25 February 2025 - SysCAD 9.3 Build 139.37016

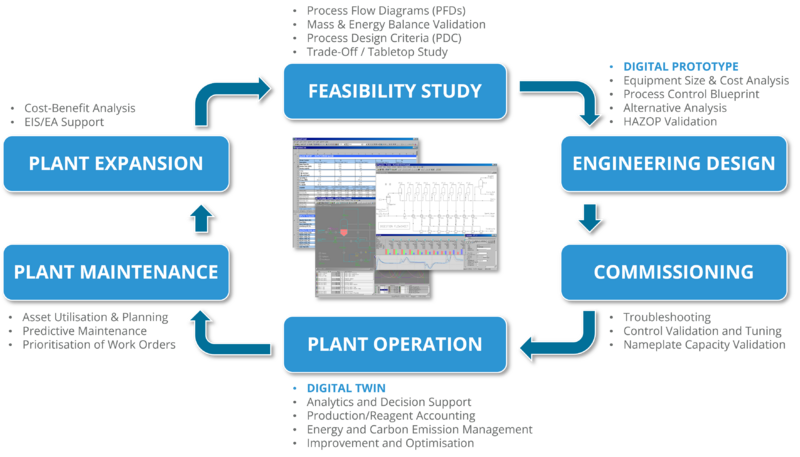

Process Design

- SysCAD in Steady State mode computes mass and energy balances quickly allowing for the evaluation of alternative flowsheets.

Process Plant Operation

- A metallurgical facility is usually a complicated chemical process, with many unique issues due to varying mineral composition, energy sources, plant design and condition, control systems and water quality. In addition to this, most operations have recycle-streams and often energy is recovered between different parts of the process, so a change anywhere in the process usually affects many other parts of the process. Therefore, all areas must work in concert for the plant to operate well.

- Consistent and optimal plant operation requires a detailed knowledge of the performance and capabilities of each area and an understanding of the interactions between the areas and equipment. A detailed comprehensive SysCAD model with predictive capability aids operational personnel to fully understand and optimize the plant.

Project Justification and Process Design

- SysCAD in Process Balance (ProBal) mode is used when designing Greenfield plants as well as for plant enhancements or expansions, project justifications or feasibility studies.

- When determining project justifications, the incremental production costs are generally different to the average costs. Extra tonnes may have significantly cheaper production costs. The true project benefits must include the net of all changes in production rate as well as reagent, energy and resource usages. Often the benefits do not add linearly, and the proposed changes must be evaluated simultaneously to establish true benefits. For these reasons, SysCAD is an invaluable tool to understand and justify a range of projects.

- A full plant model provides a consistent basis for evaluating proposed process changes and projects.

- SysCAD can be easily linked to production cost models for an integrated approach to project evaluation and justification.

- A good tool for prioritising small projects.

- Invaluable for Expansion – can incorporate all available process knowledge to use for planning, design and evaluation.

Plant Design Audit

- SysCAD dynamic simulator allows the designer to check equipment sizing under different dynamic operating conditions as well as other design parameters.

Process Control Strategy Design

- SysCAD dynamic simulator allows control to be superimposed on the process. Hence it is possible to design an effective control and operation strategy that requires the minimum amount of instrumentation.

Process Control System Pre-Commissioning

- SysCAD dynamic simulator allows control to be superimposed on the process. Hence it is possible to design an effective control and operation strategy that requires the minimum amount of instrumentation.

- As SysCAD can be connected to a process control system, rigorous control software testing can be done prior to installation of the DCS or PLC/supervisory system. AT the same time the operator interface, MMI or SCADA system can be tested for configurations, ranges and IO.

Operator Training

- Training can be done prior to the start-up of new plants or as part of training programs at existing plants or for plant upgrades.

Simulation Toolkit

- In general, a Steady State or Dynamic model in SysCAD is a powerful tool for a wide range of applications. A model is useful what if toolkit for design, optimisation, operations, planning, training etc. A model is an excellent repository of plant knowledge including design criteria, configuration, control methods, operation criteria and so on.

Planning and Surge & Availability Studies

- A SysCAD Dynamic macro level model can be developed to simulate the process over longer periods of time (e.g. 6 months to 3 years). This type of simpler model has applications for analysis of operation strategies, surge and availability and related long-term effects. This model is an excellent tool to analyse true cause and effects of the operation based on production planing. This leads to the ability to refine and optimise future planing based on changing cost models, market demands and practical process limitations.

Process Optimisation

- As SysCAD can be connected to a process control system, it can run in tandem with the plant. By comparing the model and plant performance, considerable insight into the process can be obtained. SysCAD may then be used as part of the on-line control or for display of additional information for operators. Further, in design mode the simulator is used to predict performance. However when connected to the actual plant the model can be tuned to estimate model parameters such as heat exchange efficiency, pump impeller wear, line friction losses etc. This facility allows the operations to get insight into non-measurable variables.

Research and Development

- Primarily through the developers kit advanced users are able to code new process unit models or stream properties model and compile these as an add-on for use in SysCAD. This allows new technologies, operation philosophies, unit operations to be evaluated in the context of a full flowsheet. It allows researches to concentrate on areas of technical interest and utilise the SysCAD functionality for testing evaluation, marketing and roll-out to users and clients. There are applications for research and development of flowsheet options, operating conditions and control options using the standard features without having to code new models.