DirectLink

Navigation: Models ➔ Other General Models ➔ DirectLink

| Makeup Source | Makeup Block (MU) | Discard Sink | Discard Block (DB) | DirectLink | Flange | Tear |

|---|

General Description

The DirectLink model is automatically created. Most DirectLinks are a direct link I/O (input/output) between two models in special cases. E.g. between a model that has a Makeup Block (MU) configured and the Makeup Source. Similar to a Flange, a DirectLink represents a connection between two models and it is used to transfer material between them. Some types of DirectLinks are entry or exit points and represent flow into or out of the project flowsheet. There are no user configurable options in the DirectLink model that affect its behaviour.

A DirectLink between units is conceptually similar to a simplified Pipe in that its flow (Qo) is reported in the same way, it has a graphics symbol, no changes in behaviour through the link and included in overall stream reports along with pipes.

The graphics symbol for a DirectLink (with UnitGroup Stream) is not drawn by the user, but created automatically at the relevant unit when applicable (e.g. when a Makeup Source is connected, or when a tank spills in Dynamic). The graphics symbol cannot be deleted, but can be repositioned and changed in the same way as other graphics symbols using the Change Symbol command. The graphics symbol can also be replaced by a pipe symbol using the Redraw Link command.

Some types of DirectLinks are entry or exit points of material from the flowsheet (i.e. inlet or outlet for the project). They have models connected on one side only. Examples include feeder inlets, sink outlets, spills, RB Source/Sink, etc. These DirectLinks do not have graphics symbols.

DirectLink Types

The list of possible DirectLink types (SubClass) are shown in the following table:

| SubClass | UnitGroup | Source Unit | Destination Unit | Description |

| Makeup | Stream | Makeup Source | Any with Makeup Block (MU) | Link between a makeup source and unit/pipe model with Makeups enabled. |

| Discard | Stream | Any with Discard Block (DB) | Discard Sink | Link between a unit/pipe model with Discards enabled and a discard sink. |

| SrcSnk | Stream | Makeup Source | Feeder-Cross Page Connector | Link between a makeup source and a Feeder configured with "Link to MakeupSrc" selected for Operation. |

| Spill | Stream | Any that can spill | None | Dynamic mode only. Outlet (flowsheet material exit) from a unit/pipe model that "spills". |

| Vent | Stream | Any that can vent | None | Dynamic mode only. Outlet (flowsheet material exit) from a unit/pipe model that automatically "vents" (i.e. vapour spill). |

| Source | Other | None | Feeder (as Feeder) or Makeup Source RB Source |

Inlet (flowsheet material entry). For example to a feeder (configured as material source), to a makeup source or to a RB configured with a Reaction Source. |

| Sink | Other | Feeder (as Sink) or Discard Sink or RB Sink |

None | Outlet (flowsheet material exit). For example from a feeder (configured as material sink) or from a RB configured with a Reaction Sink. |

Data Sections

The default sections and variable names are described in the following table. The number of Tabs in the access window may increase or decrease, based on user configuration.

- DirectLink - The first section, contains general information relating to material flowing through the Direct Link.

- Qo - This and subsequent tabs show the properties of the Direct Link. This tab is always visible.

- Sp - This tab shows the composition of material flowing through the Direct Link.

- The Info section contains general settings for the unit and allows the user to include documentation about the unit.

DirectLink Tab Page

Unit Type: DirectLink - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| SubClass | Display | This will display the type of Direct Link, i.e. Makeup, Discard, SrcSnk, Source, Sink, Spill, Vent. |

| Connections | ||

| SourceTag / SrcTag | Display | The tag of the source unit. Blank if SubClass is Source. For example for SubClass Makeup it will come from a Makeup Source. |

| DestinationTag / DstTag | Display | The tag of the destination unit. Blank if SubClass is Sink, Spill or Vent. For example for SubClass Discard it will be going to a Discard Sink. |

| SourceLink / SrcIO | Display | Available from Build 139.33098. The tag of the DirectLink's source unit, including the I/O connection point (PortID) of that unit. Blank if SubClass is Source. |

| DestinationLink / DstIO | Display | Available from Build 139.33098. The tag of DirectLink's destination unit, including the I/O connection point (PortID) of that unit. Blank if SubClass is Sink, Spill or Vent. |

| SourceUitType / SrcUnitType | Display | Available from Build 139.33098. The UnitType of the source unit. |

| DestinationUitType / DstUnitType | Display | Available from Build 139.33098. The UnitType of the destination unit. |

Qo Tab Page

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

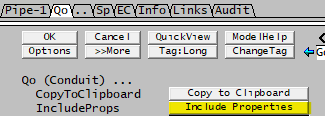

| CopyToClipboard | The mass flow, temperature, pressure and composition of the material in the pipe will be copied to the clipboard. This can then be used to configure a Feeder using the PasteData Button in the Options Section. See How do I copy Stream data to a Feeder? | |

| Include Properties |  Displays a list of properties that the user can view or hide by clicking on the required property. Displays a list of properties that the user can view or hide by clicking on the required property.

| |

| Energy | Fields related to Thermodynamic properties, e.g. Hz, Hs, Cp, etc. | |

| Saturation | Fields related to the properties of the default Saturation species (usually H2O). | |

| pH_Estimate | Fields related to the pH estimate | |

| Charge | Fields related to Charge | |

| Transport | Transport properties such as viscosity and thermal conductivity | |

| DensityCorrections | Additional density correction variables | |

| HeatsOfCombustion | The Heat of Combustion is the heat released (i.e. enthalpy change) if the stream components undergo complete combustion with oxygen to produce carbon dioxide gas and water. Available from Build 139. (Replaces old Heating Values option.) | |

| ValuesAtUserTandP | Additional variables will be evaluated at the user defined temperature and pressure | |

| SolutionImpurities | Impurity flows, fractions and concentrations. | |

| H2OProperties | Properties of pure water and steam | |

| WaterQuality | Properties of water streams such as hardness, alkalinity and oxygen demand | |

The following variables defines the species model that is used to calculate the physical properties of the stream, such as density, heat capacity, etc.

| ||

| SpModel.Reqd | Inherit | Upstream configuration will be used. |

| Standard | All the variables are calculated using the Mass Weighted Mean of the species. | |

| Species Model | Use an alternative species model, such as 'Bayer3' or 'Potash'. | |

| SpModel.Used | Standard | The Standard species model is being used. |

| Species Model | An alternative species model is being used. | |

| SpModelType | Display | This field displays the Species Model type (or Name) used. |

| SpModelIdNo | Display | This field displays a unique number generated when the Species Model is created. |

| ShowHeatingValues | Tickbox | Removed in Build 139. If ticked, then the calorific Heating Values of the material in the stream will be displayed. From Build 139, refer to Heats Of Combustion. |

| RangeChecksOn | Tickbox | This field is only shown on a QFeed page of units. If ticked, then range checks will be not be performed on the QFeed. Range checks can be globally switched off on the Plant Model - Settings tab page. |

Qualities | ||

| Lockup.Action | Input / Display | The user may select Modify Content. The 'Lockup' values are set on the 'DLockup' tab. The field displays the actual state of the Lock Up function: If this has been enabled then this will display 'Lockup.Action(On)', otherwise it will display 'Lockup.Action'. Please see LockUp for more information. Note: Lockup must first be enabled on the Plant Model - Qualities Tab and created upstream of the surge unit before the user may modify it here. |

| MatTrack.Action | Input / Display | The user may select Modify Content. The 'Tracking' values are set on the 'DTrack' tab. The field displays the actual state of the Material Tracking function: If this has been enabled then this will display 'MatTrack.Action(On)', otherwise it will display 'MatTrack.Action'. Please see Material Tracking for more information. Note: Material Tracking must first be configured on the Plant Model - Qualities Tab and created upstream of the surge unit before the user may modify it here. |

| SzDist.Action | Input / Display | The user may select Modify Content. The 'Size Distribution' values are set on the 'DSz' tab. The field displays the actual state of the Size Distribution function: If this has been enabled then this will display 'SzDist.Action(On)', otherwise it will display 'SzDist.Action'. Please see Size Distribution (PSD) for more information. Note: Size Distribution must first be created upstream of the surge unit before the user may modify it here. |

| SzSSA.Action | Input / Display | The user may select Modify Content. The 'SSA' values are set on the 'SSA' tab. The field displays the actual state of the SSA function: If this has been enabled then this will display 'SzSSA.Action(On)', otherwise it will display 'SzSSA.Action'. Please see Specific Surface Area (SSA) for more information. Note: SSA must first be created upstream of the surge unit before the user may modify it here. |

| Lockup.InUse | Display | Displays the state of the LockUp function: Yes or No. |

| MatTrack.InUse | Display | Displays the state of the Material Tracking function: Yes or No. |

| SzDist.InUse | Display | Displays the state of the Size Distribution (PSD) function: Yes or No. |

| SzSSA.InUse | Display | Displays the state of the Specific Surface Area (SSA) function: Yes or No. |

PropertiesThese properties are related to the material flowing in the stream, e.g. mass fraction, volumetric flow, density, etc. | ||

| Temperature / T | Calc | The temperature of the incoming material. |

| Pressure / P | Calc | The pressure of the incoming material. |

| Mass Flow | ||

| MassFlow / Qm | Calc | The total mass flow into the pipe. |

| SolidMassFlow / SQm | Calc | The mass of solids flowing into the pipe. |

| LiquidMassFlow / LQm | Calc | The mass of liquids flowing into the pipe. |

| VapourMassFlow / VQm | Calc | The mass of vapour flowing into the pipe. |

| SlurryMassFlow / SLQm | Calc | The mass of slurry flowing into the pipe. |

| AqDissolvedMassFlow / AqDissQm | Calc | The mass of dissolved aqueous species flowing into the pipe. This will be the flow of all aqueous species excluding water. |

| AqueousMassFlow / AqQm | Calc | The mass of all aqueous species (including water) flowing into the pipe. |

| Volume Flow | ||

| VolFlow / Qv | Calc | The total volume flow into the pipe. |

| SolidVolFlow / SQv | Calc | The volume of solids flowing into the pipe. |

| LiquidVolFlow / LQv | Calc | The volume of liquids flowing into the pipe. |

| VapourVolFlow / VQv | Calc | The volume of vapour flowing into the pipe. |

| SlurryVolFlow / SLQv | Calc | The volume of slurry flowing into the pipe. |

| Normal Volume Flow | ||

| NVolFlow / NQv | Calc | The normalised volumetric flow through the pipe. The volume is calculated at Normal Temperature and Presure (NTP). NTP can be specified by the user in the configuration file (see Project Configuration (cfg File)). Default values are 20°C and 101.325kPa. |

| SolidNVolFlow / SNQv | Calc | The Normal volume of solids flowing into the pipe. |

| LiquidNVolFlow / LNQv | Calc | The Normal volume of liquids flowing into the pipe. |

| VapourNVolFlow / VNQv | Calc | The Normal volume of vapour flowing into the pipe. |

| SlurryNVolFlow / SLNQv | Calc | The Normal volume of slurry flowing into the pipe. |

| Totalised Mass Flow

These fields are only visible in a dynamic project, when Audit is turned on from the Plant Model. Only some of these fields may be shown depending on the Totaliser Flow options chosen. | ||

| Total.TotalMass / Total.Mt | Calc | The total mass which has flowed through the pipe since the model started running. |

| Total.SolidMass / Total.SMt | Calc | The total mass of solids which has flowed through the pipe since the model started running. |

| Total.LiquidMass / Total.LMt | Calc | The total mass of liquids which has flowed through the pipe since the model started running. |

| Total.VapourMass / Total.VMt | Calc | The total mass of vapour which has flowed through the pipe since the model started running. |

| Total.SlurryMass / Total.SLMt | Calc | The total mass of slurry (solids + liquids) which has flowed through the pipe since the model started running. |

| Totalised Volume Flow

These fields are only visible in a dynamic project when Audit is turned on from the Plant Model. Only some of these fields may be shown depending on the Totaliser Flow options chosen. | ||

| Total.TotalVolume / Total.Vt | Calc | The total volume which has flowed through the pipe since the model started running. |

| Total.SolidVolume / Total.SVt | Calc | The total volume of solids which has flowed through the pipe since the model started running. |

| Total.LiquidVolume / Total.LVt | Calc | The total volume of liquids which has flowed through the pipe since the model started running. |

| Total.VapourVolume / Total.VVt | Calc | The total volume of vapour which has flowed through the pipe since the model started running. |

| Total.SlurryVolume / Total.SLVt | Calc | The total volume of slurry (solids + liquids) which has flowed through the pipe since the model started running. |

| First Flow

These fields are only visible in a dynamic project when Audit is turned on from the Plant Model. Only some of these fields may be shown depending on the First Flow options chosen. | ||

| Qm.At.Step | Calc | The step that flow first occurs in the pipe since the model started running. |

| Qm.At.Time | Calc | The time that flow first occurs in the pipe since the model started running. |

| Density See the section on Density for further information. | ||

| Density / Rho | Calc | Calculated Density of the material |

| SolidDensity / SRho | Calc | Density of the solids phase |

| LiquidDensity / LRho | Calc | Density of the liquid phase |

| VapourDensity / VRho | Calc | Density of the vapour phase |

| SlurryDensity / SLRho | Calc | Density of the Slurry (Liquid and Solid phase) |

| SolidConc | Calc | The solids concentration at stream temperature. |

Density CorrectionPlease see included properties - Density Correction. | ||

| Mass Fractions | ||

| SolidFrac / Sf | Calc | Solids mass fraction |

| LiquidFrac / Lf | Calc | Liquid mass fraction |

| VapourFrac / Vf | Calc | Vapour mass fraction |

| SlurryFrac / SLf | Calc | Available from Build 139.31388. Slurry (solids + liquids) mass fraction. |

| Slurry.SolidFrac / Slurry.Sf | Calc | Solids mass fraction on slurry basis (solids + liquids) |

| Slurry.LiquidFrac / Slurry.Lf | Calc | Liquid mass fraction on slurry basis (solids + liquids) |

| Volume Fractions | ||

| SolidVolFrac / Svf | Calc | Solids volume fraction |

| LiquidVolFrac / Lvf | Calc | Liquid volume fraction |

| VapourVolFrac / Vvf | Calc | Vapour volume fraction |

| SlurryVolFrac / SLvf | Calc | Available from Build 139.31388. Slurry (solids + liquids) volume fraction. |

| Slurry.SolidVolFrac / Slurry.Svf | Calc | Available from Build 139.31388. Solids volume fraction on slurry basis (solids + liquids) |

| Slurry.LiquidVolFrac / Slurry.Lvf | Calc | Available from Build 139.31388. Liquid volume fraction on slurry basis (solids + liquids) |

| Molar Flow | ||

| MoleFlow / QMl | Calc | The total number of moles flowing through the unit. |

| SolidMoleFlow / SQMl | Calc | The number of moles of solids flowing through the unit. |

| LiquidMoleFlow / LQMl | Calc | The total number of moles of liquids flowing through the unit. |

| VapourMoleFlow / VQMl | Calc | The total number of moles of vapours flowing through the unit. |

| SlurryMoleFlow / SLQMl | Calc | The total number of moles of solids and liquids flowing through the unit. |

| Molar Fractions | ||

| MlSolidFrac / MlSf | Calc | Solids molar fraction |

| MlLiquidFrac / MlLf | Calc | Liquid molar fraction |

| MlVapourFrac / MlVf | Calc | Vapour molar fraction |

| MlSlurryFrac / MlSLf | Calc | Available from Build 139.31388. Slurry (solids + liquids) molar fraction. |

| MoleWt | Calc | The average molecular weight of all the species. |

| SolidMoleWt / SMoleWt | Calc | Available from Build 139. The average molecular weight of all solid species. |

| LiquidMoleWt / LMoleWt | Calc | Available from Build 139. The average molecular weight of all liquid species. |

| VapourMoleWt / VMoleWt | Calc | Available from Build 139. The average molecular weight of all vapour species. |

Energy ValuesPlease see included properties - Energy. | ||

Values at User Defined T and PPlease see included properties - Values at User Defined T and P. | ||

Solubility ValuesPlease see included properties - Solubility. | ||

Saturation ValuesPlease see included properties - Saturation . | ||

Acidity (pH)Please see included properties - Acidity | ||

ChargePlease see included properties - Charge | ||

Transport PropertiesPlease see included properties - Transport | ||

Heating ValuesRemoved in Build 139. Please see included properties - Heating Values. From Build 139, refer to Heats of Combustion. | ||

Heats of CombustionAvailable from Build 139. Please see included properties - Heats of Combustion. | ||

Solution ImpuritiesPlease see included properties - Solution Impurities | ||

H2O PropertiesPlease see included properties - H2O Properties | ||

User Property CalculationsUsers can define their own calculations (called User Property Calculations) in the Project Configuration (cfg File) which will be displayed on the Qi/Qo page. Refer to Calculation Configuration for more details. | ||

WQ Tab Pages

Please see included properties - Material Flow Section - Water Quality.

Sp and EC Tab Pages

The Sp tab shows the actual species flows in a stream. It has mainly read only variables, except for the options that determine the species fractional basis and how the flows in columns 2 onwards are displayed. The method by which Fractions and Concentrations is calculated is affected by the Phase which is chosen. The Sp tab shows the species flows. The optional EC tab shows the elemental and component flows. Elements and Components are listed alphabetically.

The View Options allow the user to display the Species, Component and Elemental flows in columns 2 onwards in different ways. Not all options are available for the Species, Compounds and Elements.

If the BasisPerColumn option is ticked on the Views Tab of the Plant Model, then the basis can be selected for each individual column on the Sp page. If the BasisPerColumn option is NOT ticked, then the Basis can only be set once for all columns on the Sp page.

The Basis and Display options for the Elements section of the EC page and the Components section of the EC page can only be set once for all columns.

Phase Basis

| Tag | Option | Description |

| Species Page (Sp) | ||

| SpBasis | All | The total mass or volume of the DirectLink will be used when calculating fractional values or concentrations. |

| Phase | The mass or volume of each phase (solid, liquid or gas) will be used when calculating fractional values or concentrations. | |

| Individual Phase | The mass or volume of each Individual phase (solid, liquid, aqueous, organic, gas, etc.) will be used when calculating fractional values or concentrations. | |

| Elements and Compounds Page (EC) | ||

| EleBasis | All | The total mass or volume of the DirectLink will be used when calculating elemental fractional values or concentrations. |

| Phase | The mass or volume of each phase (solid, liquid or gas) will be used when calculating elemental fractional values or concentrations. | |

| Individual Phase | The mass or volume of each Individual phase (solid, liquid, aqueous, organic, gas, etc.) will be used when calculating elemental fractional values or concentrations. | |

| EleDisplay Only visible if Phase or Individual Phase is chosen for EleBasis |

Sol,Liq,Vap | Only visible if Phase is chosen for EleBasis. The solid, liquid and vapour elemental displays will be shown. |

| Sol,Liq | Only visible if EleBasis = Phase. The solid and liquid elemental displays will be shown. | |

| Liq,Vap | Only visible if EleBasis = Phase. The liquid and vapour elemental displays will be shown. | |

| Sol,Vap | Only visible if EleBasis = Phase. The solid and vapour elemental displays will be shown. | |

| Sol | Only visible if EleBasis = Phase. Only the solid elemental displays will be shown. | |

| Liq | Only visible if EleBasis = Phase. Only the liquid elemental displays will be shown. | |

| Vap | Only visible if EleBasis = Phase. Only the vapour elemental displays will be shown. | |

| IPhaseX | Only visible if EleBasis = Individual Phase. Only the elemental displays for the chosen IPhase will be shown. | |

| CmpBasis | All | The total mass or volume of the DirectLink will be used when calculating component fractional values or concentrations. |

| Phase | The mass or volume of each phase (solid, liquid or gas) will be used when calculating component fractional values or concentrations. | |

| CmpDisplay Only visible if Phase is chosen for CmpBasis |

Sol,Liq,Vap | The solid, liquid and vapour component displays will be shown. |

| Sol,Liq | The solid and liquid component displays will be shown. | |

| Liq,Vap | The liquid and vapour component displays will be shown. | |

| Sol,Vap | The solid and vapour component displays will be shown. | |

| Sol | Only the solid component displays will be shown. | |

| Liq | Only the liquid component displays will be shown. | |

| Vap | Only the vapour component displays will be shown. | |

View Options

| View Option | Visible on Sp Tab |

Visible on EC Tab |

Description |

|---|---|---|---|

| Mass Flow | Yes | Yes | Mass Flow Rate of the species, element or component. |

| Mass Frac | Yes | Yes | Mass Fraction of the species, element or component. |

| Conc | Yes | Yes | The species, element or component concentration at DirectLink temperature and pressure, as mass/volume. |

| Conc25 | Yes | Yes | The species, element or component concentration at 25°C and DirectLink pressure, as mass/volume. |

| Mole Flow | Yes | Yes | Mole Flow Rate of the species, element or component. |

| Mole Frac | Yes | Yes | Mole Fraction of the species, element or component. |

| Mole Conc | Yes | Yes | The species, element or component molar concentration at DirectLink temperature and pressure, as moles/volume. |

| Mole Conc25 | Yes | Yes | The species, element or component molar concentration at 25°C and DirectLink pressure, as moles/volume. |

| Molality | Yes | Yes | The molar concentration per unit mass of water (solvent) for aqueous species only, excluding water. Available from Build 139. |

| Vol Flow | Yes | No | Volume Flow Rate of the species. |

| Vol Frac | Yes | No | Volume Fraction of the species. |

| NVol Flow | Yes | No | Normalised Volume Flow Rate of the species. This is calculated at the user defined normal temperature and pressure. |

| NVol Frac | Yes | No | Normalised Volume Fraction of the species. This is calculated at the user defined normal temperature and pressure. |

| Equiv Conc | Yes | No | Only relevant for ionic charged species. The equivalent concentration at DirectLink temperature and pressure, as equivalent/volume. Based on calculated equivalent weight. |

| Equiv Conc25 | Yes | No | Only relevant for ionic charged species. The equivalent concentration at 25°C and DirectLink pressure, as equivalent/volume. Based on calculated equivalent weight. |

| PartialP | Yes | No | The partial pressure of the gaseous species only. |

| PartialPFrac | Yes | No | The partial pressure fraction of the gaseous species only. |

| Specific Hf | Yes | No | Specific enthalpy of the species, expressed as energy per unit mass. |

| Specific Hz | Yes | No | Specific Hz of the species, expressed as energy per unit mass. |

| Specific Hs | Yes | No | Specific Hs of the species, expressed as energy per unit mass. |

| Total Hf | Yes | No | Total enthalpy of the species, expressed as energy per unit time. |

| Total Hz | Yes | No | Total Hz of the species, expressed as energy per unit time. |

| Total Hs | Yes | No | Total Hs of the species, expressed as energy per unit time. |

Please see Species Flow Section for more details.