Sugar Juice Screen

Navigation: Models ➔ Sugar Models ➔ Sugar Juice Screen

| Sugar Properties | Sugar Unit Models | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sugar Species Model | Sugar Cane Shredder | Sugar Crusher | Sugar Crystalliser | Sugar Dryer | Sugar Fugal | Sugar Fugal 2 | Sugar Juice Screen | Sugar Mud Filter | Sugar Vacuum Pan |

Latest SysCAD Version: 19 March 2024 - SysCAD 9.3 Build 139.35102

General Description

The SysCAD Sugar Juice Screen unit operation is available with the SysCAD Sugar add-on.

The sugar juice screen is used to separate mud solids and fibre from juice expressed during crushing operations. The juice screen also includes options for the evaporation of water and for heat loss to the environment.

Juice is fed to the screen (the screen allows for multiple feed streams to it). There are two product streams exiting from the unit, a Mixed Juice Stream and a Return Stream. There is also an optional Vent stream out. Any vapours coming into the system and any water vapour from evaporation leave via the vapour line connection.

The unit is assumed to have perfect mixing before separation. Juice, mud solids and fibre are then split independently to the outlet streams to meet the specified operating criteria.

Input and Output Connections

A number of the inputs and outputs for the sugar juice screen are optional. You connect the ones that you want to use depending on how you want the unit to operate.

| Label | Required / Optional | Input /Output | Number of Connections | Description | |

| Min | Max | ||||

| Feed | Required | In | 1 | 5 | Feed streams to the Juice Screen. |

| Mixed Juice | Required | Out | 1 | 1 | Mixed Juice Stream out (to processing). |

| Return Stream | Required | Out | 1 | 1 | Return Stream out (back to milling train). |

| Vent | Optional | Out | 0 | 1 | Vapour Outlet Stream containing all Vapours - NB required if vapours are present. |

Behaviour when Model is OFF

The juice screen may be turned Off by de-selecting the On tick box in the access window.

When the unit is off the following behavior occurs:

- All input feed streams are perfectly mixed and exit via the Mixed Juice stream. There is no environmental heat loss however, energy is conserved and product temperature will be adjusted accordingly if Feed streams are at different temperatures.

- NB any gases in any of the input streams will remain with those streams when the unit is off and are not sent to the Vent stream.

Model Theory

Physical Model

Feed - The only required input stream connection to the juice screen is the Feed stream (there may be up to 5 feed streams). All feed streams to the juice screen are assumed to mix perfectly. The feed streams must contain some mud solids and some fibre or a warning will be displayed.

Environmental Heat Transfer - Environmental heat transfer is included in the model. Any heat exchange with the environment is included in the energy balance calculations.

Evaporation - Evaporation is included in the model and the enthalpy of vaporisation is included in the energy balance calculations.

Gases - If there are gases in any of the feed streams or evaporation is enabled then a Vent stream connection is also required and all gases are split to the vent stream. If there are gases and no vent is connected all gases are sent to the Mixed Juice stream and a warning will be displayed.

Product Streams The screen output stream connections for the Mixed Juice and "Return Stream" are required. The Juice composition liquid composition is the same for both output streams. However, juice liquid, mud solids (which includes all solid material except fibre) and fibre (or true fibre from the sugar cane) are all split independently to meet the required screen performance criteria.

Product Temperature - Feed streams may be at different temperatures and have different compositions, the screen may exchange heat with the environment and water may evaporate from the juice during operation. All of these effects (including any enthalpy of dilution/concentration due to mixing or evaporation) are included in the energy balance and product temperature calculation. All product streams are assumed to be at the same temperature.

Environmental Heat Exchange Options

The sugar juice screen may lose heat to the environment. The heat loss options are set from a drop down list and include;

- None - No Environmental Heat Exchange occurs.

- Fixed_Loss - A Fixed Heat Flow Rate to the Environment is specified by the user.

- Ambient - A Heat Loss Constant is specified and heat loss is calculated as heat loss constant times the temperature difference between the product stream and ambient temperatures, [math]\displaystyle{ Q_{EnvLoss} = Constant \times \left(T_{prod} - T_{amb}\right) }[/math]

- SetTprod - A Product Temperature is specified and the required heat loss is calculated. NB This will force the product temeprature to be whatever value is specified and may result in heat gain to the unit which is probably not physically realistic.

For all the above options the heat flow is displayed. The Heat Flow is displayed for all options and heat flow from the juice screen to the environment is positive in sign. NB If a negative heat flow is reported, it indicates heat flow to the juice screen from the environment.

