Thermocompressor

Navigation: Models ➔ Energy Transfer Models ➔ Thermocompressor

General Description

A Thermocompressor is a form of steam ejector in which a flow of higher pressure primary steam is used to entrain lower pressure secondary steam. The discharge stream is at an intermediate pressure between the high and low pressure steam flows. This potentially enables recovery of some of the energy in the low grade steam.

One of the methods of the Thermocompressor model in SysCAD is based on data sheets from the Shutte and Koerting company.

The model operates in a Flash Train where the steam line follows Secondary Steam feed through to Product. Separately General Demand can be used on the Primary Steam Feed.

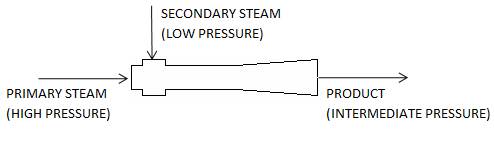

Diagram

The diagram shows the default drawing of the Thermocompressor, with the required connecting streams. The unit will not operate unless ALL of the above streams are connected.

The physical location of the connections is not important, the user may connect the streams to any position on the drawing.

Inputs and Outputs

| Label | Required /Optional |

Input /Output |

No. of Connections | Description | |

| Min | Max | ||||

| Primary | Required | Input | 1 | 1 | The High Pressure steam feed to the unit. |

| Secondary | Required | Input | 1 | 1 | The Low Pressure steam feed to the unit. |

| Discharge | Required | Output | 1 | 1 | The discharge from the unit. This contains the steam at the Intermediate pressure. |

Behaviour when Model is OFF

If the user disables the unit, by un-ticking the On tick box, then the following actions occur:

- If the unit is set up in 'Demand' mode, then the demand for the high pressure steam will be set to 0;

- Otherwise, the unit will perform all calculations on the high and low pressure steams and produce an intermediate pressure steam product.

So basically, turning the unit 'Off' only has an effect if the high pressure steam is in 'Demand' mode.

Model Theory

The options for predicting the behaviour of a Thermocompressor are:

- Simple energy balance model with empirical corrections derived from the data; or

- A simple 1 dimensional model with fitted parameters from manufacturers data; or

- Full steam 1 dimensional model.

A large database, extracted from data curves produced by the Shutte and Koerting company, has been used to fit an energy balance model and a simple 1D model.

Key Performance Parameters

Pp - Primary (motive) Pressure

Ps - Secondary (suction) Pressure

Pc - Discharge Pressure

[math]\displaystyle{ \mathbf{\mathit{\omega}} }[/math] - Entrainment ratio = Mass of Secondary Steam/Mass of Primary Steam

Er - Expansion ratio = Primary Steam Pressure/Secondary Steam Pressure

Cr - Compression ratio = Discharge Pressure/Secondary Steam Pressure

Energy Balance Mode

The Energy Balance mode assumes that the flow through the Thermocompressor is adiabatic.

In this mode the user chooses the efficiency of the Thermocompressor and the enthalpy of the product steam is calculated using the following equation:

- [math]\displaystyle{ \mathbf{\mathrm{h_c = h_s + \cfrac{\eta(h_p-h_s)}{1+\omega}}} }[/math]

where:

- hc - Product steam Enthalpy

- hp - Primary (HP) steam Enthalpy

- hs - Secondary (LP) steam Enthalpy

- [math]\displaystyle{ \eta }[/math] - Thermocompressor Efficiency

Assuming that the product steam is saturated, then the discharge pressure, Pc, can be calculated.

The user can specify the desired entrainment ratio and the model can set the flow of Primary (HP) steam to achieve this if the user enables the Demand functionality.

Alternatively, the user can specify the desired discharge pressure.

1D Model based on S&K Data

This model is based on the one dimensional analysis which:

- Is based on Shutte & Koerting data curves;

- Does not depend on any explicit assumptions about the dimensions and the internal geometry of the thermocompressor;

- Requires at the most 1 user specified parameter - the entrainment ratio or discharge pressure;

- Superheats or partially condenses the discharge steam in order to make maintain the energy balance (adiabatic process).

Full Steam 1D Model

This model is based on the one dimensional analysis which:

- Does not depend on any explicit assumptions about the dimensions and the internal geometry of the thermocompressor;

- Requires as few user specified parameters as possible.

- Can be "tuned" to manufacturer's data.

- Is based on the properties of steam, rather than an ideal gas approximation.

Excess energy is assumed to be present as kinetic energy in the discharge stream which is dissipated downstream of the Thermocompressor.

Demand Connection

If the Entrainment Ratio or Discharge Pressure method is chosen, then the user can choose from one of three options for the demand connection. This applies to either the Primary (HP) Inlet or Secondary (LP) Inlet, based on user selection.

- None (Calc Only): The required flow will be calculated but no warning will be given if it is not met. No demand is set in the inlet pipe.

- None (Manual): The required flow will be calculated and a warning will be given if it is not met. No demand is set in the inlet pipe. It is expected the user will configure another controller to set the required flow (e.g. Set Tag Controller, PID Controller or General Controller).

- General Demand: The required flow will be calculated and a warning will be given if it is not met. The demand is set in the inlet pipe.

Assumptions, Limitations and comments

- The secondary pressure is always less than the primary pressure.

- The discharge pressure is less than the primary pressure and greater than the secondary pressure.

- There is an envelope of pressures and flow rates within which the device operates.

- The Entrainment ratio is restricted to a reasonable range. The default range is between 10 and 400%. The user can change these limits.

References

- WeiXiong Chen, Ming Liu, DaoTong Chong, JunJie Yan, Adrienne Blair Little, Yann Bartosiewicz. A 1D model to predict ejector performance at critical and subcritical operational regimes. International Journal of Refrigeration 36 (2013) 1750-1761.

- Shutte & Koerting. Performance Data on Jet Compressors. Bulletin 4F Supp.

- Hisham El-Dessouky, Hisham Ettouney, Imad Alatiqi, Ghada Al-Nuwaibit. Evaluation of Steam Ejectors. Chemical Engineering and Processing (2002) 551-561.

- Yveline Marnier Antonio, Christelle Périlhon, Georges Descombes, Claude Chacoux. Thermodynamic Modelling of an Ejector with Compressible Flow by a One Dimensional Approach. Entropy 2012, 14, 599-613.

Data Sections

The default access window consists of several sections:

- Thermocompressor tab - contains the main configuration information relating to the unit.

- QPrimary - Available from Build 139. Optional tab, visible if ShowQPrimary is enabled. This and subsequent tab pages, e.g. QPrimary.. and Sp, shows the properties of the primary steam (high pressure) stream. The tags in the QPrimary tab are valid even when the ShowQPrimary option is not selected.

- QSecondary - Available from Build 139. Optional tab, visible if ShowQSecondary is enabled. This and subsequent tab pages, e.g. QSecondary.. and Sp, shows the properties of the secondary steam (low pressure) stream. The tags in the QSecondary tab are valid even when the ShowQSecondary option is not selected.

- QProd - Optional tab, visible if ShowQProd is enabled. This and subsequent tab pages, e.g. QProd.. and Sp, shows the properties of the discharge stream. The tags in the QProd tab are valid even when the ShowQProd option is not selected.

- Info tab - contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Thermocompressor Page

Unit Type: Thermocompressor - The first tab page in the access window will have this name.

| Tag (Long/short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

Requirements | ||

| On | Tick Box | This is used to enable or disable the unit. If the unit is disabled and the unit is configured to act in 'Demand' mode, then the configured Steam flow to the unit will be set at the minimum flow. |

| CalculationModel / Model | Energy Balance | User specifies desired efficiency and model calculates pressure of Discharge stream. |

| 1D Model - S&K Data | Model calculates outlet parameters assuming adiabatic operation. User can specify desired entrainment ratio or discharge pressure and model will calculated required (primary or secondary) flow and can optionally set this via demand logic. | |

| Full Steam 1D Model | User specifies Mixing Efficiency and Area Ratio and model calculates other parameters. | |

| CalculationMethod / Method | None | The model will calculate the entrainment ratio of High pressure to Low pressure steam. There are no flow requirements for either feed stream. |

| Entrainment Ratio | The user specifies the desired entrainment ratio of High pressure to Low Pressure steam. The Thermocompressor will calculate the required amount of steam (either Primary or Secondary) to achieve the specified Entrainment Ratio. The Primary (HP) inlet or Secondary (LP) inlet can be set as a 'Demand' connection and the calculated flow requirement will be sent to the relevant inlet connection. | |

| Discharge Pressure | The user specifies the desired discharge pressure. The model calculates a target Entrainment Ratio. The Thermocompressor will calculate the required amount of steam (either Primary or Secondary) to achieve the target Entrainment Ratio. The Primary (HP) inlet or Secondary (LP) inlet can be set as a 'Demand' connection and the calculated flow requirement will be sent to the relevant inlet connection. | |

| Demand.Connection (Only visible if Method = Entrainment Ratio or Discharge Pressure) |

None (Calc Only) | No demand connection. Both steam flows are set externally to the model. No warnings will be given if flow requirement is not met. |

| None (Manual) | No demand connection. The model expects an external controller to set the flow of the selected stream (Primary or Secondary) to the calculated requirement. Warnings will be given if the flow requirement is not met. | |

| General Demand | The select steam feed (Primary or Secondary) comes from (directly or indirectly) a Feeder with Demand.On selected. The demand logic will aim to match the steam mass flowrate to the Thermocompressor requirements. | |

| Demand.Source (Only visible if Method = Entrainment Ratio or Discharge Pressure) |

Primary | Mass flow calculations will be performed for the Primary (HP) steam feed. If the General Demand Connection is chosen, the demand requirement will be passed through to the Primary steam feed. |

| Secondary | Mass flow calculations will be performed for the Secondary (LP) steam feed. If the General Demand Connection is chosen, the demand requirement will be passed through to the Secondary steam feed. | |

| EntrainmentRatioReqd / EntRatioReqd | Input | Only visible if Method = Entrainment Ratio. The user defined entrainment ratio: Entrainment Ratio = Secondary (LP) Steam Flow / Primary (HP) Steam Flow The allowable range for this variable is set by the user defined MinER and MaxER variables. The default range is 10 to 400% (Shutte & Koerting range). |

| DischargePressureReqd / DischgPReqd | Input | Only visible if Method = Discharge Pressure. The user defined Discharge Pressure. This must be higher than the pressure of the Secondary (LP) steam feed but lower than the pressure of the Primary (HP) steam feed. |

| EntRatioForDischgP / ERforDischgP | Calc | Only visible if Method = Discharge Pressure. This is the entrainment ratio required to achieve the user specified Discharge Pressure. The allowable range for this variable is set by the user defined MinER and MaxER variables. The default range is 10 to 400% (Shutte & Koerting range). |

| EfficiencyReqd / EffReqd | Input | Only visible if Model = Energy Balance. The user specifies the required efficiency of energy transfer from the High Pressure steam to the product steam. |

| MixingEfficiency / MixEff | Input | Only visible if Model = Full Steam 1D Model. The mixing efficiency parameter to account for frictional losses in the mixing zone. |

| AreaRatio | Input | Only visible if Model = Full Steam 1D Model. The ratio of the area at the diffuser exit to the area of the straight section of the thermocompressor. Used when calculating the stream conditions at the diffuser exit. |

Options | ||

| ShowQPrimary | Tickbox | Available from Build 139. When selected, the QPrimary and associated tab pages (e.g. Sp) will become visible, showing the properties of the primary steam (high pressure) stream. See Material Flow Section. Tags in the QPrimary tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQSecondary | Tickbox | Available from Build 139. When selected, the QSecondary and associated tab pages (e.g. Sp) will become visible, showing the properties of the secondary steam (low pressure) stream. See Material Flow Section. Tags in the QSecondary tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. |

| ShowQProd | Tickbox | When selected, the QProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the discharge stream. See Material Flow Section. Tags in the QProd tab can be used for controllers (e.g.: PGM files) and reports even when this option is not selected. This is the actual flow from the Thermocompressor unit, after temperature and pressure changes. |

| UserWarningLimits | Tick Box | Allows the user to view the Warning Limits for the Thermocompressor (see following group of parameters). These limits are used to decide if warnings are required and to range input parameters. They are applied even when UserWarningLimits is not ticked. |

| (If UserWarningLimits is ticked, then the following section will be shown:) | ||

Warning Limits | ||

| MinSecPressure | Input | The minimum pressure expected for the Secondary (LP) steam feed. If the pressure of the Secondary feed is below this value, the user will receive a warning. |

| MaxSecToPrmRatio | Input | The maximum expected ratio of Secondary (LP) steam pressure / Primary (HP) steam pressure. If the ratio is above this value, the user will receive a warning. |

| MaxDisToPrmRatio | Input | The maximum expected ratio of Discharge (product) steam pressure / Primary (HP) steam pressure. If the ratio is above this value, the user will receive a warning. |

| MinEntRatio / MinER | Input | The minimum expected Entrainment Ratio (Secondary (LP) steam flow / Primary (HP) steam flow). If the Entrainment Ratio Method is used, the user will be prevented from entering a Required Ratio lower than this. |

| MaxEntRatio / MaxER | Input | The maximum expected Entrainment Ratio (Secondary (LP) steam flow / Primary (HP) steam flow). If the Entrainment Ratio Method is used, the user will be prevented from entering a Required Ratio higher than this. |

| ResetToDefaults | Button | If pressed, this will reset the 5 parameters above to their default values. |

Results | ||

| EntrainmentRatio / EntRatio | Calc | This is the entrainment ratio of the LP steam with the HP steam. Entrainment Ratio = LP steam mass/HP steam mass. If the HP steam is in 'Demand' mode, then this value should be equal to the Entrainment Ratio specified by the user. |

| ExpansionRatio / ExpRatio | Calc | Expansion Ratio = HP steam pressure/LP steam pressure. |

| CompressionRatio / CompRatio | Calc | Compression Ratio = Discharge steam pressure/LP steam pressure. |

| ActSecToPrmRatio | Calc | The calculated ratio of Secondary (LP) steam pressure / Primary (HP) steam pressure. |

| ActDisToPrmRatio | Calc | The calculated ratio of Discharge (product) steam pressure / Primary (HP) steam pressure. |

| IdealWork | Calc | Only visible if Model = Energy Balance. The maximum amount of work that the HP steam can produce, i.e. if Efficiency = 100%. |

| ActualWork | Calc | Only visible if Model = Energy Balance. The actual amount of work available from the HP steam. |

| DischargeHz | Calc | Only visible if Model = Energy Balance. |

| HeatFlow | Calc | Energy Out - Energy In |

| HeatFlowFrac | Calc | (Energy Out - Energy In) / Energy In |

| GridDisplay | Tick Box | This is a global selection, if this is selected, then where available, variables will display in a table format, if not selected, they will be listed in separate groups as a single list. |

| (If Model = Full Steam 1D Model, then the following section will be shown:) | ||

Diffuser Exit | ||

| Dis.KineticEnergy / Dis.KE | Calc | Kinetic energy of the discharge stream (at the diffuser exit). This is should be equal (but opposite in sign) to the calculated HeatFlow (energy difference). |

| Dis.Velocity | Calc | Velocity of the discharge stream (at the diffuser exit). |

| (If Method = Entrainment Ratio or Discharge Pressure and Demand.Source = Primary, then the following section will be shown:) | ||

Calculated Primary Vapour Flow Demand | ||

| Prm.MassFlow.Reqd | Calc | The required mass flow of the primary (high pressure) stream. |

| Prm.MassFlow.Actual | Calc | The actual mass flow of the primary (high pressure) stream. |

| Prm.MassFlow.Error | Calc | The difference between the required and actual mass flow of the primary (high pressure) stream, Prm.MassFlow.Reqd - Prm.MassFlow.Actual. |

| Prm.MassFlow.RelErr | Calc | The relative difference between the required and actual mass flow of the primary (high pressure) stream, (Prm.MassFlow.Reqd - Prm.MassFlow.Actual)/Prm.MassFlow.Reqd. |

| (If Method = Entrainment Ratio or Discharge Pressure and Demand.Source = Secondary, then the following section will be shown:) | ||

Calculated Secondary Vapour Flow Demand | ||

| Sec.MassFlow.Reqd | Calc | The required mass flow of the secondary (low pressure) stream. |

| Sec.MassFlow.Actual | Calc | The actual mass flow of the secondary (low pressure) stream. |

| Sec.MassFlow.Error | Calc | The difference between the required and actual mass flow of the secondary (low pressure) stream, Sec.MassFlow.Reqd - Sec.MassFlow.Actual. |

| Sec.MassFlow.RelErr | Calc | The relative difference between the required and actual mass flow of the secondary (low pressure) stream, (Sec.MassFlow.Reqd - Sec.MassFlow.Actual)/Sec.MassFlow.Reqd. |

Feed and Product Conditions | ||

| The following values will be displayed for the Primary Steam (Prm), Secondary Steam (Sec) and Discharge (Dis) streams. If the 'GridDisplay'box is ticked, then they will be displayed in a grid, otherwise the variables for each stream will be displayed together in a group. | ||

| MassFlow / Qm | Calc | The mass flowrate of each stream. |

| Temperature / T | Calc | The Temperature of each stream. |

| Pressure / P | Calc | The Pressure of each stream. |

| SuperHeat | Calc | The degrees of superheat of each stream (T - Saturation temperature). |

| VapourFraction / Vf | Calc | The Vapour fraction in each stream. |

Adding this Model to a Project

Insert into Configuration file

Add to Configuration File

Sort either by DLL or Group:

| DLL: | HeatExchange.dll |

→ | Units/Links | → | Heat Transfer: Thermocompressor | |

| or | Group: | Energy Transfer |

→ | Units/Links | → | Heat Transfer: Thermocompressor |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Heat Transfer | → | Thermocompressor |

See Insert Unit for general information on inserting units.