Pressure Exchanger

Navigation: Models ➔ Pressure Changing Models ➔ Pressure Exchanger

General Description

The pressure exchanger unit model can be used to model energy recovery devices such as those used in reverse osmosis plants to recover energy from high pressure brine streams.

The unit has two feeds, one at low and one at high pressure, and two products, one at low and one at high pressure. The total flows of the two feeds are usually very similar. The unit acts like a pump for the low pressure stream, increasing its pressure.

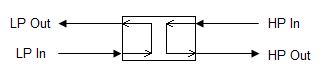

Diagram

The diagram shows the default drawing of the Pressure Exchanger, with the required connecting streams. The unit will not operate unless all of the above streams are connected.

The physical location of the connections is not important, the user may connect the streams to any position on the drawing.

Uses

The model can be used to model a wide variety of physical devices including:

- Transfer of hydraulic power in a high pressure stream to a pump via a rotating shaft (e.g. Pelton wheel and Francis turbines), also known as a reverse pump.

- Use of hydraulic power in a high pressure stream to drive a pump (e.g. Turbocharger).

- Direct transfer of hydraulic power in a high pressure stream to hydraulic power in a low pressure stream (e.g. PX).

In some of these devices, there is no mixing of the two streams (i.e. similar to a heat exchanger), while in other cases, such as the PX, a small amount of mixing can occur. The model includes a leakage parameter which can be set to zero if modelling the type of device where no mixing occurs.

Within a flowsheet, the Pressure Exchanger can be:

- placed downstream of a pump (i.e. in series), providing a boost in stream pressure

- placed in parallel to a pump, providing an equivalent boost in stream pressure as the pump, but for a fraction of the flow

Inputs and Outputs

| Label | Required /Optional |

Input /Output |

No. of Connections | Description | |

| Min | Max | ||||

| LP In | Required | Input | 1 | 1 | The Low Pressure feed to the unit. |

| LP Out | Required | Output | 1 | 1 | The Low Pressure outlet. This corresponds to the Low Pressure feed. |

| HP In | Required | Input | 1 | 1 | The High Pressure feed to the unit. |

| HP Out | Required | Output | 1 | 1 | The High Pressure outlet. This corresponds to the High Pressure feed. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- The 'LP In' stream will flow straight out of 'LP Out' with no change in pressure, temperature or composition;

- The 'HP In' stream will flow straight out of 'HP Out' with no change in pressure, temperature or composition;

- No pressure exchange will occur between the Low Pressure and High Pressure streams.

So basically, the unit will be 'bypassed' without the user having to change any connections.

Model Theory

The efficiency of the unit is based on the transfer of energy from the High Pressure (HP) stream to the Low Pressure (LP) stream:

- [math]\displaystyle{ \mathbf{\mathit{Eff=\cfrac{(Q_{HPo}*P_{HPo})+(Q_{LPo}*P_{LPo})}{(Q_{HPi}*P_{HPi})+(Q_{LPi}*P_{LPi})}}} }[/math]

- where

- Q - volumetric flowrate of given stream

- P - pressure of given stream

Subscripts:

- LPi - inlet conditions of Low Pressure stream

- HPi - inlet conditions of High Pressure stream

- LPo - outlet conditions of Low Pressure stream

- HPo - outlet conditions of High Pressure stream

The inlet conditions are known and the user can specify the outlet pressure of the High Pressure stream (usually atmospheric). The user then has the option to either specify the efficiency of the unit or the outlet pressure of the Low Pressure stream, and SysCAD will calculate the alternate parameter.

Data Sections

The default access window consists of several sections:

- PressureExchanger tab - contains the main configuration information relating to the unit.

- QLPFeed - Available from Build 139. Optional tab, visible if ShowQLPFeed is enabled. This and subsequent tab pages, e.g. QLPFeed.. and Sp, shows the properties of the low-pressure feed stream. The tags in the QLPFeed tab are valid even when the ShowQLPFeed option is not selected.

- QHPFeed - Available from Build 139. Optional tab, visible if ShowQHPFeed is enabled. This and subsequent tab pages, e.g. QHPFeed.. and Sp, shows the properties of the high-pressure feed stream. The tags in the QHPFeed tab are valid even when the ShowQHPFeed option is not selected.

- QLPProd - Available from Build 139. Optional tab, visible if ShowQLPProd is enabled. This and subsequent tab pages, e.g. QLPProd.. and Sp, shows the properties of the low-pressure product stream. The tags in the QLPProd tab are valid even when the ShowQLPProd option is not selected.

- QHPProd - Available from Build 139. Optional tab, visible if ShowQHPProd is enabled. This and subsequent tab pages, e.g. QHPProd.. and Sp, shows the properties of the high-pressure product stream. The tags in the QHPProd tab are valid even when the ShowQHPProd option is not selected.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Pressure Exchanger Page

Unit Type: PressureExchanger - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick Box | This is used to enable or disable the unit. If the unit is disabled, then there is no pressure transfer between the two streams. |

| Method | Set Efficiency | User specifies desired efficiency and model calculates outlet pressure of Low Pressure stream. |

| Set Pressure | User specifies desired outlet pressure of Low Pressure stream and model calculates efficiency. | |

| EfficiencyReqd / EffReqd | Input | Only visible if Method = Set Efficiency. The required efficiency of the energy transfer. |

| LP.PressureReqd / LP.P_Reqd | Input | Only visible if Method = Set Pressure. The required outlet pressure of the Low Pressure stream. |

| Efficiency | Calc | The actual efficiency of the energy transfer. This may be less than the Efficiency Required if this would result in the Low Pressure stream having a higher outlet pressure than the High Pressure stream inlet. |

| LP.DemandConnection | None | No demand connection. The inlet flows are set externally to the model. |

| General Demand | The Low Pressure feed comes from (directly or indirectly) a Feeder with Demand.On selected. The demand logic will aim to match the Low Pressure mass flowrate to the High Pressure mass flowrate. | |

| HP.Leakage | Input | The mass fraction of the High Pressure stream which is transferred to the Low Pressure stream. For equipment with no direct contact between the streams, set the leakage to zero. |

| HP.PressureReqd / HP.P_Reqd | Input | The required outlet pressure of the High Pressure stream. |

Options | ||

| GridDisplay | Tick Box | This is a global selection, if this is selected, then where available, variables will display in a table format, if not selected, they will be listed in separate groups as a single list. |

| ShowQLPFeed | Tickbox | Available from Build 139. When selected, the QLPFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the low-pressure feed stream. See Material Flow Section. Tags in the QLPFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQHPFeed | Tickbox | Available from Build 139. When selected, the QHPFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the high-pressure feed stream. See Material Flow Section. Tags in the QHPFeed tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQLPProd | Tickbox | Available from Build 139. When selected, the QLPProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the low-pressure product stream. See Material Flow Section. Tags in the QLPProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQHPProd | Tickbox | Available from Build 139. When selected, the QHPProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the high-pressure product stream. See Material Flow Section. Tags in the QHPProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| TrackFeeds | Tick Box | Option to produce a warning if the difference between the feed flowrates is greater than a user specified tolerance, see below. |

| FeedsMaxRelDiff | Input | The fractional difference allowed between the two feed stream flowrates without a warning being given if TrackFeeds is enabled. |

Results | ||

| FeedsRelDiff | Calc | The fractional difference between the two feed stream flowrates. |

| Low Pressure Side | ||

| LP.TemperatureIn / LP.Ti | Calc | The inlet temperature of the Low Pressure stream. |

| LP.TemperatureOut / LP.To | Calc | The outlet temperature of the Low Pressure stream. |

| LP.PressureIn / LP.Pi | Calc | The inlet pressure of the Low Pressure stream. |

| LP.PressureOut / LP.Po | Calc | The outlet pressure of the Low Pressure stream. |

| LP.MassFlowIn / LP.Qmi | Calc | The mass flowrate of the inlet of the Low Pressure stream. |

| LP.MassFlowOut / LP.Qmo | Calc | The mass flowrate of the outlet of the Low Pressure stream. |

| LP.VolFlowIn / LP.Qvi | Calc | The volumetric flowrate of the inlet of the Low Pressure stream. |

| LP.VolFlowOut / LP.Qvo | Calc | The volumetric flowrate of the outlet of the Low Pressure stream. |

| High Pressure Side | ||

| HP.TemperatureIn / HP.Ti | Calc | The inlet temperature of the High Pressure stream. |

| HP.TemperatureOut / HP.To | Calc | The outlet temperature of the High Pressure stream. |

| HP.PressureIn / HP.Pi | Calc | The inlet pressure of the High Pressure stream. |

| HP.PressureOut / HP.Po | Calc | The outlet pressure of the High Pressure stream. |

| HP.MassFlowIn / HP.Qmi | Calc | The mass flowrate of the inlet of the High Pressure stream. |

| HP.MassFlowOut / HP.Qmo | Calc | The mass flowrate of the outlet of the High Pressure stream. |

| HP.VolFlowIn / HP.Qvi | Calc | The volumetric flowrate of the inlet of the High Pressure stream. |

| HP.VolFlowOut / HP.Qvo | Calc | The volumetric flowrate of the outlet of the High Pressure stream. |

| Leakage | ||

| Leakage.MassFlow / Leakage.Qm | Calc | The mass flowrate of the leakage of material from the High Pressure stream to the Low Pressure stream. |

| Leakage.VolFlow / Leakage.Qv | Calc | The approximate volumetric flowrate of the leakage of material from the High Pressure stream to the Low Pressure stream. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Piping2.dll |

→ | Units/Links | → | Piping: Pressure Exchanger | |

| or | Group: | Mass Transfer |

→ | Units/Links | → | Piping: Pressure Exchanger |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Piping | → | Pressure Exchanger |

See Insert Unit for general information on inserting units.