Tank - Dynamic Mode

Navigation: Models ➔ General Models ➔ Tank ➔ Dynamic Mode

| Tank | Tank - Dynamic Mode | Dynamic Tank - Optional Data Sections |

|---|

General Description

This page is for the Tank model when used in Dynamic mode. For help on the Tank model in Steady State mode, please see Tank.

The general purpose tank serves as a storage unit for material in the Dynamic mode:

- The level can vary and hence Flow In is not always equal to Flow Out.

- It is commonly used to store solids, liquids, slurries and gases and can either be open or closed.

- Material can enter and leave from various positions and vents.

- There is no single Product stream from the Dynamic tank, and hence QProd is NOT available in the Dynamic Tank.

- If the user 'Resets' or uses the 'Empty Process' SetState option, then all connecting flanges will also be set to zero flow.

The tank can be operated in either of the following modes:

- Perfectly Mixed: In this mode a homogeneous product is produced from all outlets, except the Vent, which will always have gases only.

- Layered Tank: In this mode the tank acts as a true plug flow model - the different layers in the tank may have different compositions. Please note that each Segment in the Layered Tank may consist of a number of layers, and each layer is part of the plug flow evaluation.

- For layered tanks the following sub-models will NOT be available:

- CRB - reactions cannot be set on the Tank contents

- HX - the user cannot enable the Heat Exchange model

- CEHX - environmental heat exchange cannot be set on the Tank contents

- CVLE - vapour-liquid equilibrium cannot be set on the Tank contents

- Vapour Control - the Tank will act like an open tank, i.e. gases will not be retained

- If MixFeeds is NOT selected, then NONE of the EB sub models will be available

- For layered tanks the following sub-models will NOT be available:

Available Sub-Models

Two groups of sub-models are allowed in a Dynamic Tank:

- Evaluation Block (EB) sub-models that act of the feed stream, QFeed, to the tank, i.e. NOT on the tank contents, but rather on the combined feed streams to the tank. This will give a results equivalent to the those obtained in ProBal.

- Content Evaluation Block (CEB) sub-models that act on the actual content of the tank.

These will be described below:

Evaluation Block Sub-Models

- Makeup Blocks (one or more) may be enabled. This allows the user to control the addition of streams such as reagents, water, air, etc. to the QFeed of the tank, often without having to use a PID or General controller.

- The Reaction Block (RB) allows the user to configure any number of reactions on the QFeed of the tank.

- The Environmental Heat Exchanger Block allows the user to add or remove energy from the QFeed of the tank using a number of different methods.

- The Evaporation Block allows the user to set the evaporation of either water only or a mixture of water and all other species that are specified as both liquid and vapour.

- The Vapour Liquid Equilibrium Block will attempt to ensure that the vapours and liquids of the selected species will be in equilibrium in the QFeed of the Tank. For example, if the equilibrium species is water and the tank is at atmospheric pressure, then SysCAD will maintain the temperature at, or below, the saturated temperature of 99.97°C by evaporating water if required.

- Discard Blocks (one or more) may be enabled. This allows the user to control the discarding of material from the QFeed of the Tank, usually without having to use a PID or General controller.

Content Evaluation Block Sub-Models

These are NOT available in Layered Tanks.

- The Content Reaction Block (CRB) allows the user to configure any number of reactions on the content of the unit.

- The Heat Exchanger (HX) may be enabled (only available in Tanks. The user must also connect links to the HX input and the HX output. The Heat Exchange page needs to be configured with the relevant heat exchange area and overall heat transfer coefficient. The model carries out the heat exchange operation on the Tank contents and the HX flow. Please note that the fluid in the heat exchanger will transfer energy via sensible heat ONLY. There is NO condensing or boiling in the heat exchanger.

- The Environmental Heat Exchanger Block allows the user to add or remove energy from the content of the unit using a number of different methods.

- The Vapour Liquid Equilibrium Block will attempt to ensure that the vapours and liquids of the selected species will be in equilibrium in the unit contents. For example, if the equilibrium species is water and the unit is at atmospheric pressure, then SysCAD will maintain the temperature at, or below, the saturated temperature of 99.97°C by evaporating water if required.

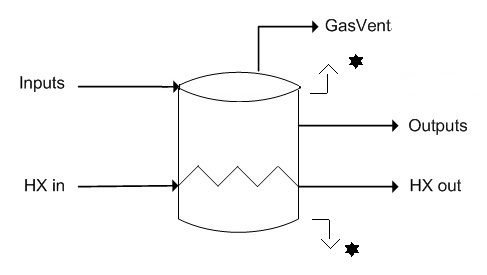

Diagram

- The diagram shows a drawing of the tank, with a number of connecting streams.

