Split Flows (Split)

Navigation: Models ➔ Sub-Models ➔ Split Flows (Split)

| Split Material Flow | Split Thermal (Requires SplitFlow = On) | |

|---|---|---|

| Split Flows (Split) | SplitFlow - General Operation | Split Thermal (SplitT) |

Related Links: PGM Examples - PGM Class to Set Species Splits

General Description

By enabling the SplitFlows sub-model, within a unit, the user has control over the split to the outgoing streams. If this sub-model is NOT enabled, then the unit will split the material from the unit equally between the outgoing streams.

- To enable the Split Flows, the user must tick the SplitFlows tickbox on the first tab page of the unit;

- The Split tab is then available for configuration.

- The user may configure the split between the outgoing flows.

- The streams may then be split purely on a mass percentage basis, or the phase split may be specified, or user defined species may be controlled in certain streams.

- This sub-model is commonly used in the Tie and Tank in Steady State models to control the flows from these units.

Video Links

There are a number of videos describing the various operational methods available in the SplitFlows sub-model - these links are shown in the table below. This link describes how to enable the SplitFlows Model and set pipe priorities: YouTube link.

Data Sections

The first variable that can be configured on the access page for the "General Split Flows Model" is "Operation". Depending on the option chosen by the user, the access page will change. Each option and its associated access page are described in the sections below.

The Split tab page can be used to specify how flow is distributed down stream.

| Tag (Long/Short) | Input/ Outputs | Description |

|---|---|---|

| GM ... | ||

| General Split Flows Model | ||

| Operation | General | Configure outgoing streams using mixture of methods. |

| Mass Frac | Split by mass fraction. | |

| Mass Flow | Specify mass flows. | |

| Volume Frac | Split by volume fraction. | |

| Volume Flow | Specify volume flows. | |

| Phase Mass Frac | Split each phase by mass fraction. | |

| Phase Mass Flow | Specify mass flows for each phase. | |

| Phase Volume Flow | Specify volume flows for each phase. | |

| Species Mass Frac | Split each species by mass fraction. | |

| Species Mass Flow | Specify mass flows for each species. | |

| Demand Mass Flow | Specify demand mass flows. | |

| Phase Recovery | Recover a fraction of a chosen phase to a particular stream. NOTE: This option is only available for models with only two output streams. | |

| Solids Recovery | Recover a fraction of solids to a particular stream. NOTE: This option is only available for models with only two output streams. | |

| Water Recovery | Recover a fraction of water to a particular stream. NOTE: This option is only available for models with only two output streams. | |

| Gas Vent | Recover a fraction of gases to a particular stream. NOTE: This option is only available for models with only two output streams. | |

| Target Stream | Available from Build 139.32925. Specify a single stream for all flow to exit by. | |

| Feed.MassFlow / Qm | Feedback | Available from Build 139.31388. The mass flow of the mixture before splitting of streams. |

| Feed.Temperature / T | Feedback | Available from Build 139.31388. The temperature of the mixture before splitting of streams - this is the temperature in the unit. |

OPERATION - General | ||

| ||

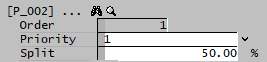

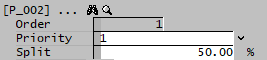

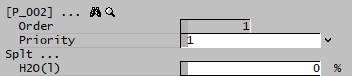

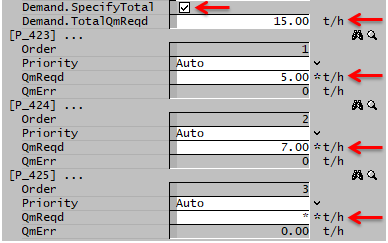

OPERATION - Mass Frac | ||

|

| |

| Order | Display | The actual stream solving order of priority. |

| Priority | Drop list | Lets the user select the stream solving order. |

| Split | Input | Allows the user to specify the fraction of the total mass which is to be directed to this stream. |

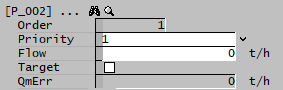

OPERATION - Mass Flow | ||

|

| |

| Order | Display | The actual stream solving order of priority. |

| Priority | List | Lets the user select the stream solving order. |

| Flow | Input | Allows the user to specify the mass flow of this stream. |

| Target | Tickbox | If this is ticked (On) then the user will NOT receive warning messages if the user specified requirements for this stream are not met, i.e. it is only a target. |

| QmErr | Display | Displays the difference between the mass flow specified by the user and the actual mass flow of the stream. |

