Flash Train Control

(Redirected from FlashTrainControl)

Jump to navigation

Jump to search

Navigation: Models ➔ Control 2 Models ➔ Flash Train Control

Related Links: Flash Tank 2 in Dynamic Mode

General Description

- The Flash Train Control unit operation is used to balance the pressure for flash train models in dynamic mode.

- Standalone unit - no Pipe connections.

- Dynamic simulation only.

- Currently works for Flash train involving Flash Tank 2 and Shell and Tube Heat Exchanger 2 models only.

- Only work for certain combinations, not all combinations will work.

Diagram

The diagram shows the default drawing of the Flash Train Control unit.

Inputs and Outputs

There are no connections to this unit.

Model Theory

The flash train control is used to balance the pressure between flash train units in dynamic projects.

- It assumes all flash vapours from the flash train (including multiple flash tanks) will combine into a single point.

- It assumes all flash vapours are 100% steam, therefore no non-condensables present.

- It assumes the pressure drop (if any) occurs in the flash vapour line exiting the flash tanks (prior to ties)

- It assumes all flash tanks in the flash train will have the same flash pressure. If different pressure drops are entered in the exit pipes (where number of FT > 1), then the higher pressure drop value will be used in all flash tanks.

The Flash Train control model CAN handle:

- Single or Multi flash tank 2 models (Flash vapour must combine prior to distribution)

- Single or Multi shell and tube 2 Heat Exchangers (flash Vapour split based on heat exchanger configuration)

- Pressure drop in flash tank vapour exit stream

- Vent steam from Heat Exchanger shell side.

- Heat loss from Flash tanks and/or Shell and Tube heat exchanger.

- Export vapour (flash vapour split to other units)

- Import vapour (steam input from other sources)

The Flash Train control model CANNOT handle:

- Barometric condensers

- Direct contact heater

- Desuperheaters

- Evaporators

- Multiple flash tank vapour streams not mixing prior to distribution.

- Non-condensables in the vapour stream.

- Heat loss/gain in the pipes / ties.

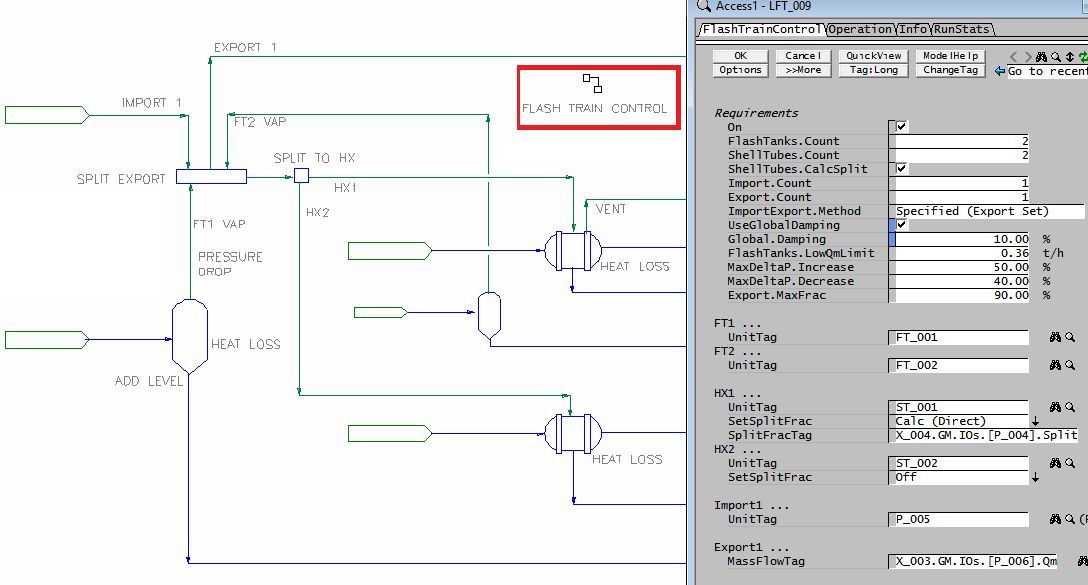

Example

NOTES:

- Flash Tanks - adjust pressure to match heater duty, SysCAD will automatically change the Target Method to "Stand Alone". Additional variations are:

- Can add Level/volume to the Flash Tanks

- Add Heat Loss

- Add exit pipe pressure drop

- All Flash vapours within the same flash train must combine.

- Shell and Tube Heat Exchanger - can demand steam from the flash tanks based on theoretical duty. SysCAD will automatically change the Method to "Condensing" And Condensing Method to "Demand (UA)". Additional variations are:

- Vent steam

- Heat Loss

- Steam to the heat exchangers should have the export steam taken out first, as per drawing above.

- Import/Export Steam should combine/split off first prior to sending to heater steam distribution.

Data Sections

Summary of Data Sections

- FlashTrainControl tab - Contains the user input parameters for the unit.

- Operation tab - This page contains the results for the flash train Control.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

FlashTrainControl

Unit Type: FlashTrainControl - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Requirements | ||

| On | Tick Box | The Flash Train Control unit will be enabled or disabled using this box. |

| FlashTanks.Count | Input | The number of Flash Tank 2 units to include in the Flash Train. Valid numbers are 0 - 6. |

| ShellTube.Count | Input | The number of Shell and Tube 2 Heat Exchanger units to include in the Flash Train. Valid numbers are 1 - 4. |

| ShellTubes.CalcSplit | Input | Visible when ShellTube.Count > 1. Selecting this option will allow heater demand based on heater configuration to work. All heat exchanger will be set to Condensing mode with Demand (UA) method. |

| Import.Count | Input | The number of user input steam stream to include in the Flash Train. Valid numbers are 0 - 10. |

| Export.Count | Input | The number of export steam to include in the Flash Train. Valid numbers are 0 - 10. |

| ImportExport.Method | Measured Difference | Import and export streams do not have to be defined within the Flash Train Control model, (thus Import.Count and Export.Count can remain at 0). SysCAD takes the difference between total Flash Tank Vapour, total shell and tube vent and total shell and tube condense steam to work out the total import/export amount. The model is more responsive to step changes if using a "Specified" method. |

| Specified (Export Measured) | Export count is specified in the flash train controller, user also specifies the tag where export steam is located, the flash train control model reads the amount of export steam. | |

| Specified (Export Set) | Export count is specified in the flash train controller, user also specifies the tag where export steam is located, the export steam amount is specified within the flash train control model, located on the Operations Tab. This is the recommended method. | |

| UseGlobalDamping | Tick Box | Damping specified will be applied to all the Flash Train Control models. |

| Global.Damping | Input | Visible with UseGlobalDamping selected. Damping specified will be applied to all the Flash Train Control models. |

| Damping | Input | Visible with UseGlobalDamping not selected. Damping specified will be applied to the current Flash Train Control model only. |

| FlashTanks.LowQmLimit | Input | The low limit for the flash tank where no flash will occur. |

| MaxDeltaP.Increase | Input | The maximum delta pressure increase. Valid values are 0.10 - 75%. |

| MaxDeltaP.Decrease | Input | The maximum delta pressure decrease. Valid values are 0.10 - 75%. |

| Export.MaxFrac (%) | Input | Visible with the Specified (Export Set) method. The maximum fraction of flash vapour available for export. |

| FT(n)... Visible when FlashTanks.Count is >1. One group of tags per Flash Tank. | ||

| UnitTag | Input | The Tag of the Flash Tank 2 unit to be included in the flash train model for pressure balancing. |

| ConnOK | Feedback | Check the validity of the tag. |

| HX(n)... Visible when ShellTube.Count is >1. One group of tags per HX. | ||

| UnitTag | Input | The Tag of the Shell and Tube 2 HX unit to be included in the flash train model for pressure balancing. |

| ConnOK | Feedback | Check the validity of the tag. |

| SetSplitFrac (Visible when ShellTubes.CalcSplit is on.) |

Off | No calculation is performed. (One of the HX should have this method selected to take the balancing steam) |

| User Value | User specified split fraction (value entry is located on the Operation tab). When using this method, not all heater demands maybe met. | |

| Calc Direct | Steam split to the Shell and tube will be adjusted based on heater demand. Use this method where the tie distribution excludes import/export steam. | |

| Calc Scaled | Steam split to the Shell and tube will be adjusted based on heater demand. Use this method where the tie distribution includes import/export steam. (note, this is not as efficient as separating out the import/export steam first, then use the Calc Direct method for HX steam distribution). | |

| SplitFracTag | Input | The tag where the steam split takes place. This is normally in the Tie - Split, General - PercSplit. The balance stream should be left in (Demand) mode. |

| Import(n)... Visible when Import.Count is >1. One group of tags per Import Tag. | ||

| UnitTag | Input | The Tag of the pipe that contains the input steam. |

| Export(n)... Visible when Export.Count is >1. One group of tags per Export Tag. | ||

| MassFlowTag | Input | The Tag of the export steam, this is where the split flow is specified, such as the Tie - Split, set as mass flow. |

Operation

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Requirements | ||

| SetFlashP | Off | The Flash Tank pressure will not be adjusted automatically. |

| User Value | The Flash Tank pressure will be set to the User Flash Pressure. | |

| From Calc | The Flash Tank pressure will be adjusted based on the flash train pressure balance. | |

| User.FlashP | Input | Visible when SetFlashP is set to User Value. Sets the Flash Tank pressure to the specified value. |

| Results | ||

| FlashTanks.MassFlow / FlashTanks.Qm | A | The combined flashed tank vapour from all flash tanks in the flash train. |

| FlashTanks.MaxMassFlow /FlashTanks.MaxQm | Feedback | The calculated maximum flashed tank vapour in the flash train using the minimum pressure allowed (based on the user specified limits) |

| Import.Qm | Feedback | The total input steam to the flash train |

| Export.QmReqd | Feedback | the total required export steam from the flash train. |

| Export.QmUsed | Feedback | the actual export steam from the flash train. Could be less than required due to limits. |

| ShellTubes.VentQmReqd | Feedback | The vent steam required from the shell and tube heaters. |

| ShellTubes.VentQm | B | The vent steam from the shell and tube heaters. Could be less than required due to limits. |

| ShellTubes.VapQm | C | The flash vapour for condensing in the shell and tube heaters. |

| ShellTubes.DemandQmReqd | C | The required flash vapour for condensing in the shell and tube heaters. |

| ImportExport.Qm | =A-B-C | The overall import / export steam. -ve indicates more import than export steam. +ve indicates more export steam than import steam. |

| TheoreticalDuty / TheorDuty | Feedback | The theoretical duty of the shell and tube heat exchangers. |

| DutyDifference / DutyDiff | Feedback | The duty difference between actual duty and theoretical duty. |

| Calc.PMin | Feedback | Minimum pressure for the flash train based on user specified limits. |

| Calc.Iterations | Feedback | number of iterations used to calculate the flash train pressure. |

| Calc.FlashP | Feedback | The calculated flash tank pressure based on heater configurations. |

| Used.FlashP | Feedback | The used flash tank pressure, if using user specified method. |

| FT(n)... Visible when FlashTanks.Count is >1. One group of tags per Flash Tank. | ||

| UnitTag | Feedback | The Flash Tank tag name |

| Feed.MassFlow / Feed.Qm | Feedback | The feed flow to the flash tank |

| Feed.Temperature / Feed.T | Feedback | The feed temperature to the flash tank |

| Feed.FracOfTotal | Feedback | Liquor Feed to this flash tank as a percentage of the total Liquor feed to the flash train. |

| VapFracToCond | Feedback | The vapour sent to the condensing HX (referenced to HX1) as a percentage of the flash vapour from this flash tank. |

| Prev.VapMassFlow / Prev.VapQm | Feedback | The amount of flash vapour calculated in the previous time step. |

| Prev.FlashT | Feedback | The Flash tank temperature calculated in the previous time step. |

| Prev.FlashP | Feedback | The Flash tank pressure calculated in the previous time step. |

| PressDrop / PDrop | Feedback | Pressure drop for the flash tank, as specified in the flash tank exit pipe. The pressure drop is assumed to be the same for all flash tanks in the flash train. The highest pressure drop value will be used if different values are specified. |

| Calc.FlashT | Feedback | The Flash tank temperature |

| Calc.FlashP | Feedback | The Flash tank pressure, all flash tanks in the flash train will have the same pressure. |

| HX(n)... Visible when ShellTube.Count is >1. One group of tags per HX. | ||

| UnitTag | Feedback | The Shell and Tube heat exchanger tag name. |

| VentQmReqd | Feedback | The required amount of steam to be sent to the vent as specified in the heat exchanger. |

| VentQm | Feedback | The actual amount of steam sent to the vent, could be limited by amount available for venting. |

| VapQm | Feedback | The amount of steam available for condensing (less vent) |

| DutyDifference / DutyDiff | =TheorDuty-Duty | The duty difference between theoretical and actual. When the solutions is solved, this should be close to 0. If this in non-zero, it normally implies the flash train configuration cannot be solved with this controller, either review the configuration or have to add in other type of control. |

| Demand.QmReqd | C | The required flash vapour for condensing in the shell and tube heaters. |

| Demand.Frac | Feedback | Only visible when HX>1 and using ShellTubes.CalcSplit option. The fraction of vapour split based on heater demand. |

| Import(n)... Visible when Import.Count is >1. One group of tags per Import Tag. | ||

| UnitTag | Feedback | The pipe name of the import steam. |

| MassFlow / Qm | Feedback | The flowrate of the import steam. |

| Temperature / T | Feedback | The temperature of the import steam. |

| Pressure / P | Feedback | The pressure of the import steam. |

| Export(n)... Visible when Import.Count is >1. One group of tags per Export Tag. | ||

| MassFlowTag | Feedback | The Tag name of the export steam. This was specified by the user on the FlashTrainControl Tag. |

| MassFlow / Qm | Feedback | The mass flow of the export steam. Visible with the Measure Difference or Specified (Export Measured) method. |

| MassFlowReqd / QmReqd | Feedback | The required mass flow of the export steam. Visible with the Specified (Export Set) method. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Control 2: Flash Train Control | |

| or | Group: | General |

→ | Units/Links | → | Control 2: Flash Train Control |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Control 2 | → | Flash Train Control |

See Insert Unit for general information on inserting units.