Cooling Tower

Navigation: Models ➔ Energy Transfer Models ➔ Cooling Tower

General Description

The cooling Tower has two calculation modes:

- Simple - This is a very basic water evaporation model. The models assumes the cooling effect comes from water evaporation only and does not take into account the heat exchanged with air flow or tower design.

- Merkel - The implementation of the Merkel method allows the user to obtain some tower design characteristics and calculate the tower outlet temperature based on the Air Wet bulb temperature and Liquid to Gas mass flow ratio.

The cooling tower unit can pass back downstream liquid out flowrate Demand, based on the feed to cooling tower and total losses, it can calculate the water make up required through a demand feeder. For information on how to set up the cooling tower in demand mode, please see Hints and comments.

Note: The Cooling Tower Project and Evaporation Project, which are distributed with SysCAD in the Examples folder, demonstrate the use of this model in a SysCAD project.

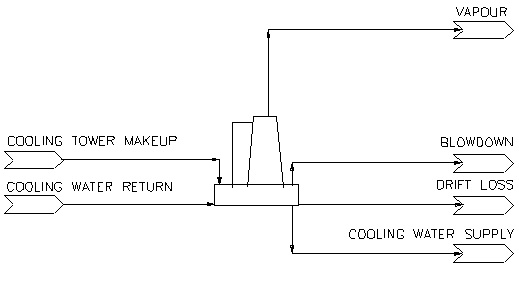

Diagram

The diagram shows the default drawing of the cooling tower, with the required connecting streams. The unit will not operate unless all of the above streams are connected. There are two optional output connections for the loss streams.

The physical location of the connections is not important; the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | The warm water feed. |

| Vapour | 1 Required | Out | 1 | 1 | The evaporation loss. |

| LiquorLoss | Optional | Out | 1 | Cooling tower water loss. | |

| DriftLoss | Optional | Out | 1 | Cooling tower drift loss. | |

| Liquor | 1 Required | Out | 1 | 1 | The cooled water outlet. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- No no evaporation or cooling will occur, all cooling water feed will report to the "Liquor" output stream.

Model Theory

Simple Method

The way this model works is to cool the water inlet by water evaporation. The user is required to specify the air wet bulb temperature, and the approach temperature to this wet bulb temperature. Enough water is then evaporated to achieve this.

Please NOTE: This method does NOT take into account the heat loss by contact with air. It is cooling by water evaporation only. For a better estimation of heat balance, please use the Merkel method.

Merkel Method

The warm water entering the tower is cooled by transferring Sensible and latent heat from water droplets to the surrounding air.

Merkel has developed a method to analyse this heat transfer base on the enthalpy potential difference as the driving force. Please refer to references for the full theory. However, the equations implemented by SysCAD will be briefly outlined below for quick reference. NB Cooling towers are generally analyzed on the basis of cooling per unit of tower internal ground area.

The integrated form of the Merkel equation is:

- (1) [math]\displaystyle{ \cfrac{KaV}{L} = \int\limits_{T2}^{T1}\cfrac{CdT}{h_w-h_a} }[/math]

Where:

- KaV/L = tower characteristic

- K = mass transfer coefficient (lb water/h ft2)

- a = contact area/tower volume (ft2/ft3)

- V = active cooling volume/plan area (ft3/ft2)

- L = water loading, mass flow of liquid per unit of ground area into the top of the tower (lb/h ft2)

- C = specific heat of water (assumed to be a constant 1.0 BTU/lb°F)

- T1 = hot water temperature (°F)

- T2 = cold water temperature (°F)

- T = bulk water temperature (°F)

- hw = enthalpy of air-water vapour mixture at bulk water temperature (Btu/lb dry air)

- ha = enthalpy of air-water vapour mixture at wet bulb temperature (Btu/lb dry air)

Thermodynamics also dictate that the heat removed from the water must be equal to the heat absorbed by the surrounding air, thus:

- (2) [math]\displaystyle{ \cfrac{L}{G} = \cfrac{h_2-h_1}{C(T_1-T_2)} }[/math]

where:

- G = air loading, mass flow of dry air per unit of ground area into bottom of the tower (lb/h ft2)

- L/G = liquid to gas mass flow ratio (lb/lb or kg/kg)

- C = specific heat of water (assumed to be a constant 1.0 BTU/lb°F)

- T1 = hot water temperature (°F)

- T2 = cold water temperature (°F)

- h2 = enthalpy of air-water vapour mixture at exhaust wet-bulb temperature (Btu/lb dry air)

- h1 = enthalpy of air-water vapour mixture at inlet wet-bulb temperature (Btu/lb dry air)

Using the above equations, the user can either solve for:

- KaV/L -- by providing the L/G ratio, ambient wet bulb temperature, and water outlet temperature required (or the approach temperature).

- Water outlet temperature -- by providing the L/G ratio, ambient wet bulb temperature, and tower characteristic (KaV/L).

- NOTE: Tower characteristic values can be obtained through vendors or by looking up nomographs, such as the one found in Perry's Chemical Engineer's Handbook 6th edition page 12-15. Typical numbers used for mechanical draft cooling towers are:

- L/G ranging from 0.75 to 1.5, and

- KaV/L ranging from 0.5 to 2.5.

Water Losses

A number of methods are available to calculate the water losses. Water losses include evaporation, drift (water entrained in discharge vapour), and blowdown (water released to discard solids). See Perry's Chemical Engineer's Handbook for more information.

1) LossMethod: Drift and Blowdown

- Evaporation Factor = 0.00085

- Evaporation Loss = Evaporation Factor * water flowrate * (T1-T2) [T1 and T2 in °F]

- Drift losses = typically 0.1 to 0.2% of water supply

- Blowdown Loss = Evaporation Loss/(Cycles-1)

- where Cycles = the ratio of total dissolved solids (TDS) in the circulating water to the TDS in the make-up water. Normal number of Cycles is between 3 and 7.

- Total Losses = Evaporation Losses + Drift Losses + Blowdown Losses

2) LossMethod: None

- There are no drift or blowdown losses.

3) LossMethod: Mass Fraction and Mass Flow

- Can specify the required loss directly as fraction or flow. In addition, using FracOfLossToDrift, the amount of this loss that reports to drift (remainder goes to blowdown ) can be set.

Optional stream connections for losses

The output streams LiqLoss and DriftLoss are optional connections. The drift and blowdown losses report as follows depending on if these streams are connected:

- No LiqLoss and No DriftLoss : All losses exit with Liquor stream

- LiqLoss present and No DriftLoss : All losses exit with LiqLoss stream

- LiqLoss present and DriftLoss present : Blowdown reports to LiqLoss stream and drift reports to DriftLoss stream

- No LiqLoss and DriftLoss present : Blowdown reports to Liquor stream and drift reports to DriftLoss stream

Assumptions, Limitations and comments

- The Simple method only accounts for the cooling effect of water evaporation in the cooling tower. Cooling by airflow is not accounted for neither is the tower design.

- The feed stream must contain water.

For Merkel method:

- The merkel method uses the air enthalpy difference to calculate the water outlet temperature; SysCAD does this internally using hardwired air enthalpy equations. Therefore, the user does not need to put in an air stream to the cooling tower. The required air flowrate is calculated from the required L/G ratio.

- The maximum valid air temperature (for air enthalpy calculation) is 70dC or 158dF.

- The ambient wet bulb temperature is required as an input. The cooling tower model in SysCAD does not handle relative humidity and so on.

- It is important to check for the validity of L/G and KaV/L values from nomographs otherwise you may have conditions where a solution cannot be found.

- L/G ratio is the actual ratio; design L/G and tower efficiency have not been accounted for.

For Air Water Mixture Estimates:

- The airflow to the cooling tower is not an actual connection on the flowsheet, but rather it is an estimate of what it should be based on user specified L/G ratio. The air-water mixture outlet properties are also estimated using user specified air feed conditions.

- If the psychrometric charts are handy, user should refer to it for wet bulb temperature and air humidity information.

