Underflow Washer

Navigation: Models ➔ Mass Separation Models ➔ Underflow Washer

| General Separator | Thickener | Classifier | Washer | Counter Current Washer | Underflow Washer |

|---|

General Description

The Underflow Washer is used to separate the solids from the liquids in the feed stream and then wash the solids with a wash stream. This unit is similar to the Washer and the Counter Current Washer.

- The user defines the percentage solids in both the underflow and the overflow from the unit.

- If there is insufficient solids in the feed to the Underflow Washer to satisfy both the under and over flow requirements, the unit will try to satisfy the underflow solids / liquids requirements first.

- The wash stream combines with the underflow solids and 'washes' the feed liquid out of the solid stream.

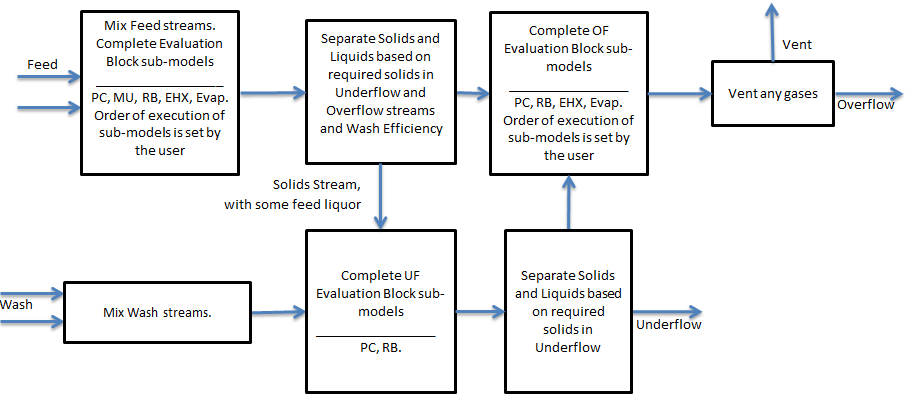

- The model allows the user to set sub-models in the Feed section, Underflow and Overflow sections. The following sub-models are available in each section:

- The Feed section, EB, allows the user to set Solubility, Reactions, Makeups, Environmental Heat Exchange and Evaporation.

- The Overflow section, OFEB, allows the user to set Solubility, Reactions, Environmental Heat Exchange and Evaporation.

- The Underflow section, UFEB, allows the user to set Solubility and Reactions.

- The temperature of the solids and liquids is calculated after any reactions and/or heat loss has occurred.

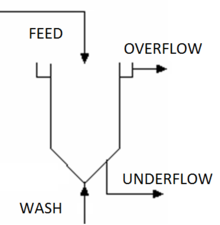

Diagram

The diagram shows the default drawing of the Underflow Washer, with all of the streams that may be connected for the unit to operate.

The physical location of the streams connecting to the Underflow Washer is unimportant. The user may connect the streams to any position on the unit.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | The slurry feed to the Underflow Washer. |

| Wash | Optional | In | 0 | 20 | The Washing Stream to the Underflow Washer. |

| Overflow | Required | Out | 1 | 1 | Underflow Washer overflow |

| Underflow | Required | Out | 1 | 1 | Underflow Washer underflow |

| Vent | Optional | Out | 0 | 1 | Vent Stream (Vapour Only) |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then they may specify:

- The fraction of the Feed streams that will report to the 'Underflow' outlet;

- The fraction of the Wash streams that will report to the 'Underflow' outlet.

This means:

- All of the streams to the unit could report to the underflow, if both fractions are set to 100%; or

- All of the streams to the unit could report to the overflow, if both fractions are set to 0%; or

- The Feed and Wash streams report to different locations and do not mix at all if the user sets one fraction to 100% and the other to 0%.

- Any combination of the above.

Model Theory

The liquid associated with the solids in the Feed stream is washed from underflow stream, based on the user defined washing efficiency. For example, if the washing efficiency is set at 90%, then 10% of the liquid in the underflow stream will come from the Feed streams.

NOTES:

- The user may enable sub-models in the Feed, Overflow and the Underflow sections of the unit. This does mean that the solid composition may be different in the over and underflow streams.

Flowchart

The following shows the sequence of events if sub model options are switched on.

Data Sections

The default access window consists of several sections,

- UnderflowWasher tab - Contains general information relating to the unit.

- PC - Optional tab, only visible if the Solubility is enabled in the Feed section.

- RB - Optional tab, only visible if the Reactions are enabled in the Feed section.

- EHX - Optional tab, only visible if the EnvironHX is enabled in the Feed section.

- Evap - Optional tab, only visible if the Evaporation is enabled in the Feed section.

- MUx - Optional tab, only visible if the Makeups have been added in the Feed section.

- UFPC - Optional tab, only visible if the Solubility is enabled in the Underflow section.

- UFRB - Optional tab, only visible if the Reactions are enabled in the Underflow section.

- OFPC - Optional tab, only visible if the Solubility is enabled in the Overflow section.

- OFRB - Optional tab, only visible if the Reactions are enabled in the Overflow section.

- OFEHX - Optional tab, only visible if the EnvironHX is enabled in the Overflow section.

- OFEvap - Optional tab, only visible if the Evaporation is enabled in the Overflow section.

- QFeed - Available from Build 139. Optional tab, visible if ShowQFeed is enabled. This and subsequent tab pages, e.g. QFeed.. and Sp, shows the properties of the combined Feed stream. The tags in the QFeed tab are valid even when the ShowQFeed option is not selected.

- QWash - Available from Build 139. Optional tab, visible if ShowQWash is enabled. This and subsequent tab pages, e.g. QWash.. and Sp, shows the properties of the combined Wash stream. The tags in the QWash tab are valid even when the ShowQWash option is not selected.

- QUF - Available from Build 139. Optional tab, visible if ShowQUF is enabled. This and subsequent tab pages, e.g. QUF.. and Sp, shows the properties of the Underflow stream. The tags in the QUF tab are valid even when the ShowQUF option is not selected.

- QOF - Available from Build 139. Optional tab, visible if ShowQOF is enabled. This and subsequent tab pages, e.g. QOF.. and Sp, shows the properties of the Overflow stream. The tags in the QOF tab are valid even when the ShowQOF option is not selected.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - Contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Underflow Washer Page

Unit Type: UnderflowWasher - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick Box | This allows the user to enable or disable the unit. The user may choose the fraction of flows reporting to the Underflow of both the Feed and Wash streams. See Behaviour when Model is OFF. |

| FeedFracToUF_WhenOff / FeedFracToUF | Input | Only visible when the unit is NOT On. This lets user select how much of the Feed streams report to the Underflow. |

| WashFracToUF_WhenOff / WashFracToUF | Input | Only visible when the unit is NOT On. This lets user select how much of the Wash streams report to the Underflow. |

| WashEfficiencyReqd / WashEffReqd | Input | The required washing efficiency of the underflow solids by the Wash streams. |

| UFSolidFracReqd | Input | The required percentage of solids in the underflow stream. |

| OverFlowMethod / Method | OverFlowSolidsFraction | The user specifies the fraction of solids in the overflow. |

| OverFlowSolidsConcentration25 | The user specifies the overflow solids concentration at 25°C. | |

| OverFlowSolidsConcentration | The user specifies the overflow solids concentration at the stream temperature. | |

| OFSolidFracReqd | Input | The required percentage of solids in the overflow stream. This is only visible if the user has chosen OverFlowSolidsFraction above. |

| OFSolidConcReqd25 | Input | The required overflow Solids concentration at 25°C. Visible only with the OverFlowSolidsConcentration25 method. |

| OFSolidConcReqd | Input | The required overflow Solids concentration. Visible only with the OverFlowSolidsConcentration method. |

| OFSolidsRecoveryUsed | Calc | Shows the value used by SysCAD for the O/F solids in the solver. |

| WashFracToUF | Calc | The fraction of the wash streams reporting to the underflow stream. |

| WashEfficiencyUsed/WashEffUsed | Calc | Shows the actual wash efficiency achieved in the unit. |

| OperatingP - NOTE: this pressure is applied to the (combined) feed, before sub-models (if any). | ||

| Method | AutoDetect | If there are any liquids AND no vapours present in the feed, outlet streams will take the highest pressure of the feeds. Else (e.g. some vapours present) outlet streams will take the lowest pressure of the feeds. |

| LowestFeed | Outlet streams will take the lowest pressure of the feeds. | |

| HighestFeed | Outlet streams will take the highest pressure of the feeds. | |

| Atmospheric | Outlet streams will be at Atmospheric Pressure. The atmospheric pressure is calculated by SysCAD based on the user defined elevation (default elevation is at sea level = 101.325 kPa). The elevation can be changed on the Environment tab page of the Plant Model. | |

| RequiredP | Outlet streams will be at the user specified pressure. | |

| IgnoreLowMassFlow / IgnoreLowQm | Tick Box | This option is only visible if the AutoDetect, LowestFeed or HighestFeed methods are chosen. When calculating the outlet pressure and temperature of the tank, SysCAD will ignore the low flow feed streams should this option be selected. The low flow limit is set in the field below. |

| LowMassFlowFrac / LowQmFrac | Input | This field is only visible if the IgnoreLowQm option is selected. This is the amount any stream contributes to the total flow. For example, if the total feed to the tank is 10 kg/s, and this field is set to 1%. Then any feed streams with less than 0.1 kg/s will be ignored in the pressure calculations. |

| PressureReqd / P_Reqd | Input | This field is only visible if the RequiredP method is chosen. This is user specified pressure. |

| Result | Calc | The actual pressure used for the sum of the feeds which will also be the outlet pressure (unless further model options change the pressure). |

EB (Feed Evaluation Block) | ||

| This allows the user to enable sub-models in the Feed section of the unit. | ||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. |

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. |

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Makeups | Input | The number of Makeup Blocks required. Extra dropdown options Makeup1, Makeup2, etc. will be added to allow these to be switched on and off and prioritised in relation to the other sub-models. |

| MakeupX | List | This can be used to switch the Makeup Block (MU) on or off and prioritise it in relation to the other sub-models. If this is 'On' then the associated page, MUX becomes visible and may be configured. Note: This field is only visible if the entry for 'Makeups' is greater than 0. If there is one makeup then X=1. If there are two makeups, then X=1 and X=2, etc. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

| EnvironHX | List | Environmental Heat Exchanger (EHX) - Enable or disable Environmental Heat Exchange and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, EHX becomes visible and may be configured. Note: The user does not have to configure an environmental heat exchange, even if this block is checked. |

| Evaporation | List | Evaporation Block (Evap) - Enable or disable the Evaporator and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, Evap becomes visible and may be configured. Note: The user does not have to configure an evaporator, even if this block is checked. |

UFEB (Underflow Evaluation Block) | ||

| This allows the user to enable sub-models in the underflow, or wash, section of the unit. | ||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. |

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. |

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

OFEB (Overflow Evaluation Block) | ||

| This allows the user to enable sub-models in the Overflow section of the unit. | ||

| Solubility.On | Tickbox | Only visible if Solubility has been defined for at least one species in the project. Allows the user to switch on any predefined solubility curve to adjust the composition of material in the unit. |

| [email protected] | Tickbox | Only visible if Phase Change at Temperature has been defined for at least one species in the project and Plant Model - Species Tab - PhaseChange@T = OFF. Allows the user to switch on any predefined phase changes at temperature in the unit. |

| EvalSequence | Calc | The sequence in which the sub models (which are part of the evaluation blocks) will be calculated. The sequence is determined by the priority selection for the individual sub-models. Note: If the user chooses On-AutoSequence then SysCAD will determine the sequence of the sub-models. The auto evaluation sequence followed will be the order the sub models are listed below. |

| Reactions | List | Reaction Block (RB) - Enable or disable Reactions and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, RB becomes visible and may be configured. Note: The user does not have to configure a reaction file, even if this block is checked. |

| EnvironHX | List | Environmental Heat Exchanger (EHX) - Enable or disable Environmental Heat Exchange and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, EHX becomes visible and may be configured. Note: The user does not have to configure an environmental heat exchange, even if this block is checked. |

| Evaporation | List | Evaporation Block (Evap) - Enable or disable the Evaporator and set the sequence in relation to the other sub-models. If this is 'On' then the associated page, Evap becomes visible and may be configured. Note: The user does not have to configure an evaporator, even if this block is checked. |

Options | ||

| ShowQFeed | Tick Box | QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined feed stream. See Material Flow Section. This will be prior to any sub-model (e.g. reactions) actions. |

| ShowQWash | Tickbox | Available from Build 139. When selected, the QWash and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined wash stream. See Material Flow Section. Tags in the QWash tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQUF | Tickbox | Available from Build 139. When selected, the QUF and associated tab pages (e.g. Sp) will become visible, showing the properties of the Underflow stream. See Material Flow Section. Tags in the QUF tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQOF | Tickbox | Available from Build 139. When selected, the QOF and associated tab pages (e.g. Sp) will become visible, showing the properties of the Overflow stream. See Material Flow Section. Tags in the QOF tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| TrackStatus | Tick Box | This is used to enable warning messages. |

Separation Results | ||

| WashEfficiency/WashEff | Calc | The actual wash efficiency achieved in the unit. |

| UFSolidsRecovery | Calc | The fraction of solids in the feed streams reporting to the underflow stream. |

| UFLiquidRecovery | Calc | The fraction of liquids in the feed streams reporting to the underflow stream. |

| VapourMassFlow/VQm | Calc | The shows the vapour mass flow, may show a value if the evaporation sub model is used. |

| The following table displays the flows and compositions of the Underflow stream. Note: This for slurry only, vapours are excluded. | ||

| UF.MassFlow / UF.Qm | Calc | The total mass flow of the Underflow stream. |

| UF.VolFlow / UF.Qv | Calc | The total volume flow of the Underflow stream. |

| UF.SolidMassFlow / UF.SQm | Calc | The solids mass flow in the Underflow stream. |

| UF.LiquidMassFlow / UF.LQm | Calc | The liquid mass flow in the Underflow stream. |

| UF.SolidFrac / UF.Sf | Calc | The solids mass fraction in the Underflow stream. |

| UF.LiquidFrac / UF.Lf | Calc | The Liquid mass fraction in the Underflow stream. |

| UF.Temperature / UF.T | Calc | Temperature of the Underflow stream. |

| UF.Density / UF.Rho | Calc | The total density of the Underflow stream. |

| UF.SolidConc | Calc | The solid concentration (mass of solids/density of slurry) of the Underflow stream. |

| UF.SolidConc25 | Calc | The solid concentration at 25°C (mass of solids/density of slurry at 25°C) of the Underflow stream. |

| The following table displays the flows and compositions of the Overflow stream. Note: This for slurry only, vapours are excluded. | ||

| OF.MassFlow / OF.Qm | Calc | The total mass flow of the Overflow stream. |

| OF.VolFlow / OF.Qv | Calc | The total volume flow of the Overflow stream. |

| OF.SolidMassFlow / OF.SQm | Calc | The solids mass flow in the Overflow stream. |

| OF.LiquidMassFlow / OF.LQm | Calc | The liquid mass flow in the Overflow stream. |

| OF.SolidFrac / OF.Sf | Calc | The solids mass fraction in the Overflow stream. |

| OF.LiquidFrac / OF.Lf | Calc | The Liquid mass fraction in the Overflow stream. |

| OF.Temperature / OF.T | Calc | Temperature of the Overflow stream. |

| OF.Density / OF.Rho | Calc | The total density of the Overflow stream. |

| OF.SolidConc | Calc | The solid concentration (mass of solids/density of slurry) of the Overflow stream. |

| OF.SolidConc25 | Calc | The solid concentration at 25°C (mass of solids/density of slurry at 25°C) of the Overflow stream. |

| GridDisplay | Tick Box | If this is ticked then the above fields are displayed in a table. Otherwise, they are displayed in individual fields. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Separation.dll |

→ | Units/Links | → | Separation: Thickener - Underflow Washer | |

| or | Group: | Mass Separation |

→ | Units/Links | → | Separation: Thickener - Underflow Washer |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Separation | → | Thickener - Underflow Washer |

See Insert Unit for general information on inserting units.

Hints and Comments

- There may be mass entering or leaving the Underflow Washer via the Reaction Block source or sink, so if the outgoing mass is not the same as the incoming mass, this may be a place to check first.

- If the reaction block is enabled in the model, there may be small errors resulting in the calculation of Overflow/underflow solids due to the feed composition change.