OPERATION - Volume Frac | ||

|

| |

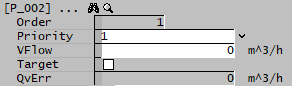

OPERATION - Volume Flow | ||

|

| |

| Order | Display | The actual stream solving order of priority. |

| Priority | Drop list | Lets the user select the stream solving order. |

| VFlow | Input | Allows the user to specify the volume flow of this stream. |

| Target | Tickbox | If this is ticked (On) then the user will NOT receive warning messages if the user specified requirements for this stream are not met, i.e. it is only a target. |

| QvErr | Display | Displays the difference between the volume flow specified by the user and the actual volume flow of the stream. |

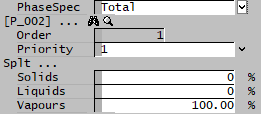

OPERATION - Phase Mass Frac | ||

|

| |

| PhaseSpec | Drop List | Allows user to choose either Total phases (solids, liquids and vapours) or Individual phases. |

| Order | Display | The actual stream solving order of priority. |

| Priority | Drop list | Lets the user select the stream solving order. |

| If Total is chosen for the PhaseSpec, then the user will have the following fields for each stream: | ||

| Solids | Input | Allows the user to specify the mass fraction of the total solids which is to be directed to this stream. |

| Liquids | Input | Allows the user to specify the mass fraction of the total liquids which is to be directed to this stream. |

| Vapours | Input | Allows the user to specify the mass fraction of the total gases which is to be directed to this stream. |

| If Individual is chosen for the PhaseSpec, then the fields will be the same except instead of Solids, Liquids and Vapours, the user will be able to specify fractions for each individual phase defined in the project (for example, aq (aqueous), o (organic), sl (slag), etc.). | ||

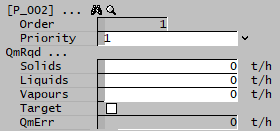

OPERATION - Phase Mass Flow | ||

|

| |

| Order | Display | The actual stream solving order of priority. |

| Priority | Drop list | Lets the user select the stream solving order. |

| Solids | Input | Allows the user to specify the mass flow of solids in this stream. |

| Liquids | Input | Allows the user to specify the mass flow of liquids in this stream. |

| Vapours | Input | Allows the user to specify the mass flow of gases in this stream. |

| Target | Tickbox | If this is ticked (On) then the user will NOT receive warning messages if the user specified requirements for this stream are not met, i.e. they are only targets. |

| QmErr | Display | Displays the difference between the total mass flow specified by the user (sum of all three phases) and the actual total mass flow of the stream. |

OPERATION - Phase Volume Flow | ||

|

| |

OPERATION - Species Mass Frac | ||

|

| |

OPERATION - Species Mass Flow | ||

|

| |

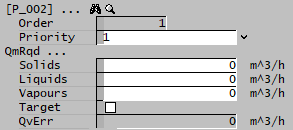

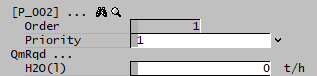

OPERATION - Demand Mass Flow | ||

|

| |

| Demand.SpecifyTotal | Tick Box | This option allows the user to specify the Total Demand mass flow and up to n-1 individual stream flows. When the Total flow is specified, at least one stream needs to be * (unspecified). When not used, all n individual output stream flows must be specified. |

| Demand.TotalQmReqd | Input | Only visible if Demand.SpecifyTotal option is selected. Allows the user to input the total Demand flow. |

| Demand.TotalQmErr | Display | Available from Build 139.32925. Only visible if Demand.SpecifyTotal option is selected. Displays the flowrate error between the total demand and the current feed flowrate. |

| Order | Display | The actual stream solving order of priority. |

| Priority | List | Lets the user select the stream solving order. |

| QmReqd | Input | Allows the user to specify the Demand mass flow to this stream. Enter * (unspecified) for the balance stream(s) when using Demand.SpecifyTotal. |

| QmErr | Display | Displays the difference between the Demand mass flow specified by the user and the actual mass flow of the stream. |

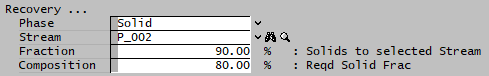

OPERATION - Phase Recovery | ||

|

| |

| Phase | Drop List | The phase to be recovered (solid, liquid or gas) |

| Stream | Drop List | The stream which the user wishes to specify the fraction and composition. |

| Fraction | Input | The (mass) fraction of the chosen phase which will be sent to the chosen stream. In the above example, we are sending 90% of the feed solids to the specified Stream. |

| Composition | Input | The (mass) fraction of the chosen phase in the chosen stream. The fractions of the other phases (other than the phase to be recovered) will be automatically adjusted in order to achieve this composition. In the above example, we are requesting the chosen stream to be 80% solids. |