- The 2 streams shown with a * are Direct Links, automatically constructed by SysCAD if there is a gas or slurry 'spillage' from the Tank.

- When the user inserts the tank into a flowsheet, a different graphics symbol can be selected from a pull down menu.

- The streams may be connected to any area of the drawing without affecting the actual connection point as SysCAD ignores the physical position of the connection.

- In dynamic mode, you can set the connection height of the links.

- In dynamic mode, it is possible to have no outlet connections. The model will overflow when full and there is too much feed.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Input | Optional | In | 0 | 30 | General purpose inlet (limit increased from 20 in Build 138.25939) |

| Output | Optional | Out | 0 | 20 | General purpose outlet |

| GasVent | Optional | Out | 0 | 1 | Outlet for vapour species (Dynamic mode only) |

| HX_in | Optional | In | 0/1* | 20 | Heat exchanger inlet (*only required if HX block is selected) |

| HX_Out | Optional | Out | 0/1* | 20 | Heat exchanger outlet (*only required if HX block is selected) |

Model Behaviour

Vapour Control

Vapours can ONLY exit a tank via a Gas Vent Link, if the user has connected it, or via a direct link, Vent - created automatically by SysCAD. Gas cannot exit via an Output link.

In a Perfectly Mixed Tank, the vapours in the tank can be controlled by two methods.

- The user can choose to specify the (maximum) volume of vapours retained in the tank using the FixedVolume method. This volume can be zero (i.e. no vapours are retained in the tank) and can also be larger than the volume specified for the tank itself. This is not related to the volume of solids and liquids in the tank or the volume specified for the tank itself.

- The user can choose to allow the vapours to fill up the available space in the tank using the AvailVolume method. The available volume is the total volume of the tank minus the volume occupied by liquids and solids retained in the tank. Thus the allowable volume of vapours could change from one iteration to the next as the amount of liquids and solids in the tank changes.

No vapour will exit the tank until the vapour volume has been filled. If a gas vent is connected, then any vapours exiting will be sent to this connection. Otherwise the vapours will be sent to a vent direct link, similar to spills.

The vapour retained in the tank will be available to participate in any reactions on the content of the tank.

Pipe Connection Levels

If pipes have filters enabled, then they should NOT be connected at the same height as other pipes, as this can lead to multiple solutions. If the model is configured this way, then the user will be warned when the model is run and the results may be unpredictable. The filters that may be selected include:

- Pass Water;

- Block Solids;

- Block Liquids; and

- Species Filter.

So, if the user requires a pipe to Pass Water, then that pipe should be located at a different height to any other pipes connected to the tank. The height difference should be greater than 0.5%, either higher or lower.

Level Control

The Level Control option can be enabled on the first tab page. The relevant parameters will appear on the Control tab page.

The user has the option to control either the level, mass or volume of the contents of the tank. This is controlled by allowing SysCAD to set the flow in one of the outlet pipes. The user can put restrictions on the outlet flow such as minimums and maximums as well as controlling the rate of change. This restriction can be mass or volume flow basis for perfectly mixed tanks, but is limited to mass flow basis for layered tanks.

NOTE: Where there are more than one active slurry outlets (excluding gas vents and overflow pipes), the height of the controlled outlet must be higher than outlets with fixed flows for the control to work correctly.

Layered Flow

With the layered tank contents model, SysCAD stores discrete layers of material. The size of these layers can vary and is dependent on iteration time step, pipe connection heights, flowrates, etc. The display of segments and overall contents is simply an aggregation of underlying layers for reporting purposes and does not represent the underlying data. A single species model is applied to all internal layers, so a change in species model is applied to all individual layers immediately.

The CEB actions, such as contents reactions (CRB) are not available with layered flow. Other operations on tank contents such as heat exchange (HX) are also not available.

There are two ways that the inlet streams can be handled based on the user option "MixFeeds":

- MixFeeds is selected: Then the EB actions (acting on feed mixture before adding to contents) is available. The QFeed page will show the sum of all input streams and the QCFeed page will display the results after the EB actions. With MixFeeds selected, the user can select what the mixed single stream inlet connection height would be, the connection heights of the inlet pipes are ignored.

- MixFeeds is NOT selected: Then the EB actions are NOT available. The QFeed page will be the same as the QCFeed page, and will show for reporting purposes only the sum of the inputs. In practice, the individual inlet pipes add the material to the layered contents at the inlet pipe connection height (can insert material below the surface).

There is no mixing between adjacent layers.

The layered tank contents model is effectively a queue model. Material can be added to top or inserted into the queue based on the feed pipe height. Similarly material is removed from the top, middle or bottom based on the outlet pipe height and configuration. The number of underlying discrete layers is limited so, for example, layers of material added in an iteration may sometimes be added (perfectly mixed) with an existing layer rather than added as a new layer.

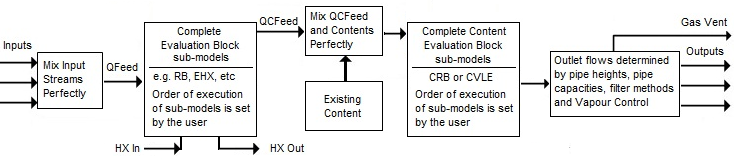

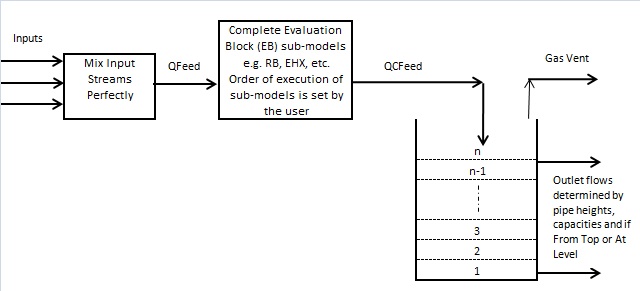

Flowcharts

The following flowchart shows the sequence of events if any Evaluation Block or Content Evaluation Block sub-model options or the HX Block are enabled:

Perfectly Mixed Tanks

Layered Tanks (with MixFeeds selected)

Data Sections

The following fields appear in the access window for the tank in Dynamic mode only.

Summary of Data Sections

- Tank-1 tab - contains general information relating to the unit.

- Control - Optional tab, only visible if Level Control or Vapour Control is enabled. Allows the user to set the control values for these two control methods.

- Connect tab - contains information about the link connections to the tank, e.g. connection heights and Filter methods.

- Filters tab - contains information about the filter options for link connections to the tank.

- PC - Optional tab that is visible if EB.Solubility.On and/or [email protected] is enabled in the Flow Evaluation Block.

- RB - Optional tab, only visible if the Reactions are enabled in the Flow Evaluation Block.

- EHX - Optional tab, only visible if the EnvironHX is enabled in the Flow Evaluation Block.

- Evap - Optional tab that is visible if Evaporation is enabled in the Flow Evaluation Block.

- VLE - Optional tab, only visible if the VLEquilibrium is enabled in the Flow Evaluation Block.

- MU - Optional tab, or multiple tabs if more than 1 Makeup is selected. Only visible if one of more Makeups are enabled in the Flow Evaluation Block.

- DB - Optional tab, or multiple tabs if more than 1 Discard Block is selected. Only visible if one of more Discard Blocks are enabled in the Flow Evaluation Block.

- CRB - Optional tab, only visible if the Reactions are enabled in the Content Evaluation Block.

- HX - Optional tab, only visible if the HeatXChg is enabled in the Content Evaluation Block. (In this case the HX should be connected).

- CEHX - Optional tab, only visible if the EnvironHX is enabled in the Content Evaluation Block.

- CVLE - Optional tab, only visible if the VLEquilibrium is enabled in the Content Evaluation Block.

- LL - Optional tab, only visible if Level lookup is enabled. Allows the user to create and populate the Level lookup table.

- QFeed - Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the combined feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- This is before any Evaluation Block models are evaluated.

- QCFeed - Optional tab, only visible if ShowQCFeed is enabled. This page shows the properties of the stream AFTER the Evaluation Block BEFORE it mixes with the Tank contents.

- Settings tab - Allows the user to set the tank dimensions, spillage and vent settings, etc.

- Content tab - contains data on the material in the tank.

- Segments - Optional tab, only visible if Mixing.Model = Layered_Flow or Layered. Allows the user to view segments of the Layered Tank. (Each segment may consist of a number of Layers).

- Detail - This series of tabs allows the user to view the content of an individual segment. These tabs will only be visible if Segment.ShowIndex is >= 0. Only available if Mixing.Model = Layered_Flow or Layered.

- Layer - This series of tabs allows the user to view the content of an individual layer. These tabs will only be visible if Layer.ShowIndex is >= 0. Only available if Mixing.Model = Layered_Flow or Layered.

- Content - Optional tab, only visible if MeanResTimes option is enabled on the Settings tab page. Displays the mean residence times of each species.

- PresetImg - Optional tab, only visible if UseImage option is enabled on the Settings tab page under Preset heading. Allows user to define the Preset Image composition.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- MP tab - Optional tab, only visible if Procedures have been enabled on the Info tab page.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Unit Type: Tank-1 - The first tab page in the access window will have this name.

Tank-1

| Tag (Long/Short) | Input / Calc | Calculated Variables / Options |

|---|---|---|

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Results Summary | ||

| Temperature / T | Calc | The temperature of the tank contents. |

| Pressure / P | Calc | The pressure in the tank. |

| Density / Rho | Calc | The density of the tank contents. |

| Level / Lvl | Calc | The slurry level in the tank. |

| TotalMass / Mt | Calc | The total mass of material in the tank. |

| InitTtlMass / InitMt | Calc | The mass in the tank at the start of the solver run. |

| DeltaTtlMass / DeltaMt | Calc | The total change in mass in the tank from the start of the solver run. |

| MassRateofChange / QmAcc | Calc | The rate of accumulation of mass of in the content of the tank. Note: This includes any Vapours in the tank. |

| VolumeRateofChange / QvAcc | Calc | The rate of accumulation of volume of in the content of the tank. Note: This includes any Vapours in the tank. |

| Requirements | ||

| OperatingP - NOTE: this pressure is applied to the (combined) feed, before sub-models (if any). | ||

| Method | AutoDetect | If there are any liquids AND no vapours present in the feed, outlet streams will take the highest pressure of the feeds. Else (e.g. some vapours present) outlet streams will take the lowest pressure of the feeds. |

| LowestFeed | Outlet streams will take the lowest pressure of the feeds. | |

| HighestFeed | Outlet streams will take the highest pressure of the feeds. | |

| Atmospheric | Outlet streams will be at Atmospheric Pressure. The atmospheric pressure is calculated by SysCAD based on the user defined elevation (default elevation is at sea level = 101.325 kPa). The elevation can be changed on the Environment tab page of the Plant Model. | |

| RequiredP | Outlet streams will be at the user specified pressure. | |

| IgnoreLowMassFlow / IgnoreLowQm | Tick Box | This option is only visible if the AutoDetect, LowestFeed or HighestFeed methods are chosen. When calculating the outlet pressure and temperature of the tank, SysCAD will ignore the low flow feed streams should this option be selected. The low flow limit is set in the field below. |

| LowMassFlowFrac / LowQmFrac | Input | This field is only visible if the IgnoreLowQm option is selected. This is the amount any stream contributes to the total flow. For example, if the total feed to the tank is 10 kg/s, and this field is set to 1%. Then any feed streams with less than 0.1 kg/s will be ignored in the pressure calculations. |

| PressureReqd / P_Reqd | Input | This field is only visible if the RequiredP method is chosen. This is user specified pressure. |

| Result | Calc | The actual pressure used for the sum of the feeds which will also be the outlet pressure (unless further model options change the pressure). |

| EB (Flow Evaluation Block) The Evaluation Block works as in ProBal and the sub-models act on the feed to the tank. Not available in the Layered Tank when MixFeeds is not selected. | ||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. |

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. |

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Makeups | Input | The number of Makeup Blocks required. Extra dropdown options Makeup1, Makeup2, etc. will be added to allow these to be switched on and off and prioritised in relation to the other sub-models. |

| MakeupX | List | This can be used to switch the Makeup Block (MU) on or off and prioritise it in relation to the other sub-models. If this is 'On' then the associated page, MUX becomes visible and may be configured. Note: This field is only visible if the entry for 'Makeups' is greater than 0. If there is one makeup then X=1. If there are two makeups, then X=1 and X=2, etc. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

| EnvironHX | List | Environmental Heat Exchanger (EHX) - Enable or disable Environmental Heat Exchange and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, EHX becomes visible and may be configured. Note: The user does not have to configure an environmental heat exchange, even if this block is checked. |

| Evaporation | List | Evaporation Block (Evap) - Enable or disable the Evaporator and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, Evap becomes visible and may be configured. Note: The user does not have to configure an evaporator, even if this block is checked. |

| VLEquilibrium | List | Vapour Liquid Equilibrium (VLE) - Enable or disable Vapour Liquid Equilibrium and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, VLE becomes visible and may be configured. Note: This option may automatically adjust the species make-up. |

| Discard | Input | The number of discard blocks required. Extra dropdown options Discard1, Discard2, etc. will be added to allow these to be switched on. |

| DiscardX | List | This can be used to switch the Discard Block (DB) on or off and prioritise it in relation to the other sub-models. If this is 'On' then the associated page, DBX becomes visible and may be configured. Note: This field is only visible if the entry for 'Discards' is greater than 0. If there is one discard then X=1. If there are two discards, then X=1 and X=2, etc. |

| CEB (Content Evaluation Block) In this case the sub-models act on the tank contents. Not available in the Layered Tank. | ||

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

| HeatXChg | List | This can be used to switch on the Heat Exchanger (HX). If this is 'On' then the associated page, HX becomes visible and may be configured. Note: The user does not have to configure the heat exchange, even if this block is checked. |

| EnvironHX | List | Environmental Heat Exchanger (EHX) - Enable or disable Environmental Heat Exchange and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, EHX becomes visible and may be configured. Note: The user does not have to configure an environmental heat exchange, even if this block is checked. |

| VLEquilibrium | List | Vapour Liquid Equilibrium (VLE) - Enable or disable Vapour Liquid Equilibrium and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, VLE becomes visible and may be configured. Note: This option may automatically adjust the species make-up. |

| Requirements | ||

| Mixing.Model | Perfectly_Mixed | This is the default behaviour. All material inside the tank is perfectly mixed with the feed to the tank to produce a homogenous result. The composition of all Outlet streams will be the same, except where the Filter method is used. |

| Layered | (Originally named Layered_Flow prior to Build 139.) Segments tab will be visible if this is enabled and additional fields will be visible on the Settings. The material fed to the tank is layered on top of the existing material in the tank, or inserted at inlet connection height. Outlet compositions will reflect the layer of material which is at the height of the outlet. | |

| LevelControl | Tick Box | Control tab will be visible if this is enabled. This control acts as a built-in PID level controller in the tank and the user can set the Level Control variables on the Control tab. This option is only available when using Inline mode. |

| VapourControl | Tick Box | Control tab will be visible if this option is enabled. This allows the user to retain vapours in the tank and to set the volume available for the vapours. The user can set the Vapour Control variables on the Control tab. This option is only available when using a Perfectly Mixed Inline Tank. Layered Tanks will not retain any gases. |

| LevelLookUp | Tick Box | LL tab will become visible if this is enabled. This allows the user to set the Apparent level, and Area if required, based on the volume in the Tank and lookup tables on the LL tab. |

| Options | ||

| ShowQFeed | Tick Box | QFeed and associated tab pages (e.g. Qm) will become visible if this is enabled. These tabs will show the properties of the combined feed stream to the Tank. These values are BEFORE the Evaluation Block actions. |

| ShowQCFeed | Tick Box | QCFeed and associated tab pages (e.g. Qm) will become visible if this is enabled. These tabs will show the properties of the feed to the Tank contents. These values are AFTER the Evaluation Block actions and BEFORE the stream enters the contents. |

Connect Tab Page

Notes:

- Each link to the Tank will be displayed on this tab - Input links under Input Connection Options and Output links under Output Connection Options.

- The user may not set the height or filter for the Gas Vent link.

- All gases exit via the Gas Vent and cannot exit via normal Outlet links.

- If no Gas Vent is connected, then any Gas will exit via an automatically created Gas Spill direct link.

| Tag (Long/Short) | Input/ Calc | Description |

|---|---|---|

| IO Options | ||

| ShowAllOutlets | Tickbox | If enabled, all outlets will be shown on a separate Filters tab page, regardless of whether the Species Filter method has been chosen. |

| Input or Output Connection Options | ||

| IOOpts.[Link name.O](I) | ||

| HeightFrac | Input | The connection height of the pipe on the tank, expressed as a percentage or fraction of the tank height. This is especially important for outlet pipes as material will not flow out of the pipe unless the level in the tank reaches the height of the pipe. Notes

|

| Height | Calc | The actual height of the pipe from the tank floor. |

| Head.Height | Calc | The static head, the height of material above the outlet. |

| Head.DeltaP / DP | Calc | The static head pressure due to material above the outlet = density*g*Head.Height. |

| Pressure / P | Calc | The calculated pressure of the outlet. If WithStaticHead option is enabled then this will be the sum of the tank pressure and the static head. Otherwise it will simply be equal to the tank pressure. |

| Perfectly Mixed Tanks | ||

| Filter.Method | None | All liquid and solid material which is at the level of the pipe will be able to exit via the pipe. |

| Pass-Water | Only water is allowed to exit via the pipe. | |

| Block-Solids | Solids will be not be allowed to exit via the pipe. | |

| Block-Liquids | Liquids will be not be allowed to exit via the pipe. | |

| Species-Filter | Allows the user to select (on separate Filters tab page) which individual solid and liquid species can exit via the pipe. | |

| Layered Tanks | ||

| Filter.Method | At-Level | All liquid and solid material in the segment adjoining the pipe will be removed via the pipe. |

| Output Connection Options | ||

| Extra Tags visible for the Output connection are listed below. | ||

| Overflow | Tickbox | Overflow tick box to mark an outlet pipe as an unrestrained exit point. (i.e. this pipe must be in Transfer-Push FlowCalc mode and will take all material so that tank remains at connection height). |

| These additional Output connection tags are also available on the Pipe access window. Any changes made here will be updated on the pipe access window and vice-versa. | ||

| FlowCalc | Transfer Push | In Transfer Push mode the pipes act as chutes where flow is instantaneously transferred from the source to the destination unit. |

| Transfer Pull | In Transfer Pull mode simple networks are established, and this will determine the flow through the individual pipes. | |

| CapacityControl | Off | The maximum mass flow through the outlet will be set to unlimited amount (uncontrolled). |

| ByMassFlow | The maximum mass flow through the outlet. | |

| ByVolumeFlow | The maximum volumetric flow through the outlet. | |

| Qm.ReqdCapacity / Qm.Capacity | Input | Visible when ByMassFlow option is selected. The required pipe Capacity in mass flow if the pump is operating at 100% speed. |

| Qm.MinCapacity / Qm.MinCap | Input | Visible with the ByMassFlow method. The minimum user specified flow capacity by mass. |

| Qm.MaxCapacity / Qm.MaxCap | Input | Visible with the ByMassFlow method. The maximum user specified flow capacity by mass. Enter * for unlimited flow. |

| Qv.ReqdCapacity / Qv.Capacity | Input | Visible when ByVolumeFlow option is selected. The required pipe Capacity in volumetric flow if the pump is operating at 100% speed. |

| Qv.MinCapacity / Qv.MinCap | Input | Visible with the ByVolumeFlow method. The minimum user specified flow capacity by volume. |

| Qv.MaxCapacity / Qv.MaxCap | Input | Visible with the ByVolumeFlow method. The maximum user specified flow capacity by volume. Enter * for unlimited flow. |

| MeasRho | Display | The stream density used when converting between mass and volume flows. |

| OverCapacity | Spill | If more material enters the pipe then the Maximum Capacity value, then the excess material will be 'spilled' and sent to the Spills area. |

| Accept | If more material enters the pipe then the Maximum Capacity value, then the pipe must accept the excess material. | |

| BatchMethod | None | The Batch functionality is not enabled. |

| Total Mass | The Batch functionality is enabled and the required batch size is defined in terms of Mass flow. Further fields will become visible if this option is selected allowing the user to set the required batch mass. | |

| Total Volume | The Batch functionality is enabled and the required batch size is defined in terms of Volume flow. Further fields will become visible if this option is selected allowing the user to set the required batch volume. | |

| The following fields will be visible if Total Mass is selected as the Batch method. | ||

| M.BatchAddition | Input | The Mass of the required Batch. This amount of material will be allowed to flow out of the pipe at the rate specified in Qm.Capacity or Qv.Capacity. When this value is set the amount of material will be added to the amount of material already in M.BatchRemaining (the field below), and then this field will revert to 0. |

| M.BatchRemaining | Calc / Input | The Mass of material currently in a Batch, i.e. the amount of material in a Batch that still has to flow through the pipe. Normally this value is initialised at the start of a run and then it is calculated by SysCAD from the amount required in M.BatchAddition and the amount already delivered by the batch. However, the user may set this value and hence override the calculated Batch amount at any stage. If the users sets this as Undefined (or '*') this is equivalent to any infinite Batch and therefore the flow through the pipe will not be restricted. |

| M.BatchTotal | Display | The Total Mass that has flowed through the pipe using the Batch addition method. |

| The following fields will be visible if Total Volume is selected as the Batch method. | ||

| V.BatchAddition | Input | The Volume of the required Batch. This amount of material will be allowed to flow out of the pipe at the rate specified in Qm.Capacity or Qv.Capacity. When this value is set the amount of material will be added to the amount of material already in V.BatchRemaining (the field below), and then this field will revert to 0. |

| V.BatchRemaining | Calc / Input | The Volume of material currently in a Batch, i.e. the amount of material in a Batch that still has to flow through the pipe. Normally this value is initialised at the start of a run and then it is calculated by SysCAD from the amount required in V.BatchAddition and the amount already delivered by the batch. However, the user may set this value and hence override the calculated Batch amount at any stage. If the users sets this as Undefined (or '*') this is equivalent to any infinite Batch and therefore the flow through the pipe will not be restricted. |

| V.BatchTotal | Display | The Total Volume that has flowed through the pipe using the Batch addition method. |

| The following fields will be visible if Total Mass or Total Volume is selected as the Batch method. | ||

| BatchState | None | No Batch mode has been set. |

| Inactive | A Batch method has been selected, but the Batch is undefined. | |

| Busy | A Batch method has been selected, there is material remaining in the Batch, and hence there is flow in the pipe due to the Batch. | |

| Stop Flow | A Batch method has been selected, there is NO material remaining in the Batch, and hence there is no flow in the pipe, i.e. the Batch will prevent any flow in the pipe. | |

| BatchUsePreset | Tickbox | This enables the use Preset for the Batch amount. |

| M or V.BatchUsePreset | Input | The Mass or Volume of the Batch when the model is Preset. Refer to Preset for more information. |

Filters Tab Page

This page appears if the 'ShowAllOutlets' option is ticked and/or if any of the outlet connections have the 'Species-Filter' option selected.

If the 'ShowAllOutlets' option is ticked, then a column will be included for each outlet. If the 'ShowAllOutlets' option is NOT ticked, then only the outlets which have the 'Species-Filter' option selected will be shown.

| Tag (Long/Short) | Input/ Calc | Description |

|---|---|---|

| IO Options | ||

| ShowAllOutlets | Tickbox | If enabled, all outlets will be shown on a separate Filters tab page, regardless of whether the Species Filter method has been chosen. |

| Output Species Filters | ||

| Select.Solids | Only shown if 'Species-Filter' option has been selected for this outlet. | |

| Pass | All solid species will be allowed to pass to the outlet pipe. | |

| Block | All solid species will be blocked from passing to the outlet pipe. | |

| Select | The user can individually select which solid species will be allowed to pass to the outlet pipe. | |

| Select.Liquids | Only shown if 'Species-Filter' option has been selected for this outlet. | |

| Pass | All liquid species will be allowed to pass to the outlet pipe. | |

| Block | All liquid species will be blocked from passing to the outlet pipe. | |

| Select | The user can individually select which liquid species will be allowed to pass to the outlet pipe. | |

| Species | Tickbox/Display | If 'Select' option has been chosen for this phase (solids or liquids), then a Tickbox will appear. If this is ticked, then this species will be allowed to pass to the outlet. Otherwise, this field will display 'Pass' or 'Block' for each species based on the options selected either at the Select field or on the Connect tab page. |

Settings Tab Page

| Tag (Long/Short) | Input/ Calc | Description |

|---|---|---|

| Content... | ||

| Shape | Display | Vertical Unit. The tank is modelled with vertical sides. |

| Height | Input/Display | The required height of tank. This field cannot be changed while SysCAD is solving. |

| Volume | Input | The required volume of tank. |

| Area | Display | The surface area of tank based on the height and volume. |

| Diameter | Display | The diameter of tank based on the area and assuming a circular cross-section. |

| Level.SLResidenceTime / SLResTime | Calc | The residence time of the slurry in the tank. This value is based on the current tank level and the flows Out of the tank. |

| Level.ResidenceTime / ResTime | Calc | The residence time of the total mass, slurry and vapours, in the tank. This value is based on the current tank level and the flows Out of the tank. |

| SLResidenceTime / Full.SLResTime | Calc | The residence time of the slurry in the tank. This value is based on the full tank volume and the flows Out of the tank. |

| ResidenceTime / Full.ResTime | Calc | The residence time of the total mass, slurry and vapours, in the tank. This value is based on the full tank volume and the flows Out of the tank. |

| Layered Tank Options (These fields are only visible if the Layered or Layered_Flow Mixing Models are chosen) | ||

| MixFeeds | Tickbox | If this is enabled then all the input streams are first perfectly mixed and then available to EB before being added to the layered tank contents. If this is not enabled then EB options are not available and each stream is added to the layered tank at its respective connection height. |

| MixedFeedHeight | Input | The connection height fraction at which the mixed inputs (QCFeed) are added to the layered tank contents. This is only visible if MixFeeds is selected. |

| FixedP | Tickbox | If this is selected then the same tank pressure is used in all the layers within the tank, so any change in pressure is immediately applied to all layers. |

| Segment.Count | Input | The user may specify the number of Segments that are visible for viewing in the layered tank. Note This is not the same as the number of layers, which is dynamically calculated by SysCAD. |

| Segment.ShowIndex | Input | Available from Build 138.27330. The user defines which segment information to be displayed on the Detail and associated tabs. For example, if 0 is specified, the first segment information will be displayed on the Detail tabs. If -1 is specified, then the Detail tabs will not be displayed. Note: The tags on the Details tabs are NOT unique for each segment, values may change as a different segment is selected for display. Therefore it is NOT recommended to use these tags for control or reporting. |

| Layer.ShowIndex | Input | Available from Build 138.27330. The user defines which layer information to be displayed on the Layer and associated tabs. For example, if 0 is specified, the first layer information will be displayed on the Layer tabs. If -1 is specified, then the Layer tabs will not be displayed. Note: The tags on the Layer tabs are NOT unique for each layer, values may change as a different layer is selected for display. Therefore it is NOT recommended to use these tags for control or reporting. |

| MinLayerHeight | Input | The minimum height for any layer in the tank. Each layer will be approximately 10 times this value. Therefore, if the minimum layer height = 0.1% (the default value), each layer will be approximately 1% of the tank volume. |

| Solids.BulkSpace | Input | Only visible if the Separate Slurry option is selected. This defines the space (or volume) NOT occupied by the solids in any layer. This space is available for liquids but not solids. |

| Layered Tank Results (These fields are only visible if the Layered or Layered_Flow Mixing Models are chosen) | ||

| Layers | Calc | Only visible if the Separate Slurry option is NOT selected. This is the total number of layers created in the tank. |

| Level.Solids | Calc | Only visible if the Separate Slurry option is selected. This is the solids level in the tank. |

| Level.Liquids | Calc | Only visible if the Separate Slurry option is selected. This is the liquids level in the tank. |

| Layers.Solids | Calc | Only visible if the Separate Slurry option is selected. This is the number of solid layers created in the tank. |

| Layers.Liquids | Calc | Only visible if the Separate Slurry option is selected. This is the number liquid layers created in the tank. |

| Content Options | ||

| WithStaticHead | Tickbox | If this is enabled, the calculated static head pressure will be added to the tank pressure to determine the pressure of the outlet stream. |

| Networked | Tickbox | Removed in Build 139. |

| Mixed | Tickbox | Removed in Build 139. |

| MeanResTimes | Tickbox | If this is enabled then a new tab page Content will be displayed which shows the mean residences times of each species. |

| Content.Preset... (This section is used when the tank contents are preset) | ||

| AllowGlobal | Tickbox | If this is enabled then this tank will be preset when the Global Preset selection is enabled (this can be set in Plant Model. If this is disabled than a Global Preset will be ignored by this tank. |

| TemperatureReqd / T_Reqd | Input | The required temperature that is used when the tank contents are preset. |

| LevelReqd / LvlReqd | Input | The required level that is used when the tank contents are preset. |

| UseImage | Tickbox | PresetImg and associated PSp page will become visible if this is enabled. The user may define the composition required in the tank on these tabs and this composition will be used when the tank contents are preset. If this is disabled, then the actual composition in the tank will be used to adjust the masses in the tank when the tank contents are preset. |

| CopyContentToPreset | Button | When this is pressed, the current composition of the content of the tank will be transferred to the Preset Image. |

| Content.Spill... | ||

| HeightFrac | Display | The tank level at which solid and liquid spillage will occur. The default value is 101% - this allow a user to set a slurry line at 100%. |

| Target | Input | The Plant Area to which spills will be sent. The default area is usually the GlobalArea, but if the user has defined additional Plant areas, these can be selected. This allows the user to collect the spillages from different areas of the plant to separate Plant Areas. |

| Rate | Calc | The current spillage rate. |

| Total | Calc | The total amount of spillage from this tank since the start of the current run. |

| Content.Vent... | ||

| Target | Input | The Plant Area to which gas vents will be sent. The default area is usually the GlobalArea, but if the user has defined additional Plant areas, these can be selected. This allows the user to collect the vents from different areas of the plant to separate Plant Areas. |

| MaxRate | Calc | The maximum rate that the tank has vented during the current run. |

| Rate | Calc | The current rate of venting. |

| Total | Calc | The total amount of gas vented from this tank since the start of the current run. |

| Content.Safety... | ||

| LowestIOPt | Input | The lowest level allowed for a input or output connected to the tank. The default level is 1%. |

| Content.DynStats... | ||

| CollectStats | Tickbox | If ticked, SysCAD will calculate some basic statistics for the tank variables and display them below |

| The following fields are only displayed if the CollectStats tickbox is enabled. | ||

| Reset_Stats | Button | Resets all the statistics for this tank to zero. |

| Time | Calc | The amount of time that has passed since the statistics were last reset. |

| LevelAverage / LvlAvg | Calc | The average level of the tank since the statistics were last reset. |

| LevelMin / LvlMin | Calc | The lowest (minimum) level of the tank since the statistics were last reset. |

| LevelMax / LvlMax | Calc | The highest (maximum) level of the tank since the statistics were last reset. |

| OverflowTime | Calc | The amount of time that the tank was spilling (overflowing) since the statistics were last reset. |