Evaporation Option

The sugar juice screen has the option of evaporation of water from the juice. The evaporation rate is a user input. If no evaporation is required this can be simply set to zero. An approximate heat loss rate due to evaporation is displayed. The Heat Flow is displayed is positive for heat loss due to evaporation.

Solids Separation

When the unit operation is solved, all streams into the juice screen are assumed to be perfectly mixed, any heat transfer or evaporation occurs, the product temperature is adjusted and then the liquid, mud solids and fibre are split as per the inputs. Efficiencies are defined by the mass fraction of the feed going to the return stream.

- [math]\displaystyle{ \begin{align} \text{TrueFibreSeparationEfficiency}, \eta_{TF} & =\left(\frac{\text{Mass True Fibre in Return Stream}} {\text{Mass True Fibre in Feed}}\right) \\ \text{SolidsSeparationEfficiency},\eta_{Sol} & =\left(\frac{\text{Mass Solids in Return Stream}} {\text{Mass Solids in Feed}}\right)\\ \text{TrueFibreFactor}, TFF & =\left(\frac{\eta_{TF}} {\eta_{Sol}}\right) \\ \text{MudSolidsSeparationEfficiency},\eta_{Mud} & =\left(\frac{\text{Mass Mud Solids in Return Stream}} {\text{Mass Mud Solids in Feed}}\right) \end{align} }[/math]

True Fibre - True fibre is the actual solid phase plant fibre material. In the SysCAD Sugar Properties Model plant fibre is a defined species, Fibre(s). The mass fraction of true fibre is specified for the mixed juice and return streams - the mass fraction is the mass of true fibre per total mass which includes both liquid and solids.

Mud Solids - Mud Solids include all solid material except true fibre. The SysCAD Sugar Properties Model includes a MudSolids species, however the calculated mud solids also includes any other solids except fibre that are present in the system.

The split of mud solids may be specified in two ways;

- Setting the True Fibre Factor which is the ratio of the true fibre separation efficiency to the overall solids separation efficiency) which includes both fibre and mud solids). The split of mud is then determined by the split of fibre and this parameter.

- Directly Setting the Fraction of Mud solids to Juice. In this case the fraction of mud that goes with the Mixed Juice stream is a fixed user input.

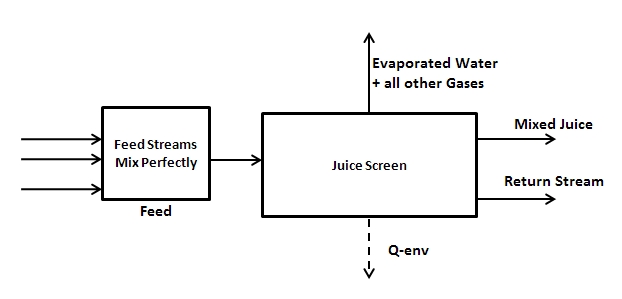

Flow Chart

The process is shown schematically in the flow chart below for the juice screen. Feed streams are mixed going in and product exits via the mixed juice and return streams. All gases exit via the vapour stream. Heat is exchanged the environment.

Data Sections

JuiceScreen

Unit Type: JuiceScreen - The first tab page in the access window will have this name. Configuration and connection inputs and results are displayed on this page.

Tag / Symbol |

Input / Calc |

Description

|

| Common Data on First Tab Page | ||

| Requirements | ||

| On | Tickbox | Tickbox used to turn the unit ON or OFF (off behavior is described above). |

| ShowQFeed | Tickbox | Tickbox to display or hide Feed data tab. |

| TackStatus | Tickbox | Option to display warnings. |

| Environmental Heat Loss | ||

| EnvLossMethod | None | No heat exchange with the environment. |

| FixedLoss | User specified environmental heat loss rate. | |

| Ambient | Heat loss determined as a constant times temperature difference from ambient. | |

| Set_Tprod | Final Product Temperature specified by user. | |

| EnvLossRqd | Input | The Required Environmental Heat Loss Rate - This is only visible if the FixedLoss Method is selected. |

| EnvLossCoeff | Input | The Environmental Heat Loss Rate Coefficient(kW/K) - This is only visible if the Ambient Method is selected. |

| FixedProductT | Input | User Specified Product Temperature - This is only visible if the Set_Tprod Method is selected. |

| Evaporation Loss | ||

| EvaporationLossQm | Input | User specified evaporation rate. |

| ApproxEvapHeatLoss | Display | Approximate rate of heat loss due to evaporation. |

| True Fibre Separation | ||

| RetStrmTFConcRqd | Input | Return stream true fibre concentration required (mass fraction). |