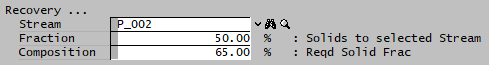

OPERATION - Solids Recovery | ||

|

| |

| Stream | Drop List | The stream which the user wishes to specify the fraction and composition. |

| Fraction | Input | The (mass) fraction of the solid phase which will be sent to the chosen stream. In the above example, we are sending 50% of the feed solids to the specified Stream. |

| Composition | Input | The (mass) fraction of the solid phase in the chosen stream. The fractions of the other phases (other than the solid phase) will be automatically adjusted in order to achieve this composition. In the above example, we are requesting the chosen stream to be 65% solids. |

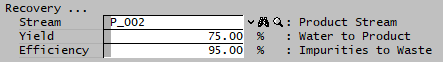

OPERATION - Water Recovery | ||

|

| |

| ProductStream / Stream | Drop List | The stream which the user wishes to represent the clean water stream. (The other stream will be the brine) |

| Yield | Input | The (mass) fraction of water to be recovered. In the above example, we are sending 75% of the feed water to the Product Stream. |

| Efficiency | Input | The (mass) fraction of other liquid compounds removed. In the above example, we are requesting 95% of all other liquid compounds in the feed be removed and sent to the brine. That means, 5% of other liquid compounds present in the feed will be in the water product stream. |

OPERATION - Gas Vent | ||

| ||

| VentStream / Stream | Drop List | The stream which the user wishes to represent the vent stream. |

| Fraction | Input | The (mass) fraction of all gases in the feed to be sent to the vent. In the above example, we are sending 90% of the feed gaseous compounds to the specified Stream. |

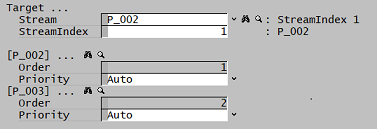

OPERATION - Target Stream | ||

|

| |

| Stream | Drop List | The stream which the user wishes to send all flow to. Can also be changed via StreamIndex. |

| StreamIndex | Input | The index of the stream which the user wishes to send all flow to. The index of each stream is based on the priority setting for each stream. Can also be changed via Stream droplist. |

| Order | Display | The actual stream index. |

| Priority | Drop list | Lets the user select the stream index for each outlet stream. |

Hints and comments

- If there are n streams leaving the unit, then the user may control (n-1) streams. The nth stream must be free to balance the incoming and outgoing flows.

- For example, if there are 3 outgoing streams, then the user may configure 2 streams, and the 3rd stream will be the balance stream.

- The only exception to this rule is if the user selects Operation = 'Demand Mass Flow', in which case the user must set the Demand flow for ALL outgoing streams.

- It is strongly recommended that the user sets the priority field for all configured streams in the GM to avoid order swapping. (see the following points)

- It is useful (and recommended) to set the Priority of one of the streams to "Last" so that it remains last (balance stream) as any other streams are added/removed.

- If the user configures the SplitFlows GM, and then at a later stage adds or removes a stream from the unit operation containing the GM, this may have an impact on the GM configuration. It is recommended that the user checks the GM settings every time a stream change is made.

- If the GM configuration data is read in from MS Excel or text files, it is recommended that the priority field be included as part of the settings.

- For users using the "Species Mass Frac" split method, it may be easier to use a PGM file to assist with the setting of the species, please see PGM Examples - PGM Class to Set Species Splits for pre-defined PGM functions and classes.

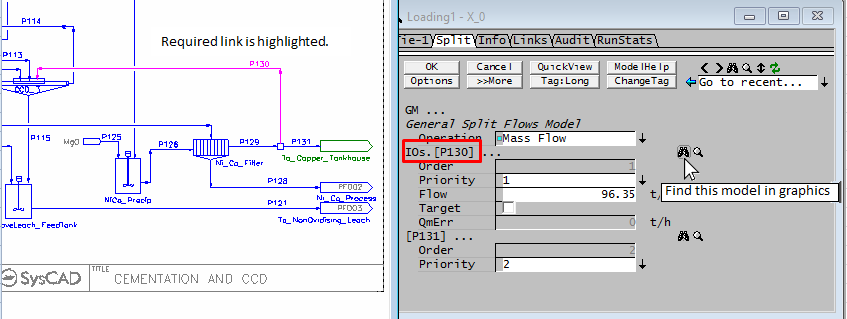

- Users may Find or Access each link listed in the Splitter section by clicking on the binoculars or magnifying glass displayed next to each link name - as shown in the diagram below: