Discussion: Rare Earths Example Project

Navigation: Product Blog ➔ Discussion Pages ➔ Rare Earths Example Project

Related Links: Rare Earths Project

Rare Earths Example Project

A new example project was released with Build 139.29706: Rare Earths Project. This example project demonstrates how SysCAD can be used to simulate a typical Rare Earths processing plant and could be used as the foundation for building your own.

In this discussion page, we'll go through an overview of the model, controls and SysCAD features. We'll also discuss potential improvements which could be made if adapting this model to a match a real-world plant.

If you have the latest version of SysCAD, it may be useful to have a copy of the model while reading this. You can find the files at: ..\SysCADXXX\Examples\60 Rare Earths\Demo Rare Earths Project.spf (available with the latest version of Build 139 or later). This article assumes you know the basics of Rare Earth processing.

Process Overview

Monazite ore is concentrated by flotation and then roasted with sulfuric acid. The roaster product is leached with water and then the leached solution is neutralised.

A portion of the leached solution is sent to a Mixed Rare Earth process, consisting of the processes of precipitation, dissolution, crystallisation and drying, to produce a dry Mixed Rare Earth product.

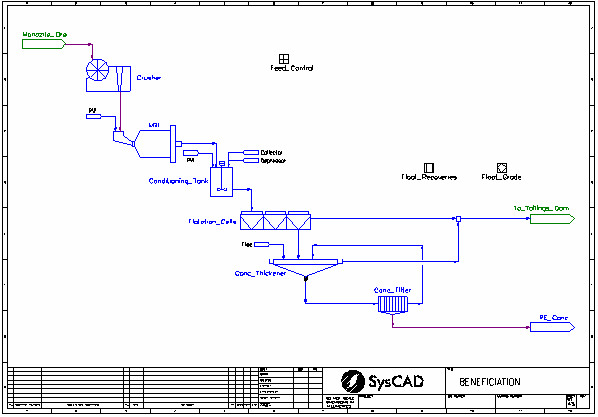

Beneficiation

In Beneficiation (shown on graphics page 01 Beneficiation), a General Controller is used to set the Monazite Ore composition as Rare Earth phosphates based on rare earth oxide equivalents and Total Equivalent Rare Earth Oxide (TREO).

The crushing and milling processes are not modelled in detail, i.e. size distributions are not modelled, and hence are simply modelled using the Tie model. This approach is often used in projects where either size distribution information is not available or is not the focus of the simulation.

Makeup Blocks are used to add process water to the Mill and Conditioning Tank to achieve target solids fractions. The use of the makeup block here allows the target solids fraction to be achieved immediately and avoid the use of a feedback controller such as a PID Controller.

Makeup Blocks are also used to add flotation reagents (Collector and Depressor) to the Conditioning Tank based on a ratio to the solids in the feed. The use of the makeup block here allows the target ratio to be immediately achieved based on the current feed and avoid the use of a feedback controller such as a Set Tag Controller.

The Flotation Cell model is used to simulate the flotation process using the Grade & Recovery method. This method allows you to specify the recovery and concentrate grade of a single solid species, in this case, CePO4. A Set Tag Controller was used to ensure that the same recovery was used for all rare earth phosphates. A PID Controller was used to vary the concentrate grade of CePO4 to achieve a target TREO (Total Rare Earth Oxide equivalent) grade. Equivalent rare earth oxide amounts are automatically calculated in each stream as they have been defined as Species Calculations.

Chemical Treatment

In Chemical Treatment (shown on graphics page 02 Chemical Treatment), a Makeup Block is used to add sulfuric acid (H2SO4(aq)) to the Roaster based on a ratio to the solids in the feed. The use of the makeup block here allows the target ratio to be immediately achieved based on the current feed and avoid the use of a feedback controller such as a Set Tag Controller. It also allows the ratio to be based on a specific species, in this case H2SO4(aq), so you don't have to take account of the fraction of the species of interest in the reagent.

The Roaster is modelled as a Tank with reactions. A Set Tag Controller was used to ensure that the same reaction extent for the conversion of phosphates to sulfates was used for all rare earth phosphates.

To assist in modelling the Neutralisation Tank, a Model Procedure was used to calculate the MgO required based on reaction extents and an excess requirement and then set the MgO makeup. The use of the model procedure here allows the required amount of MgO to be calculated and set immediately and avoid the use of a feedback controller such as a PID Controller or General Controller.

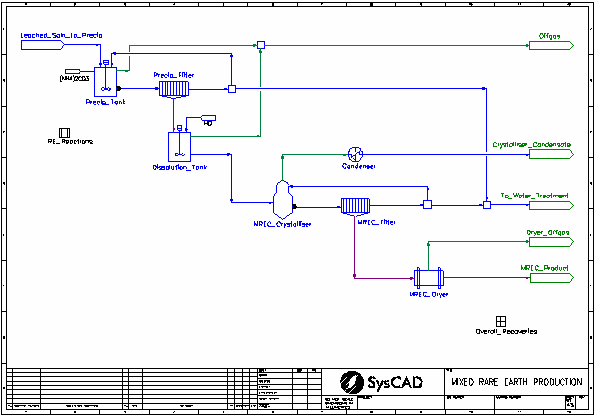

Mixed Rare Earth Production

In Mixed Rare Earth Production (shown on graphics page 03 Mixed Rare Earth Production), similar approaches to those on the Chemical Treatment flowsheet are used, namely, Set Tag Controllers to set reaction extents to a single value and Model Procedures to calculate and set reagent amounts.

A General Controller is used to calculate the TREO recoveries in each process area.

Future Improvements

- Thermodynamic data for the rare earth compounds should be reviewed. In some cases data was assumed or simply didn't exist. For this reason, in some units the Override Product Temperature Option was used and so the heats of reaction were not calculated.

- At several points in the process, it was assumed that all rare earth compounds would act in the same way. This should be reviewed based on real test data.

- Reagent concentrations, ratios and excesses were often assumed and should be reviewed.

- The project allows for the leached solution to be sent to either a Mixed Rare Earth process or single rare earth separation processes. This split is assumed to be 60:40 but could easily be altered to 100% to the Mixed Rare Earth process to increase production of the final mixed rare earth product. Alternatively, you may wish to add a new flowsheet/s to simulate the single rare earth separation processes and send a portion or all of the leached solution to these added processes.

References

- "Extractive metallurgy of rare earths" by F Habashi (2013), Canadian Metallurgical Quarterly, 52:3, 224-233 (https://www.tandfonline.com/doi/full/10.1179/1879139513Y.0000000081)

- "A critical review on solvent extraction of rare earths from aqueous solutions", by F Xie, T.A. Zhang, D. Dreisinger and F. Doyle (2014), Minerals Engineering 56, 10-28 (esp. Figures 1 & 11)

First Posted: 03 November 2021

Reference Build: 139.29706

For questions or feedback, please contact us at info@syscad.net.