Crusher2

Navigation: Models ➔ Size Distribution Models ➔ Crusher2

| Crusher2 | Crusher 2 Model Theory |

|---|

General Description

This model implements predictive comminution with a number of open literature correlations. The model can handle multiple ore streams with different selection and breakage functions and includes optional internal classification to model various closed circuit configurations.

- Partition Curves

- Whiten Crusher Model

- Selection/Breakage Models

- Test Data

The specific model is selected with the Method drop down list on the Crusher2 or Crusher tab.

Modelling Crushing and Comminution

If you are using these models you should be aware that getting useful results requires information about both the performance of the specific crusher type, and the mechanical properties of the ore. There are many different crusher and mill types, and each crusher type will perform differently for a given ore. At the same time, different ore characteristics will have a major impact on the performance of a specific crusher - the same unit may produce large quantities of fines with one ore and much coarser product with a different ore.

The recommended use for these models is to have existing data on the performance of a specific unit with a specific ore - and to tune the parameters of the model to match plant data. Changes in the ore flow or incoming size distribution should be modeled accurately. If a new ore has similar characteristics and mechanical testing is done to determine the new ore parameters, then the models should give a reasonable indication of how the new ore will behave in an existing plant.

Predictive crushing modelling is not an exact science and requires considerable background knowledge, as well as actual test data, to get useful results. The references below provide useful background information on modelling, as well as indicating the specific test data needed for the SysCAD model.

Diagram

The diagram shows the default drawing of the Crusher, with all of the streams that must be connected to the unit.

The physical location of the streams connecting to the Crusher is unimportant. The user may connect the streams to any position on the unit.

Inputs and Outputs

| Label | Required Optional |

Input Output |

Number of Connections | Description | |

| Min | Max | ||||

| Feed | 1 Required | In | 1 | 20 | The feed to the Crusher |

| Product | Required | Out | 1 | 1 | The product from the Crusher |

Model Theory

Crusher Methods available are:

Please see separate section for Crusher 2 Model Theory.

Data Sections

The default sections and variable names are described in detail in the following tables. The default Crusher access window consists of three sections. This number may increase or decrease, based on user configuration.

- Crusher2 tab - Contains general information relating to the unit.

- QFeed - Optional tab, only visible if ShowQFeed is enabled. This page shows the properties of the mixed stream as the feed to the Crusher2 model.

- Crusher tab will have different fields depending upon the Method selected by the user:

- Fixed Partition - The fields visible if the user selects the 'Fixed Partition' method.

- Whiten Crusher - The fields visible if the user selects the 'Whiten Crusher' method.

- Selection/Breakage - The fields visible if the user selects the 'Selection/Breakage' method.

- Test Data - The fields visible if the user selects the 'Test Data' method.

- Results - Only visible if Method is set to 'Whiten Crusher' and ShowResults is enabled.

- Selection/Breakage - Visible when method is set to Selection/Breakage.

- QProd - Optional tab, only visible if ShowQProd is selected. This page shows the properties of the final product stream from the Crusher2 model.

- Info tab - Contains general settings for the unit and allows the user to include documentation about the unit and create Hyperlinks to external documents.

- Links tab, contains a summary table for all the input and output streams.

- Audit tab - Contains summary information required for Mass and Energy balance. See Model Examples for enthalpy calculation Examples.

Crusher2 Page

Unit Type: Crusher2 - The first tab page in the access window will have this name.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Tag | Display | This name tag may be modified with the change tag option. |

| Condition | Display | OK if no errors/warnings, otherwise lists errors/warnings. |

| ConditionCount | Display | The current number of errors/warnings. If condition is OK, returns 0. |

| GeneralDescription / GenDesc | Display | This is an automatically generated description for the unit. If the user has entered text in the 'EqpDesc' field on the Info tab (see below), this will be displayed here. If this field is blank, then SysCAD will display the UnitType or SubClass. |

| Requirements | ||

| On | CheckBox | This enables the unit. If this box is not checked, then the material will pass straight through the crusher with no change to the size distribution. |

| Method | Pass Through | The crusher will not change the feed (=product). This is an alternative to switching the model off and can be used when there is no PSD defined for the feed. |

| Fixed Partition | The user defines a discharge partition curve from the Crusher. This can be one size distribution for all solids or one for each solid which can have its own size distribution. | |

| Whiten Crusher | The product size distribution will be determined using the Whiten empirical model which incorporates breakage and classification, based on a number of parameters. Different parameters can be used for different solids. | |

| Selection/Breakage | The user defines the Selection and Breakage criteria for the crusher. Different methods are available and different parameters can be used for different solids. | |

| Test Data | The user defines a Feed and Product size distribution. This can be one set of size distributions for all solids or one set for each solid which can have its own size distribution. These distributions are normally obtained from test work. | |

| Power Calculation | ||

| BondWorkIndex / BondWI | Input | The Bond Work Index of the rock. This number will be used to calculate the power required to produce the final product. |

| Options | ||

| ShowQFeed | CheckBox | QFeed and associated tab pages (e.g. Sp) will become visible, showing the properties of the combined feed stream. See Material Flow Section. |

| ShowQProd | CheckBox | QProd and associated tab pages (e.g. Sp) will become visible, showing the properties of the products. See Material Flow Section. |

| SizeForPassingFracCalc | Input (global) | Size fraction for % Passing calculation. The size fraction input here will be shown in the results section. |

| FracForPassingSizeCalc | Input (global) | Fraction passing for Size calculation. The fraction input here will be shown in the results section. |

| Intervals | Toggle Button (Intervals_Ascending), the size distribution will be displayed with the largest sizes at the top of the list. | |

| Toggle Button (Intervals_decending) The size distribution will be displayed with the smallest sizes at the top of the list. | ||

| Results | ||

| Power | Calc | The calculated power to grind the product.

|

| DistributionUsed | Result | The number of size distribution being used. If only one size distribution has been defined in the configuration file, then the distribution number used will be 0. The name of the distribution will be shown in brackets. |

| Stream Result Summary The following fields are shown in a table for the Feed and Product streams. | ||

| MassFlow / Qm | Calc | The mass flow rate of the Feed/Product streams. |

| SolidMassFlow / SQm | Calc | The solid mass flow rate of the Feed/Product streams. |

| LiquidMassFlow / LQm | Calc | The liquid mass flow rate of the Feed/Product streams. |

| VolFlow / Qv | Calc | The volumetric flow rate of the Feed/Product streams. |

| Temperature/ T | Calc | The temperature of the Feed/Product streams. |

| Density / Rho | Calc | The density of the Feed/Product streams. |

| SolidFrac / Sf | Calc | The solids fraction of the Feed/Product streams. |

| LiquidFrac / Lf | Calc | The liquid fraction of the Feed/Product streams. |

| Passing | Calc | Returns the % Passing of the user defined size (defined above) of the Feed/Product streams. |

| Passes | Calc | Returns the size that has the user defined % Passing (defined above) of the Feed/Product streams. |

Crusher Page - Fixed Partition

The fields that will be visible when the Method selected is 'Fixed Partition'. See Model Theory - Fixed Partition Method for more information.

Crusher Page - Whiten Crusher

The fields that will be visible when the Method selected is 'Whiten Crusher'. See Model Theory - Whiten Crusher Method for more information.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options | ||

| DisplayOre: | Input |

| ||

| Requirements | ||||

| Method | Whiten Crusher | The product size distribution will be determined using the Whiten empirical model which incorporates breakage and classification, based on a number of parameters. Different parameters can be used for different solids. | ||

| ShowResults | CheckBox | If this box is ticked, then the user will see a Results tab with the selection / breakage values displayed. | ||

| Crusher Data (Ore Independent) | ||||

| CalcKs | CheckBox | If this box is ticked, then the user enters all the parameters required to calculate the K1 and K2 values. If the box is NOT ticked, then the user specifies the K values directly. Note that K3 is specified directly by the user in both cases. | ||

| The fields shown below are only visible if the 'CalcKs' box is ticked (except for the K values). | ||||

| ClosedSideSetting/CSS | Input | The Closed Side Setting of the crusher. Also visible if the 'CalcT10' box is ticked. | ||