References

- Perry et al Perry's Chemical Engineers' Handbook 6th or 7th Edition, pp 12-12 to 12-17, McGraw-Hill 1984

- DQ Kern Process Heat Transfer, Chapt 17, McGraw-Hill 1983 (this book gives an excellent development of the equations used)

- Merkel, F., Forschungsarb.. 275, 1-48 (1925)

Data Sections

The default sections and variable names are described in detail in the following table. The default Cooling Tower access window consists of 3 sections:

- CoolingTower tab - This first tab contains general information relating to the unit

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab - contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Cooling Tower Page

Unit Type: CoolingTower - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick Box | If this option is deselected, the cooling tower will not be operational and thus all material will report to the liquor stream. |

| Method | Simple | The cooling is provided by water evaporation only and does NOT take into account the heat exchange with air. |

| Merkel | See model theory. | |

Characteristics | ||

| Merkel Method | ||

| CalcType | KaV/L | The water outlet temperature is calculated from the KaV/L. |

| OutletT | The tower characteristics are calculated from required water outlet temperature. | |

| AirWetBulbT | Input | The ambient air wet bulb temperature. |

| ApproachT | Input/Calc | The difference between the water outlet temperature and the ambient air wet bulb temperature. This is an Input when using the KaV/L method, and it is calculated when using the OutletT method. |

| LG_Ratio | Input | L/G - The liquid to Gas mass flow ratio. |

| KaVL | Input/Calc | KaV/L - The tower characteristic (see model theory). This is an calculated when using the KaV/L method, and it is an input when using the OutletT method. |

| Feed.MassFlow / Feed.Qm | Display | The mass flowrate of the tower inlet is displayed. |

| Feed.Temperature / Feed.T | Display | The feed water temperature. |

| TempDrop / TDrop | Calc | The temperature change between the Feed and the Outlet temperatures. |

| FinalT | Calc | The water outlet temperature. |

| HeatTransfer | Calc | The amount of energy transferred to heat up the air stream. |

| FinalP | Calc | The pressure of the cooling tower. NOTE: the cooling tower works at atmospheric pressure. |

| Simple Method | ||

| AirWetBulbT | Input | The ambient air wet bulb temperature. |

| ApproachT | Input | The difference between the water outlet temperature and the ambient air wet bulb temperature. |

| Feed.MassFlow / Feed.Qm | Display | The mass flowrate of the tower inlet is displayed. |

| Feed.Temperature / Feed.T | Display | The feed water temperature. |

| TempDrop / TDrop | Calc | The temperature change between the Feed and the Outlet temperatures. |

| FinalT | Calc | The water outlet temperature. |

| FinalP | Calc | The pressure of the cooling tower. NOTE: the cooling tower works at atmospheric pressure. |

Water Loss / Makeup | ||

| LossMethod | None | No water loss. |

| MassFrac | Specify the total water loss required as a mass fraction (does not include the evaporation loss). | |

| MassFlow | Specify total water loss required as mass flow (does not include the evaporation loss). | |

| Drift&Blowdown | Alternative method to specify separate drift and blowdown losses. | |

| LossFracReqd | Input | Only available when MassFrac Loss Method is selected. Total loss required specified as fraction of feed. |

| LossQmReqd | Input | Only available when MassFlow Loss Method is selected. Total loss required specified as a flow rate. |

| FracOfLossToDrift | Input | Only available when MassFlow or MassFrac Loss Method is selected. Portion of total loss that reports to drift loss, the remainder reports to blowdown (or liquid) loss. |

| DriftLoss | Input | Only available when the Drift&Blowdown method is selected. (0.1 - 0.2) |

| Cycles | Input | This is the ratio of total dissolved solids (TDS) in the circulating water to the TDS in the make-up water. Normal number of Cycles is between 3 and 7, but must be greater than 2. This is only available when the Drift and Blowdown method is selected. |

| MaxEvapFrac | Input | This is for the simple method only, where the user can limit the % of water evaporation. The minimum amount the user can set is 1%. NOTE: if this is used, the outlet temperature may not meet specifications. |

| EvapFactor | Input | This is for the merkel method only. The default is 0.00085 (see model theory). |

| DriftLossQm | Calc | Loss due to Drift in mass flow. |

| BlowdownLossQm | Calc | The blowdown loss in mass flow. |

| LossQm | Calc | Total loss mass flow (sum of drift and blowdown loss). |

| EvapLossQm | Calc | The mass flow of water evaporated. |

| TotalLossQm | Calc | The mass of total water loss including evaporation. Excludes any steam or gases in the feed. Can be used for water makeup requirements when no vapour in feed. |

| WaterEvapQm / EvapQm | Calc | The mass flow of water evaporated. |

| WaterVapFrac | Calc | The percent feed water loss through evaporation. |

| Vapour.Qm | Calc | The mass flow of vapour (evaporation + other vapour in the feed). |