| FeedTFConc | Display | Mixed Feed true fibre concentration (mass fraction). |

| MixedJuiceTFConcRqd | Input | Mixed juice true fibre concentration required (mass fraction). |

| MixedJuiceTFConc | Display | Mixed juice true fibre concentration (mass fraction). |

| FibreRetention | Display | True fibre retention in return stream (mass fraction). |

| FeedFibreQm | Display | True fibre mass flow in feed. |

| RetStrmFibreQm | Display | True fibre mass flow in return stream. |

| MixedJuiceFibreQm | Display | True fibre mass flow in mixed juice stream. |

| Mud Solids Separation | ||

| SetMudtoJuice | Tickbox | Ticked Select user input mud mass fraction to juice / Unticked Control by true fibre factor. |

| MudtoJuiceRqd | Input | Set mass fraction of mud in feed to juice. |

| MudtoJuice | Display | Mass fraction of feed mud in juice. |

| MudSolRetention | Display | Feed mud solids fraction retained in return stream. |

| TrueFibreFactorRqd | Input | Required true fibre factor (dimensionless). |

| TrueFibreFactor | Display | Actual true fibre factor (dimensionless). |

| TrueFibreSepEff | Display | True fibre separation efficiency (%). |

| SeparationEfficiency | Display | Solids separation efficiency (%). |

| FeedMudSolids | Display | Feed mud solids mass flow. |

| RetStrmMudSolidsQm | Display | Return stream mud solids mass flow. |

| MixedJuiceMudSolQm | Display | Mixed juice mud solids mass flow. |

| FeedMudSolFrac | Display | Feed stream mud solids mass fraction. |

| RetStrmMudSolids | Display | Return stream mud solids fraction. |

| MixedJuiceMudSolids | Display | Mixed juice stream mud solids fraction. |

| FeedTotalSolidsQm | Display | Feed total solids mass flow. |

| RetStrmTotSolidsQm | Display | Return stream total solids mass flow. |

| MixedJuiceTotSolQm | Display | Mixed juice total solids mass flow. |

| FeedSolidsFrac | Display | Feed stream total solids mass fraction. |

| RetStrmTotSolids | Display | Return stream total solids mass fraction. |

| MixedJuiceTotSolids | Display | Mixed juice stream total solids mass fraction. |

Data Access Page

The second tab has the name Data and displays some results and information for the screening process.

Tag / Symbol |

Input / Calc |

Description

|

| True Fibre Fraction (of solids) | ||

| FeedFibreFrac | Display | Feed stream true fibre fraction (as percent of total solids). |

| RetStrmFibreFrac | Display | Return stream true fibre fraction (as percent of total solids). |

| MixedJuiceFibFrac | Display | Mixed Juice stream true fibre fraction (as percent of total solids).. |

| RetStrmSols@25 | Display | Return stream solids concentration at 25°C. |

| MixedJuiceSol@25 | Display | Mixed Juice solids concentration at 25°C. |

| FeedBrix | Display | Feed stream Brix. |

| RetStrmBrix | Display | Return stream Brix . |

| MixedJuiceBrix | Display | Mixed juice Brix. |

| FeedBrixQm | Display | Feed Brix mass flow. |

| RetStrmBrixQm | Display | Return stream Brix mass flow. |

| MixedJuiceBrixQm | Display | Mixed juice Brix mass flow. |

Warnings

The model will report errors and warnings for the following conditions.

| Warning Message | Comments |

| Vapour in Feed or Evaporation and NO Vent Connected | Vent stream must be connected if gases are present. |

| NO FIBRE in Feed - Check Stream Compositions | There is no fibre in the feed, some is required. |

| NO MUD in Feed - Check Stream Compositions | There is no mud in the feed, some is required. |

| Required Return Stream Fibre Fraction NOT Achieved! | Model cannot achieve set point - check input parameters. |

| Required Mixed Juice Fibre Fraction NOT Achieved! | Model cannot achieve set point - check input parameters. |

| Required Mud Fraction to Juice NOT Achieved | Model cannot achieve set point - check input parameters. |

| Required True Fibre Factor NOT Achieved | Model cannot achieve set point - check input parameters. |

| Return Stream Fibre Set Point Less than Feed | Target is less than input - check set point. |

| Mixed Juice Fibre Set Point > than Feed or Return Stream | Target is too high for filtered juice. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | SugarUnits.dll |

→ | Units/Links | → | Sugar: Sugar Juice Screen | |

| or | Group: | Sugar |

→ | Units/Links | → | Sugar: Sugar Juice Screen |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Sugar | → | Sugar Juice Screen |

See Insert Unit for general information on inserting units.