Boiler

Navigation: Models ➔ Energy Transfer Models ➔ Boiler

General Description

The Boiler model requires a feed water inlet and produces steam, either saturated or superheated and a blow-down water stream. The model calculates the energy required to produce the steam.

The user can set the following parameters:

- Temperature and pressure of the produced steam

- Required drum pressure

- Blowdown fraction

- Efficiency of the boiler

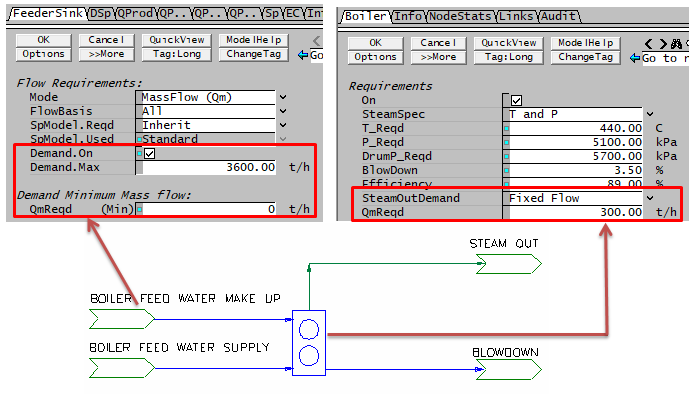

If the user sets a Demand value in the Steam pipe, then the Boiler unit will calculate the required amount of feed water to satisfy the steam demand plus the blowdown stream. This required value will be passed to the feed water inlet pipe. For an example on how to set up the boiler in steam out demand mode, please see Hints and comments below. Alternatively, there is an option in the model itself to set the required steam flow using the SteamOutDemand function.

This simple Boiler model does not include a Heater section. Therefore, there is no requirement for the user to specify the fuel type or the method of heating the water and steam. However, the unit does calculate the energy required by the boiler and therefore this information can be used elsewhere to set the amount of fuel required by the boiler.

Note: The Boiler & Combustion Project, which is distributed with SysCAD in the Examples folder, demonstrates the use of this model.

- The user may attach a Hot stream (usually containing hot gases) to the Heat Exchange connections on the Boiler model and the model will remove the required amount of energy from the Hot stream to accomplish the boiler steam conditions.

- The user may select between saturated or superheated steam for the final steam conditions.

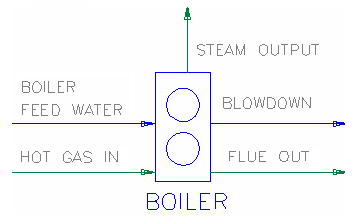

Diagram

The diagram shows the default drawing of the Boiler, with the connecting streams. The physical location of the connections is not important; the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | The Boiler Feed Water. |

| Steam | 1 Required | Out | 1 | 1 | The superheated Steam Outlet. |

| Blowdown | Optional | Out | 0 | 1 | The boiler blow down. |

| Heat Exchange | Optional | In | 0 | 10 | The hot input stream that provides heat for the boiler. |

| Heat Exchange | Optional | Out | 0 | 1 | The exhausted heating stream. NOTE: if Heat Exchange In is connected, then this stream must also be connected. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- No energy will be added to the incoming feed water stream, and hence no evaporation or heating will occur.

- If a stream is connected to the 'Blowdown' connection, then all the feed flowing into the unit will flow out of the 'Blowdown' pipe (at the incoming temperature and pressure).

- If there is no stream connected to the 'Blowdown' connection, then all of the feed will flow out of the Steam connection (at the incoming temperature and pressure).

- If Heat Exchange streams are connected, Heat exchange In will exit Heat Exchange Out with no heat exchange.

Model Theory

The Boiler is designed to

- Heat a stream of high pressure Boiler Feed Water to Saturated conditions at the specified Drum pressure.

- A specified fraction of the saturated liquid is split off to blow down. A typical blow down is 2 to 8%.

- The remaining liquor is heated to vapour at the specified outlet temperature and pressure (superheated steam).

The energy required to do the above divided by the boiler efficiency is reported as fuel energy required.

Assumptions and Limitations

- The Feed (Boiler Feed Water) stream will contain water and is at a pressure higher than the Boiler Drum pressure.

- The drum pressure should be higher than the outlet steam pressure.

- All feed water will be evaporated to steam. Thus the outlet steam conditions specified must be at saturated or superheated conditions.

- Heat Exchanger Out temperature must be higher than the Drum Temperature, to avoid temperature cross over error.

Data Sections

The default sections and variable names are described in detail in the following tables. The default Boiler access window may consist of a number of sections. This number may increase, based on user configuration.

- Boiler tab - The first tab contains general information relating to the unit as well as a tick box for ShowQFeed.

- QFeed - Optional tab, only visible if ShowQFeed is enabled. This page shows the properties of the combined feed to the unit.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab - contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Boiler Page

Unit Type: Boiler - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick Box | If this option is deselected, the boiler will not be operational and thus all material will report to the blow down stream, if it is connected. |

| SteamSpecification / SteamSpec | T and P | Both TemperatureReqd and PressureReqd can be user specified. |

| SuperHeat T,P / SuperHeat | Both TemperatureReqd and PressureReqd can be user specified, TemperatureReqd must be greater than or equal to the Saturated Temperature at the specified pressure. | |

| SuperHeat dT,P | Both SuperHeatReqd and PressureReqd can be user specified, SuperHeatReqd must be greater than or equal to zero, so that TemperatureReqd will be greater than or equal to the Saturated Temperature at the specified pressure. | |

| Saturated T | TemperatureReqd can be user specified, PressureReqd is Saturated pressure at the specified temperature. | |

| Saturated P | PressureReqd can be user specified, TemperatureReqd is Saturated temperature at the specified pressure. | |

| TemperatureReqd / T_Reqd | Input / Display | The temperature required for the outlet steam. Note: this must be >= Saturation Temperature @ outlet pressure. |

| PressureReqd / P_Reqd | Input | The pressure required for the outlet steam. Note: This must be lower than or equal to the drum pressure. |

| SuperHeatReqd | Input | Only visible if SuperHeat dT,P is chosen for the SteamSpecification. The degrees of superheat required for the outlet steam. Note: this must be >= 0. |

| DrumP_Reqd | Input | The drum pressure. Note: Feed Water P > Drum P >= outlet P. |

| Blowdown | Input | The amount of boiler blow down. Note this will be ignored (assumed 0) if the physical blowdown connection is not present. |

| Efficiency | Input | This is the efficiency of the boiler. This value is used when calculating the energy required by the boiler. |

| SteamOutDemand | None | The amount of steam produced will be a function of the feed flow and unit configuration. |

| Fixed Flow | The user can specified the desired mass flow of steam to be produced. This requirement will be fed back to the feed stream/s using the General Demand functionality. | |

| Flow From Tag | The user can specify a tag that contains the desired mass flow of steam to be produced. This requirement will be fed back to the feed stream/s using the General Demand functionality. | |

| MassFlowReqd / QmReqd | Input | This field is only visible if Fixed Flow is chosen for SteamOutDemand. The required mass flow of steam to be produced. |

| QmReqdTag | Input | This field is only visible if Flow From Tag is chosen for SteamOutDemand. The required SysCAD Tag for desired mass flow of steam to be produced, e.g. P_001.Qm (t/h). |

| QmReqd.Meas | Calc | This field is only visible if Flow From Tag is chosen for SteamOutDemand. The current value of the SysCAD Tag for the desired steam flow. |

| QmReqdFactor | Input | This field is only visible if Flow From Tag is chosen for SteamOutDemand. The mass flow factor. Desired mass flow = QmReqd.Meas * QmReqdFactor. The Factor must be ≥ 0. |

Options | ||

| ShowQFeed | Tick Box | QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined feed stream. See Material Flow Section. |

Feed | ||

| Feed.MassFlow / Feed.Qm | Calc | The total mass flow of the combined Feed stream. |

| Feed.Temperature / Feed.T | Calc | The temperature of the combined Feed stream. |

| Feed.Pressure / Feed.P | Calc | The pressure of the combined Feed stream. If different feed streams have different pressures, then the lowest pressure is used. |

Drum | ||

| DrumTemperature / DrumT | Calc | Drum Temperature. This is the saturation temperature at the Drum Pressure. |

Energy | ||

| HeatReqd1 | Calc | The energy required for heating boiler feed water to Saturation Temperature at the Drum Pressure. |

| HeatReqd2 | Calc | The energy required to evaporate all the preheated water (less boiler blow down) to the required outlet temperature and pressure. |

| TotalHeatReqd / TtlHeatReqd | Calc | The Total Heat (energy) required = HeatRqd1 + HeatRqd2 |

| FuelEnergyReqd | Calc | This is the amount of fuel required to run the boiler = Total Heat Required / Boiler Efficiency. |

| HeatFlow | Calc | This is the amount of energy lost due to inefficiency. HeatFlow = Total Heat Required - Fuel Energy Required. Since this is a loss of energy, it will be displayed as negative heat flow. |

Blowdown | ||

| BlowDown.MassFlow / BlowDown.Qm | Calc | This is the mass flow of the boiler blow down. |

| BlowDown.Temperature / BlowDown.T | Calc | Drum Temperature. |

| BlowDown.Pressure / BlowDown.P | Calc | Drum Pressure. |

Steam | ||

| SteamOut.MassFlow / SteamOut.Qm | Calc | This is the mass flow of the boiler steam outlet. |

| SteamOut.Temperature / SteamOut.T | Calc | The boiler steam outlet temperature. |

| SteamOut.Pressure / SteamOut.P | Calc | The boiler steam outlet pressure. |

| SteamOut.SatT | Calc | The boiler steam outlet Saturation Temperature. |

| SteamOut.SuperHeat | Calc | This is the degree of superheat the steam outlet contains. Thus, the temperature above its saturation temperature. |

General Demand(Only visible if Steam outlet pipe (or downstream pipe) has demand specified or using SteamOutDemand functionality) | ||

| SteamOut.DemandQm | Calc | Displays the Steam outlet flowrate required (as specified in the outlet pipe Qm_Demand.Reqd or via the SteamOutDemand settings within the Boiler model). |

| SteamOut.MassFlow / SteamOut.Qm | Calc | Displays the Steam outlet actual flowrate |

| SteamOut.MassFlowErr / SteamOut.QmErr | Calc | Displays the difference between the Steam outlet flowrate required and Steam outlet actual flowrate (SteamOut.DemandQm - SteamOut.Qm). |

| Feed.DemandQm | Calc | Displays the makeup stream flowrate into the Boiler. (This flow is from the feeder with Demand.On selected.) |

| Feed.FixedQm | Calc | Displays the remaining feed rates into the Boiler (less the make up stream). |

Heat Exchange(Only visible if Heat Exchange In and Out are connected) | ||

| HX.MassFlow / HX.Qm | Calc | The Mass flow of the combined Heat Exchange In streams. |

| HX.TemperatureIn / HX.Ti | Calc | The Temperature of the combined Heat Exchange In streams. |

| HX.TemperatureOut / HX.To | Calc | The Temperature of the Heat Exchange Out stream. |

| HX.Pressure / HX.P | Calc | The Pressure of the combined Heat Exchange In streams. |

| HX.Duty | Calc | The Heat Exchange Duty. |

Hints and Comments

A) Example Project: Boiler and Combustion Example

B) Setting the Boiler Water Makeup on demand mode:

|

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Heat Transfer: Boiler | |

| or | Group: | Energy Transfer |

→ | Units/Links | → | Heat Transfer: Boiler |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Heat Transfer | → | Boiler |

See Insert Unit for general information on inserting units.

Example Project

Please see Boiler & Combustion Project, Nickel Copper Project