Air-Water Mixture Estimates(Only visible with the Merkel method.) | ||

| AirEnthOut | Calc | The enthalpy of exhaust air-water vapour mixture, which can used to look up the Air-Water mixture outlet wet bulb T from the psychometric charts. |

| HeatAvailable | Calc | The amount of heat available to heat up the air stream. |

| AirQm | Calc | The air mass flowrate is calculated based on liquid feed flowrate and user specified L/G ratio. |

| AirCp | Input | The air Cp is used to estimate the Air outlet Temp. |

| AirInDryBulbT | Input | The air inlet dry bulb temperature is used to estimate the Air outlet temp. |

| AirTRise | Calc | This is the temperature rise assuming HeatAvailable is used to heat up the dry air only. |

| AiroutT | Calc | This is the temperature out assuming HeatAvailable is used to heat up the dry air only. |

| AirWaterMixQm | Calc | This is the estimate of the total air-water vapour mixture flow rate. NOTE that the airflow is not an actual stream in SysCAD. |

| AirWaterMixCpEst | Calc | This is an estimate of the air-water vapour mixture Cp. Using a simple mass weighted mean calculation. |

| AirWaterMixTEst | Calc | This is an estimate of the air-water vapour mixture Temperature. Using a simple mass weighted mean calculation. NOTE: This would serve as an estimate for the air-water outlet wet bulb T, if the psychrometric charts were not at hand. |

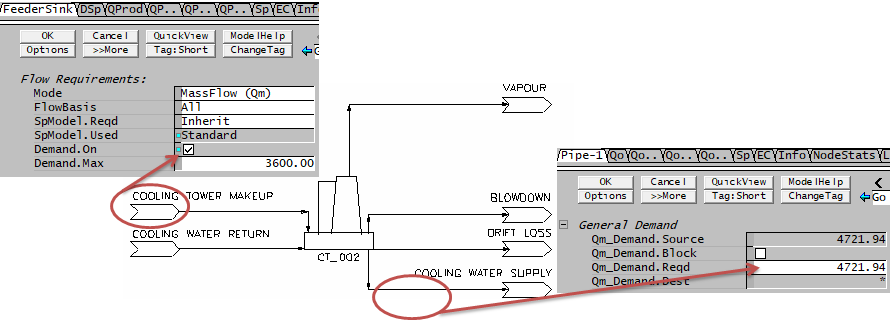

General Demand(Only visible if Liquid Outlet pipe (or downstream pipe) has demand specified, and the project has completed at least one iteration after project load.) | ||

| Liquor.DemandQm | Calc | Displays the Liquor Outlet flowrate required (as specified in the outlet pipe Qm_Demand.Rqd. |

| Liquor.Qm | Calc | Displays the Liquor Outlet actual flowrate |

| Feed.DemandQm | Calc | Displays the Makeup stream flowrate into the cooling tower. (This flow is from the feeder with Demand.On selected.) |

| Feed.FixedQm | Calc | Displays the remaining feed rates into the cooling tower (less the make up stream). |

Hints and Comments

Setting the Cooling Tower Water Makeup on demand mode:

- Set up one feeder with Demand.On, any remaining feeder must have feed rates defined or cross-page connected.

- Set up the Cooling Tower Liquor Out pipe with a demand flowrate in the Qm_Demand.Reqd field. (This can be on a downstream pipe if preferred, the demand will pass back to this pipe.)

- SysCAD will then calculate how much makeup water is required.

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Heat Transfer: Cooling Tower | |

| or | Group: | Energy Transfer |

→ | Units/Links | → | Heat Transfer: Cooling Tower |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Heat Transfer | → | Cooling Tower |

See Insert Unit for general information on inserting units.

Example Project

Please see the following projects: