Example PGM Files - Using Counter, While and Random functions

Jump to navigation

Jump to search

Navigation: PGMs ➔ Example PGM Files ➔ Counter, While, Random

| Simple Examples | Subroutines Examples | Dynamic Examples | Steady State Overall Mass Balance | Array and Matrix Examples | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Basic Layout | Simple Calculations | Initialise PreStart | Multi-Step Trigger | Checking Project | Counter, While and Random | Belt Filter Wash Loss | Startup Actions | Mass Balance | Mass Balance | Species Balance | Elemental Balance | Lookup Value | Set Values | Tridiagonal System |

Related Links: Trigger Subroutines, Predefined Functions

Sample PGM File (File layout when using counters)

Example 1 ;--- SysCAD General Controller (PGM) program logic file ---

; Basic file structure for utilising counters.

;---- Define Variables ------------------------

long Counter@

Checkbox ControlOn*

bit Error1@

String AssessmentMessage1@

;--- Logic ------------------------------------

Sub InitialiseSolution()

["PID_2.Cfg.[1].On"] = ControlOn

EndSub

Sub TerminateSolution()

Error1 = ;place any solution checking logic here

if (Error1)

AssessmentMessage1 = "Run not successful, do this..." ;message as required...

LogWarning(AssessmentMessage1)

endif

EndSub

;NOTE counter must be placed in this section to count the iterations as the project solves.

Counter = Counter + 1

$ ;END OF FILE

|

Example 2 ;--- SysCAD General Controller (PGM) program logic file ---

; How to use a counter to assign different values to a variable.

;--- variable declarations ---

CheckBox UseInitFeed* ;trigger for using initial feed

integer IterationCount@ ;counter

Integer FeedOffCount*<<1>> ;sets flow to 0 when it reaches this value

Sub InitialiseSolution()

;--- Logic executed during initialisation before first iteration

;For example to set initial values, or set values in units

If UseInitFeed

["XPG_001.QmReqd (t/h)"] = 20

IterationCount = 0

Endif

EndSub

;--- Logic - executed at EVERY step ---

If UseInitFeed AND (IterationCount < FeedOffCount)

IterationCount = IterationCount + 1

If (IterationCount >= FeedOffCount)

["XPG_001.QmReqd (t/h)"] = 0

Endif

Endif

$

|

Example PGM File - Using While loop to set user defined value to multiple equipment

Long i, NumberofTanks*<<14>>

Real AggRateCorrection*<<0.35>>

Sub InitialiseSolution()

i = 1

While i <= NumberofTanks

[Concatenate("PC_", IntStr0(i, 3), ".Agglom.Rate.Correction")] = AggRateCorrection

i = i + 1

EndWhile

EndSub

;Inside the while loop, tags PC_001 to PC_014.Agglom.Rate.Correction will be set to the user defined value.

;The function IntStr0 will convert integers "1 to 14" to 3-character length strings, padding with 0 (zeros).

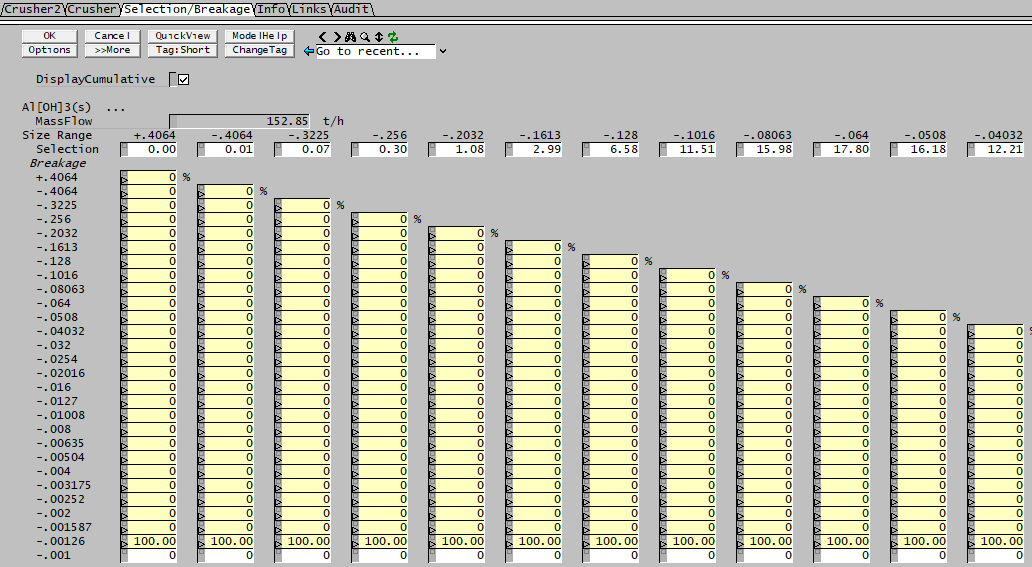

Example PGM File - Using While loop to set Selection/Breakage Function Table values