| LLEN | Input | Liner Length | ||

| LHR | Input | Liner age | ||

| ET | Input | Eccentric Throw | ||

| K1, K2, K3 are calculated via 6.5-6.7 in MCC K1 = A0+A1*CSS-A2*TPH+A3*F80+A4*LLEN K2 = B0+B1*CSS+B2*TPH+B3*F80-B4*LHR+B5*ET K3 = CO (Specified directly) These parameters should be found by data fitting View "All Fields" to see additional parameters | ||||

| A0 to A4 | Input | Parameters required to calculate K1: K1 = A0 + A1*CSS - A2*TPH + A3*F80 + A4*LLEN | ||

| B0 to B5 | Input | Parameters required to calculate K2: K2 = B0 + B1*CSS + B2*TPH + B3*F80 - B4*LHR + B5*ET | ||

| K1 | Input/Calc | Size below which all particles escape breakage. If CalcKs is ticked this is a result field, otherwise it is an input field. | ||

| K2 | Input/Calc | Size above which all particles are crushed. If CalcKs is ticked this is a result field, otherwise it is an input field. SysCAD will force K2 to always be greater than K1. | ||

| K3 | Input | Exponent. This is usually a fixed value of 2.3. | ||

| CalcT10 | CheckBox | If this box is ticked, then the user must enter all of the parameters required to calculate T10. If the box is NOT ticked, then the user specifies T10 directly. | ||

| The fields shown below are only visible if the 'CalcT10' box is ticked (except for the T10 value). | ||||

| T10 is calculated from the correlation 6.8 in MCC T10 = D0-D1*CSS+D2*TPH-D3*F80 These parameters should be found by data fitting | ||||

| D0 to D3 | Input | Parameters required to calculate T10: T10 = D0 - D1*CSS + D2*TPH - D3*F80 | ||

| T10 | Input/Calc | For a given feed particle, the percentage of product passing 10% of the original particle size after breakage. If CalcT10 is ticked this is a result field, otherwise it is an input field. The minimum value for T10 is 0.1. | ||

| Calculated T_ values | ||||

| T75 | Calc | The calculated T_75 value, the percentage of product passing 75% of the original particle size after breakage. | ||

| T50 | Calc | The calculated T_50 value, the percentage of product passing 50% of the original particle size after breakage. | ||

| T25 | Calc | The calculated T_25 value, the percentage of product passing 25% of the original particle size after breakage. | ||

| T10 | Calc | The calculated T_10 value, the percentage of product passing 10% of the original particle size after breakage. | ||

| T4 | Calc | The calculated T_4 value, the percentage of product passing 4% of the original particle size after breakage. | ||

| T2 | Calc | The calculated T_2 value, the percentage of product passing 2% of the original particle size after breakage. | ||

| BreakageAtSize | Input | Display of Napier-Munn Appearance function on Results tab is calculated at this size. This parameter is for display of additional results only. | ||

| Power parameters (Ore Independent) | ||||

| NoLoadPower/Pn | Input | The power draw of the Whiten Crusher with no feed. | ||

| Scaling/A | Input | The dimensionless scaling factor for the actual crusher. | ||

| TotalPendulmPower/Pp | Calc | The calculated Pendulum Power. | ||

| CrusherPower/Pc | Calc | The crusher power draw with the feed load. | ||

| Ore Specific Data - One set for each ore (These values are per solid ore type. Use the "DisplayOre:" scroll buttons (top of the tab page) to move between ore types.) | ||||

| Breakage parameters for SolidX | ||||

| SolidX... | ||||

| (The user enters the data for the General appearance function for the crusher model for each ore into the table. The table contains 3 rows, corresponding to T10 values of 10, 20 and 30. The columns are described below:) | ||||

| t75 | Input | The required t75 value corresponding to the T10 value of 10, 20 or 30%. | ||

| t50 | Input | The required t50 value corresponding to the T10 value of 10, 20 or 30%. | ||

| t25 | Input | The required t25 value corresponding to the T10 value of 10, 20 or 30%. | ||

| t4 | Input | The required t4 value corresponding to the T10 value of 10, 20 or 30%. | ||

| t2 | Input | The required t2 value corresponding to the T10 value of 10, 20 or 30%. | ||

| Power parameters for SolidX | ||||

| Pendulum ECS Data: kWh/ton | ||||

| (The user enters the Pendulum Ecs (specific comminution energy) data for each ore into the table. The table contains 3 columns, corresponding to 3 different pendulum tests. The rows are described below:) | ||||

| Init Size (mm) | Input | The initial material size for each of the 3 tests. | ||

| T10=10 | Input | The specific comminution energy (Ecs) value for each of the 3 tests when T10=10%. | ||

| T10=20 | Input | The specific comminution energy (Ecs) value for each of the 3 tests when T10=20%. | ||

| T10=30 | Input | The specific comminution energy (Ecs) value for each of the 3 tests when T10=30%. | ||

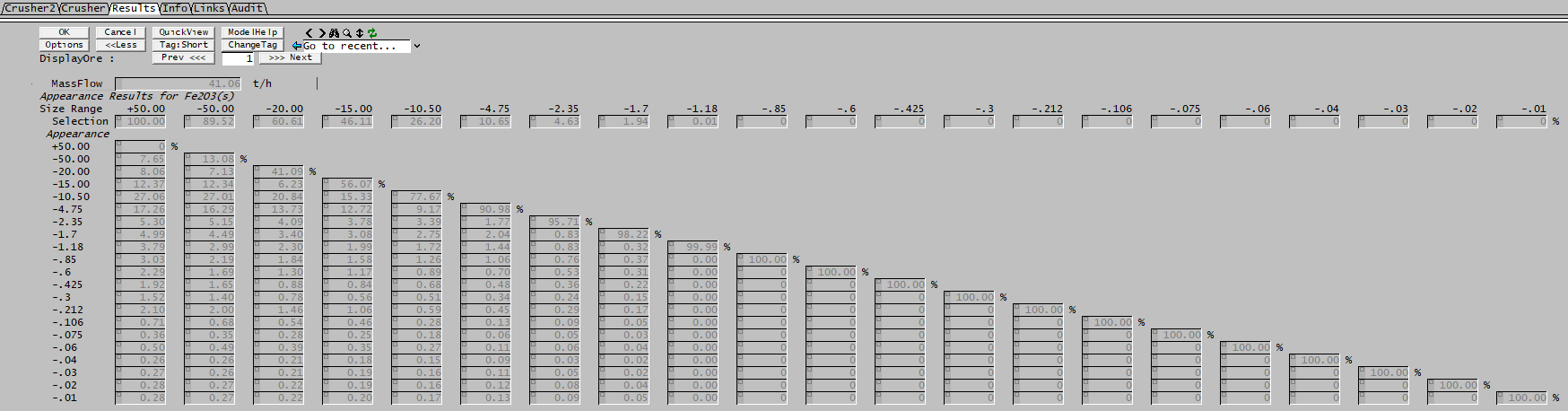

Results Page - Whiten Crusher

This tab will be visible when the Method selected is 'Whiten Crusher'. See Model Theory - Whiten Crusher Method for more information.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options | ||

| DisplayOre: | Input |

| ||

| MassFlow / Qm | Calc | The mass flow of the selected ore. | ||

| Appearance Results for SolidX | ||||

| Selection | Calc | The calculated selection fraction of each size interval. Values can range from 0-100%. Material selected will be redistributed to smaller size intervals as defined by the appearance function. | ||

| Appearance | ||||

| (The following table is a triangular matrix showing the calculated appearance function. For each size interval, it shows how this is redistributed to other size fractions. The fractions must add to 1 (100%). Since it can not be redistributed to larger size fractions, the number of possible values decreases as the size interval reduces.) | ||||

| Additional Results for SolidX | ||||

| (The following table has one row for each size interval. The columns are explained below. IMPORTANT: this table is for Access window display of currently selected Ore only! Tags are not accessible for reporting.) | ||||

| Appearance | Calc | The appearance function is Napier-Munn terminology for the breakage function calculated for the size specified by tag BreakageAtSize above. | ||

| Classification | Calc | The calculated fraction that is classified (selected for breakage) for the given size interval. Values can range from 0-100%. Material classified (selected) will be redistributed to smaller size intervals as defined by the appearance function. This is the same as the Selection fractions shown at the top of the Results page. | ||

| MassInBreakage | Calc | |||

| PowerPerTon | Calc | The calculated specific comminution energy (Ecs) for the given size interval. | ||

| Power | Calc | The calculated pendulum power (Pp) for the given size interval = MassInBreakage * PowerPerTon | ||

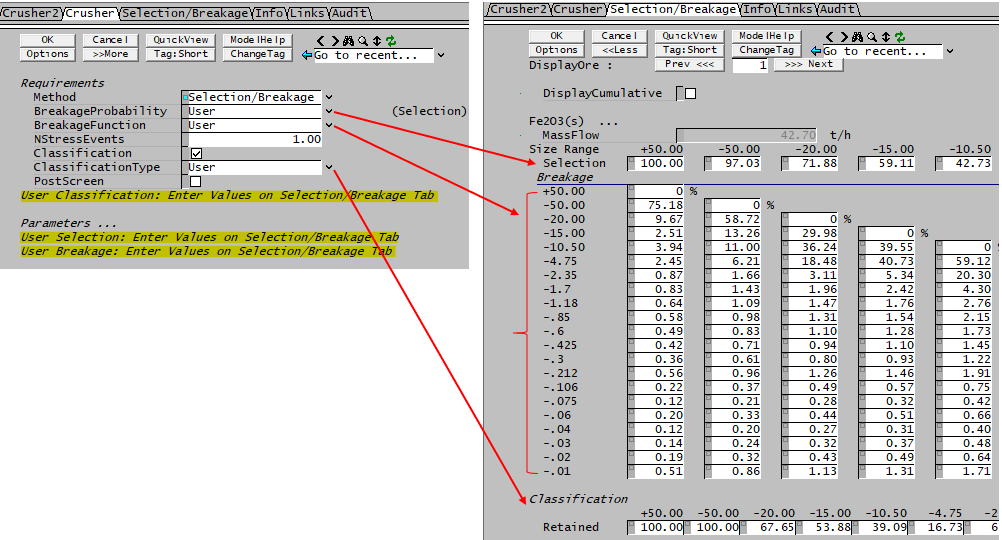

Crusher Page - Selection/Breakage

The fields that will be visible when the Method selected is 'Selection/Breakage'.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Requirements | ||

| Method | Selection/Breakage | The user defines the Selection and Breakage criteria for the crusher. Different methods are available and different parameters can be used for different solids. |

| ShowRecalc | CheckBox | Tick this box to show when data arrays are recalculated. |

| BreakageProbability | Vogel-Peukert | Uses the Vogel Selection Function to determine the Selection fraction for each size interval. The results are shown on the Selection/Breakage tab page. |

| Austin | Uses the Austin Selection Function to determine the Selection fraction for each size interval. The results are shown on the Selection/Breakage tab page. | |

| User | The user specifies the Selection fraction for each size interval on the Selection/Breakage tab page. | |

| BreakageFunction | Reid-Stewart | Uses the Reid-Steward Breakage Function. The results are shown on the Selection/Breakage tab page. |

| Austin | Uses the Austin Breakage Function. The results are shown on the Selection/Breakage tab page. | |

| User | The user specifies the Breakage fractions for each size interval on the Selection/Breakage tab page. | |

| Vogel-Peukert | Uses the Vogel-Peukert Breakage Function. The results are shown on the Selection/Breakage tab page. | |

| Tavares | Uses the Tavares Breakage Function. The results are shown on the Selection/Breakage tab page. | |

| Logarithmic | Uses the Logarithmic Breakage Function. The results are shown on the Selection/Breakage tab page. | |

| Weibull | Uses the Weibull Breakage Function. The results are shown on the Selection/Breakage tab page. | |

| NStressEvents | Input | The number of Multiple Impact Events. See Multiple Impact Events. This may be an integer, or it may be a fractional value, such as 1.5. |

Impact Methods | ||

| ImpactType | Hammer | The impact velocity is calculated from the rotation speed and rotor diameter. |

| Impact | The user specifies the Impact velocity. | |

| RotorSpeed | Input | Only visible if ImpactType = Hammer. Rotational Speed for a Hammer Mill. |

| RotorDiameter | Input | Only visible if ImpactType = Hammer. Rotor Diameter for a Hammer Mill. |

| ImpactVelocity | Input/Calc | The impact velocity. This is used by some of the breakage probability (selection) and breakage function methods. If ImpactType = Hammer this is a result field, otherwise it is an input field. |

Classification | ||

| Classification | Checkbox | If this box is ticked, then the unit will apply internal classification. |

| (The following fields are only visible if Classification is ticked.) | ||

| ClassificationType | NapierMunn | Uses the Napier Munn classification. |

| Whiten | Uses the Whiten classification. | |

| User | The user enters their own classification data on the Selection/Breakage tab page. | |

| PostScreen | Checkbox | Transfer Model for closed loop classifier. |

| K1 | Input | Only visible if ClassificationType=NapierMunn. K1 parameter for Napier Munn classification model. |

| K2 | Input | Only visible if ClassificationType=NapierMunn. K2 parameter for Napier Munn classification model. |

| K3 | Input | Only visible if ClassificationType=NapierMunn. K3 parameter for Napier Munn classification model. |

| Parameters... | ||

Breakage Probability Selection Methods | ||

| Vogel Selection Function The user enters the following variables for each ore type. | ||

| fMat is the material parameter, units kg/J/m xWm_min is the size independent threshold energy, units Jm/kg See Vogel-Peukert Mastercurve References | ||

| fMat | Input | Material Parameter that characterises the resistance of particulate material against fracture in impact comminution. |

| xWm_min | Input | Mass-specific threshold energy for particle breakage, i.e. the specific energy which a particle can take up without fracture. |

| k | Input | Number of impact events. |

| Austin Selection Function The user enters the following variables for each ore type. | ||

| S1 | Input | Material Parameter. 0 <= S1 <= 1 |

| x1 | Input | Minimum particle size. 0 <= x1 <= Maximum particle size in the feed stream. |

| a | Input | Parameter. 0 <= a <= 1 |

Breakage Functions | ||

| Reid-Steward Breakage Function The user enters the following variables for each ore type. | ||

| Phi | Input | Experimentally determined material parameter. |

| Gamma | Input | Experimentally determined material parameter. |

| Beta | Input | Experimentally determined material parameter. |

| Austin Breakage Function The user enters the following variables for each ore type. | ||

| Phi | Input | Experimentally determined material parameter. |

| Gamma | Input | Experimentally determined material parameter. |

| Beta | Input | Experimentally determined material parameter. |

| Vogel Breakage Function The user enters the following variables for each ore type. | ||

| c | Input | Experimentally determined material parameter. |

| d | Input | Experimentally determined material parameter. |

| MinFragSize | Input | The minimum size to which the material can break. |

| Tavares Breakage Function The user enters the following variables for each ore type. | ||

| alpha | Input | Material Parameter based on experimental data. |

| t10 | Input | Material Parameter. |

| Simple Log Breakage Function The user enters the following variable for each ore type. | ||

| A | Input | Material Parameter. |

| Weibull Breakage Function The user enters the following variables for each ore type. | ||

| xu | Input | User Parameter. |

| xStar | Input | User Parameter: xStar>xu |

| n | Input | User Parameter: n>0 |

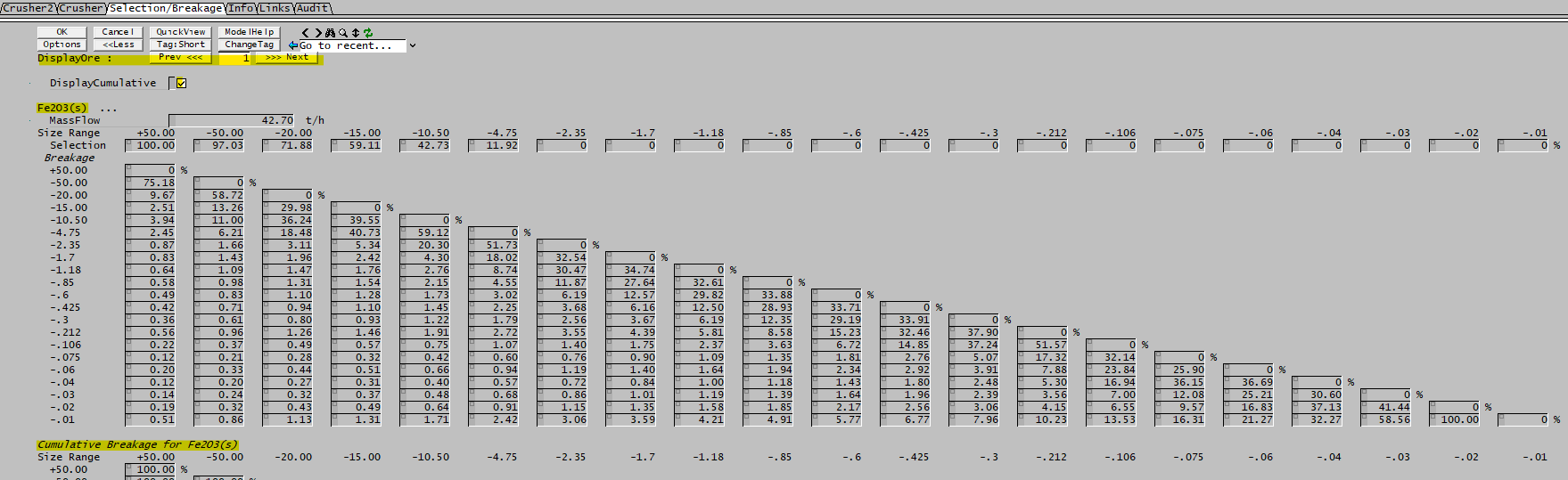

Selection/Breakage Page

The selection, breakage fraction, cumulative breakage (and classification if enabled) data is available in tabular form. When User options are selected data may be entered manually.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options | ||

| DisplayOre: | Input |

| ||

| DisplayCumulative | CheckBox | Display Cumulative breakage. | ||

| SolidX... | ||||

| MassFlow / Qm | Calc | The mass flow of the selected ore. | ||

| Selection | Input/Calc | The specified/calculated selection fraction of each size interval. Values can range from 0-100%. Material selected will be redistributed to smaller size intervals as defined by the breakage function. | ||

| Breakage | ||||

| (The following table is a triangular matrix showing the specified/calculated breakage function. For each size interval, it shows how this is redistributed to other size fractions. The fractions must add to 1 (100%). Since it can not be redistributed to larger size fractions, the number of possible values decreases as the size interval reduces.) | ||||

| Cumlative Breakage for SolidX | ||||

| (Only visible if DisplayCumulative is ticked. The following table is a triangular matrix showing the calculated cumulative breakage. Since it can not be redistributed to larger size fractions, the number of possible values decreases as the size interval reduces.) | ||||

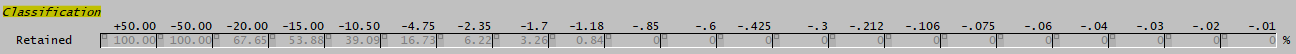

| Classification | ||||

| Retained | Input/Calc | Only visible if Classification is ticked on Crusher tab page. The specified/calculated fraction of each size interval to be retained. Values can range from 0-100%. | ||

| ||||

| NOTE: If User options are selected, the parameters can be entered manually (or by user calculation in a PGM): | ||||

See also PGM - Initialise to zero Example See also PGM - Initialise to zero Example

| ||||

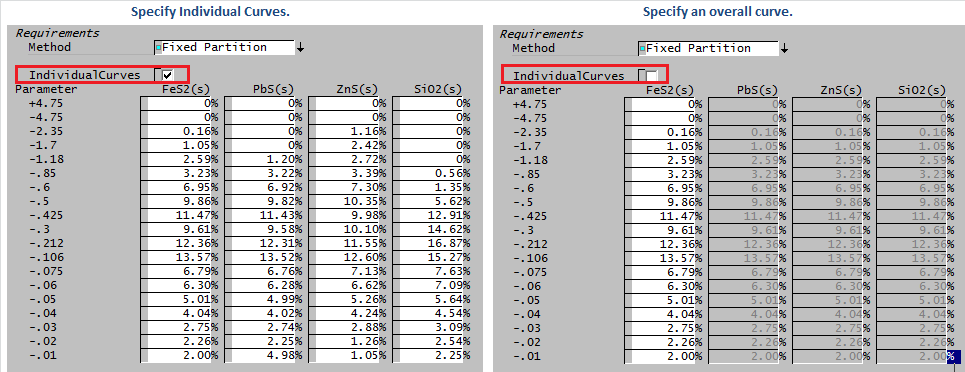

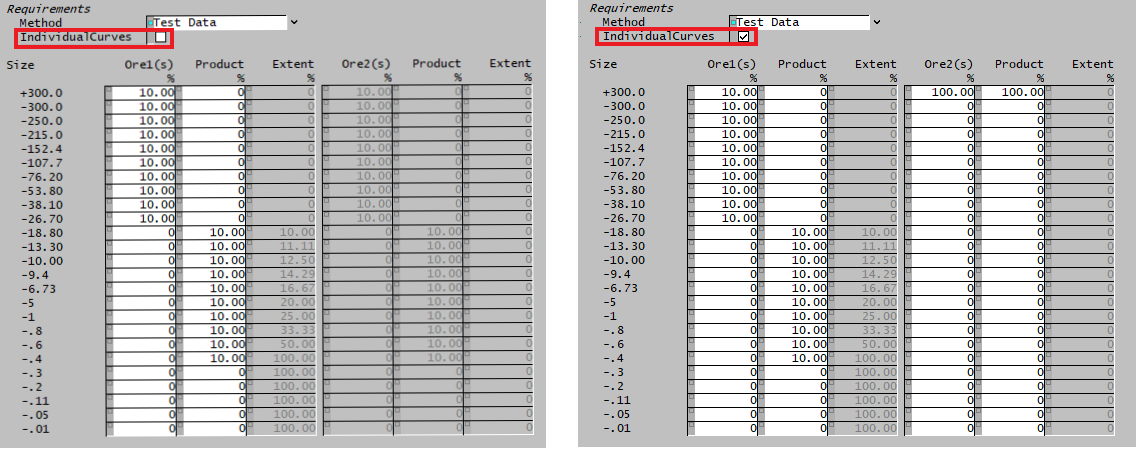

Crusher Page - Test Data

The fields that will be visible when the Method selected is 'Test Data'. See Model Theory - Test Data for more information.

| Tag (Long/Short) | Input / Calc | Description/Calculated Variables / Options |

| Requirements | ||

| Method | Test Data | The user defines a Feed and Product size distribution. This can be one set of size distributions for all solids or one set for each solid which can have its own size distribution. These distributions are normally obtained from test work. |

| IndividualCurves | CheckBox | If this is ticked, then the user enters Feed and Product size distributions for each individual solid. If the box is NOT ticked, then the user enters a single set of Feed and Product size distributions that is used for all of the solids. This is shown in the image below. |

| SolidX | Input | The user enters the Feed size distribution based on test work. (see image below) |

| Product | Input | The user enters the corresponding Product size distribution based on test work. (see image below) |

| Extent | Calc | The calculated Extent of the size fraction that is retained. See Model Theory - Test Data for more information. |

| ||

| Results | ||

| SolidX(s).MassFlow / SolidX(s).Qm | Calc | The mass flow of the specified solid species. If it is the default solid species, then it will include the flow of any solids that were NOT specified to have an associated size distribution in the project cfg file. |

Adding this Model to a Project

Add to Configuration File

Sort either by DLL or Group:

| DLL: | Comminution.dll |

→ | Units/Links | → | Size Alteration: Crusher2 | |

| or | Group: | Size Distribution |

→ | Units/Links | → | Size Alteration: Crusher2 |

See Model Selection for more information on adding models to the configuration file.

Insert into Project Flowsheet

| Insert Unit | → | Size Alteration | → | Crusher2 |

See Insert Unit for general information on inserting units.