Evaporation Project

Jump to navigation

Jump to search

Navigation: User Guide ➔ Example Projects ➔ 10 Alumina: Evaporation

Related Links: Falling Film Evaporation (FFE4) Project

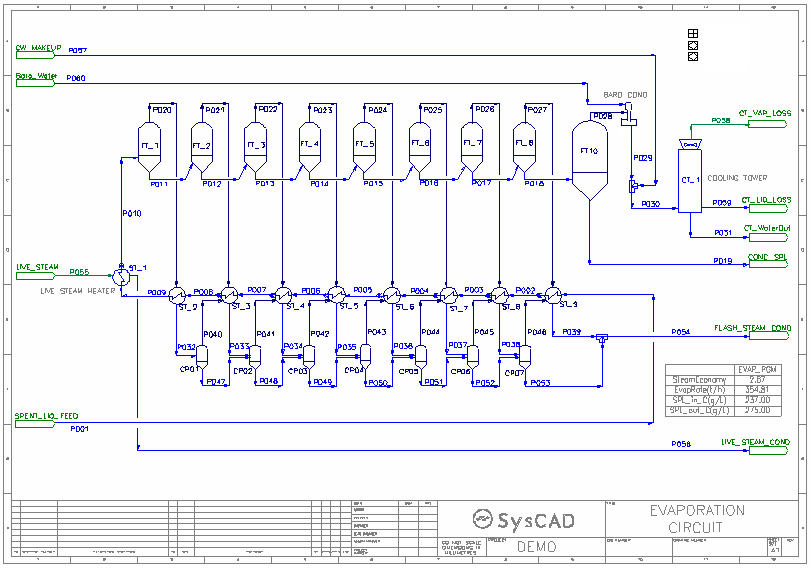

Example 1: Evaporation Project - using Flash Tanks and Heat Exchanges

Project Location

This is a Steady State project and is stored at:

..\SysCADXXX\Examples\10 Alumina\Evaporation with Cooling Tower Example.spf

Features Demonstrated

- Shows the use of Bayer3 properties model.

- Shows how to set up a multistage Flash Trains.

- Shows how to set up Barometric Condenser

- Shows how to set up a Cooling Tower.

- Shows how to set up a simple PGM file.

- Shows how to set up PID controls.

- Shows how to set up Annotation Blocks.

Brief Project Description

- Weak Spent liquor is concentrated via evaporation of water through 9 stages of flashing.

- A majority of the circuit is under vacuum.

- Live steam heater is added to heat up the liquor feeding to the first flash tank.

- A barometric condenser is used to condense the flash vapour from the last stage.

- A cooling tower is set up to cool the hotwell mixture.

- PID controllers are used to adjust the steam and cooling water additions.

- Cooling tower water make up is calculated using the PGM file.

Project Configuration

- Spent Liquor Feed to the project is defined using the DefineLiquor option.

- Spend Liquor feed location is to the last stage.

- The steam addition to the circuit is set as a cascade control, to meet a target concentration on the output stream. (Alternatively controls can be modified to control the evaporation rate)

- The set up of the flash stages are as per the Digestion Projects.

- The Barometric water addition is used to control the cold end temperature.

- The Cooling water make up is to counter for losses in the cooling tower (evaporation and blow down loss)

- The cooling tower is set up:

- Using the Merkel method

- User defined outlet Air Wet buld Temperature

- User defined Liquid to Gas Ratio

- User defined tower characteristic factor

- Cooling tower will estimate the require air flow and energy

- Steam economy and cooling water make up side calculations are done in the PGM file.

Included Excel Reports

- Evaporation.XLS - this excel report show some basic report formats for the project, these include Input Criteria and simple overall balance and Stream data report