Example 1

This example sets fines into the crusher to represent Attrition Control for Alumina Precipitation circuit:

Real Breakage*

Long k, n

Sub InitialiseSolution()

n = 27

While n > 1

k = n

While (k > 1)

[Concatenate("CR_001.Al[OH]3(s).BRK[", IntToStr(k), "][", IntToStr(n), "] (%)")] = 0

[Concatenate("CR_001.Al[OH]3(s).BRK[1][", IntToStr(n), "] (%)")] = Breakage

[Concatenate("CR_001.Al[OH]3(s).BRK[0][", IntToStr(n), "] (%)")] = 100 - Breakage

k = k - 1

EndWhile

n = n - 1

EndWhile

EndSub

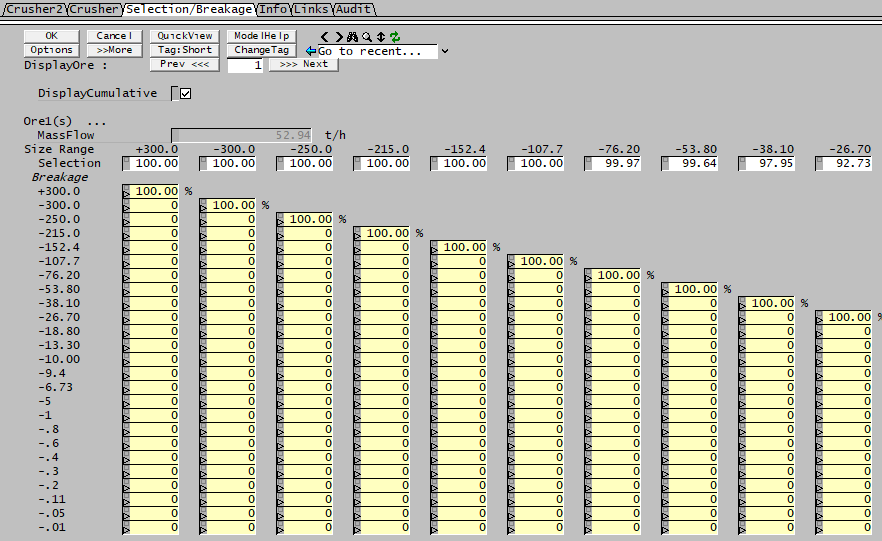

Example 2

This example initialises Crusher2 Breakage function table values to 0:

String OreTag1*

Long k, n

Sub InitialiseSolution()

OreTag1 = "CR001.Ore1(s)"

n = 24

While n > 1

k = n

While (k > 1)

[Concatenate(OreTag1, ".BRK[", IntToStr(k), "][", IntToStr(n), "] (%)")] = 0

[Concatenate(OreTag1, ".BRK[1][", IntToStr(n), "] (%)")] = 0

[Concatenate(OreTag1, ".BRK[0][", IntToStr(n), "] (%)")] = 0

k = k - 1

EndWhile

n = n - 1

endwhile

EndSub

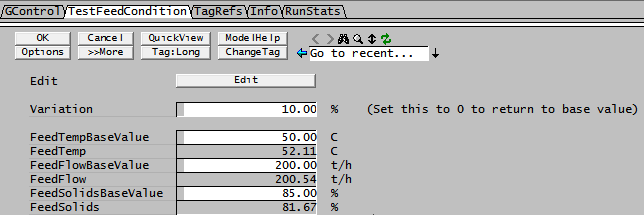

Example: Using random for testing plant models

The following is an example of a PGM file that can be used to "drive" a plant model around nameplate or design condition by introducing small variations in each of the key parameters.

- Each time the model is run, the base values are subject to a small random variation, controlled by the variable Variation.

- When you are done testing, just set Variation to zero and nameplate conditions will be reset!